Showing 3797 items

matching machines

-

Monbulk RSL Sub Branch

Monbulk RSL Sub BranchBook, Salamander Books, Suicide squads: the men and machines of World War II special operations, 1981

... Suicide squads: the men and machines of World War II ...An examination of the machinery and motives of self sacrifice during World War TwoIndex, bibliography, ill, diagrams, p.281.non-fictionAn examination of the machinery and motives of self sacrifice during World War Twoworld war 1939 – 1945 – aerial operations - japan, kamikaze attacks -

Monbulk RSL Sub Branch

Monbulk RSL Sub BranchBook, Peerage books, Encyclopedia of war machines, 1984

... Encyclopedia of war machines ...This encyclopedia details the breakthroughs in military technology from the earliest days.Index, ill, p.386.non-fictionThis encyclopedia details the breakthroughs in military technology from the earliest days.weaponry - history, military technology - history -

Robin Boyd Foundation

Robin Boyd FoundationBook, Bering, Super Flame Guns and Flame Machines

... Super Flame Guns and Flame Machines ...Paperbackwalsh st library -

Lakes Entrance Regional Historical Society (operating as Lakes Entrance History Centre & Museum)

Lakes Entrance Regional Historical Society (operating as Lakes Entrance History Centre & Museum)Book, Beck, Doreen, Digging Stick to Rotary Hoe - Men and Machines in Rural Australia, 1973

... Digging Stick to Rotary Hoe - Men and Machines in Rural ...A guide to the history and collection of types of bottles from around the world.collections -

Stawell Historical Society Inc

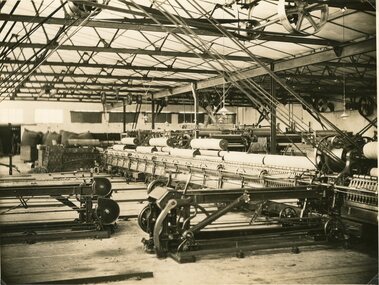

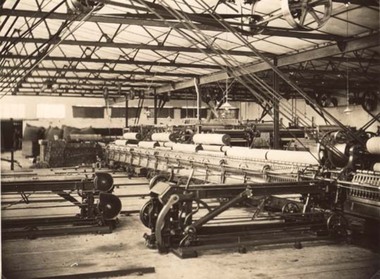

Stawell Historical Society IncPhotograph, North Western Woollen Mills -- Spinning Machines

... North Western Woollen Mills -- Spinning Machines ...North Western Woollen Mills - Framed - Spinning Departmentstawell industry -

Stawell Historical Society Inc

Stawell Historical Society IncArchive - Laboratory Books, Mechanics of Machines - An Introduction to, J.L.M. Morrison and B. Crossland

... Mechanics of Machines - An Introduction to, J.L.M ...From Dye Laborataory AUNDE / Norwellan North Western Woolen Mills became Norwellan Textiles then AUNDEDark Green Cover with artwork or EngineJohn Bennett, Lyddon Hall Leeds 8/10/69manufacturing -

Tramways/East Melbourne RSL Sub Branch - RSL Victoria Listing id: 27511

Tramways/East Melbourne RSL Sub Branch - RSL Victoria Listing id: 27511Book, Manuel De Landa et al, WAR IN THE AGE OF INTELLIGENT MACHINES(The power and efficiency of new computerized weapons and surveillance technology), 1991

... WAR IN THE AGE OF INTELLIGENT MACHINES(The power and ...isbn: 0-942299-75-2 -

Moorabbin Air Museum

Moorabbin Air MuseumPamphlet (Item) - Ansett The Tools Of Our Trade Drilling Machines

... Ansett The Tools Of Our Trade Drilling Machines ... -

Moorabbin Air Museum

Moorabbin Air MuseumBooklet (Item) - Ansett Notes On Automatic Bar Machines

... Ansett Notes On Automatic Bar Machines ...Ministry Of Munitions Commonwealth Of Australia -

Moorabbin Air Museum

Moorabbin Air MuseumBook - EARLY FLYING MACHINES -1799 - 1909, CHARLES GIBBS-SMITH, 1976

... EARLY FLYING MACHINES -1799 - 1909 ... -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, North Western Woollen Mills -- Spinning Machines

