Showing 78 items

matching steam industry

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBadge - Gripman Badge, Stokes & Sons, Jul 1916 - Nov. 1919

This cable tram Gripman’s badge, or driver’s badge, was part of a tram driver’s uniform. The inscriptions on the front of the badge identify it as belonging to Gripman number 14, at the South Melbourne Car House depot of the Tramways Board. The Gripman Badge would be re-issued whenever another Gripman takes over the position. Cable trams were invented in America in 1873. In Melbourne, cable trams were in use from 1885 until 1940, with a network of up to 1200 cable cars or 'dummies' and trailers travelling at around 9.5 miles (15km) per hour along 46 miles (74km) of double tracks. The Gripman drove the dummy car, operating the heavy levers to connect the gripping gears to the cable installed in a slot in the road. To turn at intersections he would skilfully disconnect, freewheel around the corner and carefully reconnect to the continuously operating steel cable. Large winding gears in an Engine House along the line pulled the cable along, powered by steam engines and later electric engines. The gripping gears were in the centre of the car's floor with seating all around the sides, a dangerous place for curious children. , whose worried parents would guide them into the tram that was towed behind the dummy car. The Melbourne Tramways Board operated the cable trams between July 1916 and November 1919 after taking over from the privately operated Melbourne Tramway and Omnibus Company. In 1919, the Melbourne and Metropolitan Tramways Board (MMTB) took over the Tramways Board. Stokes & Sons: - The maker of the badge, Thomas Stokes, migrated to Melbourne from Birmingham in 1854 and set up business in Mincer Lane as a die-sinker, producing medals, tokens, buttons and silverware, and an engraving service. He moved to Flinders Lane in 1856. After a time, in 1894, the business became Stokes & Sons Pty: Ltd, electroplates and badge makers at Post Office Place in Melbourne. The maker's mark 'Stokes & Sons' was made on badges until 1962. LOCAL CONNECTION: -t was common practice to recycle the used cables from the tramway. For example, the Wollaston Bridge in Warrnambool, Victoria, is suspended by recycled cable tram Melbourne. (Other recycled cables were used for fencing wire.) -Portland's cable tram is an example of the cable trams used in Melbourne from 1885 to 1940.This badge was used to identify a Gripman who operated a cable car tram's dummy car for the Tramways Board in Melbourne between 1916 and 1919. It represents the need for people to be able to identify workers in the service industry, a need still addressed today by staff ID badges and digital identification. The badge also represents the period in Melbourne's history when cable cars were used for public transport for over four decades, gradually changing from steam to electric power. Trams still have an important role in Melbourne's public transport. Badge, round hollow metal dome with two open metal guides on the back. A cable tram Gripman (driver) badge with embossed inscriptions on the front and stamped on the back. There is a logo of entwined letters T and B on the front. It identifies Gripman number 14, South Melbourne, Tramway Board. It was made by Stokes & Sons of Melbourne. Impressed into the front: "S / 14 / M" "GRIPMAN" Logo intertwined "T" and "B" Embossed on reverse "STOKES &o SONS"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, badge, gripman, stokes & sons, numesmatics, tramway, tram, tram driver, uniform, cable tram, identification, cable car driver, tramway board, south melbourne, melbourne tramways board, tb, mtb, mmtb, melbourne and metropolitan tramways board, tramway button, gripman button, id, identification badg, staff badge, name badge, employee, grip car, dummy car -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Bush Sawmill beside the Wimmera River in Dunolly 1993

Dunolly 1993. Bush Sawmill beside the Wimmera River. Wooden buildings in Background. Chimney of what appears to be a steam driven engine with flywheel and belt driving a saw bench. Several men in photo. Original photographic taken by Charles Nettleton.Black & white photograph of timber and logs beside a water body with buildings and a tall chimney in the background. Around seven people in the background.Bush Saw Mill Wimmera River near Stawell 1877 Negative Reversed copy also 2641water industry -

Bendigo Military Museum

Bendigo Military MuseumUniform - JACKET, SERVICE DRESS, ARMY, Australian Defence Industries, 1989/90

