Showing 101 items

matching sharpening tool

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Awl, Mid to late 20th century

... tool with a sharpened point and a Bradawl is similar... and a Bradawl, the Awl is a small hand-held tool with a sharpened point ...An Awl is used to make indentations in wood or other materials in order to ease the insertion of a nail or screw. The blade is placed across the fibers of the wood, cutting them when pressure is applied. The Awl is then twisted through 90 degrees which displaces the fibers creating a hole. This then gives a start to the nail or screw being inserted into the work piece. There is a difference between an Awl and a Bradawl, the Awl is a small hand-held tool with a sharpened point and a Bradawl is similar but is flattened at its tip to produce a sharp chisel edge.An everyday tool used in carpentry, the subject item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as believed to have been produced during the 20th century.Awl with wooden handle with brass ferrule & steel pointed shaftStamped on handle J McArthur (owner)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, awl, j mcarthur, carpenders tools, woodworking tools, nail starter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Saw gauge, Henry Disston, 1890-1920

Disston Saw Works of Philadelphia was one of the better known and highly regarded manufacturers of handsaws in the United States. During the Machine Age, the company was known as Henry Disston & Sons, Inc. a supplier of industrial saw blades. History: The story of handsaws in the United States mirrors the technical and development of steel in Sheffield, England, which was the center of handsaw production during the 18th century and through most of the 19th century. England's political and economic lock-on steel making in the colonies held American saw makers at bay until well after the Revolutionary War. American steel producers were unable to compete until the US government introduced import tariffs to level the playing field in 1861. Henry Disston: Henry Disston (1819–1878) began his career as an American saw maker in Philadelphia. He had emigrated from England in 1833 and started making saws and squares in 1840. In 1850, he founded the company that would become the largest saw maker in the world, the Keystone Saw Works. Some five years later, Disston built a furnace—perhaps the first melting plant for steel in America and began producing the first crucible saw steel ever made in the United States. While his competitors were buying good steel from Britain, he was making his own, to his specification, for his own needs. Disston subsequently constructed a special rolling mill exclusively for saw blades. Over the following decade, the Disston company continued to grow, even while dedicating itself to the Union Army's war effort. In 1865, when his son Hamilton Disston rejoined the business after serving in the Civil War, Disston changed the company's name to Henry Disston & Son. Henry Disston and his sons began to set the standards for American saw makers, both in terms of producing high-quality saws and files in 1865 through his development of innovative manufacturing techniques. In September 1872, Henry Disston and two other men dug a part of the foundation for what was to become the largest saw manufacturing facility in the world: Disston Saw Works. This was in the Tacony section of Philadelphia. Having previously moved his expanding business from near Second and Market Streets to Front and Laurel Streets. It took over 25 years to move the entire facility to Tacony. Henry Disston was renowned for having one of the first industries that exhibited environmental responsibility, as well as a paternalistic view towards his employees. For example, he had thousands of homes built in Tacony for his workmen. Funds to purchase these homes were made available through a building and loan association set up by the Disston firm. His caring influence on the community was evident in everyday life. To meet employees' cultural needs, a hall and a library were built with Henry Disston agreeing to pay a fixed sum towards its maintenance. The Tacony Music Hall was erected in 1885, also with the assistance of Disston money. Henry Disston had fallen ill by 1877 and never truly recovered; he suffered a stroke and died the next year. This came only one and a half years after seeing his products receive the highest honors at the great Philadelphia Centennial Exposition of 1876. His vision of a working-class community and the completion of the transfer of his enormous saw plant was carried out by his wife and his sons. The company, by the early 20th century, cast the first crucible steel in the nation from an electric furnace in 1906. The firm's armor-plate building near Princeton Avenue and Milnor Street contributed tremendously to the World War II effort. But the company's innovation and industriousness would not last forever. In 1955, with mounting cash-flow problems and waning interest on the family's part to run the firm, Henry Disston and Sons were sold to the H.K. Porter Company of Pittsburgh. Porter's Disston Division was sold in 1978 and became the Henry Disston Division of Sandvik Saw of Sweden. This division was then sold in 1984 to R.A.F. Industries of Philadelphia and became known as Disston Precision Incorporated, a maker of specialized flat steel products. In 2013, R.A.F. Industries sold Disston Precision Inc. in a private sale. Although the company has ceased making Disston handsaws, the Disston brand name still exists in this firm. A tool used to set and sharpen cross cut saws used to fell trees for building construction made by a well known American maker whos firm pioneered the making of saws and their related items including files.combination cross cut saw raker and gauge/jointerDisston USA in the castingflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, stainless steel pen-knife, 20thC

