Showing 151 items matching "scouring"

-

National Wool Museum

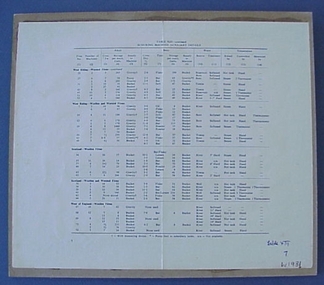

National Wool MuseumSheet, Instruction

Instruction sheet for mill floor operator, Table XIII Scouring Machine Auxiliary Details - continued.Other side of sheet.textile mills, collins bros mill pty ltd -

Bendigo Military Museum

Bendigo Military MuseumEquipment - UTENSILS, post 1970's

.1) & .2) Utensils from 1 man 24 hr ration pack, comprising metal can opener one end & spoon the other end. .3) - .5) Utensil kit comprising knife, fork & spoon made of metal. .6) Clear cellophane packet containing scouring pads..3) - .5) Stamped into back of metal handle: "Grosvenor 1070"domestic items-cutlery, military equipment, passchendaele barracks trust, kfs -

National Wool Museum

National Wool MuseumFunctional object - Auctioneer's Gavel, c. 1950s

Michael Crooks was the auctioneer responsible for selling Australia's million dollar wool bale on the 11th January, 1995 in Geelong, using this gavel. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Small wooden hammer, with handle and double sided face.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore -

National Wool Museum

National Wool MuseumPhotograph - Appledore Family, Growers Gallery, National Wool Centre, Geelong, 11 January 1995

This photograph depicts people gathered in the Growers Gallery on the 11th January, 1995 at the National Wool Centre, Geelong. It shows the emotions of Murray, Ian and Kaye Appledore while bidding took place for the million dollar bale. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing an interior view of rows of people seated and standing in room.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room -

National Wool Museum

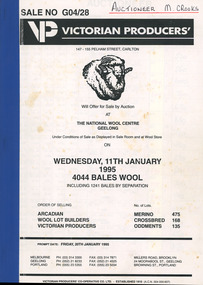

National Wool MuseumDocument - Victorian Producers' Sale Catalogue, National Wool Centre, Geelong, Victorian Producers' Co-operative Limited, 11 January 1995

This sales catalogue was the one used by Auctioneer Michael Crooks on 11th January 1995 when the million dollar bale was sold at the National Wool Centre, Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Bound paper booklet, approximately 35 pages, with printed and handwritten text.Front: [handwritten] AUCTIONEER M. CROOKS Front: [printed] SALE NO G04/28 / VICTORIAN PRODUCERS' / 147-155 PELHAM STREET, CARLTON / Will Offer for Sale by Auction / AT / THE NATIONAL WOOL CENTRE / GEELONG / Under Conditions of Sale as Displayed in Sale Room and at Wool Store / ON / WEDNESDAY, 11TH JANUARY / 1995 / 4044 BALES WOOL / INCLUDING 1241 BALES BY SEPARATIONmichael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

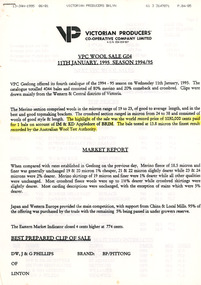

National Wool MuseumDocument - Victorian Producers' Market Report, Victorian Producers' Co-operative Limited, 11 January 1995

Victorian Producers Market Report, featuring details of the sale of the million dollar bale on Wednesday 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Two pages held with staple in top left corner with printed black text.Front: [printed] VP / VICTORIAN PRODUCERS' / CO-OPERATIVE COMPANY LIMITED / A. C. N. 004 059 607 / VPC WOOL SALE G04 / 11TH JANUARY, 1995 SEASON 1994/95michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

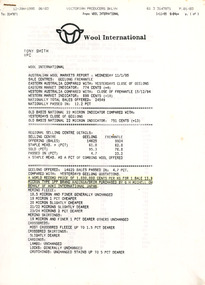

National Wool MuseumDocument - Australian Wool Markets Report, Wool International, 11 January 1995

Australian Wool Markets Report, featuring details of the sale of the million dollar bale on Wednesday 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Three pages held with staple in top left corner with printed black text.Front: [printed] Wool International / TONY SMITH / VPC / WOOL INTERNATIONAL / AUSTRALIAN WOOL MARKETS REPORT: WEDNESDAY 11/1/95michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