Uniform issued to "LOCKYER" 114493.Jacket - khaki colour wool/polyester fabric. Service dress style, gold colour plastic buttons with metal shank and split ring. Buttons have raised emblem of Queens crown, crossed swords and Kangaroo. Royal Australian Army. Collar, shoulder epaulettes, four front pockets, top two with button and two metal studs on flap, lower button down flap. Green colour polyester fabric lining with white cotton manufacturers labels inside right.Manufacturers information on labels - black ink print faded to light grey/blue. "RUSS JOHNSTON/ -TAILOR- /VIC^ 1989/90/ DEN 8405-66-019-8188/ DRYCLEAN ONLY/ REPRESS USING IRON AND DAMP CLOTH/ OR MEDIUM TO HOT STEAM IRON/ CREASE UPPER HALF OF LAPELS ONLY" "REGIMENTAL NO./NAME" Handwritten, blue ink pen "LOCKYER". uniform, army, service dress, lockyer -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Bottle, J. S Rowley

The making of cordials and aerated waters was an important industry in Warrnambool from the time of the first settlement up to the 1980s. John Rowley was a prominent producer of aerated waters and cordials from 1868 to his death in 1893 (the Warrnambool Steam Aerated Works). He was known for his originality in the production of soft drinks and produced 20 varieties of drinks, including his own Henneberry Wine and Lime Fruit Champagne, both non-alcoholic. In the 1870s he was producing 600 dozen bottles a day and in the 1880s his cordial factory occupied half an acre of land and employed 13 people. He won many awards for his products at local Agricultural Shows. Warrnambool cordial bottles are of considerable significance as examples of an important industry now gone. Rowley is a significant person in the history of 19th century Warrnambool industries and Rowley bottles are of considerable importance, especially this one, made for efferverscent drinks. This is a heavy glass bottle (no stopper) possibly used for hop bitters or ginger wine or some contents that had high efferverscent qualities. The bottle has a heavy indented base. Oval etching ‘J.S.,Rowley Warrnambool’ with ‘Trade Mark’ and monogram. ‘J.R.’ in the centre of the oval. ‘Made in France’ is at the bottom edge of the oval inscriptions.warrnambool, john rowley warrnambool, rowley softdrinks, warrnambool steam aerated works, rowley bottle -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Heatherlie Quarry with Engine and carriages on the rail track

Heatherlie Quarry. Engine and carriages on rail trackTwo Black and White Photgraphs 213-4 One showing two people. One woman in the fore ground and one Male standing on the back of a Steam eanine behind carraiges. This photo is estimated to be taken between 1923- 1925.. 213-4a Black and White Photgraph showin train carriages in bushland with hills behind the carriages, and train tracks in foreground.stawell grampians industry -

Whitehorse Historical Society Inc.

