Showing 73 items

matching shearing machinery

-

National Wool Museum

National Wool MuseumBook, Australian Inventions and Innovations

... Shearing Spinning Spinning Machinery Wool staple - measurement ..."Australian Inventions and Innovations" - Robert Ingpen, 1982merino sheep - history sheep breeding - history shearing, spinning, spinning machinery, wool staple - measurement, merino sheep - history, sheep breeding - history, shearing -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - Shearing Hand Set

... first commercially successful sheep shearing machinery... commercially successful sheep shearing machinery by Frederick York ...The wool industry has been critical to the Australian economy from the early days of European settlement. The increase in wool production in the mid to late 19th century led to the need to replace the hand shears with some mechanized forms of shearing.The first commercially successful sheep shearing machinery by Frederick York Wolseley in New South Wales who was granted a patent for his machine on 28 March 1877. Many of the early settlers to North East Victoria droved sheep overland from both Sydney and South Australia and established large pastoral runs in the district. Wodonga became a major service centre for the industry and established major saleyards for the pastoral and cattle industries. The handset has the company name "Heiniger" on the side. Heiniger is a Swiss company with subsidiaries in Australia and New Zealand. It was originally established in 1946.This item is connected to a major rural industry in North East Victoria.A metal handpiece for a sheep shearing. A toothed blade is held in place with metal adjustable screws at one end. A jointed metal pipe at the other end allows attachment to the shearing machine. The hinge has been covered with leather.On adjustment knob "Heinger"shearing industry, shearing equipment, shearing handset -

National Wool Museum

National Wool MuseumDrench Gun

... company whose products, including windmills and shearing machinery... company whose products, including windmills and shearing machinery ...The Kettle Drum Drenching Gun was invented and predominately used in the 1940s and 1950s. This Drench Gun was constructed by Moffat-Virtue Ltd, an Australian company formed by John Moffat and William Wright Virtue. Moffat-Virtue Ltd were a Sydney company whose products, including windmills and shearing machinery, were well known in rural NSW throughout the mid twentieth century. The company was taken over by Fire Fighting Enterprises Ltd in June 1966 (Rudder, G 2020). The Drench Gun was likely used to drench sheep with carbon tetrachloride for internal parasite control. These guns were widely used in Australia. There were problems with the product, however, which contributed to its demise. On hot days and if the sheep struggled while being drenched, some fluid would go into the wind-pipe and into the lungs of the sheep, sometimes with fatal results. At times nearly one-third of a flock could be found dead. Inexperienced operators, overdose and weather were often blamed for the deaths (Davidson, K 2012). A brass drenching kettle consisting of a brass bowl and a detachable plunger mechanism. The plunger is alloy and the handle has a hinge to create suction to spray liquid out the brass nozzle.Moffatt-Virtue Limited 3841 C V ROBERTS/ PATENTEE Pest Arrestorsheep - diseases sheep - parasites -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, c1900

A black and white photograph depicting seven men and four women surrounded by tunnel boring machinery. A tunnel boring machine (TBM), also known as a "mole", is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata. They may also be used for microtunneling. They can be designed to bore through anything from hard rock to sand. Tunnel boring machines are used as an alternative to drilling and blasting (D&B) methods in rock and conventional "hand mining" in soil. TBMs have the advantages of limiting the disturbance to the surrounding ground and producing a smooth tunnel wall. This significantly reduces the cost of lining the tunnel, and makes them suitable to use in heavily urbanised areas. The major disadvantage is the upfront cost. TBMs are expensive to construct, and can be difficult to transport. The longer the tunnel, the less the relative cost of tunnel boring machines versus drill and blast methods. This is because tunneling with TBMs is much more efficient and results in shortened completion times, assuming they operate successfully. Drilling and blasting however remains the preferred method when working through heavily fractured and sheared rock layers.This photograph is significant as it shows the machinery used and attire worn by men and women during the gold rush era. Black and white rectangular photograph printed on photographic paperburke museum, mining, beechworth, boring machinery, excavate, gold, gold fields, gold rush, miners -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Barometer, 1867

