Showing 195 items matching "gold price"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Reference, The Birds of Australia Vol 12 Part 1

The Birds of Australia is a 12 volume work, in a total of 14 books. The books were used as an ornithological handbook. They contain scientific text as well as over 600 hand-coloured lithographed plates by J.G. Keulemans, H. Grönvold, Roland Green, H. Goodchild and G.E. Lodge. The work was written, sponsored and organised by Gregory M. Matthews, F.R.S.C. Erc. who was a wealthy Australian and an amateur ornithologist. His titles included – -Fellow of the Linnean and Zoological Societies of London -Member of the British Ornithologists’ Union -Corresponding Fellow of the American Ornithologists’ Union The volumes in our collection were originally donated to the Warrnambool Mechanics’ Institute and Free Library by William Lindsay. THE LINDSAYS (quoted from the book Of Many Things – A History of Warrnambool Shire by C.E. Sayers) The Lindsays were amongst the most prominent families in the Shire of Warrnambool, as pastoralists, sportsmen, municipal councillors, community leaders. The first of the family William arrived in Melbourne in 1841 and started business as a livestock agent. The gold rushes sent him to the central Victoria diggings dealing in cattle. This was a business that boomed in the early 1850s, and he prospered. In 1859 he took over the Quamby run near Woolsthrope from Paul de Castella, the Yarra Valley Swiss vigneron who had brought the leasehold and improvements in 1853 from George Youl, who had pioneered the run. Quamby was originally 25,000 acres. It was heavily timbered, rough country, much of it swampy, a characteristic of the district. Lindsay used it to fatten cattle which gave large returns with the booming gold diggings towns paying high prices for beef. In 1862 purchases at auction made Quamby a freehold. In the next six years a further 20,000 acres of Crown land were brought at auction to make the run one of the largest in the south-west district. The great profits from his cattle trading enabled Lindsay to make improvements to the holding, and to Union which was added in 1864. Much of the thick timber was cleared and the worst of the swamps drained. Union was 15,000 acres of freehold when Kennedy sold it to Lindsay. It was heavily timbered, mostly blackwood, with large belts of wattle and honeysuckle. Much of the heavy native was ringbarked and cleared; much more was swept away by bushfire. It was expensive work, but Lindsay’s bank passbook was heavy with credit, and he did not spare money to make both Quamby and Union heavily developed stock runs. He was as lavish in social living; the bluestone Quamby homestead was one of the most hospitable in the district when William Lindsay was host there; its paddocks carried high quality thoroughbreds: its stables housed steeplechasers and flat racers which won many races on Warrnambool and other courses; its coach houses were filled with carriages which took his guests to the great racing carnivals of the district. After William Lindsay died in 1897, in his eighty-fifth year, his two sons, William and James, managed Union and Quamby as a joint venture. This partnership ended in 1906 when William took over Union and James kept Quamby. The following year 10,000 acres of Union were subdivided and sold in lots of 100 acres to 700 acres for dairying and general farming. It was well improved country, much of it alluvial flats. By then many of the paddocks were sheltered with blue gum belts, and they carried good pastures. The three Lindsays, father and two sons, gave many years of service to the Shire, and to many charitable, sporting, social and community organisations in the Warrnambool district. William Lindsay senior, was a Shire councillor for 15 years, and President several times. James Lindsay followed his father as a north riding councillor. He served nineteen years, from 1887 until his death in March 1908. He was President four times. Jimmy Lindsay was one of the most popular men in the south-west of Victoria. He was a fine sportsman: horse breeder, owner and a dashing amateur rider. He lived lavishly and played hard. For many years he guarded a herd of kangaroos, as many as 100 head, at Quamby. Descendants of the Lindsay kangaroos are still in the district. James Lindsay’s wife, Margaret Esther was a daughter of Samuel Shaw Parker, the first engineer of the Shire. Nell Lindsay, a daughter, lives in the Bluestone Quamby homestead. Only a little more than 60 acres of the original run still belongs to the property. William Lindsay junior succeeded his brother as a Shire councillor. He served for 25 years from 1908 until his death in 1934. So, the Lindsays, father and two sons, served as Shite councillors for an unbroken period of sixth-five years. William Lindsay junior had a life-long interest in horse racing, as breeder, owner and enthusiastic amateur steeplechase rider. He was elected a member of the Warrnambool racing club in 1901 and was president of the club for thirty-two years. He raced and rode horses for the love of the sport. He won the Villiers and Heytesbury Hunt Cup in the 1870s on his own horse, Ventura. In the year he died his horse Flavedo won the Warrnambool Grand Annual steeplechase. It was a sensational race. All of the contestants fell, or lost their riders. When Flavedo baulked at a jump, its jockey R. Sweetman, remounted and completed the course to win the race. All of the Lindsays were passionately fond of the thoroughbred horse. Nell Lindsay talking to the author in the drawing room of Quamby homestead - with many memories for her of its lavish years – said of a brother that he was put on a horse when he was two years old and never got off. William Lindsay junior made Union into a fine, high-producing