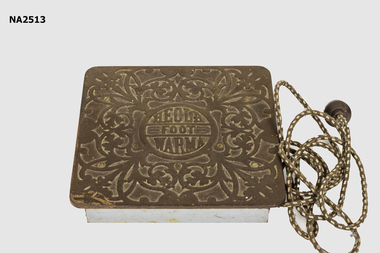

Whitehorse Historical Society Inc.Functional object - Electric Foot Warmer

Used by Colin Sach during his employment as Manager of the Chemistry Dept. at the University of Melbourne over a period of forty years.Manufacturing History Museum Victoria Commentary: Australian manufacturing history Philip Wollen Many years ago, when I was an ambition young man, I took over a company called Hecla.|This business was formed in 1872, long before Federation was even contemplated. The company established a rich tradition in the Australian manufacturing industry. The prodigious product range included kettles, mixers, toasters, hairdryers, urns, pie warmers, bain maries, and electric blankets for the domestic and commercial market. During the war it even manufactured parts for aircraft. It was one of Melbourne's largest employers.|Hecla was one of the pioneers in TV advertising, led by icons like Bert Newton, Bobby Limb, Evie Hayes and Graham Kennedy who ad Jibbed his way through irreverent and unscripted naughtiness about Hecla electric blankets and foot warmers. The slogan was 'By Hecla, its good1'. One can imagine the fun Bert and Graham had with their double entendres.|In the 60's Hecla entered into a partnership with General Electric and expanded rapidly. The massive factory, on the corner of Alexandra Parade and Chapel Street overlooking the Yarra River was a Melbourne landmark.|The business was formed by one of the scions of Melbourne industry. Mr Marriott was a metal worker of some repute, building the lights in front of Melbourne's Parliament House, the first steam car, the sideboard at the RACY Club, and the first factory to run on electricity.|By the time I acquired the company it was a shadow of its former self, incapable of competing with cheap Chinese imports. Wandering around the warehouse late one night I discovered a large, boarded up storeroom which appeared not to have been opened in decades.|Over several months I combed through the room, unearthing a treasure trove of products from a bygone era. Dusty files, engineering drawings, wooden prototypes, patent records, and correspondence from distributors on every continent.|I decided to track down an old man, Ray, long retired after 50 years with Hecla. He was not well off financially and welcomed the paid work. It turned out that he had done his apprenticeship with the company and there wasn't much he didn't know about it. He had been personally involved in the manufacture of almost every type of product on the Hecla smorgasbord's of products.|So for over 2 years he methodically assembled a mini museum of Hecla products, painstakingly polishing them and ensuring they were in working order. He attached the original brochure of each product and their respective warranty cards. For him it was ,a labour of love. For me it was a fascinating, if vicarious journey, into Australia's manufacturing past.|My colleagues complained that I was wasting money on his salary, our time and factory space on stuff that should have been dumped years ago. I tried to explain that I was merely a steward of the Hecla tradition, not merely an owner. Besides, the look on Ray's face convinced me that there was another dynamic at work. One I could see, but didn't really understand.|After he Passed away I faced a dilemma. What to do with this 'museum' of Hecla history. Nobody was interested.|So I kept the 'stuff' in private storage, hoping that same day someone would be interested in it. And the years passed.|Finally, I had a brainwave. Perhaps the Melbourne Museum would be interested. It was a long shot but I made the call. I had a nagging suspicion that they would think I was simply trying to get them to relieve me of paying for this huge collection to be taken to the tip.|To my surprise they said they would be willing to take a look, I secretly hoped that they would take the whole collection and not leave me with an incomplete jumble of appliances that I would indeed have to take to the tip.|On the appointed day, four serious looking young people showed up. Armed with digital cameras, note books and poker faces they spent four hours analysing the goods and the supporting materials. I asked them if they had any interest and their response was decidedly non-committal. It depends on the acquisitions committee, I was told. I was disheartened and packed up the exhibits to go back into storage.|Imagine my surprise when months later they telephoned to say that they had researched the history of the company, and yes, they would like to take the whole collection. And a truck with 'handlers' would arrive the following day to pick it up. Two years ago all Hecla's archives left me forever and went to the Museum's warehouse.|Well, to my delight I received a call yesterday inviting me to a private viewing of the exhibition at the Melbourne Museum. These young historians had meticulously assembled an impressive display of Melbourne's industry and technology going back to the 1800's. They thanked me like a significant benefactor when it is I who should have thanked them.|I saw the excitement in the eyes of these young people who had somehow managed to dig out and assemble memories from Australia's past. If this is the standard of care that the curators of the Melbourne Museum show all their exhibits, our history is in safe hands.|Their meticulous work took me back to those years long ago when I saw an old man lovingly assembling and cataloging a lifetime of his work.|It took me back to the day when Australians actually made things. Long before we became a nation of quarrymen. Before we became animal-factory 'farmers'. Of a time when products didn't break down, or dumped and replaced before the warranty expired. When men like Mr Marriott cared deeply about what their hands produced.|It reminded me of the call I received from an elderly lady in Tasmania asking for the electrical element for a Hecla K7 kettle. I searched the archives and called her back. The K7 was produced decades earlier and we no longer carried that spare part. She was quite disheartened and told me her kettle had finally 'given up the ghost' and she couldn't bear to part with it. It was a present from her husband on their wedding day 45 years ago. Her final words were 'they don't make them like that, do they? By Hecla they were good1'|I'm glad I followed my instinct and put Ray back on the payroll all those years ago..|I like to think Mr Marriott would have been pleased.Square metal box with electrical elements inside. Used to stand on or to put feet on when sitting. Elaborate pattern in centre with inscription.Hecla Foot Warmerdomestic items, heating -