... North Western Woollen Mills -- Spinning Machines ...North Western Woollen Mills - Spinning Departmentstawell industry -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Combing Machines, China, 1990s

... Combing Machines, China ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing interior of a factory, depicting combing machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Gill Box Machines, 1990s

... Gill Box Machines ...This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing factory interior with gill box machinery.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

Thompson's Foundry Band Inc. (Castlemaine)

Thompson's Foundry Band Inc. (Castlemaine)Sheet Music, Maginicent Men In Flying Machines

... Maginicent Men In Flying Machines ... -

Park Orchards Community House

Park Orchards Community HousePhotograph, Ladies on sewing machines at the Park Orchards Community Centre

... Ladies on sewing machines at the Park Orchards Community ...Photo date stamp says 16th August 2012 -

Monbulk RSL Sub Branch

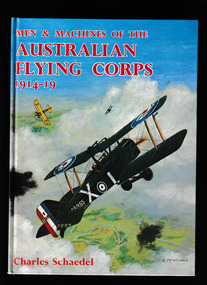

Monbulk RSL Sub BranchBook, Kookaburra Technical Publications, Men and machines of the Australian Flying Corps 1914-1919, 1972

... Men and machines of the Australian Flying Corps 1914-1919 ...Chapter 1: Point Cook and Mesopotamia Chapter 2: The desert war Chapter 3: The eyes of the Army Chapter 4: The first fighter unit Chapter 5: Last but not least.Ill, p.56.Chapter 1: Point Cook and Mesopotamia Chapter 2: The desert war Chapter 3: The eyes of the Army Chapter 4: The first fighter unit Chapter 5: Last but not least.world war 1914-1918 - aerial operations - australia, world war 1914-1918 - australian flying corps -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing machine kit

Used by donor until replaced by modern machine equipped with inbuilt button attachmentSewing machine attachments in red plastic box. Buttonhole attachment cream coloured with red measures and knobs for adjustments. A total of 4 items in the set.Singer; Singer Sewing Machine (on box)|Singer Bight Space (on attachment)domestic items, sewing -

Stawell Historical Society Inc

Stawell Historical Society IncFunctional object - Realia, New National Treadle Sewing Machine

Treadle home Sewing machine - pre-electric. Rusted partsBlack "pre-electric treadle sewing machine with "fly wheel" "New national"Gold leaf floral design on machine and flat greyhound trademark inside floral circle, fastened to wooden lid of tableclothing manufacture -

Greensborough Historical Society

Greensborough Historical SocietySewing machine accessories, Singer Manufacturing Company, Singer Sewing Machine Discs, 1960c

Commonly used removable cams from a Singer sewing machine of the 1960s. These cams enabled the home sewer to use fancy stitches in their work and were later superseded by integrated electronic controls.Box containing four sewing machine cams and leaflet containing sewing patterns and instructions for use. Accessories to a Singer sewing machine.Fashion discs for Singer Automatic swing-needle machine. Set no. 2, 276401, 306 class. Shell, Solid scallop, Icicle and Banner singer sewing machines -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine, G Stibbe and Co, c.1928

... Machines ...Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Dellruss Pty Ltd original owner Llyold Henry Coburg. Mock ribber fitted post World War 2. In use from c.1928 until 1978.Stibbe Maxim circular sock knitting machine.sock knitting machine, manufacturing, textiles, socks, machines, circular, clothing, industry, wool -

National Wool Museum

National Wool MuseumArchive - Manual, Dubied Instructions for the Hand Knitting Machine Type M or MR

Instruction manual for the Dubied Type M or MR hand knitting machine.A4 sized instruction book. Green stapled book with black text for headings on front page. Contains instructions and diagrams for the knitting machine. 64 pages.Dubied Neuchatel (Switzerland) Instructions for the Hand Knitting Machine Type M or MRknitting, machine, instructions, dubied -