property, breeding cattle and horses. He added to the bluestone house that David Kennedy started, established plantations of pines and gums, and made an attractive garden. WARRNAMBOOL MECHANICS’ INSTITUTE Warrnambool's Mechanics' Institute (or Institution as it was sometimes called) was one of the earliest in Victoria. On 17th October 1853 a meeting was held where it was resolved to request the Lieutenant Governor of the Colony to grant land for the erection of a Mechanics' Institutes building. A committee was formed at the meeting and Richard Osburne chaired the first meeting of this committee. The land on the North West corner of Banyan and Merri Streets was granted but there were no funds to erect the building. The Formal Rights of the Warrnambool Mechanics' Institute's encompassed its aims and these were officially adopted in1859; "This Institution has for its object the diffusion of literary, scientific, and other useful knowledge amongst its members, excluding all controversial subjects, religious or political. These objects are sought to be obtained by means of a circulating library, a reading room, the establishment of classes, debates, and the occasional delivery of lectures on natural and experimental philosophy, mechanics, astronomy, chemistry, natural history, literature, and the useful and ornamental arts, particularly those which have a more immediate reference to the colony." The Warrnambool Mechanics' Institute opened its first meeting room in November1854 in the National School building at the corner of Banyan and Timor Streets. The Institute was funded by member subscription, payable on a quarterly, half yearly or yearly basis. Samuel Hannaford, the Manager of the Warrnambool Bank of Australasia, was the first Honorary Secretary of the Mechanics' Institutes, and an early President and Vice-President. He also gave several of the early lectures in the Reading Room. Another early Secretary, Librarian and lecturer was Marmaduke Fisher, the teacher at the National School. Lecture topics included The Poets and Poetry of Ireland', 'The Birth and Development of the Earth', 'The Vertebrae - with Remarks on the pleasures resulting from the study of Natural History' and 'Architecture'. In 1856 the Reading Room was moved to James Hider's shop in Timor Street, and by 1864 it was located in the bookshop of Davies and Read. In the 1860's the Mechanics' Institute struggled as membership waned but in 1866, after a series of fund raising efforts, the committee was able to purchase land in Liebig Street, on a site then called Market Square, between the weighbridge and the fire station. A Mechanics' Institute building was opened at this site in August 1871. The following year four more rooms were added to the main Reading Room and in 1873 the Artisan School of Design was incorporated into the Institute. The same year Joseph Archibald established a Museum; however it deteriorated when he was transferred to Bendigo in 1877. In 1880, with Archibald's return to Warrnambool, the Museum was re-established, and in 1885 a new building was built at the back of the Institute to accommodate the re-created School of Design, the Art Gallery and the Museum. In 1887 the Museum section was moved to the former court house in Timor Street (for some time the walls of the building formed part of the TAFE cafeteria but all is now demolished)). In 1911 the Museum was transferred back to the original building and the management of the Mechanics' Institute was handed over to the Warrnambool City Council. The Museum and Art Gallery became one and housed many fine works of art, and the Library continued to grow. The building was well patronised, with records showing that at the beginning of the 20th century there were between 500 and 800 visitors. During World War One the monthly figures were in the thousands, with 3,400 people visiting in January 1915. The Museum was a much loved Institution in Warrnambool until the contents of the Museum and Art Gallery were removed to make room for the Warrnambool City Council Engineers' Department. The contents were stored but many of the items were scattered or lost. When the original building was demolished the site became occupied by the Civic Centre, which included the new City Library. (The library was temporarily located in the old Palais building in Koroit Street.) In the process of reorganisation the Collection was distributed amongst the community groups: -The new City Library took some of the historic books and some important documents, historic photographs and newspapers. -The Art Gallery kept the 19th Century art collection and some of the artefacts from the museum. -The Historic Society has some items -The State Museum has some items -Some items were destroyed -Flagstaff Hill Maritime Village has old newspapers, Government Gazettes, most of the Mechanics' Institute Library, ledgers and documents connected to the Mechanics' Institute Library, some framed and unframed art works and some photographs. The Warrnambool Mechanics' Institute Library book collection is deemed to be of great importance because it is one of the few collections in an almost intact state, and many of the books are now very rare and of great value. THE PATTISON COLLECTION This book is also part of the ‘Pattison Collection’, a collection of books and records that was originally owned by the Warrnambool Mechanics’ Institute, which was founded in Warrnambool in 1853. In 1935 Ralph Pattison was appointed as City Librarian to establish and organise the Warrnambool Library, as the Warrnambool Mechanics’ Institute was then called. When the Warrnambool Mechanics’ Institute building was pulled down in 1963 a new civic building was erected on the site and the new Warrnambool Library, on behalf of the City Council, took over all the holdings of the