Langlands Company History: Langlands foundry was Melbourne's first foundry and iron shipbuilder established in 1842, only 8 years after the founding of the Victorian colony by two Scottish immigrants, Robert Langlands and Thomas Fulton, who had formed a partnership before emigrating (1813–1859). The business was known as the 'Langlands Foundry Co'. Henry Langlands (1794-1863), left Scotland in 1846 with his wife Christian, née Thoms, and five surviving children to join his brother Robert. By the time he arrived in early January of 1847 the partnership of Robert Langlands and Fulton had dissolved as Fulton had gone off to establish his own works. It was at this time that the two brothers took over ownership of Langlands foundry. Several years later Robert retired and Henry became sole the proprietor. The foundry was originally located on Flinders Lane between King and Spencer streets. Their sole machine tool, when they commenced as a business, was a small slide rest lathe turned by foot. In about 1865 they moved to the south side of the Yarra River, to the Yarra bank near the Spencer Street Bridge and then in about 1886 they moved to Grant Street, South Melbourne. The works employed as many as 350 workers manufacturing a wide range of marine, mining, civil engineering, railway and general manufacturing components including engines and boilers. The foundry prospered despite high wages and the lack of raw materials. It became known for high-quality products that competed successfully with any imported articles. By the time Henry retired, the foundry was one of the largest employers in Victoria and was responsible for casting the first bell and lamp-posts in the colony. The business was carried on by his sons after Henry's death. The company was responsible for fabricating the boiler for the first railway locomotive to operate in Australia, built-in 1854 by Robertson, Martin & Smith for the Melbourne and Hobson's Bay Railway Company. Also in the 1860s, they commenced manufacture of cast iron pipes for the Board of Works, which was then laying the first reticulated water supply system in Melbourne. Langlands was well known for its gold mining equipment, being the first company in Victoria to take up the manufacture of mining machinery, and it played an important role in equipping Victoria's and Australia's first mineral boom in the 1850s and 1860s. Langlands Foundry was an incubator for several engineers including Herbert Austin (1866–1941) who worked as a fitter at Langlands and went on to work on the Wolesely Shearing machine. He also founded the Austin Motor Company in 1905. Around the 1890s Langlands Foundry Co. declined and was bought up by the Austral Otis Co. in about 1893. History for Grimoldi: John Baptist Grimoldi was born in London UK. His Father was Domeneck Grimoldi, who was born in Amsterdam with an Italian Father and Dutch mother. Domeneck was also a scientific instrument maker. John B Grimoldi had served his apprenticeship to his older brother Henry Grimoldi in Brooke Street, Holburn, London and had emigrated from England to Australia to start his own meteorological and scientific instrument makers business at 81 Queens St Melbourne. He operated his business in 1862 until 1883 when it was brought by William Samuel and Charles Frederick, also well known scientific instrument makers who had emigrated to Melbourne in 1875. John Grimoldi became successful and made a number of high quality measuring instruments for the Meteorological Observatory in Melbourne. The barometer was installed at Warrnambool's old jetty and then the Breakwater as part of the Victorian Government's insistence that barometers be placed at all major Victorian ports. This coastal barometer is representative of barometers that were installed through this government scheme that began in 1866. The collecting of meteorological data was an important aspect of the Melbourne Observatory's work from its inception. Just as astronomy had an important practical role to play in navigation, timekeeping and surveying, so the meteorological service provided up to date weather information and forecasts that were essential for shipping and agriculture. As a result, instruments made by the early instrument makers of Australia was of significant importance to the development and safe trading of companies operating during the Victorian colonies early days. The provenance of this artefact is well documented and demonstrates, in particular, the importance of the barometer to the local fishermen and mariners of Warrnambool. This barometer is historically significant for its association with Langlands’ Foundry which pioneered technology in the developing colony by establishing the first ironworks in Melbourne founded in 1842. Also, it is significant for its connection to John B Grimoldi who made the barometer and thermometer housed in the cast iron case. Grimoldi, a successful meteorological and scientific instrument maker, arrived in the colony from England and established his business in 1862 becoming an instrument maker to the Melbourne Observatory. Additional significance is its completeness and for its rarity, as it is believed to be one of only two extant barometers of this type and in 1986 it was moved to Flagstaff Hill Maritime Village as part of its museum collection. Coast Barometer No. 8 is a tall, red painted cast iron pillar containing a vertical combined barometer and thermometer. Half way down in the cast iron framed glass door is a keyhole. Inside is a wooden case containing a mercury barometer at the top with a thermometer attached underneath, each with a separate glass window and a silver coloured metal backing plate. Just below the barometer, on the right-hand side, is a brass disc with a hole for a gauge key in the centre. The barometer has a silvered tin backing plate with a scale, in inches, of "27 to 31" on the right side and includes a Vernier with finer markings, which is set by turning the gauge key. The thermometer has a silvered tin backing plate with a scale on the left side of "30 to 140". Each of the scales has markings showing the units between the numbers.Inscription at the top front of the pillar reads "COAST BAROMETER" Inscribed on the bottom of the pillar is "No 8". and "LANGLANDS BROS & CO ENGINEERS MELBOURNE " The barometer backing plate is inscribed "COAST BAROMETER NO. 8, VICTORIA" and printed on the left of the scale, has "J GRIMOLDI" on the top and left of the scale, inscribed "Maker, MELBOURNE". There is an inscription on the bottom right-hand side of the thermometer scale, just above the 30 mark "FREEZING" Etched into the timber inside the case are the Roman numerals "VIII" (the number 8)flagstaff hill, warrnambool, maritime village, maritime museum, flagstaff hill maritime museum & village, shipwreck coast, great ocean road, warrnambool breakwater, coast barometer, coastal barometer, barometer, weather warning, ports and harbours, fishery barometer, sea coast barometer, austral otis co, coast barometer no. 8, henry grimoldi, henry langlands, john baptist grimoldi, langlands foundry co, meteorological instrument maker, robert langlands, scientific instrument maker, thermometer, thomas fulton -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - CONNELLY, TATCHELL, DUNLOP COLLECTION: MORTGAGE MR. J.J. JEWELL TO T. LUXTON ESQ