A penknife, or pen knife, is a small folding knife. It was originally used to describe a knife used for cutting or sharpening a quill to make a dip pen nib. Originally, penknives were used for thinning and pointing quills to prepare them for use as writing instruments and, later, for repairing or re-pointing the quills. They did not necessarily have folding blades, but resembled a scalpel or wood knife by having a short, fixed blade at the end of a long handle. Today a penknife can have single or multiple blades, and with additional tools incorporated into the design. The most famous example of a multi-function penknife is the Swiss Army knife A folding pen-knife with 2 stainless steel bladeson long blade end; STAINLESS / MADE IN / SHEFFIELDpen-knife, scouts, cheltenham, moorabbin, bentleigh, tools, early settlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

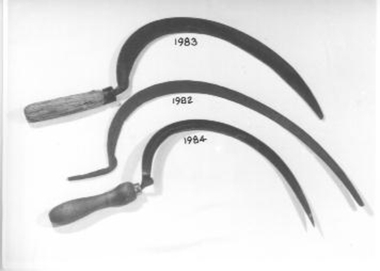

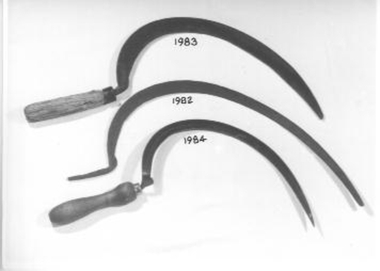

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, metal scythe, c1880

A scythe is an agricultural hand tool for mowing grass or reaping crops. It was largely replaced by horse-drawn and then tractor machinery. A scythe consists of a wooden shaft and a long, curved blade is mounted at the lower end, perpendicular. Scythes always have the blade projecting from the left side when in use. Mowing is done by holding the handle , with the arms straight, the blade parallel to the ground and very close to it, and the body twisted to the right. The body is then twisted steadily to the left, moving the scythe blade along its length in a long arc from right to left, ending in front of the mower, thus depositing the cut grass to the left. Mowing proceeds with a steady rhythm, stopping at frequent intervals to sharpen the blade. The correct technique has a slicing action on the grass, cutting a narrow strip with each stroke Mowing grass is easier when it is damp, and so hay-making traditionally began at dawn and often stopped early, the heat of the day being spent raking and carting the hay cut on previous daysEarly settlers and market gardeners used these scythes as they established their farms in Moorabbin Shire c1880A large metal scythe with a wooden handle x 2early settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools, blacksmiths -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, hand made wood plane, c1880

A hand plane is a tool for shaping wood Hand planes are generally the combination of a cutting edge, such as a sharpened metal plate, attached to a firm body, that when moved over a wood surface, take up relatively uniform shavings, by nature of the body riding on the 'high spots' in the wood, and also by providing a relatively constant angle to the cutting edge, render the planed surface very smooth. A cutter which extends below the bottom surface, or sole, of the plane slices off shavings of wood. A large, flat sole on a plane guides the cutter to remove only the highest parts of an imperfect surface, until, after several passes, the surface is flat and smooth.The family of Mr Lamb were early settlers in Moorabbin Shire and had to be self reliant and made their own clothes and tools as they established homes and farms for their families.c1880 A hand made wood planeearly settlers, pioneers, market gardeners, moorabbin, bentleigh, brighton, cheltenham, tools -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Spokeshave steel ornate, c1900