Warrnambool Mechanics’ Institute. At this time some of the items were separated and identified as the ‘Pattison Collection’, named after Ralph Pattison. Eventually the components of the Warrnambool Mechanics’ Institute were distributed from the Warrnambool Library to various places, including the Art Gallery, Historical Society and Flagstaff Hill. Later some were even distributed to other regional branches of Corangamite Regional Library and passed to and fro. It is difficult now to trace just where all of the items have ended up. The books at Flagstaff Hill Maritime Village generally display stamps and markings from Pattison as well as a variety of other institutions including the Mechanics’ Institute itself. RALPH ERIC PATTISON Ralph Eric Pattison was born in Rockhampton, Queensland, in 1891. He married Maude Swan from Warrnambool in 1920 and they set up home in Warrnambool. In 1935 Pattison accepted a position as City Librarian for the Warrnambool City Council. His huge challenge was to make a functional library within two rooms of the Mechanics’ Institute. He tirelessly cleaned, cleared and sorted a disarrayed collection of old books, jars of preserved specimens and other items reserved for exhibition in the city’s museum. He developed and updated the library with a wide variety of books for all tastes, including reference books for students; a difficult task to fulfil during the years following the Depression. He converted all of the lower area of the building into a library, reference room and reading room for members and the public. The books were sorted and stored using a cataloguing and card index system that he had developed himself. He also prepared the upper floor of the building and established the Art Gallery and later the Museum, a place to exhibit the many old relics that had been stored for years for this purpose. One of the treasures he found was a beautiful ancient clock, which he repaired, restored and enjoyed using in his office during the years of his service there. Ralph Pattison was described as “a meticulous gentleman whose punctuality, floorless courtesy and distinctive neat dress were hallmarks of his character, and ‘his’ clock controlled his daily routine, and his opening and closing of the library’s large heavy doors to the minute.” Pattison took leave during 1942 to 1945 to serve in the Royal Australian Navy, Volunteer Reserve as Lieutenant. A few years later he converted one of the Museum’s rooms into a Children’s Library, stocking it with suitable books for the younger generation. This was an instant success. In the 1950’s he had the honour of being appointed to the Victorian Library Board and received more inspiration from the monthly conferences in Melbourne. He was sadly retired in 1959 after over 23 years of service, due to the fact that he had gone over the working age of council officers. However he continued to take a very keen interest in the continual development of the Library until his death in 1969. The Birds of Australia by Gregory M. Matthews is now considered a rare and valuable scientific and historic work on its own. These 12 volumes were donated in 1934 to The Warrnambool Mechanics’ Institute and were included as part of the Pattison Collection. The Warrnambool Mechanics’ Institute Collection is primarily significant in its totality, rather than for the individual objects it contains. Its contents are highly representative of the development of Mechanics' Institute libraries across Australia, particularly Victoria. A diversity of publications and themes has been amassed, and these provide clues to our understanding of the nature of and changes in the reading habits of Victorians from the 1850s to the middle of the 20th century. The collection also highlights the Warrnambool community’s commitment to the Mechanics’ Institute, reading, literacy and learning in the regions, and proves that access to knowledge was not impeded by distance. These items help to provide a more complete picture of our community’s ideals and aspirations. The Warrnambool Mechanics Institute book collection has historical and social significance for its strong association with the Mechanics Institute movement and the important role it played in the intellectual, cultural and social development of people throughout the latter part of the nineteenth century and the early twentieth century. The collection of books is a rare example of an early lending library and its significance is enhanced by the survival of an original collection of many volumes. The Warrnambool Mechanics' Institute’s publication collection is of both local and state significance. The Birds of Australia Vol 12 Part 1 Author: Gregory M Mathews Publisher: H. F. & G. Witherby 326 HIGH HOLBORN LONDON Date: 1925-1927 Tan leather bound illustrated work.Label on spine cover with typed text RA 598.2994 MAT Pastedown front endpaper has sticker from Warrnambool Mechanics Institute and Free Library that reads “Presented by W. Lindsay Esq. ‘Union’ Woolsthrope” Accession Number: 15244 Date Received: 3-34 “W. Lindsay” embossed in gold on front cover, bottom right of book flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, the birds of australia, gregory m. matthews, witherby & co., h.f. & g. witherby, w lindsay, william lindsay, quamby woolsthorpe, union woolsthorpe, pattison collection, warrnambool library, warrnambool art gallery, joseph archibald, warrnambool mechanics’ institute and free library, ralph eric pattison, warrnambool city librarian, mechanics’ institute library, victorian library board, warrnambool books and records, warrnambool children’s library, the birds of australia vol 12 part 1, quamby station, union station, woolsthrope -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook - Reference, The Birds of Australia Vol 12 Part 2

