Showing 262 items

matching numbering machine

-

Flagstaff Hill Maritime Museum and Village

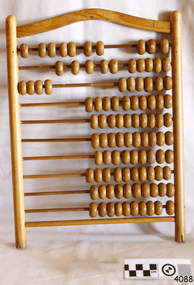

Flagstaff Hill Maritime Museum and VillageArticle - Abacus, Probably second half of 19th Century or first half of the 20th Century for this particular item

The abacus has been used by many civilisations, and is still in use today. Its origin is masked in the depths of time, but it is believed to have originated in crude form around the years c.2500 BCE. It is interesting to note that this abacus, although in use in Australian schools, contains ten rows, each containing ten beads, suggesting that it was heavily influenced by the decimal system. The number 12 was quite prominent in Australia, no doubt introduced by the British during the first settlements. It's use, as in dozens, twelve shillings in the pound and twelve inches in a foot, was widespread until decimalisation in 1966. Even today, many items are sold in dozens or sixes.Before more sophisticated adding machines and then calculators were developed in the 19th and 20th centuries, the abacus would have been in worldwide use.Abacus or counting frame with ten rows, each containing ten wooden beads.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood, abacus -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Lathe, 1920-1923

The lathe-making business incorporated in 1902 as Drummond Bros Ltd originated in the fertile mind of Mr Arthur Drummond, said to have been living at that time at Pinks Hill, on the southern edge of Broad Street Common, west of Guildford. Mr Drummond, whose accomplishments included several pictures hung in the Royal Academy, was unable to find a lathe suitable for use in model engineering. In 1896 he designed for himself a ‘small centre lathe … which had a compound slide rest with feed-screws and adjustable slides’. He also designed and built ‘lathes of 4.5 inch and 5 inch centre height, which had beds of a special form whereby the use of a gap piece was eliminated but the advantages of a gap-bed lathe were retained’. Assisted by his brother, Mr Frank Drummond, who had served an apprenticeship to an engineering firm at Tunbridge Wells, the first lathes were made in a workshop adjoining Arthur Drummond’s house. The demand that speedily built up led to the decision to form a company and manufacture the lathes for sale commercially. Land was acquired nearby, at Rydes Hill, and the first factory built. The enterprise was a success, and the company quickly established ‘a high reputation in this country and abroad for multi-tool and copying lathes, and gear-cutting machines’. Other lathes were added to the range, including the first of the ’round bed’ machines for which the firm became widely known. A Drummond 3.5 inch lathe was among the equipment of Captain Scott’s 1912 expedition to the South Pole, and large numbers of 3.5 inch and 4 inch designs were exported to Australia, Canada and India. By the outbreak of war in 1914, 5 inch, 6 inch and 7 inch screw cutting lathes, arranged for power drive, were on sale. Large orders were received from the government for 3.5 inch lathes, for use in destroyers and submarines, and 5 inch lathes for the mechanised section of the Army Service Corps. The latter were used in mobile workshops. The factory worked night and day to supply the forces’ needs, until production was disrupted by a fire which destroyed a large part of the works in May 1915. As soon as rebuilding was complete work restarted. At the end of the war the entire production was being taken by the Government departments, a special feature being a precision screw lathe, bought by the Ministry of Munitions in 1918. Between the wars Drummond Bros Ltd introduced new machines for the motor vehicle, and later the aircraft industry, and the works were extended on many occasions to fulfill the increasing orders. The Maxicut multi-tool lathe (1925), designed for high-production turning operations, was one of the first machines of this type to be built in England. It was followed (1928) by an hydraulic version for turning gear blanks, and similar work. Further developments provided machines which, during the Second World War, turned all the crankshafts and propeller shafts for Bristol engines. Others, ordered by the Ministry of Supply were employed in turning shells, and many other specific needs of vehicle and aircraft manufacture were catered for by new types of Drummond lathes. Production of the small centre lathes ceased during the war when the company needed to concentrate on building multi-tool lathes and gear shapers. After the war a completely new Maxicut range was introduced, replacing the older versions, and fully automatic. The types were continually developed, and new versions manufactured until the end of the company’s life in 1980. The disappearance from the scene of Mr Arthur Drummond in 1946, and the end of the company’s autonomous existence in 1953 when the company was acquired by William Asquith Ltd, which was in turn bought by Staveley in 1966, meant that the factory at Rydes Hill became one – albeit very effective – part of a large national engineering company. Achievements at the Guildford works during its last years included the development of automated Maxicut gear-shapers in what was ‘probably the most fully automated gear shop in the country’, while a machine from Guildford was sent to the Osaka Fair in 1962. In 1963 an agreement was signed with Hindustan Machine Tools for the manufacture of Maxicut gear-shapers in state owned factories in Bangalore and Chandigarh. During 1963 the two largest multi-tool lathes ever made in the UK were installed in Ambrose Shardlow’s works in Sheffield for handling cranks up to 14 foot long. In 1976 Drummond lathes were included in Staveley’s £14,000,000 installation in Moscow of an automated production line for Zil motor cars. Up to the end invention continued at Guildford: a new Drummond Multi-turn memory-controlled machine was shown at the International Machine Tool Exhibition in 1977. This could not save the works from the pressures of the late 1970s, and Staveley Industries closed its Guildford site in 1980.An early example of a lathe that was designed primarily for the hobbyist model maker. It is in good condition and sought today by collectors as many of it's attributes were innovative at the time and lead to further development and incorporation of some of its features into more industrial models of production machinery. Lathe, round bed, treadle powered lathe, Drummond Type A, Serial number and maker's inscription. 1920-1923, Made by Drummond Brothers in Guildford, Surrey, England. Lathe is complete with Chuck, Tool post and Tail Stock in situ (30 extra parts)"MADE BY DRUMMOND BROTHERS LIMITED - PATENT TEES - RYDE'S HILL n GUILDFORD SURREY", "Serial Number 01470," "L44" or "L45 " flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, lathe 1920-1923, round bed lathe, treadle lathe, drummond type a, guildford surrey, drummond brothers guildford surrey england, tread'e -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone in two pieces. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pump, circa 1930's - 1940's