A spokeshave is a tool used to shape and smooth wooden rods and shafts - often for use as wheel spokes, chair legs . Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. Spokeshaves can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, whilst the body and handles were wood. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached. Like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth century metal handles and detachable blades had become the most common. Preston Tools was an English tool making company also known as E.P. Tools and Edward Preston Tools. Edward Preston Sr. (1805-1883) was first listed as a plane maker at 77 Lichfield Street in the 1833 Birmingham Directory but it is believed he may have started business there as early as 1825. Around 1850 his son, Edward Preston Jr. (1835-1908) left school to join his father's business and he later started up his own "wood and brass spirit level manufactory" at 97-1/2 Lichfield Street by 1864. By 1866 Edward Jr. had added planes, routers, joiners, coach, gun, cabinet and carpenters tools to his line, and the following year he moved his shop from his father's address and relocated to 26 Newton Street, before moving again to a much larger premises at 22-24 Whittall Street. This later became the office and factory of Edward Preston and Sons, who were forced to liquidate in 1934, due mainly to the Great Depression and mismanagement of the company. The plane making concern was sold to the Sheffield firm of C. & J. Hampton, who had subsequently merged in 1932 with Record Ridgeway Ltd.An ornate steel spokeshave wood plane with an adjustable screw.PRESTONS PATENTwoodwork, tools, spokeshave, moorabbin, cheltenham, bentleigh, early settlers, pioneers, market gardeners, woodplanes, craftwork, bicycle wheels, furniture, cabinetmaking, cartwheels, wagons, drays, preston edward, preston tools ltd -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, Knife, curved, Sheffield c1900, 20thC

John Oxley was a shoe and butchers’ knife manufacturer, who was listed in Whitecroft UK in 1822 . By 1825, he was based in Hollis Croft. John apparently died in about 1837. He had two sons – George (1808-1879) and James (1811-1881) who took over the business. George moved to Indianna, USA and in 1868 James continued to manufacture 'Cooks’ and palette knives and steels" Oxley’s trade mark was a butcher’s knife crossed with a sharpening steel (and the letters ‘JO’). The firm stayed in the family until 1960. Early settlers were self reliant and repaired their own equipment for kitchen,dairy, farm, horses, carts using various tools . This strong steel knife is typical of the type used by early settlers in Moorabbin Shire c1900Heavy duty curved steel knife with a wide blade encased in 2 thick leather straps secured with steel rivets Blade ; James Oxley with Trade Mark - a butcher’s knife crossed with a sharpening steel (and the letters ‘JO’). scratched into leather handle ; J EVANSknives, sheffield steel, oxley james ltd. , leatherworkers, saddles, horses, bootmakers, shoes, boots, builders, carpenters, early settlers, market gardeners, blacksmiths, tools, building equipment, hammers, moorabbin shire, bentleigh, mckinnon, highett, cheltenham,mcewan james pty ltd, melbourne, bunnings pty ltd, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher, at one time mostly used in chair making.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used. Curved Spokeshave with metal handlesNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, hand plane, joiners tools, wagoner's tools, spokeshave -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Prior to 1950

A spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Spokeshaves can be made from flat-bottom, concave, or convex soles, depending on the type of job to be performed. They can include one or more sharpened notches along which the wooden shaft is pulled in order to shave it down to the proper diameter. Historically, spokeshave blades were made of metal, and the body and handles were wood. Unlike a drawknife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. By the twentieth-century metal handles and detachable blades had become the most common. A convex, wooden, variant of the spokeshave is called a travisher; at one time mostly used in chairmaking.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Spokeshave, with two wooden handles on either side. Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, spokeshave, barrel making, wood plane, wagon making, joiners tools, carpenter tools -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - RAZOR STROP

Leather razor strop for sharpening cut throat razors, black leather mounted on wood, gold eagle emboosed on handle.Gold Eagle specially preparedpersonal effects, shaving, razor strop -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - METAL BROAD AXE

Metal Broad Axe. Sharpened To Bevel On One Side. 300 cm Wide x 230 cm High. Previous Catalogue Number 116.tools, multipurpose, broad axe -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - 'IVORY?' CHISEL FOR LEATHERWORK

'Ivory?' Chisel. Approximately 10cm long. One end is sharpened and flattened, the other is carved to form a 12-sided shape. Each end is separated by a circular stem approx. 2cm in diameter. The chisel is part of the contents of the John M Okey Tool box.. John Martin Okey, Kangaroo Flat died 6/08/1943 and is buried in The Methodist section of The Kangaroo Flat Cemetery -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Grindstone, 1920s