National Wool MuseumPhotograph - Million Dollar Bale, National Wool Centre, Geelong, 11 January 1995

This photograph shows Grower Ian Appledore, Auctioneer Michael Crooks and Wool Manager Keith Jackson posing with the million dollar bale after it was sold on 11th January 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three men standing around a bale of wool.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

National Wool Museum

National Wool MuseumPhotograph - Armed Guards with Million Dollar Bale, 11 January 1995

This photograph shows armed guards and Wool Manager Keith Jackson posing with the million dollar wool bale after it was sold by auctioneer Michael Crooks on the 11th January, 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three men with a bale of wool in front of an armaguard truck. Two of the men are armed guards standing either side of the wool bale, one is holding a shotgun. Another man in a suit and tie is crouching near the bale.gavel, michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, armed guards, armaguard -

National Wool Museum

National Wool MuseumReference Card

Reference card with tabular information on wool types and set prices, c.1940s. Includes 'Queensland Scoured Specialties and Similar Types'.wool brokering wool sales, wool brokering, wool sales -

National Wool Museum

National Wool MuseumPhotograph - Sale Room, National Wool Centre, Geelong, 11 January 1995

This photograph shows bidding underway for the million dollar bale in the Sale Room on the 11th January, 1995 at the National Wool Centre, Geelong. People depicted include Sale Team Baxter Murray, Auctioneer Michael Crooks and Wool Manager Keith Jackson. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing an interior view of people seated at rows of tables with an auctioneers stand at front of the room.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room -

National Wool Museum

National Wool MuseumPhotograph - Million Dollar Bale, National Wool Centre, Geelong, Gordon Robertson, 11 January 1995

This photograph shows Growers Ian Appledore, Kaye Appledore and Murray Appledore, Wool Manager Keith Jackson, Wool Classer Phillip Gibson, Geoff Allibon and Brendan Dart posing with the million dollar bale after it was sold on 11th January 1995 in Geelong. The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at 40,000 (cents a kilogram) and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at 1,030,000 cents per kilogram, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labelled Kadinia.Colour photograph showing three six men and one woman standing around a bale of wool.michael crooks, auctioneer, wool industry, million dollar bale, geelong, auction, kadinia, appledore, keith jackson, sale room, geelong wool centre -

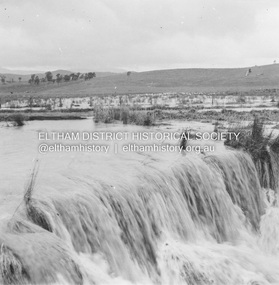

Eltham District Historical Society Inc

Eltham District Historical Society IncAlbum - Photograph, J.A. McDonald, Eltham-Yarra Glen Road, 19 Oct. 1956

Dixons Creek Road 19th October, 1956 Scour developing back onto road from Smedley’s property near Blease RoadRecord of various Shire of Eltham infrastructure works undertaken during the period of 1952-1962 involving bridge and road reconstruction projects, sometimes with Eltham Shire Council Project Reference numbers quoted. It was during this period that a number of significant improvements were made to roads and new bridges constructed within the shire that remain in place as of present day (2022). In many situations, the photos provide a tangible visible record of infrastructure that existed throughout the early days of the Shire. The album was put together by or under the direction of the Shire Engineer, J.A. McDonald.infrastructure, road construction, shire of eltham, bridge construction, eltham-yarra glen road, 1956-10-19, dixons creek bridge, dixon's creek road, floods -

Wannon Water

Wannon WaterHigh pressure scour valve mould (casting) watermains, Mould

Used to make casting moulds for the high pressure main Otway Supply System pipeline. Was used in conjunction with scour valve mould, Wf mould and valve stem mould in the 1980sUsed to manufacture spare parts for the main Otway pipeline2 wooden boxes each contain the mould for casting valves for wtaermains pipelines. Moulds lined with green coloured sealantwatermains written in black ink on outside of boxotway region, water supply, pipelines, valves -

National Wool Museum

National Wool MuseumBook, The Wet Processes of the Wool Industries

... Scouring ..."The Wet Processes of the Wool Industries" - John Schofield, 1924.wool - chemistry, scouring, milling, dyeing -

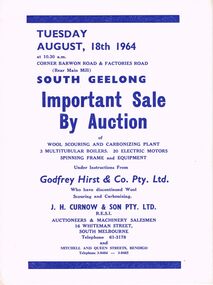

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - GODFREY HIRST & CO PTY LTD