This pump is an Ajax Type L2 Series A model, made and sold by McPherson’s Pty Ltd of Melbourne circa 1930’s to 1940’s, is a mechanical, hand operated, constant flow pressure pump. It would have been used to pump fluids from one area to another, for example from a dam to a tank or used as a bilge pump on a small vessel, mounted on the vessel’s bulkhead, floor or deck. This type of hand pump is sometimes called a ‘Reciprocating Suction Pump’. It has a mechanical pumping action of the lever moves the piston inside the pump up and down. The water is lifted from below the pump through the inlet pipe and into the pump’s cylinder. This action causes the lower valve to close and the piston’s valve opens and the pressure within the pump forces the water out of the pump through the exit pipe. The limitation of this type of pump is that it can only raise the water a maximum of about 7 metres from beneath the ground and yields 24-26 Litres per minute. This type of pump could be used for many purposes such as pumping water or fuel. McPherson’s 1940’s advertisement proclaims “For all jobs on the land – irrigation, spraying, tank, plumbing, fire-fighting – there’s a suitable “Ajax” pump. Send us the details of you pumping problem. Our Expert’s advice will help you choose the right pump – the one that will give you most years of PROFITABLE PUMPING.” (The Australasian (Melbourne) Sat. 26th October 1940.) McPherson’s Pty Ltd, the manufacturer, advertised a similar pump to this one in The Australasian (Melbourne) in 1936, calling it the Ajax Double Acting Hand Pump. In 1942 another advertisement advised that a representative for a fire-fighting equipment supplier was visiting the western district of Victoria. The company could now supply double-action two-spray Ajax pumps at lower prices than similar pumps the district had recently purchased from Adelaide. McPHERSON’S FOUNDER and COMPANY TIMELINE 1860 – Thomas McPherson, a Scottish immigrant (c. 1853 ), founded McPherson’s in Melbourne, supplying pig iron (lead ingots imported as ballast in ships) to local manufacturers. 1882 – Thomas McPherson established a warehouse in Collins St Melbourne and included tools, steam fittings and machinery in his wares. The business expanded to include steam saw mills and became known as Thomas McPherson and Sons (William Murray and Edward). 1888 – Thomas passed away and his sons inherited the business. In 1896 William Murray became the sole proprietor after his brother Edward’s death. 1900 – The firm expanded, establishing Acme Bolt Company to manufacture nuts and bolts. 1912 – McPhersons Pty Ltd established a machinery warehouse and showroom in 554-556 Collins St Melbourne. McPherson’s went on to establish branches in Sydney (1911), Adelaide (1921) and Perth (1930) 1917 - McPherson’s supplied ‘dog spikes’ for the transcontinental railway, running from Eastern to Western Australia. 1918 – A tool works set up in Kensington, Melbourne, manufacturing Macson lathes and made machine tools that previously had to be imported. 1924 – The Bolt Works was transferred to a new building in Melbourne. McPhersons began making pumps. 1929 – McPherson retired. His son (Sir) William Edward McPherson (known as ‘WE’), was born in Hawthorne, Melbourne, in 1898. After his education he began work in his father’s Melbourne hardware and machinery business He took over as governing director when his father retired. 1929-1932 – McPherson’s supplied thousands of tons of rivets from its Richmond (Melbourne) Bolt Works for the construction of the Sydney Harbour Bridge. 1936 – McPherson’s Pty Ltd is advertising Ajax Pumps in newspapers 1934 – McPhersons purchased the property adjoining the warehouse in Collins Street, and during 1935-1936 built a new office and showrooms on the site of 546-445 Collins St. 1939 - McPherson’s acquired the Tool Equipment Co. Pty. Ltd and Associated Machine Tools Australia Pty Ltd was formed to separate McPherson’s machine-tool manufacturing and merchandising interests. 