Rotary grindstones have been in consistent use for centuries as devices to sharpen or shape ferrous metals. Pedal-operated rotary grindstone on timber stand. The circular stone is attached to a four legged stand, with a length of wood linking to a pedal. Unpainted, unfinished, and slight deterioration. farm machinery, grindstone, churchill island, rotary, farm -

Churchill Island Heritage Farm

Churchill Island Heritage FarmTool - Strop

This horse hide strop was traditionally used to sharpen and polish straight edged razors, although it could be used for kitchen knives or chisels. The metal loop was designed to be hung onto a nail or peg, and the person held onto the handle and pull the strop taut. The razor was sharpened by drawing the spine down along the strop, so no pressure placed on the blade. Once the razor reached the bottom of the strop, it was flipped and drawn upwards. This process required skill, although it could be done at a great speed. Keen Kut was an American brand that sold razors, strops, and safety brands. Double sided, two strips. Metal ring one end, padded stitched handle at other. Horse hide.KEEN KUT /GENUINE HORSE HIDEchurchill island, strop, horse hide, tool, kleen kut -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Tool - PITTOCK COLLECTION: SHARPENING STONE & WOODEN WEDGE

... Pittock tools collection: contains: * Sharpening stone... Pittock tools collection: contains: * Sharpening stone in original ...Pittock tools collection: contains: * Sharpening stone in original Australian Abrasives Pty. Ltd. cardboard box. Stone is made of silicon carbide in a wedge shape 113 mm L x 45 mm W x 9 mm thick * Hardwood wedge, 110 mm L x50 mm W x 5-20 mm thick Items stored in Pittock coach builder's box, reference 13000.1. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Knife Sharpener, 1950s

... . Green dial on front for setting the utensil for sharpening. Tool ...Plastic 1950s utensilKnife Sharpener. Square green plastic base; cream plastic pyramid shaped body. Green dial on front for setting the utensil for sharpening.DIAL X SHARPENER. SHARPENS EVERYTHING.domestic items, appliances, utensils -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Knife Sharpener

Tempered steel sharpener for sharpening knives. It has a bone handle.domestic items, utensils, cutlery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sharpening stone

... with wooden cover inset inside to contain stone. Tool Sharpening stone ...Part of collection of Carpenters' tools used on sailing ship from England to AustraliaSharpening stone which may be natural stone. Set on piece of wood with wooden cover inset inside to contain stone.trades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Axe Head

... with hole for handle and the other thinned and sharpened. Tool Axe ...Iron axe head with wide end with hole for handle and the other thinned and sharpened.trades, tools -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Strap Hammer

... and thinned to a sharpened edge. Tool Strap Hammer ...Used for cutting hoop iron straps on bundles.Small hammer head with hole formed for handle and thinned to a sharpened edge.trades, coopering -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sickle

Found around Schwerkolt Cottage by donor.Large sharpened curved metal blade. Handle missing .815rural industry, agriculture -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sickle

Long curved sharpened steel blade with a wooden handle.4rural industry, agriculture -

Whitehorse Historical Society Inc.

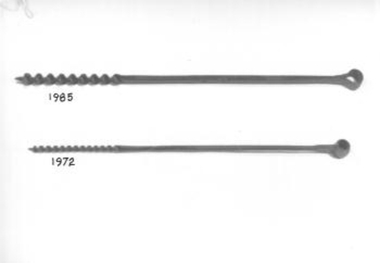

Whitehorse Historical Society Inc.Tool - Auger Bit

Long steel shaft half of which is twisted into a corkscrew shape and sharpened to make a hole in wood. The other end has been formed into a round hole so that a handle may be inserted to turn the drill. Used for drilling hole in fence post.rural industry, fencing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Carpenter's Brace and 8 bits, c1880s

Brace is a U shaped frame with a wooden handle in centre, a round metal wheel at one end and a metal handle at the other end. Bits are corkscrew shaped and sharpened to make a hole in wood.trades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Cold Chisel

Steel shaft with end flattened and sharpened and rounded at other.trades, mechanics -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Knife Sharpener, 1940's

... , used for sharpening Knife Sharpener Tool Knife Sharpener ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for repairing footwear. Lightweight and well balancedLong, handmade wooden block, with a curved handle area, also has a leather strip attached to one long side, used for sharpeningkazenwadel, blacksmith, wood, tools camp 3, leather