The Birds of Australia is a 12 volume work, in a total of 14 books. The books were used as an ornithological handbook. They contain scientific text as well as over 600 hand-coloured lithographed plates by J.G. Keulemans, H. Grönvold, Roland Green, H. Goodchild and G.E. Lodge. The work was written, sponsored and organised by Gregory M. Matthews, F.R.S.C. Erc. who was a wealthy Australian and an amateur ornithologist. His titles included – -Fellow of the Linnean and Zoological Societies of London -Member of the British Ornithologists’ Union -Corresponding Fellow of the American Ornithologists’ Union The volumes in our collection were originally donated to the Warrnambool Mechanics’ Institute and Free Library by William Lindsay. THE LINDSAYS (quoted from the book Of Many Things – A History of Warrnambool Shire by C.E. Sayers) The Lindsays were amongst the most prominent families in the Shire of Warrnambool, as pastoralists, sportsmen, municipal councillors, community leaders. The first of the family William arrived in Melbourne in 1841 and started business as a livestock agent. The gold rushes sent him to the central Victoria diggings dealing in cattle. This was a business that boomed in the early 1850s, and he prospered. In 1859 he took over the Quamby run near Woolsthrope from Paul de Castella, the Yarra Valley Swiss vigneron who had brought the leasehold and improvements in 1853 from George Youl, who had pioneered the run. Quamby was originally 25,000 acres. It was heavily timbered, rough country, much of it swampy, a characteristic of the district. Lindsay used it to fatten cattle which gave large returns with the booming gold diggings towns paying high prices for beef. In 1862 purchases at auction made Quamby a freehold. In the next six years a further 20,000 acres of Crown land were brought at auction to make the run one of the largest in the south-west district. The great profits from his cattle trading enabled Lindsay to make improvements to the holding, and to Union which was added in 1864. Much of the thick timber was cleared and the worst of the swamps drained. Union was 15,000 acres of freehold when Kennedy sold it to Lindsay. It was heavily timbered, mostly blackwood, with large belts of wattle and honeysuckle. Much of the heavy native was ringbarked and cleared; much more was swept away by bushfire. It was expensive work, but Lindsay’s bank passbook was heavy with credit, and he did not spare money to make both Quamby and Union heavily developed stock runs. He was as lavish in social living; the bluestone Quamby homestead was one of the most hospitable in the district when William Lindsay was host there; its paddocks carried high quality thoroughbreds: its stables housed steeplechasers and flat racers which won many races on Warrnambool and other courses; its coach houses were filled with carriages which took his guests to the great racing carnivals of the district. After William Lindsay died in 1897, in his eighty-fifth year, his two sons, William and James, managed Union and Quamby as a joint venture. This partnership ended in 1906 when William took over Union and James kept Quamby. The following year 10,000 acres of Union were subdivided and sold in lots of 100 acres to 700 acres for dairying and general farming. It was well improved country, much of it alluvial flats. By then many of the paddocks were sheltered with blue gum belts, and they carried good pastures. The three Lindsays, father and two sons, gave many years of service to the Shire, and to many charitable, sporting, social and community organisations in the Warrnambool district. William Lindsay senior, was a Shire councillor for 15 years, and President several times. James Lindsay followed his father as a north riding councillor. He served nineteen years, from 1887 until his death in March 1908. He was President four times. Jimmy Lindsay was one of the most popular men in the south-west of Victoria. He was a fine sportsman: horse breeder, owner and a dashing amateur rider. He lived lavishly and played hard. For many years he guarded a herd of kangaroos, as many as 100 head, at Quamby. Descendants of the Lindsay kangaroos are still in the district. James Lindsay’s wife, Margaret Esther was a daughter of Samuel Shaw Parker, the first engineer of the Shire. Nell Lindsay, a daughter, lives in the Bluestone Quamby homestead. Only a little more than 60 acres of the original run still belongs to the property. William Lindsay junior succeeded his brother as a Shire councillor. He served for 25 years from 1908 until his death in 1934. So, the Lindsays, father and two sons, served as Shite councillors for an unbroken period of sixth-five years. William Lindsay junior had a life-long interest in horse racing, as breeder, owner and enthusiastic amateur steeplechase rider. He was elected a member of the Warrnambool racing club in 1901 and was president of the club for thirty-two years. He raced and rode horses for the love of the sport. He won the Villiers and Heytesbury Hunt Cup in the 1870s on his own horse, Ventura. In the year he died his horse Flavedo won the Warrnambool Grand Annual steeplechase. It was a sensational race. All of the contestants fell, or lost their riders. When Flavedo baulked at a jump, its jockey R. Sweetman, remounted and completed the course to win the race. All of the Lindsays were passionately fond of the thoroughbred horse. Nell Lindsay talking to the author in the drawing room of Quamby homestead - with many memories for her of its lavish years – said of a brother that he was put on a horse when he was two years old and never got off. William Lindsay junior made Union into a fine, high-producing property, breeding cattle and horses. He added to the bluestone house that David