Charlton Golden Grains Museum Inc

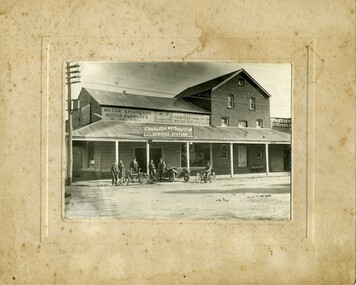

Charlton Golden Grains Museum IncPhotograph, Charlton Motors Pty Ltd Service Station c. 1918, c.1918

Charlton Motors Pty Ltd Service Station, corner of High & Armstrong Streets. Motor engineers, motor supplies of all kinds. Agents for Goodyear and Dunlop tyres, Buick cars, Indian motorcycles. Massey Harris Farm Implements c. 1918. Former Malcolm's steam operated Flour Mill 1876 - 1911. Group of six men, five standing, one on a motor bike. Car across footpath. Wischers written on building next door.Black & white photograph, mounted, unframed. Group of six men, five standing, one on a motor bike. Car across footpath. Sign on building reads "Charlton Motors Pty Ltd Service Station". Advertising for Dunlop & Goodyear Tyres, Buick and Indian Motorcycles. The words Massey and Wischers are written on the building next door.charlton motors, service station, malcolm's flour mill, wischers, massey harris, high street, charlton, business, industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyIron - Steam or Dry, Model No

The Kiewa Hydro Electric Scheme (KHES) produced electricity for the people living in the Kiewa Valley and beyond to many parts of Victoria. The people and their families working on the Kiewa Hydro Electric Scheme were encouraged by their employer the State Electricity Commission of Victoria to purchase and use electrical appliances. The iron was popular as it was quick and easy compared to those used previously. This iron belonged to Ron White who was a senior member of staff during the construction and operation of the KHES.This iron was owned by Ron White. Ron was appointed Area Operations Engineer at Kiewa in June 1956. He was later appointed as General Superintendent and then in 1974 appointed to principal Hydro Engineer of the recently titled Hydro Division.Electric iron with long cord attached at the side toward the back. Iron shape is of an oblong with pointy front. When laid down, the black handle is at the top with a red button centre front (to choose between steam and dry). Under the handle is the 'turntable' (used to select type of material/heat). At the front of the black is an outlet for the steam. Beneath the black section is the metal shiny cover and solid base.Dial (turntable) - centre red with 'Hoover' and red section on outside with 'steam'. To the left of 'steam' is 'High, Linen, Cotton, Wool'. To the right of 'steam' is 'silk, rayon, nylon'. On the handle at the front "Hoover" in gold.electric appliances; steam iron; electric iron; laundry; ron white; kiewa hydro electric scheme; hoover industries. -

Charlton Golden Grains Museum Inc

Charlton Golden Grains Museum IncPhotograph - Lithograph, Rider & Mercer, Views of Charlton

Close up photograph of part of the Charlton Lithograph showing the Charlton Steam Power Flour Mill of G & C Foreman. Located in on the bank of the Avoca river. The mill owners attempted to dam the river during the 1870s. The mill was built in 1876 as recorded by the local traveling correspondent . Foreman's flour mill established 1876 at the west end of High Street. Sold to Norske in 1925. Replaced by Noske's Flour Mill on Kays Street in 1927.Colour photo taken of a small portion of the Charlton Lithograph. Showing the Charlton Steam Flour Mill of G. C. Foreman.Charlton Steam Flour Mills. G & C Foreman proprietors.lithograph, business, industry, charlton, flour mill, noske bros, foreman -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Oil Rigs, Nought 40 pile driver, Bass Strait, 1968 c

Black and white photograph of the steam driven Nought 40 pile driver which hammered the piles through the hollow legs of jacket and a further 150 feet into the sea bed, Bass Straitoil and gas industry, engineering, bass strait -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Radiator