Two white covered catalogues with blue printing. Sale of wool scouring and carbonizing plant, 3 multi tubular boilers, 20 electric motors, spinning frame and equipment. J. H. Curnow & Son Pty. Ltd. Were the auctioneers for Godfrey Hirst & Co. Pty. Ltd. Catalogue contains Memorandum of Purchase at Auction, Special Note to Buyers, Location, Description of 183 lots and Conditions of Sale. Sale was on the 18/8/1964.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - godfrey hirst & co pty ltd, j h curnow & son pty ltd, f c dyett, l c osborne, r w e hammill -

National Wool Museum

National Wool MuseumBook, Blackall Woolscour

... Scouring ..."Blackall Woolscour" - Historical Woolscour Association Inc., 1992. Report re: the history and background of the Blackall Woolscour (the last remaining steam driven woolscour in Australia) in Queensland, attempts to preserve it, formation of the Historical Woolscour Association Inc.wool processing, historical woolscour association inc., scouring, blackall woolscour, queensland -

National Wool Museum

National Wool MuseumSlide Folder, Wool Top Manufacturing

... Scouring ...Slide folder originally containing 12 slides and 4 wool samples depicting the wool top manufacturing process. Contains information about the slides.12 COLOUR SLIDES / WOOL TOP MANUFACTURINGwool tops, scouring, carding, noble comb, noils -

National Wool Museum

National Wool MuseumPhotograph

Depicts the George Hague & Co. Western Wool Warehouse, originally located on western beach. Of the two horse-drawn wagons loaded with wool bales standing in front of store, one wagon is owned by Joseph Kerley of Geelong and is loaded with bales of scoured wool from the "Wimmera Co."GEO. HAGUE & CO. / WESTERN WOOL WAREHOUSE / GEO. HAGUE & CO. WOOL WAREHOUSE Bluestone base under existing store (Elder Smith) / Western Beachwool stores wool transportation, george hague and co. pty ltd, western wool warehouse, geelong, victoria, wool stores, wool - transportation -

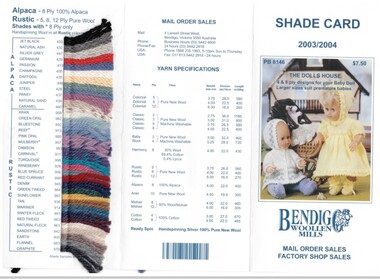

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - Shade Card, 2003

The Bendigo Woollen Mills were initially designed as a mail order company that sold its wool both domestically and internationally. The mill uses first cross merino wool from Australia that is then sent to China for scouring before returning to Bendigo for grading, dying and spinning. It now includes factory shop sales to the public.Bendigo Woolen Mills Shade Card (With samples of different coloured wool, pattern selections which were available at the Factory Shop Order Form.history, bendigo, merle lummis collection, bendigo woolen mills -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Dish, Late 19th or early 20th Century

Enamel cookware became very popular because people wanted a way of coating iron to stop metallic tastes or rust getting into food: something acid-resistant and easy to clean without laborious scouring, something more durable than the tin linings used inside copper. Enamelware dates back to 1760 in Germany.This object is significant as an example of an item in common use in the 19th and early 20th centuries.Oblong shaped enamel dish. The white enamel has been discoloured on the inside and much rust has occurred. The remains of a blue enamel line around rim.Two large rust holes in base, and a small rust hole near rim. None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, kitchenware, baking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Dish

Enamel cookware became very popular because people wanted a way of coating iron to stop metallic tastes or rust getting into food: something acid-resistant and easy to clean without laborious scouring, something more durable than the tin linings used inside copper. Enamelware dates back to 1760 in Germany.This object is significant as an example of an item in common use in the 19th and early 20th centuries.Oblong grey enamel dish. White speckles.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, kitchenware, baking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Early 20th Century

Enamel cookware became very popular because people wanted a way of coating iron to stop metallic tastes or rust getting into food: something acid-resistant and easy to clean without laborious scouring, something more durable than the tin linings used inside copper. Enamelware dates back to 1760 in GermanyThis object is significant as an example of an item in common use in the 19th and early 20th centuries.Large light blue enamel bowl.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, kitchenware, washing -

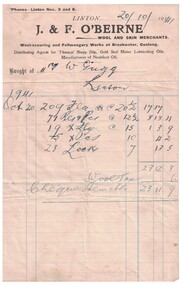

Linton and District Historical Society Inc

Linton and District Historical Society IncReceipt, J. & F. O'Beirne, Wool and Skin Merchants, Linton, 1941