Documents relating to mortgage between Mr. Joshua James Jewell of Mitiamo, farmer, and Mr. T. Luxton , The Exchange, Collins St., Melbourne for land at Parish of Terrick Terrick West, County of Gunbower, mortgage document dated 4th. July 1892. Contains 3 Conditions of Sale documents, newspaper clipping re clearing sale of 2600 acres of land on behalf of Mr. J.J. Jewell, farming implements, machinery, household effects at 'The Hill' Mitiamo.. Letters relating to transactions re above mortgage enclosed, including discharge of mortgage handwritten document between Sarah Berges and Joshua J. Jewell. Note name change from Connelly & Tatchell, to Connelly, Tatchell & Paling. Letter enclosed in file from Mr. Joshua Jewell, 'The Hill' Mitiamo, Oct 4th., 1893 to Mr. T, Luxton, requesting ' waiting another (?) for money I will be able to pay it before the month is up but at present I cannot meet it. I have just commenced to shear and of course money will be coming in now'cottage, miners, joshua james jewell, thomas luxton, terrick terrick west, gunbower, mortgage, connelly, tatchell & paling, s. berges, connelly, tatchell & dunlop, paling. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Shearing Machine

Long thin shaft standing on a three legged round base. Handle attached to the round metal piece. Handle turns shaft on other side of the metal piece.Chicago Flexible Shaft|Stewart Clipper.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Shearing Machine

Long thin shaft standing on a three legged round base. Handle attached to round metal piece. Handle turns shaft on other side of metal piece.Burman & sons|Birmingham Englandrural industry, farm machinery -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncPhotograph, Engines In front of Auntie Jack Shed Circa 2006, Circa 2006

Digital Photograph of Auntie Jack shed at the Maldon Vintage Machinery Museum on Vincents Road, Maldon. Engines L-R: Portable shearing plant, Marshall Engine "Auntie Jack", Ferguson Tractor, Blue Engine (Unknown brand at time of upload)auntie jack, photograph -

Churchill Island Heritage Farm

Churchill Island Heritage FarmMachine - Wool Press

The Churchill Island collection includes objects from the 18th and 20th centuries. The collection is presented in sets and series, of which this object belongs to the National Trust sub-collection.Wool presses were used in shearing sheds around the country to create bales of wool by hand in preparation for transport to the wool markets for purchase and distribution. Bales have been used to store and were a standard trading unit for wool for centuries. A standard wool bale holds about 60 compressed wool fleeces and weighs a minimum of 120 kgs. The square shape and weight enabled them to be stacked on wagons or in warehouses, and a large pack horse could carry one on each side. Large, retangular upright metal wool press, unpainted with some surface rust.farm machinery, wool, wool press, hand operated, shearing, national trust -

National Wool Museum

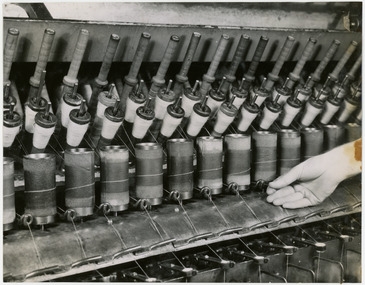

National Wool MuseumPhotograph - Twisting or Doubling, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing detail of machinery with spools of wool. A hand is shown on the right handling a thread of wool.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W18 / W18. Twisting or Doubling.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

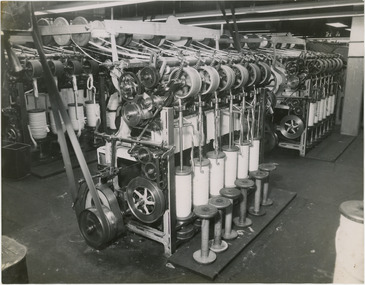

National Wool MuseumPhotograph - Open Drawing, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing machinery with spools of wool.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W16 / W16. Open Drawing.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool -

National Wool Museum

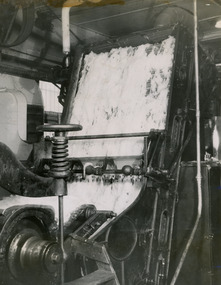

National Wool MuseumPhotograph - From Scourer to Dryer, 1960s

One of fifty one photographs originally in a photo album found in the National Wool Museum’s office. The album was water damaged and the images were removed for conservation. The images follow the process of wool. Beginning in a sheep paddock and finishing as a folded fabric. It includes all the steps in between in this process, including shearing, transporting, selling, washing and the many different steps in the process of turning a single thread of wool into fabric.Black and white image showing a wool moving through machinery.AUSTRALIAN NATIONAL PUBLICITY / ASSOCIATION / FLINDERS STREET RAILWAY BUILDING, / MELBOURNE AUSTRALIA / W11 / W11. From Scourer to Dryer.wool industry, working life, women, boonoke station, farming, sheep farming, agriculture, sheep stations, transport, wool processing, shearing, textile industry, wool