Early form of home heating and because of the copper dish was considered one of the better models|Manufacturing History Museum Victoria|Commentary: Australian manufacturing history Philip Wollen|Many years ago, when I was an ambition young man, I took over a company called Hecla.|This business was formed in 1872, long before Federation was even contemplated. The company established a rich tradition in the Australian manufacturing industry. The prodigious product range included kettles, mixers, toasters, hairdryers, urns, pie warmers, bain maries, and electric blankets for the domestic and commercial market. During the war it even manufactured parts for aircraft. It was one of Melbourne's largest employers.|Hecla was one of the pioneers in TV advertising, led by icons like Bert Newton, Bobby Limb, Evie Hayes and Graham Kennedy who ad Jibbed his way through irreverent and unscripted naughtiness about Hecla electric blankets and foot warmers. The slogan was 'By Hecla, its good.'. One can imagine the fun Bert and Graham had with their double entendres.|In the 60's Hecla entered into a partnership with General Electric and expanded rapidly. The massive factory, on the corner of Alexandra Parade and Chapel Street overlooking the Yarra River was a Melbourne landmark.|The business was formed by one of the scions of Melbourne industry. Mr Marriott was a metal worker of some repute, building the lights in front of Melbourne's Parliament House, the first steam car, the sideboard at the RACY Club, and the first factory to run on electricity.|By the time I acquired the company it was a shadow of its former self, incapable of competing with cheap Chinese imports. Wandering around the warehouse late one night I discovered a large, boarded up storeroom which appeared not to have been opened in decades.|Over several months I combed through the room, unearthing a treasure trove of products from a bygone era. Dusty files, engineering drawings, wooden prototypes, patent records, and correspondence from distributors on every continent.|I decided to track down an old man, Ray, long retired after 50 years with Hecla. He was not well off financially and welcomed the paid work. It turned out that he had done his apprenticeship with the company and there wasn't much he didn't know about it. He had been personally involved in the manufacture of almost every type of product on the Hecla smorgasbord's of products.|So for over 2 years he methodically assembled a mini museum of Hecla products, painstakingly polishing them and ensuring they were in working order. He attached the original brochure of each product and their respective warranty cards. For him it was ,a labour of love. For me it was a fascinating, if vicarious journey, into Australia's manufacturing past.|My colleagues complained that I was wasting money on his salary, our time and factory space on stuff that should have been dumped years ago. I tried to explain that I was merely a steward of the Hecla tradition, not merely an owner. Besides, the look on Ray's face convinced me that there was another dynamic at work. One I could see, but didn't really understand.|After he Passed away I faced a dilemma. What to do with this 'museum' of Hecla history. Nobody was interested.|So I kept the 'stuff' in private storage, hoping that same day someone would be interested in it. And the years passed.|Finally, I had a brainwave. Perhaps the Melbourne Museum would be interested. It was a long shot but I made the call. I had a nagging suspicion that they would think I was simply trying to get them to relieve me of paying for this huge collection to be taken to the tip.|To my surprise they said they would be willing to take a look, I secretly hoped that they would take the whole collection and not leave me with an incomplete jumble of appliances that I would indeed have to take to the tip.|On the appointed day, four serious looking young people showed up. Armed with digital cameras, note books and poker faces they spent four hours analysing the goods and the supporting materials. I asked them if they had any interest and their response was decidedly non-committal. It depends on the acquisitions committee, I was told. I was disheartened and packed up the exhibits to go back into storage.|Imagine my surprise when months later they telephoned to say that they had researched the history of the company, and yes, they would like to take the whole collection. And a truck with 'handlers' would arrive the following day to pick it up. Two years ago all Hecla's archives left me forever and went to the Museum's warehouse.|Well, to my delight I received a call yesterday inviting me to a private viewing of the exhibition at the Melbourne Museum. These young historians had meticulously assembled an impressive display of Melbourne's industry and technology going back to the 1800's. They thanked me like a significant benefactor when it is I who should have thanked them.|I saw the excitement in the eyes of these young people who had somehow managed to dig out and assemble memories from Australia's past. If this is the standard of care that the curators of the Melbourne Museum show all their exhibits, our history is in safe hands.|Their meticulous work took me back to those years long ago when I saw an old man lovingly assembling and cataloging a lifetime of his work.|It took me back to the day when Australians actually made things. Long before we became a nation of quarrymen. Before we became animal-factory 'farmers'. Of a time when products didn't break down, or dumped and replaced before the warranty expired. When men like Mr Marriott cared deeply about what their hands produced.|It reminded me of the call I received from an elderly lady in Tasmania asking for the electrical element for a Hecla K7 kettle. I searched the archives and called her back. The K7 was produced decades earlier and we no longer carried that spare part. She was quite disheartened and told me her kettle had finally 'given up the ghost' and she couldn't bear to part with it. It was a present from her husband on their wedding day 45 years ago. Her final words were 'they don't make them like that, do they? By Hecla they were good.'|I'm glad I followed my instinct and put Ray back on the payroll all those years ago..|I like to think Mr Marriott would have been pleased.Pedestal radiator. Base is cast iron with three feet with rose design on each. Pedestal supports a copper spherical reflector plate which has an electrical connection box at its base. The connection box is joined to the pedestal by a screw and nut to enable the reflector to be tilted. The element is cone shaped and is in the centre of the plate. The element is protected by a wire guard.Hecla Firedomestic items, heating -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Heater - Electric, C1940s