Receipt issued to Mrs. W. Grigg 20/10/1941.Text: " Phones - Linton Nos. 3 and 8. / LINTON / J. & F. O'BEIRNE / WOOL AND SKIN MERCHANTS. / Wool-scouring and Fellmongery Works at Breakwater, Geelong. / Distributing Agents for Thomas' Sheep Dip, Gold SeEal Motor Lubricating Oils. / Manufacturers of Neatsfoot Oil. "mrs. w. grigg, j. & f. o'beirne, linton -

National Wool Museum

National Wool MuseumBook, Proceedings: 5th International Wool Textile Research Conference vol. V, 1975

... Scouring ..."Proceedings: 5th International Wool Textile Research Conference, vol. V" Sept. 1975.textile finishing wool - chemistry, deutsches wollforschungsinstitut an der technischen hochschule aachen e.v., dyeing, scouring, textile finishing, wool - chemistry -

National Wool Museum

National Wool MuseumBook, Wool Textile Research

... Scouring ..."Wool Textile Research; CSIRO Research for Australia 9". Contains articles re: the latest CSIRO research (as of 1986) into areas such as wool marketing, wool cleaning, standard descriptions of wool, production of woollen fabric and yarn and current research trends.wool marketing woolclassing, csiro, scouring, dyeing, wool marketing, woolclassing -

National Wool Museum

National Wool MuseumRug

The rug was made at Albion Mill in Geelong. It was owned by Mr Angus Peter and Ms Mary Anne Downie, the parents of Mary Virr (the donor). They lived in Cobden. Ms Downie's family had several connections to the Geelong wool industry, in particular the Albion Mill. See attached histories and family tree.W7214 W7214 reverse. Statement from Mary Virr on offer of donation Written family history by Mary Virr, page 1 Written family history by Mary Virr, page 2 Partial family tree of Mary Virr, including connections to the wool industry. Photocopy of marriage certificate dated 13th April 1881, marriage between James Downie and Mary Cairns, the grandparents of Mary Virr. A photocopy of a reference dated 15/09/1919 from Mr E. Plumridge from the Corio Wool Scouring Company for Miss M. DownieAlbion Mills Geelong Albion Rug All Wooltextile industry textile mills, albion woollen mills co. pty ltd, weaving, albion woollen mills, geelong, victoria, textile industry, textile mills -

National Wool Museum

National Wool MuseumRug

The rug was made at Albion Mills in Geelong. It was owned by Norman Downie, the uncle of Mary Virr (the donor) who inherited the rug after Mr Downie's death in the early 1990s. Mr Downie and his family had several connections to the wool industry in Geelong. He would send pieces of fabric out to Mrs Virr and her mother in Cobden every year. See attached history.W7215 Statement from Mary Virr on offer of donation Written family history by Mary Virr, page 1 Written family history by Mary Virr, page 2 Partial family tree of Mary Virr, including connections to the wool industry. Photocopy of marriage certificate dated 13th April 1881, marriage between James Downie and Mary Cairns, the grandparents of Mary Virr. A photocopy of a reference dated 15/09/1919 from Mr E. Plumridge from the Corio Wool Scouring Company for Miss M. DownieAlbion Mills Geelong Albion Rug All Wooltextile industry textile mills, albion woollen mills co. pty ltd, albion woollen mills, weaving, geelong, victoria, textile industry, textile mills -

National Wool Museum

National Wool MuseumPhotograph

Photo depicts Cordillo Downs Shearing Shed, located 176kms north of Innaminka. Donated by Gwen Cox (Hon. Staff Member). Once the largest sheep station in the world, the shearing shed had 120 stands. The wool clip had to be carted 600km down the track to the rail head at Farina by camel train. In 1883, a complete scouring plant was installed at "Cordillo". The region now (1989) carries cattle.shearing sheds, photographs, cordillo downs -

National Wool Museum

National Wool MuseumCalendar

... Scouring ...Acquired when "Classweave Industries" closed down.With Compliments from/ G H Michell and Sons Limited,/ Wool Merchants/world war ii woollen mills wool processing, federal woollen mills ltd classweave industries pty ltd commonwealth woollen mills g.h. michell and sons (aust.) pty ltd, carbonising, scouring, world war ii, woollen mills, wool processing