Kennedy started, established plantations of pines and gums, and made an attractive garden. WARRNAMBOOL MECHANICS’ INSTITUTE Warrnambool's Mechanics' Institute (or Institution as it was sometimes called) was one of the earliest in Victoria. On 17th October 1853 a meeting was held where it was resolved to request the Lieutenant Governor of the Colony to grant land for the erection of a Mechanics' Institutes building. A committee was formed at the meeting and Richard Osburne chaired the first meeting of this committee. The land on the North West corner of Banyan and Merri Streets was granted but there were no funds to erect the building. The Formal Rights of the Warrnambool Mechanics' Institute's encompassed its aims and these were officially adopted in1859; "This Institution has for its object the diffusion of literary, scientific, and other useful knowledge amongst its members, excluding all controversial subjects, religious or political. These objects are sought to be obtained by means of a circulating library, a reading room, the establishment of classes, debates, and the occasional delivery of lectures on natural and experimental philosophy, mechanics, astronomy, chemistry, natural history, literature, and the useful and ornamental arts, particularly those which have a more immediate reference to the colony." The Warrnambool Mechanics' Institute opened its first meeting room in November1854 in the National School building at the corner of Banyan and Timor Streets. The Institute was funded by member subscription, payable on a quarterly, half yearly or yearly basis. Samuel Hannaford, the Manager of the Warrnambool Bank of Australasia, was the first Honorary Secretary of the Mechanics' Institutes, and an early President and Vice-President. He also gave several of the early lectures in the Reading Room. Another early Secretary, Librarian and lecturer was Marmaduke Fisher, the teacher at the National School. Lecture topics included The Poets and Poetry of Ireland', 'The Birth and Development of the Earth', 'The Vertebrae - with Remarks on the pleasures resulting from the study of Natural History' and 'Architecture'. In 1856 the Reading Room was moved to James Hider's shop in Timor Street, and by 1864 it was located in the bookshop of Davies and Read. In the 1860's the Mechanics' Institute struggled as membership waned but in 1866, after a series of fund raising efforts, the committee was able to purchase land in Liebig Street, on a site then called Market Square, between the weighbridge and the fire station. A Mechanics' Institute building was opened at this site in August 1871. The following year four more rooms were added to the main Reading Room and in 1873 the Artisan School of Design was incorporated into the Institute. The same year Joseph Archibald established a Museum; however it deteriorated when he was transferred to Bendigo in 1877. In 1880, with Archibald's return to Warrnambool, the Museum was re-established, and in 1885 a new building was built at the back of the Institute to accommodate the re-created School of Design, the Art Gallery and the Museum. In 1887 the Museum section was moved to the former court house in Timor Street (for some time the walls of the building formed part of the TAFE cafeteria but all is now demolished)). In 1911 the Museum was transferred back to the original building and the management of the Mechanics' Institute was handed over to the Warrnambool City Council. The Museum and Art Gallery became one and housed many fine works of art, and the Library continued to grow. The building was well patronised, with records showing that at the beginning of the 20th century there were between 500 and 800 visitors. During World War One the monthly figures were in the thousands, with 3,400 people visiting in January 1915. The Museum was a much loved Institution in Warrnambool until the contents of the Museum and Art Gallery were removed to make room for the Warrnambool City Council Engineers' Department. The contents were stored but many of the items were scattered or lost. When the original building was demolished the site became occupied by the Civic Centre, which included the new City Library. (The library was temporarily located in the old Palais building in Koroit Street.) In the process of reorganisation the Collection was distributed amongst the community groups: -The new City Library took some of the historic books and some important documents, historic photographs and newspapers. -The Art Gallery kept the 19th Century art collection and some of the artefacts from the museum. -The Historic Society has some items -The State Museum has some items -Some items were destroyed -Flagstaff Hill Maritime Village has old newspapers, Government Gazettes, most of the Mechanics' Institute Library, ledgers and documents connected to the Mechanics' Institute Library, some framed and unframed art works and some photographs. The Warrnambool Mechanics' Institute Library book collection is deemed to be of great importance because it is one of the few collections in an almost intact state, and many of the books are now very rare and of great value. THE PATTISON COLLECTION This book is also part of the ‘Pattison Collection’, a collection of books and records that was originally owned by the Warrnambool Mechanics’ Institute, which was founded in Warrnambool in 1853. In 1935 Ralph Pattison was appointed as City Librarian to establish and organise the Warrnambool Library, as the Warrnambool Mechanics’ Institute was then called. When the Warrnambool Mechanics’ Institute building was pulled down in 1963 a new civic building was erected on the site and the new Warrnambool Library, on behalf of the City Council, took over all the holdings of the Warrnambool Mechanics’ Institute. At this time some of the items were separated and identified as the ‘Pattison Collection’, named after Ralph Pattison. Eventually the components of the Warrnambool Mechanics’ Institute were distributed from the Warrnambool Library to various places, including the Art Gallery, Historical Society and Flagstaff Hill. Later some were even distributed to other regional branches of Corangamite Regional Library and passed to and fro. It is difficult now to trace just where all of the items have ended up. The books at Flagstaff Hill Maritime Village generally display stamps and markings from Pattison as well as a variety of other institutions including the Mechanics’ Institute itself. RALPH ERIC PATTISON Ralph Eric Pattison was born in Rockhampton, Queensland, in 1891. He married Maude Swan from Warrnambool in 1920 and they set up home in Warrnambool. In 1935 Pattison accepted a position as City Librarian for the Warrnambool City Council. His huge challenge was to make a functional library within two rooms of the Mechanics’ Institute. He tirelessly cleaned, cleared and sorted a disarrayed collection of old books, jars of preserved specimens and other items reserved for exhibition in the city’s museum. He developed and updated the library with a wide variety of books for all tastes, including reference books for students; a difficult task to fulfil during the years following the Depression. He converted all of the lower area of the building into a library, reference room and reading room for members and the public. The books were sorted and stored using a cataloguing and card index system that he had developed himself. He also prepared the upper floor of the building and established the Art Gallery and later the Museum, a place to exhibit the many old relics that had been stored for years for this purpose. One of the treasures he found was a beautiful ancient clock, which he repaired, restored and enjoyed using in his office during the years of his service there. Ralph Pattison was described as “a meticulous gentleman whose punctuality, floorless courtesy and distinctive neat dress were hallmarks of his character, and ‘his’ clock controlled his daily routine, and his opening and closing of the library’s large heavy doors to the minute.” Pattison took leave during 1942 to 1945 to serve in the Royal Australian Navy, Volunteer Reserve as Lieutenant. A few years later he converted one of the Museum’s rooms into a Children’s Library, stocking it with suitable books for the younger generation. This was an instant success. In the 1950’s he had the honour of being appointed to the Victorian Library Board and received more inspiration from the monthly conferences in Melbourne. He was sadly retired in 1959 after over 23 years of service, due to the fact that he had gone over the working age of council officers. However he continued to take a very keen interest in the continual development of the Library until his death in 1969. The Birds of Australia by Gregory M. Matthews is now considered a rare and valuable scientific and historic work on its own. These 12 volumes were donated in 1934 to The Warrnambool Mechanics’ Institute and were included as part of the Pattison Collection. The Warrnambool Mechanics’ Institute Collection is primarily significant in its totality, rather than for the individual objects it contains. Its contents are highly representative of the development of Mechanics' Institute libraries across Australia, particularly Victoria. A diversity of publications and themes has been amassed, and these provide clues to our understanding of the nature of and changes in the reading habits of Victorians from the 1850s to the middle of the 20th century. The collection also highlights the Warrnambool community’s commitment to the Mechanics’ Institute, reading, literacy and learning in the regions, and proves that access to knowledge was not impeded by distance. These items help to provide a more complete picture of our community’s ideals and aspirations. The Warrnambool Mechanics Institute book collection has historical and social significance for its strong association with the Mechanics Institute movement and the important role it played in the intellectual, cultural and social development of people throughout the latter part of the nineteenth century and the early twentieth century. The collection of books is a rare example of an early lending library and its significance is enhanced by the survival of an original collection of many volumes. The Warrnambool Mechanics' Institute’s publication collection is of both local and state significance. The Birds of Australia Vol 12 Part 2 Author: Gregory M Mathews Publisher: H. F. & G. Witherby 326 HIGH HOLBORN LONDON Date: 1925-1927 Tan leather bound illustrated work.Label on spine cover with typed text RA 598.2994 MAT Pastedown front endpaper has sticker from Warrnambool Mechanics Institute and Free Library that reads “Presented by W. Lindsay Esq. ‘Union’ Woolsthrope” Accession Number: 15245 Date Received: 3-34 “W. Lindsay” embossed in gold on front cover, bottom right of book flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, the birds of australia, gregory m. matthews, witherby & co., h.f. & g. witherby, w lindsay, william lindsay, quamby woolsthorpe, union woolsthorpe, pattison collection, warrnambool library, warrnambool art gallery, joseph archibald, warrnambool mechanics’ institute and free library, ralph eric pattison, warrnambool city librarian, mechanics’ institute library, victorian library board, warrnambool books and records, warrnambool children’s library, the birds of australia vol 12 part 2, quamby station, union station, woolsthrope -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Lamp, c. 1854