Manufacturing History Museum Victoria|Commentary: Australian manufacturing history Philip Wollen|Many years ago, when I was an ambition young man, I took over a company called Hecla. This business was formed in 1872, long before Federation was even contemplated. The company established a rich tradition in the Australian manufacturing industry. The prodigious product range included kettles, mixers, toasters, hairdryers, urns, pie warmers, bain maries, and electric blankets for the domestic and commercial market. During the war it even manufactured parts for aircraft. It was one of Melbourne's largest employers.|Hecla was one of the pioneers in TV advertising, led by icons like Bert Newton, Bobby Limb, Evie Hayes and Graham Kennedy who ad Jibbed his way through irreverent and unscripted naughtiness about Hecla electric blankets and foot warmers. The slogan was 'By Hecla, its good.'. One can imagine the fun Bert and Graham had with their double entendres.|In the 60's Hecla entered into a partnership with General Electric and expanded rapidly. The massive factory, on the corner of Alexandra Parade and Chapel Street overlooking the Yarra River was a Melbourne landmark.|The business was formed by one of the scions of Melbourne industry. Mr Marriott was a metal worker of some repute, building the lights in front of Melbourne's Parliament House, the first steam car, the sideboard at the RACY Club, and the first factory to run on electricity.|By the time I acquired the company it was a shadow of its former self, incapable of competing with cheap Chinese imports. Wandering around the warehouse late one night I discovered a large, boarded up storeroom which appeared not to have been opened in decades.|Over several months I combed through the room, unearthing a treasure trove of products from a bygone era. Dusty files, engineering drawings, wooden prototypes, patent records, and correspondence from distributors on every continent.|I decided to track down an old man, Ray, long retired after 50 years with Hecla. He was not well off financially and welcomed the paid work. It turned out that he had done his apprenticeship with the company and there wasn't much he didn't know about it. He had been personally involved in the manufacture of almost every type of product on the Hecla smorgasbord's of products.|So for over 2 years he methodically assembled a mini museum of Hecla products, painstakingly polishing them and ensuring they were in working order. He attached the original brochure of each product and their respective warranty cards. For him it was ,a labour of love. For me it was a fascinating, if vicarious journey, into Australia's manufacturing past.|My colleagues complained that I was wasting money on his salary, our time and factory space on stuff that should have been dumped years ago. I tried to explain that I was merely a steward of the Hecla tradition, not merely an owner. Besides, the look on Ray's face convinced me that there was another dynamic at work. One I could see, but didn't really understand.|After he Passed away I faced a dilemma. What to do with this 'museum' of Hecla history. Nobody was interested.|So I kept the 'stuff' in private storage, hoping that same day someone would be interested in it. And the years passed.|Finally, I had a brainwave. Perhaps the Melbourne Museum would be interested. It was a long shot but I made the call. I had a nagging suspicion that they would think I was simply trying to get them to relieve me of paying for this huge collection to be taken to the tip.|To my surprise they said they would be willing to take a look, I secretly hoped that they would take the whole collection and not leave me with an incomplete jumble of appliances that I would indeed have to take to the tip.|On the appointed day, four serious looking young people showed up. Armed with digital cameras, note books and poker faces they spent four hours analysing the goods and the supporting materials. I asked them if they had any interest and their response was decidedly non-committal. It depends on the acquisitions committee, I was told. I was disheartened and packed up the exhibits to go back into storage.|Imagine my surprise when months later they telephoned to say that they had researched the history of the company, and yes, they would like to take the whole collection. And a truck with 'handlers' would arrive the following day to pick it up. Two years ago all Hecla's archives left me forever and went to the Museum's warehouse.|Well, to my delight I received a call yesterday inviting me to a private viewing of the exhibition at the Melbourne Museum. These young historians had meticulously assembled an impressive display of Melbourne's industry and technology going back to the 1800's. They thanked me like a significant benefactor when it is I who should have thanked them.|I saw the excitement in the eyes of these young people who had somehow managed to dig out and assemble memories from Australia's past. If this is the standard of care that the curators of the Melbourne Museum show all their exhibits, our history is in safe hands.|Their meticulous work took me back to those years long ago when I saw an old man lovingly assembling and cataloging a lifetime of his work.|It took me back to the day when Australians actually made things. Long before we became a nation of quarrymen. Before we became animal-factory 'farmers'. Of a time when products didn't break down, or dumped and replaced before the warranty expired. When men like Mr Marriott cared deeply about what their hands produced.|It reminded me of the call I received from an elderly lady in Tasmania asking for the electrical element for a Hecla K7 kettle. I searched the archives and called her back. The K7 was produced decades earlier and we no longer carried that spare part. She was quite disheartened and told me her kettle had finally 'given up the ghost' and she couldn't bear to part with it. It was a present from her husband on their wedding day 45 years ago. Her final words were 'they don't make them like that, do they? By Hecla they were good.'|I'm glad I followed my instinct and put Ray back on the payroll all those years ago..|I like to think Mr Marriott would have been pleased.Large electric heater with two radiator bars and a protective grille at the top and false coals at the bottom.Replacements for this fire - Elements No. F314 - Illuminators No. 3P. Berry's Electric Ltd - Volts 230 - 240 -Watts 2000 V/AD/Cat No. 454 . Made in Australia by Hecla Electrics Pty Ltd Melbournedomestic items, heating -