National Wool Museum

National Wool MuseumPhotograph, Q-VEE Machine, 29/06/1937

Photographs were most likely used for promotional purposes. The Q-VEE machine is a scouring machine. When fabric is removed from the loom it is often stiff, rough or uneven. Scouring removes the oils and dirt picked up from manufacture, leaving the fabric soft and fluffy. The photographed machine was made by J. Stone & Co, a British marine and railway engineering company based in Deptford in south east London.Four black and white, blue tinged photos of a Scouring Machine from different angles. Black writing on the rear, typed with a typewriter and stamped with the company stamp.8051.1 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 849 8051.2 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 856 8051.3 - rear - "Q-VEE" Machine. Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 851 8051.4 - front on machine - FIY Chain Gear J.Stone & Co Ltd London rear - P.I.V. Dial Control Tomlinsons (Roshdale) Limited. SOHO Works Rochdale. 29.6.37 853textile machinery, wool manufacture, wool, scouring -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, Singer Sewing Machine Company, Circa 1878

The artefact is a glass sewing machine oil bottle recovered from the 1878 shipwreck of the Loch Ard near Port Campbell. It was raised by Flagstaff Hill divers in 1973. The sewing machine oil bottle was used to lubricate a sewing machine mechanism and supplied with new Singer sewing machines as part of the items tool kit. The Loch Ard was constructed on the Clyde in 1873 for the prestigious Loch Line of colonial clipper ships, designed for the Australian run. She sailed from England on 1 March 1878 carrying 37 crew, 17 passengers and a diverse general cargo ranging from luxury items to bulk railway iron. On 1 June 1878, emerging from fog and hearing too late the sound of breakers against the tall limestone cliffs, the vessel struck the southern foot of Mutton Bird Island and sank in 23 meters of water. Of the fifty-four people on board, only two survived, one young male crewman, Tom Pearce, and one young female passenger, Eva Carmichael. (See References or Notes below for further details.)The bottle is believed to be part of the cargo or passenger goods recovered from the Loch Ard that is of historical significance for Victoria. Registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from the Loch Ard. Its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck. The object gives us a snapshot into maritime history so we can interpret the story of this tragic event. The collection of marine objects is archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time with this wreck being one of the worst and best-known shipwrecks in Victoria's history. Clear glass oil bottle, rectangular body with concave sides. The bottle has raised inscriptions on the glass.The bottle contained Singer Sewing Machine Oil bottle. Recovered from the wreck of the Loch Ard. "The Singer Manufacturing Company" "Extra Quality Machine Oil."flagstaff hill, warrnambool, shipwreck coast, flagstaff hill maritime museum, flagstaff hill maritime village, maritime museum, great ocean road, shipwreck artefact, loch ard, mutton bird island, glenample, eva carmichael, tom pearce, flagstaff hill divers, singer sewing machines, lock ard artifact, oil bottle, the singer manufacturing company, extra quality machine oil -

National Wool Museum

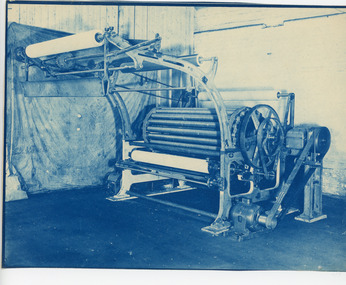

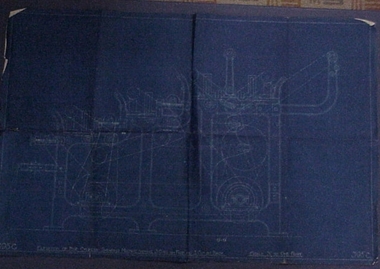

National Wool MuseumBlueprint, "Elevation of Four Cylinder Shearing Machine Shewing3 Cuts on Face and 1 Cut on Back"

Blueprint, printed white on blue paper, of the mechanical engineering drawings of "Elevation of Four Cylinder Shearing Machine Shewing3 Cuts on Face and 1 Cut on Back" -395C"Elevation of Four Cylinder Shearing Machine Shewing3 Cuts on Face and 1 Cut on Back" -395C.ELEVATIOB OF FOUR CYLINDER SHEARING MACHINE SHEWING 3 CUTS ON FACE AND 1 CUT ON BACK -395Cshearing machinery shearing sheds shearing, shearing machinery, shearing sheds, shearing -

National Wool Museum

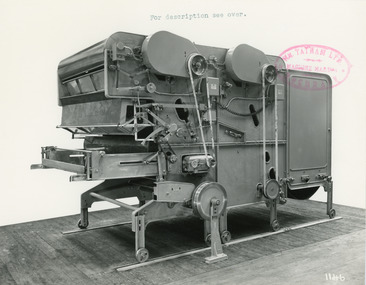

National Wool MuseumPhotograph - Product Photograph, Automatic Feeding Machine

These are sales photographs for William Tatham Ltd. of Rochdale. These photographs are taken in the fitting shop at William Tatham Ltd. where final assembly would have taken place. The Automatic Feeding Machine automatically dispenses wool to a carding machine, so that an even, constant supply is received. This eliminated the manual labour previously needed for the initial weighing and feeding of wool. The photographed machine was made by William Tatham Ltd, a textile engineering company based in Rochdale, UK. Established in 1866, Tatham developed innovative textile machinery and sent their products to Australia and other countries around the world.Two black and white photos of an Automatic Feeding Machine in a landscape format. The first photo is of the front of the machine, the second is of the rear.8037.1 - Front - top margin: For description see over. Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1146 Rear - 78” wide Automatic Feeding Machine having Dual Hoppers in which the first and large section feeds the second Hopper so as to maintain a constant level of material in the latter. The driving of both spiked lattices is by electro-magnetic clutches, the one in the first Hopper being actuated by a sensitive feeler motion in the second, the second spiked lattice however, being controlled, of course, from the Scale Pan. Through a mercury switch. The scale is of our latest super-sensitive pattern mounted diagonally across the Feed. Only the opening doors are used in the actual weighting and the trap doors placed over the scale which close immediately the correct weight is deposited, operate through a solenoid. The machine incorporates many other features and is arranged to divide for facility in cleaning. 8037.2 - Front mide right edge - Wm. TATHAM Ltd. ROCHDALE. Machine Maker Front bottom right corner - 1147 Rear - Showing opposite side of Dual Automatic Feed illustrated in photo 1146textile machinery, automatic feeding machine, tatham, feeding machine -

Broadmeadows Historical Society & Museum

Broadmeadows Historical Society & MuseumMachine - Adding Machine

Burroughs Adding Machines Ltd of Detroit Michigan was the first company to occupy a factory at Strathleven. During the European reconstruction in the late 1940's Burroughs built a major new factory at Strathleven in Scotland, initially to assemble machines from US-made parts and later to manufacture the full product range for the British and Commonwealth markets. Most of the post-war calculators and portables found in Australia are from the Strathleven factory.This manually operated calculator predates the rise of the modern computer.A manually operated Burrough's adding machine. It is a greyish green plastic and has a silver handle. It has 8 columns to add manually and has decimal currency. There is a roll of white (slightly yellowed) paper inserted in the top section.Burroughs Machine Limited, Strathleven, Scotland Made in Great Britainburroughs adding machine, office, calculator, detroit, michigan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Rocket Launcher, John Dennett, 1860s

This rocket launching machine is used in conjunction with the Dennett Rocket Set. Both are part of the rocket rescue equipment that launches the line-throwing rescue rockets. A light line is threaded through the carved holes in the 8 foot long shaft and attached to the scribed channel at the base of the shaft. The rocket head is fitted to the shaft and inserted into the machine. The machine is set at an angle determined by the person in charge of the rescue crew, and the legs and base of the machine are adjusted accordingly with the use of the quadrant, or protractor, and plumb-bob on the side of the machine. The rocket is then ignited and fired across the vessel in distress. John Dennett - John Dennett was from Carisbrooke, in the Ilse of Wight, UK. In 1826 he invented, patented and demonstrated an improved method of rocket powered, line firing rescue equipment for saving lives. The rockets had a longer range than the mortars being used, they were lighter, needed less preparation time, only needed one line for repeated shots, and fewer people were needed to move the equipment. Very favourable reports of Dennett’s rockets were received by those in charge of His Majesty’s Naval and Military services. In 1832, Dennett’s rocket-thrown line was sent out to the wreck of the ‘Bainbridge’, and was responsible for nineteen survivors coming ashore in two boatloads, along the fired line. Dennett’s rocket received national fame, and a one-year contract to supply rockets to the Coastguards. He became known as ‘Rocket Man’ and his rockets were used in rescues at least until 1890, when his son Horatio was running the business. A rocket weighing 23 lb would have a range of about 250 yards (228 metres), on average. Saving lives in Warrnambool – The coastline of South West Victoria is the site of over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built to house it. In 1858 the provision of rocket and mortar apparatus was approved for lifeboat stations in Victoria, and in 1864 a rocket house was built to safely store the rocket rescue equipment. In 1878 the buildings were moved to the Breakwater area, and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost a hundred years the lifeboat and rocket crews, mostly local volunteers, trained regularly to maintain their rescue skills. They were summoned when needed by alarms, gunshots, ringing bells and foghorns. Some became local heroes but all served an important role. By the end of the 1950s the lifeboat and rescue equipment had become obsolete. Rocket Rescue Method - The Government of Victoria adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain. It authorised the first line-throwing rescue system in 1858. Captain Manby’s mortar powered a projectile connected to rope, invented in 1808. The equipment was updated to John Dennett’s 8-foot shaft and rocket method that had a longer range of about 250 yards. From the 1860s the breeches buoy and traveller block rocket rescue apparatus was in use. It was suspended on a hawser line and manually pulled to and from the distressed vessel carrying passengers and items. In the early 1870s Colonel Boxer’s rocket rescue method became the standard in Victoria. His two-stage rockets, charged by a gunpowder composition, could fire the line up to 500-600 yards, although 1000 yards range was possible. Boxer’s rocket carried the light line, which was faked, or coiled, in a particular way between pegs in a faking box to prevent twists and tangles when fired. The angle of firing the rocket to the vessel in distress was measured by a quadrant-type instrument on the side of the rocket machine. Decades later, in about 1920, Schermuly invented the line-throwing pistol that used a small cartridge to fire the rocket. The British Board of Trade published instructions for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle measured by the quadrant, inserting a rocket that had a light-weight line threaded through its shaft, and then firing it across the stranded vessel, the line issuing freely from the faking board. A tally board was then sent out to the ship with instructions in four languages. The ship’s crew would haul on the line to bring out the heavier, continuous whip line, then secure the attached whip block to the mast or other sturdy part the ship. The rescue crew on shore then hauled out a stronger hawser line, which the ship’s crew fixed above the whip block. The hawser was then tightened using the block on the shore end of the whip. The breeches buoy and endless whip are then attached to the traveller block on the hawser, allowing the shore crew to haul the breeches buoy to and from the vessel, rescuing the stranded crew one at a time. This rocket launcher machine is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.Rocket launcher, named a Rocket Machine, and storage box. Launcher has a long open metal channel with a spike at the base, and narrow, rectangular device, which is the line-firing rocket machine, at the top, all painted blue. Two hinged wooden legs are attached where the channel and machine meet. The side of the machine has an oval cut-out window and an attached quadrant, or protractor, with a plumb-bob on it. The quadrant has angles marked in degrees. The long protective box has white stencilled letters along the side. Its lid has three hinges and is fastened with two metal latches.On box “ROCKET MACHINE” On quadrant “10” “20” “30” “40”flagstaff hill maritime museum & village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, maritime accidents, shipwreck victim, rocket crew, beach rescue, line rescue, rescue equipment, rocket firing equipment, rocket rescue equipment, rocket apparatus, beach apparatus, petticoat breeches, breeches buoy, rocket house, rocket shed, lifeboat men, rocket equipment, rocket machine, rocket head, rocket launcher, rocket line, marine technology, william schermuly, line-firing pistol, line throwing gun, schermuly pistol, pistol rocket apparatus, beach rescue set, traveller, block, running block, pulley, hawser, faking, faking box, faked line, rescue boat, lifeboat, lady bay, warrnambool harbour, port of warrnambool, tramway jetty, volunteer lifesavers, volunteer crew, breakwater, lifeboat warrnambool, rocket rescue method, rocket rescue apparatus, captain manby, mortar, henry trengrouse, sky rocket, john dennett, shore to ship, colonel boxer, two-stage rocket, italian hemp, quadrant, protractor, schermuly, line-throwing pistol, line throwing cartridge, rocket apparatus rescue, stranded vessel, tally board, light line, whip line, endless whip, petticoat buoy, traveller chair, traveller block, her majesty’s coast guard, harbour board, line thrower, line throwing, beach cart, hand barrow, sand anchor, hawser cutter, life jacket, faking board, welsh hand barrow, rocket set -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Singer Electric Sewing Machine, The Singer Manufacturing Company, 1950

Singer was first established as I. M. Singer & Co. in 1851 by Isaac Merritt Singer with New York lawyer Edward C. Clark. Best known for its sewing machines, it was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. The Singer company began to market its machines internationally in 1855 and won first prize at the Paris world's fair that year. They had offices established in both Sydney and Melbourne by the mid-1960s. The company demonstrated the first workable electric sewing machine in 1910. Singer was also a marketing innovator and a pioneer in promoting the use of instalment payment plans, making their machines more affordable for many people. According to its serial number, this machine was manufactured in 1950 and was one of the new models designed to be more portable as it only weighed about 10 KG.This sewing machine is of local, national and international significance as it represents developments in technology and the impact this had upon the work of women.The Singer 99 was a sturdy and reliable machine that was easy to use. Lighter than other machines of its time, this machine weighed only 10 Kgs. It is mounted on a wooden base with a small compartment under the balance wheel to store accessories and bobbins. It has a 'Bentwood' (polished plywood) cover which also provided some room for storage. The machine is driven by a small electric motor and a light to illuminate the work area. It is decorated with gold decals and a filigree pattern. It includes a knee control which is inserted in a hole at the front of the machine. The serial number EG045782 indicates it was manufactured in 1950.Across the top in gold script: "The Singer Manufacturing Co. / Made in Great Britain" On light cover: "SINGER" Plate with specifications also attached. On front of machine in oval badge: A CENTURY OF SEWING SERVICE/ THE SINGER MANFG. CO. 1851 - 1951singer sewing macnine, domestic appliances, women's work, technology -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncMachine - Singer Treadle Sewing Machine, The Singer Manufacturing Company, c1890

The Wodonga Historical Society Haeusler Collection provides invaluable insight into life in late nineteenth and early twentieth century north east Victoria. The collection comprises manuscripts, personal artefacts used by the Haeusler family on their farm in Wodonga, and a set of glass negatives which offer a unique visual snapshot of the domestic and social lives of the Haeusler family and local Wodonga community. The Haeusler family migrated from Prussia (Germany) to South Australia in the 1840s and 1850s, before purchasing 100 acres of Crown Land made available under the Victorian Lands Act 1862 (also known as ‘Duffy’s Land Act’) in 1866 in what is now Wodonga West. The Haeusler family were one of several German families to migrate from South Australia to Wodonga in the 1860s.| This sewing machine belonged to Isla Ilma Margaret Ernestine neeTasker, mother of Alfred Haeusler. Singer was first established as I. M. Singer & Co. in 1851 by Isaac Merritt Singer with New York lawyer Edward C. Clark. Best known for its sewing machines, it was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. The Singer company began to market its machines internationally in 1855 and won first prize at the Paris world's fair that year. They had offices established in both Sydney and Melbourne by the mid-1960s. The company demonstrated the first workable electric sewing machine in 1910. Singer was also a marketing innovator and a pioneer in promoting the use of instalment payment plans, making their machines more affordable for many people. This item is from the Hauseler Collection which documents social life of early settlers in the Wodonga community.Singer "Coffin top" treadle sewing machine with extension table. The machine is mainly black and silver metal but is extensively decorated with coloured decals. The decorations on this machine features a pheasant design which also helps to date the machine as it was only used from 1890 to 1915. The sewing machine is set into a wooden table with and extension leaf and 6 drawers, 3 on either side. The frame and treadle mechanism are iron with a thin leather belt to drive the mechanism. The "coffin" shaped top sits over the machine to protect it when not in use and is easily removed. The extension leaf provides a larger working surface and folds down when not in use. The Singer logo attached to the front of the machine features a needle, shuttle and thread.On metal base plate: "PATENTED /DEC 5 -1882/ MARCH 20 - 1883/ AUG - 21 1888. Model no: L6485622 Along top of machine: "The Singer Manufacturing Co." Front right: Singer Company Logohaeusler family, wodonga pioneers, sewing machines, singer sewing macnine