... . Burner painted flat gold. Functional object Lamp Prices Patent ...Iron with octagonal sides, folding wire handle, glass sides. Burner incomplete. Painted semi-gloss black. Burner painted flat gold.Front: Prices Patent Candle Company/ Government Immigrant Ship Lanthorn No 3610/ Registered July 5 1854 (brass plate) Back: (no inscriptions)ss lanthorn, lantern, ships light -

Kiewa Valley Historical Society

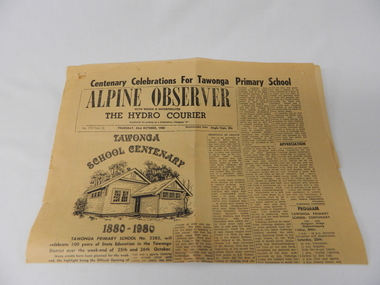

Kiewa Valley Historical SocietyNewspaper Article - Tawonga School Centenary 1980 x2, Alpine Courier incorporating The Hydro Courier, 1980

This newspaper article was produced at a time when newspapers were the main source of local information. The period before the explosion of mobile communication technology and the cost effectiveness of communication by "texting" and internet "social connections, eg. facebook and other social media networkings" The newspapers were the main links between and within large regions. The Hydro Courier was first printed in 1950 as a YMCA community service publication by Mr. Albert Clarke YMCA Officer and Mr. Alex McCullough a State Electricity Commission employee. This paper was one very important publication that provided relevant community information to all and was the major contributer to the "Valley" cohesive fibre and unity. This article not only records the celebration (centenary) of the Tawonga School but also presents the history of the school and important events such as various relocations of classrooms and how the region was settled and developed from the 1870's onward. The yawonga school opened in 1880 on 8 acres of land. It consisted of one large wooden building (22 ft x 11 ft). It had two windows, one brick chimney, bare wooden floor and a shingle roof. This article also presents the time when Mount Beauty area was likened to an island and occasionally school children could not attend school because of a flooded Kiewa river. The article also covers the changes brought about by the increased employment opportunities from SEC Kiewa Works(1935), the Sawmill(1946), the Gold mine(1949) and the Tobacco Industry (largest growing area in Australia).This item is a one page (original) article of the centenary celebrations for Tawonga Primary School came from the Alpine Observer and incorporated the Hydro Courier. It covers the arrangements for the celebration of the 100 years of the school's existence. The printed layout is typical of the typeset in use in 1980's. There are seven distinctive type collumns separated by a printed line. Three photographs are published with one photograph of a demountable classromm ,circa 1980, and the other two of student class photos of 1899 and 1914. Teacher and student names are listed below each photograph. On the back of this page are "specials" for "Sam's Cut Price Stores", specifically the Myrtleford store. Of interest is the advertisement of "Cartons of Cigarettes at cut prices". The page was produced as part of a "run" with "telltale" holes at each corner for stabilising the page in the printing process."Centenary Celebrations For Tawonga Primary School" below this in an enclosed heading "ALPINE OBSERVER" underneath in smaller print "WITH WHICH IS INCORPORATED" below this in larger print "THE HYDRO COURIER" and below this from left to right, "No. 719 (Vol. 3) THURSDAY, 23rd OCTOBER, 1980" next "in smaller print Recommended Price Single Copy, 20c "(cents)rural school development, tawonga school centenary, kiewa valley development 1880 to 1980 -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomInvitation Card, The Fourth Light Horse Regiment (AIF) Association 37th Annual Ladies' Night, 1987