Narre Warren and District Family History Group

Narre Warren and District Family History GroupBook, Val Smith, Don (Ripper) Reid : story of an Upper Yarra Valley sawmiller, 1997

Prior to 1901 the men working in the forests of the Upper Yarra Valley were mainly paling splitters and shingle cutters. When the Warburton-Lilydale Railway was completed in 1901, sawmilling became a major industry and one of the main employers in the Upper Yarra Valley. The railway enabled the sawmillers to get their timber to the Melbourne markets easily and economically. The mills were built, usually in the allotted logging area. Tramlines were used to bring timber from the mills to the railway. In the Upper Yarra Valley the tramlines were mostly horse drawn, or if it was too steep a combination of winches for lowering and then horse to complete the journey. Steam locomotives were used on the Powelltown to Yarra Junction tramline and Ezard-Richards' tramline at Starvation Creek. Donald Ambrose Reid has been a son, brother, husband, father, grandfather, Shire Councillor, firefighter and friend but through it all a Sawmiller. This is Don Reid's story. A story of a sawmilling family. Don's memories also give an insight into the early history of Upper Yarra Valley and the changes that occurred in the sawmilling and logging industry. VAL SMITH 1996/97.non-fictionPrior to 1901 the men working in the forests of the Upper Yarra Valley were mainly paling splitters and shingle cutters. When the Warburton-Lilydale Railway was completed in 1901, sawmilling became a major industry and one of the main employers in the Upper Yarra Valley. The railway enabled the sawmillers to get their timber to the Melbourne markets easily and economically. The mills were built, usually in the allotted logging area. Tramlines were used to bring timber from the mills to the railway. In the Upper Yarra Valley the tramlines were mostly horse drawn, or if it was too steep a combination of winches for lowering and then horse to complete the journey. Steam locomotives were used on the Powelltown to Yarra Junction tramline and Ezard-Richards' tramline at Starvation Creek. Donald Ambrose Reid has been a son, brother, husband, father, grandfather, Shire Councillor, firefighter and friend but through it all a Sawmiller. This is Don Reid's story. A story of a sawmilling family. Don's memories also give an insight into the early history of Upper Yarra Valley and the changes that occurred in the sawmilling and logging industry. VAL SMITH 1996/97.upper yarra valley (vic.), don reid, donald ambrose reid