1939 – Ajax Pump Works, a foundry and pump manufacturing plant, was established in Tottenham, Melbourne, and the Ajax Bolt and Rivet Co Pty Ltd began manufacturing in New Zealand. 1944 - McPherson’s became a public company, McPherson’s Ltd. 1948 - The Ajax Pump Foundry opened at Kyneton, Victoria and in the post war years it grew to became a large manufacturer. 1980’s – Ajax Pumps brochure lists the address as 6 Buckhurst St, South Melbourne, Vic 3205 with the Telephone number 03 669 3588 1988 - Ajax Pumps acquired the Forrers Company, which was established in 1921. Manufacturing in Ipswich, Queensland, specialising in submersible sewage pumps. 1991 – KSB Ajax was formed, bringing together the companies KSB and Ajax Pumps 1993 – Manufacturing was moved to state-of-the-art premises in Tottenham, Victoria 2001 - The Forrers facility was moved to Tottenham. 2007 - Company name KSB Ajax Pumps was changed to KSB Australia Pty Ltd. 2009 - KSB Australia opened a branch in Townsville, Queensland. 2011 - KSB Australia moved to its dedicated Water and Waste Water Competence Centre in Bundamba, Queensland. DISPLAY OF THIS AJAX PUMP This pump was installed at Flagstaff Hill Maritime Village as part of a working display in the village by the Friends of Flagstaff Hill, in acknowledgement of the dedicated involvement of one of its long serving members, Bob Crossman. The display was officially opened 31st March 2018 and incorporates a restored Furphy Tank and Water Pipe Stand. The pump is used to draw water from the lake, through the water stand pipe and into the reconditioned Furphy Tank. This Ajax pump made by McPherson’s Pty Ltd is significant for its association with McPherson’s, a prominent manufacturer of hardware in Victoria. McPherson’s is famous for supplying ‘dog-spikes’ for the transcontinental railway (eastern to western Australia, 1917) and rivets for the Sydney Harbour Bridge (1929-1932). The Ajax pump is also of significance because of its association with McPherson’s Governing Director (Sir) William McPherson, former premier and treasurer in Victoria 1928-1929. The former McPherson’s Pty Ltd building in Collins Street Melbourne is now on the Victorian Heritage Register VHR H0942 This pump is representative of mechanical pumps popular in the early to mid-1900’s and still used today. Hand operated pressure pump, double acting. Cast metal case, painted red, with steel hose attachments and long metal lever. Pump is bolted to wooden plank. Model of pump is AJAX, Type L2, Series A pump. Embossed on lower section of pump "L2 - 10", "L2 - -1", "AJAX" “(?) –2-1” Embossed on lower handle “3-7” “L – 4” Embossed on attached plate “FOR SPARE PARTS / TYPE L2 / SERIES A / PUMP ASSEMBLED BY T R” Manufactured by McPherson’s Pty Ltd of Melbourne circa 1930’s - 1940’s.flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ajax pump works tottenham melbourne, ajax pump factory kyneton, william edward mcpherson, thomas mcpherson of melbourne, mcpherson’s pty ltd melbourne, acme bolt company, tool equipment co. pty. ltd, associated machine tools australia pty ltd, ajax bolt and rivet co. pty ltd new zealand, forrers company ipswich queensland, ksb ajax pumps, ksb australia pty ltd, macson lathes, tool manufacturer early to mid- 20th century, ajax double acting hand pump, ajax type l2 series a pump, qisjax pumps, water pump 1940’s, fuel pump 1940’s, hand operated constant flow pressure pump, reciprocating suction pump, agricultural hand pump, plumber’s hand pump, portable hand pump -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAdding Machine

Adding machine with thirteen vertical rows of keys with clearing handle on side. Fraction keys on right hand side, and three keys missing along top row. Lever on side of machine. Two short feet at front, two long feet at back, giving slope to machine for ease of use. Serial Number "5-891861" Paper label with "Sets Mess Property" on at back of machine. Serial Number "5-891861" Paper label with "Sets Mess Property" on back of machine. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, adding machine, calculator, office equipment, commerce, business equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAudio - Phonograph, Thomas A. Edison, Edison Laboratory, c.1909

The Edison Fireside Phonograph Combination Type A model phonograph was an open horn model. This machine was produced around 1909, just after the introduction of 4-minute record cylinders in 1908.; the selection lever on the front was either 4 or 2-minute choice. This Fireside model has a fluted octagonal horn that attaches to the reproducer on the machine and is suspended by on ring by a horn crane attachment. The phonograph machine is powered purely by mechanical means, winding the crank handle on the side of the machine to start the belt-driven, spring-loaded motor inside. The sound comes from a pre-recorded, vertical cut record cylinder, which slides over the Mandle, a smooth rotating drum. The reproducer, an all-in-one needle, amplifier and speaker, is lowered onto the cylinder, the needle picks up the sound and plays it on the speaker and the attached horn amplifies the sound. The phonograph machine was invented by Thomas Alva Edison in the late 19th century. Edison adopted the idea from the technology of the telegraph machine. He patented the phonograph in early 1878. It was able to record sound and play it back. This amazing invention opened up a whole new world of entertainment, where wax cylinders of pre-recorded sound could be purchased with a wide variety of music and played over and over. The first wax cylinders were white and used a combination of bees' wax and animal fax or tallow. By 1892 Edison was using 'brown wax' cylinders that ranged from cream through to dark brown. The Edison Phonograph Company was formed in 1887 to produce these machines. He sold the company in 1855 to the North American Phonograph Company but bought that company in 1890. He then started the Edison Spring Motor factory in 1895, and the National Phonograph Company in 1896. In 1910 the company became Thomas A. Edison Inc. In 1898 Edison produced the Edison Standard Phonograph, the first phonograph to carry his own trade mark. He began mass producing duplicate copies of his wax cylinders in 1901 using moulds instead of engraving the cylinders. The wax was black and harder than the brown wax. The ends of the cylinders were bevelled so that the title's label could be added. The last phonograph machine to use an external open horn was produced in 1912 due to the much more robust round records being invented. In 1913 Edison started producing the Edison Disc Phonograph. The company stopped trading in 1929.This Edison Fireside Phonograph model is significant for being one of the last models to have an external horn. It is also significant for its connection with the invention of the phonograph, which made music and sound available for domestic enjoyment. It was used for entertainment and education, even teaching languages. It signalled a new era of music that could be reproduced and played anywhere. It is also significant for its short time span of popularity, just a few decades, due to the growing use of records, which gave a much higher quality sound and were more robust.Phonograph; Edison Fireside Phonograph, Combination Type, Model A. It is in a wooden case with a domed lid, metal catches on each side and a folding wooden handle. It has a metal drum and a reproducer mechanism. The metal and wood crank handle starts the machine’s motor. A sliding lever at the front selects the speed for four- or two-minute cylinders. The inscribed plate has the maker, serial number, patents and other information. The reproducer also has an inscription. It has a curved metal open horn attachment. Made in Orange, New Jersey in c.1909. NOTE: the fluted octagonal horn is catalogued separately.Case front, in script, Edison’s early ‘banner’ decal “Edison” On the front of the machine “Thomas A Edison TRADE MARK” On the maker’s plate; "Edison Fireside Phonograph Combination Type" Serial number “14718” Around sound outlet; “C 4076” “REPRODUCER LICENCED FOR USE ONLY ON EDISON PHOTOGRAPHS SOLD BYT.A. EDISON INC.” At the front edge “4 MINUTES 2flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck coast, gramophone, phonograph, music player, entertainment, audio equipment, edison, thomas a edison, horn, phonograph horn, amplifier, audio, sound recording, sound playback, phonograph machine, phonograph cylinder, external horn, edison phonograph company, wax cylinders, sound reproduction, edison spring motor factory, national phonograph company, thomas a. edison inc, crank-operated motor, open horn phonograph, 4 speed, 2 speed -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070. Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlane Compass, 1941-1943

This compass is the type used by an artillery unit of the Australian Military Forces during World War 2 and made by J W Handley. Although having owned the factory site since 1935 at 657 Victoria St J W Handley began to produce various items for the Australian Military forces after purchasing and expanding the factory to 655 Victoria St. It appears that he, or some one else may already have been occupying the site for industrial purposes, such as (Manufacturing, Foundry and Electroplating) since at least 1929. J W Handley Pty Ltd was actively producing items for the Military during the war years, a newspaper article from 1939 shows the factory in production and employing 420 people during 1939. J W Handley after the war moved into producing other non military items including a range of fishing reels. The company ceased trading in 1987 and was deregistered as J W Handley Pty Ltd in 1990.The item demonstrates the industrial capability of Australia at the start of World War 2, this item is actively sort by collectors of Australian Military memorabilia and represents a time in Australian history when the country was at war and the general population was concerned about an invasion from Japanese forces. It also therefor is of social significance as many Australians served in the Military forces at that time and the item is complete and in very good condition.A plane table compass, sometimes referred to as a trough compass, used by surveyors and artillery crew to accurately establish magnetic north. The compass is precision machined of brass material with a long needle to ensure accuracy. The compass scale is marked with a centre zero (for magnetic north) and graduations indicating plus and minus five degrees. The compass is housed in a protective wooden case with a sliding lid. The lid has a brass slide which locks the compass needle during periods when the compass is not in use.J.W.H./V Mark 11 D�D. Made by J W Handley Richmond Melbourne, Victoria. Serial number 1333 on boxflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, trough compass, navigation instrument, surveyor's instrument, j w handley, artillery, australian army, trough, plane compass, world war 2 -

Flagstaff Hill Maritime Museum and Village

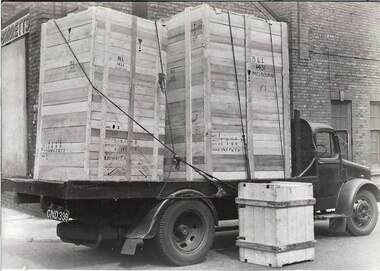

Flagstaff Hill Maritime Museum and VillageMachine - Treadle Machine, Early 20th century

... and a treadle paper numbering machine. Flagstaff Hill Warrnambool ...This foot-powered treadle machine could be used to manually operate many devices such as a sewing machine or spinning wheel. Treadle machines were used to power sewing machines, dental drills, lathes, spinning wheels and saws The machine is mounted on a board to demonstrate treadle operation.This mounted, smoothly working treadle machine demonstrates the treadle mechanism that was used in the early 20th century to power mechanical devices and in turn to save time, energy and money. The treadle was used in domestic and industrial environments. The Collection at Flagstaff Hill Maritime Museum and Village has two treadle-operated dentist's drills, a treadle sewing machine, a saw, a lathe and a treadle paper numbering machine.Treadle-powered machine; a black painted metal wheel with four curved spokes, connected to a wooden treadle. The height of the wheel is adjustable. The mechanical device is mounted on a thick rectangular wooden block. The working treadle mechanism turns smoothly. flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, treadle machine, manual machine, foot treadle, display treadle, treadle, demonstration, education, working model -

Federation University Historical Collection

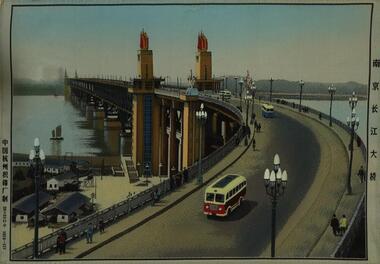

Federation University Historical CollectionTextile - Tapestry (machined), Japanese Bridge Scene, c1981

Stretched by Val D'AngriColoured scene on silk cloth, stretched over light board that has been covered in calicoJapanese symbols in side margins Serial number 1024-127 in left margin VD'A - 7/81 on back (Val D'Angri)japanese bridge, textiles -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Ballarat School of Mines Annual Report 1888, 1888

Ballarat School of Mines Annual Report 1888. President's Annual Report, Constitution and Statute of Affiliation, Monetary prize by R. M. Serjeant for Treatment of Ores, Balance Sheet: Liabilities and Assets, Certificates Granted by the Council, Fees, Honorary Correspondents, Life Governors, Number of Students attending the School of Mines, Office Bearers, Report of the Curator of the Museum and Library, Report of the Superintendent of Laboratories, Report of the Lecturer on Machine Drawing, Report of the Lecturer on Mechanical Engineering, Report of the Lecturer on Telegraphy, Report of the Lecturer on Botany, Report of the Lecturer on Freehand and Model Drawing, Report of the Lecturer on Materia, Medica and Physiology, Report of the Hon. Secretary St John Ambulance Association, Examinations Held, Scale of Charges for Assays and Analyses, Statement of Receipts and Expenditure for the year 1888 and Special Trust Funds, Statistics - Students Attending Lectures, Subjects and Lecturers, Subscriptions and Donations from 1st January to 31st December 1888, Time Table. Ballarat School of Mines annual Report. Cover attached by tape on booklet, spine missing, 108 pages. ballarat school of mines, annual report, the hon sir william foster stawell, president, andrew anderson, vice president, alf. mica smith - professor of chemistry and metallurgy, f. m. krause - professor of geology and minealogy, j. h. horwood - mechanical engineering, machine drawing and design, mining, mathematics, henry j. hall - freehand and model drawing, daniel walker - chemistry and physics, w. e. burbridge - demonstrator of chemistry and metallurgy, w. d. campbell - telegraphy, george day - botany, j. f. usher - materia, medica, pharmacy and physiology, gilbert j. dawbarn, e. thornton, charles kent - auditor, andrew berry - registrar, t. h. thompson jp - mayor of the city of ballarat, james russell jp - mayor of the town of ballarat, daniel brophy jp - chairman of the band and albion consols, walter gude, elizabeth phillips, thomas commons, kate porritt, emily mary wheeler, grace shrigley, george clendinning, rose ditchburn, cecelia h. murphy, eliza a. turpie, rebecca walton, george g. zilles, william menzies, john waters sutherland, h.w. sutherland, alfred kerr, william coltman, alfred j. dunstan, arthur bregazzi, maggie miller, serna davey, william thomas grownow, sarah davies, anna bella cravno, william corbould, thomas copeland, robert john gribble, henry lipson hancock, leigh george hancock, harry m. martell, ivan rosenblum, john la gerche, samuel barrell, walter reed bechercaise, william treloar, adolf gode, arthur e. lilburne, carl werner, isaac bernstein, george kidd, arthur lynch, henry coltman, josiah wasley, david curtain, martha maud berry, mary ann cameron, harriet mary mitchell, anna s. schloo, ellen fussell, lavinia treloar, mary drury, annie winifred eastwood, annie louisa gatliff, mary gatliff, james edward gribble, frank uren, alfred curthoys, william edwin kernot, j. ditchburn, john bradshaw, david michael curtain, alfred ernest campbell kerr, walter nettleton, william henry keast, george ja,es, donald mcgregor, john king, john bailey bullen, john trevan, patrick murray, josiah curnow, tobert taplin, samuel earnest figgis, w.h. keast -

Federation University Historical Collection

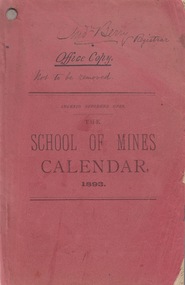

Federation University Historical CollectionBooklet, The Ballarat School of Mines, Industries and Science, Calendar and Annual Report 1893, 1893

The Ballarat School of Mines Annual Report 1893. Annual Report, Examination Papers, Associateship of The School of Mines, Syllabus for Technical Schools, Crown Grant, Affiliation Statute, Certificates Granted by the Council, Clunes Branch Report, Departmental Expenditure, Fees, Form of Bequest, General Balance Sheet and Liabilities and Assets, Honorary Correspondents, Life Governors, Meteorological Observations, Number of Students attended The School of Mines, Office Bearers, Practical Treatment of Ores, Report of the Professor of Mineralogy and Geology and Curator of the Museum, Report of the Superintendent of Laboratories, Report of the Lecturer on Engineering and Surveying, Report of the Lecturer on Mathematics, Report of the Lecturer in Mechanical Drawing, Machine Construction and Design, Report of the Lecturer on Electrical Engineering and Telegraphy, Report of the Lecturer on Botany, Report of the Lecturer on Biology, Pharmacy, Materia Medica, Report on Mining Laboratory, Examinations Held, Scale of Charges for Assays and Analyses, Statement of Receipts and Expenditure for the year 1892 and Special Trust Funds, Statistics - Students attending Lectures, Subjects and Lecturers, Subjects and Examiners, Subscriptions and Donations from 1st January to 31st December 1892, Syllabus of Lecture Courses6188: The Ballarat School of Mines Industries and Science Calendar and Annual Report, 1893. Red soft cover is browning around the edges, spine is tattered, 156 pages. 6188.2: Red soft covered booklet of 26 pages, Office Copyballarat school of mines, annual report, andrew anderson j.p. - president, f. j. martell - vice president, r. denham pinnock - vice president, rivett henry bland - trustee, the hon. sir w. j. clarke - trustee, the hon. john warrington rogers - trustee, james oddie - trustee, the hon. henry cuthbert - honorary solicitor, r. g. middleton - honorary treasurer, charles kent - auditor, andrew berry - registrar, alf. mica. smith - chemistry, metallurgy, f. m. krause - geology, mineralogy, mining, j. h. horwood - mechanical engineering, machine drawing and design, theoretica and applied mechanics, mathematics, henry j. hall - freehand and model drawing, j. a. dawson - electricity and magnetism, george day - botany, e. gutheil - biology, materia medica, pharmacy, a. e. c. kerr - mechanical drawing, machine construction and design, e. gutheil - biology, pharmacy, materia medica, henry crone - assistant registrar of titles, henry b. loch, elder gray - president, clunes branch, harry e. sando - registrar, clunes branch, w. y. witherden - hon. treasurer, clunes branch -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Berry Anderson & Co, The Ballarat School of Mines, Calendar and Annual Report 1894, 1894

The Ballarat School of Mines Calendar and Annual Report 1894. Associateship of The School, Calendar for 1894, Certificates Granted by the Council 1893, Comparative Statement of Receipts and Expenditure, Departmental Expenditure, Examiners, Examination Papers, Examination Fees, Fees, Honorary Correspondents, Life Governors, Meteorological Observations, Mining Engineering Scholarship, Number of Certificates Granted since Inception, Number of Students attended The School of Mines, Office Bearers, Plant and Appliances, Practical Treatment of Ores, Professors and Lecturers, Report of the Professor of Mineralogy and Geology and Curator of the Museum, Report of the Superintendent of Laboratories, Report of the Lecturer on Engineering and Surveying, Report of the Lecturer on Mathematics, Report of the Instructor in Mechanical Drawing and Machine Construction and Design, Report of the Lecturer on Electrical Engineering and Telegraphy, Report of the Lecturer on Geometrical Model and Perspective Drawing, Report of the Lecturer on Botany, Report of the Lecturer on Biology, Pharmacy, Materia Medica, Scale of Charges for Assays and Analyses, State School Science Classes, Statement of Receipts and Expenditure for year 1893 and Serjeant Scholarship Fund, Statistics - Student attending Lectures, Subscriptions and Donations, Syllabus of Lecture Courses, Time TableThe Ballarat School of Mines Calendar and Annual Report, 1894. Green soft cover, 116 pages. ballarat school of mines, annual report, andrew anderson j.p. - president, f. j. martell - vice president, r. denham pinnock - vice president, rivett henry bland - trustee, the hon. sir w. j. clarke - trustee, the hon. john warrington rogers - trustee, james oddie - trustee, the hon. henry cuthbert - honorary solicitor, r. g. middleton - honorary treasurer, charles kent - auditor, andrew berry - registrar, professor alf. mica smith - chemistry, metallurgy, natural philosophy, professor krause - geology, mineralogy, principles of mining, professor j. h. horwood - mine and land surveying, mining mechanics, hydraulics, civil engineering, applied mechanics, j. a. dawson - electrical engineering, d. walker - chemistry and natural philosophy, w. e. bennetts - mathematics, henry j. hall - freehand and perspective drawing, a. e. c. kerr - mechanical drawing, george p. day - botany, e. gutheil - paleontology, zoology, materia medica, w. d. snowball - veterinary science -

Federation University Historical Collection

Federation University Historical CollectionBooklet, Berry Anderson & Co, The Ballarat School of Mines, Calendar and Annual Report 1895, 1895

The Ballarat School of Mines Calendar and Annual Report 1895. Associateship of The School, Calendar for 1895, Certificates Granted by the Council 1894, Certificates Granted by the Education Department 1893, Comparative Statement of Receipts and Expenditure, Departmental Expenditure, Examiners, Examination Papers, Examination Fees, Fees, Honorary Correspondents, Life Governors, Meteorological Observations, Number of Students attended The School of Mines, Obituary, Office Bearers, Practical Treatment of Ores, Professors and Lecturers, Report of the Professor of Mineralogy and Geology and Curator of the Museum, Report of the Superintendent of Laboratories, Report of the Lecturer on Engineering and Surveying, Report of the Lecturer on Mathematics, Report of the Instructor in Engineering and Machine Construction and Design, Report of the Lecturer on Electrical Engineering, Report of the Lecturer on Geometrical Model and Perspective Drawing, Report of the Lecturer on Botany, Report of the Lecturer on Palaeontology, Materia Medica and Mining Ambulance, Scale of Charges for Assays and Analyses, Statement of Receipts and Expenditure for year 1894, Statistics - Student attending Lectures, Subscriptions and Donations, Syllabus of Lecture Courses, Time TableThe Ballarat School of Mines Calendar and Annual Report, 1895. Pale brown soft cover, 90 pages. ballarat school of mines, annual report, andrew anderson j.p. - president, f. j. martell - vice president, r. denham pinnock - vice president, the hon. sir w. j. clarke - trustee, the hon. john warrington rogers - trustee, the right reverend samuel thornton - trustee, andrew anderson - trustee, james millhinch - trustee, james oddie - trustee, the hon. henry cuthbert - honorary solicitor, r. g. middleton - honorary treasurer, charles kent - auditor, andrew berry - registrar, professor alf. mica smith - chemistry, metallurgy, natural philosophy, professor krause - geology, mineralogy, principles of mining, professor g. j. dawbarn - mine and land surveying, mining mechanics, hydraulics, civil engineering, applied mechanics, j. rowe - practical mining, j. a. dawson - electrical engineering, d. walker - chemistry and natural philosophy, w. e. bennett - mathematics, henry j. hall - freehand and perspective drawing, a. e. c. kerr - mechanical drawing (machine construction and design), george p. day - botany, e. gutheil - paleontology, zoology, materia medica, rivett henry bland - obituary, george gant scott - obituary, fiddian, bennett, r. allan, dawbarn, rosales, krause, joseph bryant, matthews, j. robinson, andrew robertson, john lynch, jonathan robinson, a.e.c. kerr, alfred mica smith, frederick mccoy, j. cosmo newberry, blackett, elelry, arnot, robert allan, bickett, kent, martin, mitchell, ferdinand von mueller, rivett henry bland, thomas bath, john rowe, museum, andrew anderson, george day, subscriptions and donations, examination papers -

Federation University Historical Collection

Federation University Historical CollectionScientific Instrument, Power Factor Meter

Item looks to have been adapted for bench top use Sindanyo high temperature insulation boards are manufactured from cement based products, reinforced with selected fibres. They have been specifically designed to provide excellent service under demanding thermal and electrical applications. Sindanyo is a non-asbestos, non-combustible product that is easily machined. This insulation board is a popular option when a high quality, strong and rigid material is required.400/500 Volt, 5 amp, 50 Hz 3-phase balanced load. Circular scale with lead and lag markings and graduations. The 22cm diameter meter rear-mounted to black sindanyo board, supported by wood brackets on wood base. Five terminal posts on panel below meter. Wire connections at rear. No maker's name Patent Number: 162471/20 Serial Number 263475scientific instruments, power factor maker, lead and lag markings, terminal posts, power factor meter, wire connections, sindanyo board, non-combustible, insulation, electrical applications -

Federation University Historical Collection

Federation University Historical CollectionInstrument - Scientific Instruments, Single Pan Balance, mid 1960s ?

According to lecturer in Chemistry, John Murray, this item was principally used by M.K. Aston, lecturer in Chemistry at the Ballarat School of Mines from 1947, and later Head of Chemistry until 1980. This balance was kept in M.K. Aston's office. A sartorius single-pan weighing machine, with optical balance display, in off whote cylindrical housing with domed lid. Front access sliding curved panels. Colour-coded weighing knob either side. Selecta Semi-micro, 100g x 0.01 mg Serial Number 104262m.k. austin, john murray, chemistry, scientific instrument, ballarat school of mines, sartorius, sartorius werke -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrinting Press, C. 1934

This small Adana letterpress was based on a larger press. It was intended for printing stationery such as business cards, visitor’s cards, shop price cards and notepaper headers, Used for letterpress printing, and advertised as “Virtually indestructible”. Used for hobby printing, schools, and similar uses. When donated to Flagstaff Hill the chase still had letter type in it, which was printed out "THE SHADOWS / apahc / the aauage / shaboogie ". Currently, the machine is used by the Flagstaff Hill "Examiner" office to make business cards for use by some of the Volunteers in the Village. HISTORY Donald Aspinall, born in London in 1899, suffered shell shock while serving in World War 1. During his recovery, while still a teenager, he worked his hobby, the design of a small flatbed printing press, then advertised it in The Model Engineer’ in 1918 and received an overwhelming response of orders. In 1922 Aspinall founded the Adana Agency, in Twickenham. His had great success in his sales of flatbed, self-inking wooden presses to hobby printing enthusiasts. Over the years Adana made a variety of machines; flatbed, lever, treadle and powered presses Adana cast its own type in 1925 and has a number of patents for press parts. In the 1980’s the company wound down, and was purchased by Caslon, who still service and supply part for the Adana machines. Printing press; hand operated small letterpress machine made by Adana. Tiny platen style. Model Five-Three (5 inch x 3 inch). Cast metal base and lever handle with rounded end, both painted dark red, rounded red metal lever handle. C. 1934 Marks on foot of stand " REG. NO. / ISIL 46 & S00575 / PATENTS PENDING" and "REG. TRADE MARK / ADANA"flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, adana letterpress, adana model three-five, mini letterpress, printing machine, donald aspinall -

Federation University Historical Collection

Federation University Historical CollectionPrinting plate, Ballarat College of Advances Education Franking Machine Printing Plate, c1980

This plate was used on a post office franking machine. The franking machine and the Ballarat School of Mines printing plate is Catalogue Number 13145.Metal printing plate to make identification stickers of Ballarat College of Advanced Education Equipment.ballarat college of advanced education, printing plate, stickers, franking machine -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Jewellery, 2 lady's hat pins mauve, c1900

A hat pin is a decorative pin for holding a hat to the head, usually by the hair that was styled in a Chignon or French Roll style and usually worn in a pair. They are typically around 20 cm in length, with the pinhead being the most decorated part. The hatpin was invented to hold veils in place, and was handmade. Birmingham, England was the centre of production when demand eventually outgrew the number that could be supplied by hand-making and they also began to be imported from France. In 1832, an American machine was invented to manufacture the pins, and they became much more affordable. During the 1880s, bonnets gave way to hats, some of which were very large and the popularity of hatpins soared. In the Victorian era, when appearance was everything, it just wouldn't do for a fashionable lady's hat to blow off in the wind. They remained a standard women's' accessory through the 1910s and were produced in a vast range of materials and types. Hat pin holder boxes were also produced. One of the most well-known makers of hatpins is silversmith Charles Horner, of Halifax, whose turn of the century jewellery company became a leader in the market by creating a series of mass-produced pins that were still of exceptional quality. As a result, thousands of Horner's pins are still on the market and on display in museums worldwide. Women of the 1920’s used hat pins as decoration on their Cloche hats that fitted snugly to their heads. The women of the pioneer families liked to dress up in their best hand made dresses and fashionable hats for Church gatherings and special occasions as a relief from the daily chores of hand washing, ironing with flat irons and cooking over open fires.2 lady's long steel hat pins with sequents in a flower design on mauve material bonnets, hats, veils, scarves, moorabbin, bentleigh, brighton, cheltenham, early settlers, pioneers, clasps, hairdressing, combs, steel pins, jewellery -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tool - Farm Machinery, Horse-drawn Plough Potato Digger, c1900