A gold edged yellow card, with the event, location, date, price etc printed in blue 4th light horse association, ladies' night -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Federation University Historical Collection

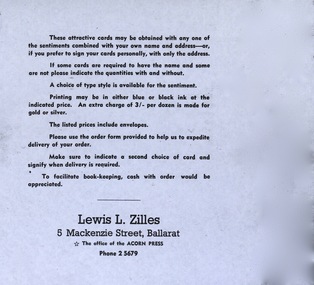

Federation University Historical CollectionCard - Card - Christmas Card Selection, ZILLES COLLECTION: Selection of Christmas Cards with various inscription options

Zilles Printers was begun by Lewis Zilles in the early 1930s. It was in McKenzie Street Ballarat. His son Jeffrey also became a printer - letterpress, offset and screen printer. The business became Zilles Printers/Graphics and was in Armstrong Street and later Bell Street Ballarat. Selection of Christmas cards that are available with inscription printed inside. A selection of sentiments to choose from plus the persons name and address - various type forms - can be printed inside. Printing maybe in either blue or black ink. An extra charge is made for gold and silver. A second choice of card is advised and date for delivery requested.Twelve black cover paper sheets with card glued on. Price information given. Two A4 information sheets. Order form pad.zilles printers, ballarat, lewis zilles, christmas cards, christmas sentiments, type forms, gold and silver, order form -

Blacksmith's Cottage and Forge

Blacksmith's Cottage and ForgeTin, pile ointment, and box, W.B. Cartwright Ltd. Rawdon (England), Sydney and Melbourne

Part of the domestic medicine chest.LocalIntact tin of pile ointment within cardboard box. Gold colour tin with blue paint and yellow decoration and white lettering/ cream paint with blue lettering. Box is similar, with directions for use. All in good condition. Unused.Cartwright's Pile Ointment. Directions for use. Price:1/9d. -

Federation University Historical Collection

Federation University Historical CollectionPlan, Berry Bank Estates

This plan is associated with former Ballarat School of Mines Student Richard Squire (1875-1876). Gift of the Squire FamilyPlan of Berry Bank Estates. Coloured plan on cream paperberry bank estates, mining, happy valley, lake rosine estates, strathvean estates proprietary, w. luplaupitfield plateau, british banner, federal mint, moller, morrow, south pitfield consols, east banner, new lallah rookh, bull dog company, mindai, j. morpoh, poliah, f. j. morrow, piggoreet east, w. m. acheson, grand trunk, field's claim south grand trunk, south grand trunk, woady yalloak creek, mount misery creek, fitzpatric's creek, illabrook creek, great western, mount bute syndicate, narringhill creek, little woady yalloak creek, piggoreet east preemptive right, southern birthday, new birthday, prince of wales, collins, brassey birthday, howarth's lead, w. price, royal birthday, a. clinton, victoria express, patons, williams fancy, hennessy, queen of the south, n, pandora proprietary gold estate, lyonbank lease, rowe's southern, rowe's extended, w. t. rowe, wallinduc company, glenfine horseshoe company, rowe's glenfine junction, wallinduc syndicate, pitfield estates, rowe's estate, southern glenfine, h. fields, christies & fields, balmoral company, glenfine united, hallett, great glenfine, rowe consuls, nicholls, london & melbourne gold mine, j. w. pascoe, christies, glenfine central, j. king, j. durston, great western extended, oswald, woadyyaloak, berringa, squire -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate