Showing 1731 items

matching street making

-

Orbost & District Historical Society

Orbost & District Historical Societybottles, first half 20th century

Australia was not self sufficient in glass making until the turn of the 20th century and many bottles were made overseas and shipped to Australia with their contents and when emptied were re-filled with other company’s products. These bottles have an aesthetic element in that the shapes are visually appealing. They reflect the type of glassware that was in circulation in the first half of the 20th century.Two very small clear glass vial bottles with flat rims. Possibly had cork stoppers.glass bottle vial -

Orbost & District Historical Society

Orbost & District Historical Societyaxe head

Inspected by Joanna Freslov, archaeologist 2.6.2008. Ground-edged axes first appeared in south-eastern Australia about 4,000 years ago and were used either with handles or hand-held. Stone tools were used for a variety of purposes, in ways similar to those of steel knives, axes, hammers and chisels. Ground-edge tools are made from fracture-resistant stone, such as basalt. This is able to withstand repeated impact making it suitable for use in objects such as stone axes. The stone was quarried, and then roughly shaped into a tool blank with blows from a hammerstone. The edges were then sharpened and refined by grinding the tool against a coarse, gritty rock. The necessary tools and equipment for hunting, fishing and warfare were one of the very few items that Aboriginals carried with them from place to place. Most were used for a multiplicity of purposes. Because many were made from raw natural materials, such as wood, generally only partial remains are found today. This item is an example of a stone tool used by the early Indigenous people of Eastern australia.A handmade stone Aboriginal axe head.axe-head aboriginal tool stone-artefact -

Orbost & District Historical Society

Orbost & District Historical Societypipe, 19th Century

The first recorded use of meerschaum for making pipes was around 1723 and quickly became prized as the perfect material for providing a cool, dry, flavorful smoke. The porous nature of meerschaum draws moisture and tobacco tar into the stone. Meerschaum became a premium substitute for the clay pipes of the day and remains prized to this day, though briar pipes have become the most common pipes starting in the mid-1800s.A pipe made in the shape of a ram's head, coloured white or bone. It fits snugly into a shaped leather case which is hinged and closes to protect the pipe.pipe smoking tobacco -

Orbost & District Historical Society

Orbost & District Historical Societymagnifying glass, c. 19th century

A pocket magnifying glass was a versatile scientific tool. It was ideal for situations in which the specimen was too small to be observed under a magnifying glass and access to a larger microscope would have been impossible.It could be taken on field expeditions and used to examine botanical, zoological and mineralogical specimens. This small magnifying glass could be used for examining specimens of plants or rocks or jewellery.Simple,pocket microscopes had a significant impact on the the general public’s appreciation of both science and the natural world by making the microscopic world accessible and exciting.A small brass pocket magnifying glass with resting arm. The cardboard box is blue / black in colour.magnifying-glass scientific-instrument -

Orbost & District Historical Society

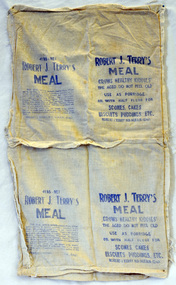

Orbost & District Historical Societypillow case, c. 1930 - 1950

Presumed to have been made by the family of Mrs. Jean Snow who donated this item. This is a classic example of the tradition of "making do" , of creating new uses for older items or bits of scrap. A pillow case made from four porridge bags which have been opened out and stitched together. The name of the porridge manufacturer is evident on the pillow case, Robert J Terry.Robert J Terry N D M B A N (Eng)pillow- case making-do depression-creativity -

The Beechworth Burke Museum

The Beechworth Burke MuseumDecorative object - Swinging Clock, Charles Frederick Falck, 1855

This clock was made by Charles Frederick Falck who was a watchmaker and jeweller in Beechworth from 1863-1908. Falck was born in Körlin, Prussia on May 22nd in 1833 and died at the age of 75 in 1908. Ovens and Murray Advertiser, Beechworth: edition June 13, 1908 OBITUARY: Falck was brought up to the business of watch-making, in which he developed exceptional mechanical ingenuity. Attracted by the favourable prospects held out by the Australian discoveries of gold he, like many other young adventurous spirits, left his native land to seek his fortune in the great southern Eldorado, arriving in Adelaide in 1854, and shortly after came to Melbourne where he worked as a journeyman, and subsequently started in business on his own account. Feeling inclined to test his fortune on the goldfields, he went to Blackwood but, meeting with little success, he returned to Melbourne where he was married. In 1862, he moved to Beechworth, where he commenced business as watchmaker and gold-buyer. He then embarked in vine-growing on the Sydney road, but eventually resumed his business avocations. His skill in practical horology was evinced in a clock of his own design and manufacture, surmounted by a golden eagle, which was exhibited at the first Melbourne Exhibition in 1856, and which afterwards formed a pre-eminent attraction in the window of his business premises in Ford Street. For many years, he filled the position of timekeeper to the Beechworth Racing Club, with complete satisfaction also at various sports meetings. He leaves a family of six sons and one daughter (Mrs. Jas. Broadfoot) all arrived at maturity. The funeral, which was well attended by a number of residents, took place at the Beechworth Cemetery on Sunday, the burial service being performed by the Ven. Archdeacon Potter. The cortege was capably supervised by Mr. D. Wilson, undertaker. The clock was returned to Beechworth in 2020 through the generous support of the Copland Foundation. Given that Mr. C. F. Falck traded as a watchmaker and jeweller in Beechworth for 45 years and traded with the 1855 clock mounted in his front window, there is a direct link between the clocks and the social, cultural and economic life of nineteenth century Beechworth at time when the town was developing and expanding in response to gold mining. This clock represent the significant skill and expertise of Charles Falck as an horologist. Medium-sized pendulum clock featuring a carved gilt wood eagle with wings outstretch (épandre - expanded with wing-tips directed upwards) and perched above a pendulum rod that holds a silver dial clock face within a reeded sunburst surround. The clock has an eight-day fuse movement with dead beat escapement wound from the clock face. C. F. F. FALCK / EXHIBITION 1856 / MELBOURNEburke museum, copland foundation, beechworth, leonard joel, auction, purchase, clock, pendulum, eagle, eagle clock, charles frederick falck, c. f. falck, falck, horology, pendulum clock, melbourne -

The Beechworth Burke Museum

The Beechworth Burke MuseumDecorative object - Swinging Clock, Charles Frederick Falck, 1870

This clock was made by Charles Frederick Falck who was a watchmaker and jeweller in Beechworth from 1863-1908. Falck was born in Körlin, Prussia on May 22nd in 1833 and died at the age of 75 in 1908. Ovens and Murray Advertiser, Beechworth: edition June 13, 1908 OBITUARY: Falck was brought up to the business of watch-making, in which he developed exceptional mechanical ingenuity. Attracted by the favourable prospects held out by the Australian discoveries of gold he, like many other young adventurous spirits, left his native land to seek his fortune in the great southern Eldorado, arriving in Adelaide in 1854, and shortly after came to Melbourne where he worked as a journeyman, and subsequently started in business on his own account. Feeling inclined to test his fortune on the goldfields, he went to Blackwood but, meeting with little success, he returned to Melbourne where he was married. In 1862, he moved to Beechworth, where he commenced business as watchmaker and gold-buyer. He then embarked in vine-growing on the Sydney road, but eventually resumed his business avocations. His skill in practical horology was evinced in a clock of his own design and manufacture, surmounted by a golden eagle, which was exhibited at the first Melbourne Exhibition in 1856, and which afterwards formed a pre-eminent attraction in the window of his business premises in Ford Street. For many years, he filled the position of timekeeper to the Beechworth Racing Club, with complete satisfaction also at various sports meetings. He leaves a family of six sons and one daughter (Mrs. Jas. Broadfoot) all arrived at maturity. The funeral, which was well attended by a number of residents, took place at the Beechworth Cemetery on Sunday, the burial service being performed by the Ven. Archdeacon Potter. The cortege was capably supervised by Mr. D. Wilson, undertaker. The clock was returned to Beechworth in 2020 through the generous support of the Copland Foundation and the Friends of the Burke. Given that Mr. C. F. Falck traded as a watchmaker and jeweller in Beechworth for 45 years and traded with the 1855 clock mounted in his front window, there is a direct link between the clocks and the social, cultural and economic life of nineteenth century Beechworth at time when the town was developing and expanding in response to gold mining. This clock represent the significant skill and expertise of Charles Falck as an horologist. Large swinging clock featuring a carved gilt wood eagle with its wings outstretched (abaisé - expanded with wing-tips lowered) and perched above a pendulum rod that holds a silvered dial clock face within a reeded sunburst surround. (Similar to #2019.056.01) The clock has an eight-day fuse movement with dead beat escapement wound from the clock face. C. F. FALCK / WATCHMAKERburke museum, copland foundation, beechworth, leonard joel, auction, purchase, clock, pendulum, eagle, eagle clock, charles frederick falck, c. f. falck, falck, horology, pendulum clock, melbourne -

The Beechworth Burke Museum

The Beechworth Burke MuseumDomestic object - Toy Cart, c1920

The Lehmann toy company exported toys to the USA from 1895 to 1929 and specialized in mechanical, friction transportation and lithographed wind-up tinplate toys. Founded by Ernest Lehmann Co. in Brandenberg, Germany, 1881. In 1951 the fim re-established and is still making friction toys. Some of the most famous include: Autobus, the Dancing Sailor and Icarus. Lehmann distinguished itself early 20th-century by releasing small tin toys which were cheaper than the toys the competition made. End of the 19th century, beginning of th 20th, competitors were producing heavy, cast-iron toys. By the 1920s the Lehmann company had a staff over 800 people and made 80+ different toy designs.How it is significant? (...this item is one of last remaining examples of German toy manufacturing prior to World War One. ) How it is significance to local history? (....this item represents the importance of preserving local history and culture.) German, clockwork, red and white tinplate cart with green and white driver with green pointed hat, being pulled by zebra with red ears and cord tail. 1881/ Lehmann 'Zikra' Marke Pat./USA Appl. / For Jan 1907, Dec 1913 lehmann, toy, beechworth, burke museum, zebra, cart, germany -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Screw Driver, F G Pearson & Co, 1902

The subject item was made by G. Pearson and Co Ltd. of the Hope Works, Sheffield England. This company was established in 1854. By 1914 the company was manufacturing many differing types of edge tools, joiners' tools, forks and garden tools. Their specialities were hay, manure and coke forks, punches, armourers' tools etc. In 1938 the Company was styled F. G. Pearson and Co (Sheffield) Ltd and they were still making plane and other sharp edged blades as late as 1957, but by the 1970s they had gone out of business.A significant company based in Sheffield England and making tools of all types and exporting same to various countries around the world. This particular item is a vintage joiners screwdriver possibly used by a local Warrnambool carpenter (J Rob).Screw driver wooden handle shaped blade & brass metal ferrule1902 Sheffield marked on blade, F Rob owner Marked on handlewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, joiners tools, screwdriver, carpenters tools, f g pearson sheffield -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Broad Axe, Prior to 1950

A cooper's broad axe (or Cooper's side axe) is a short one-handed axe that has a long cutting edge intended for initial dressing of staves and heading pieces used in the making of barrels and other associated items made from wood.A tool of the cooper and other woodworking tradesmen that has been in use since the making of barrels and wooden buckets for hundreds of years without much change to the design or how the tool is used.Broad head axe with wooden handle with handle on an angle to allow use. Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, maritime village, coopers tools, broad axe, barrel making, cutting staves -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Circle/Convex Faced Plane, Prior to 1950

Before setting the barrel head, the cooper smooths the inside surface of some barrels with a stoup, compass or circle plane and an inside shave (or in shave plane). A stoup or compass plane has a convex sole in both directions to work within the doubly curved staves of a barrel. The cooper smooths the outside of the barrel with a downright, another large-handled shave, and a similar scraping tool to finish off called a buzz. The final step is to fit the head and drive on wooden or steel hoops. Making the barrel has taken a number of planes similar but different from those of other trades, each perfectly adapted to a cooper’s work shaping curved surfaces. And if he has done his work well, the barrel will hold the exact amount of liquid and not leak.A tool unique to the cooper used to smooth out the inside of a barrel that has been in use since the making of wooden barrels and buckets for hundreds of years without much change to the design or how the tool is used.Compass or Circle face PlaneNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Groove Plane, Prior to 1950

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. The subject planes blade is designed to cut a groove and it's blade maker (M Gilmour) is not listed by collectors of vintage planes as a known plane makers of the 19th or 20th century.A vintage tool made by an unknown maker, this item was made commercially for firms and individuals who worked in wood and needed a tool that could produce an ornamental finish to timber. These profiled planes came in various shapes and sizes to achieve the required decorative finish. This item is a significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Grooving PlaneM Gilmour stamped on bladewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, moulding plane, groove plane, joiners tools, hand plane, carpenters tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Downright/Pluckers Plane, Prior to 1950

The downright shave is a tool used by coopers in the preliminary stages of smoothing the outside of a cask, before it is finished with a buzz shave. The shave is pushed downwards, hence its name, away from the operator to take away the wood shavings. A significant tool used by a cooper in the production of making wooden barrels a design that has not changed much in many hundreds of years of barrel making.Coopers Downright/Pluckers PlaneNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, coopers tools, coopers plane, barrel making, carpenters tools, smoothing plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bow Saw, Prior to 1950

A coopers turning or bow saw is a woodworking tool used for straight or curved cuts. A bow saw is a type of frame saw with a thin toothed blade that is held in tension by a frame with two long narrow handles called "cheeks" that are supported and separated by a thin stretcher in the center of the handles, making a wide H shape (the cheeks form the uprights of the H, the stretcher the crossbar of the H). The blade is kept in tension with a turnbuckle that runs parallel to the blade between the two cheeks but on the opposite side of the stretcher.An age old tool used for cutting timber for hundreds of years before the modern cross cut saws were invented. This design of saw was part of a Coopers tool kit and used in the production of making barrels. However this item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Bow saw wooden handle with metal blade missingNonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bow saw, turning saw, coopers tools, cutting wood, sawing timber, coopering -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Coopers Flagging Iron, Prior to 1950

A cooper would use a flagging iron to insert reeds around the head of a barrel to tighten the head and stop any leaks. First the cooper removes the full and quarter metal hoops around the barrel, this loosens the staves and insert reeds around the head, prying the stave apart from the head with a flagging iron. Then he replaces the hoops to tighten the staves against the head and the inserted reeds to form a leakproof seal.An age old tool used for many hundreds of years in the making and repairing of wooden barrels and an essential tool in a coopers tool kit.Flagging iron metal painted black Nonewarrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagging iron, coopers tools, barrel making, repairing barrel leaks, barrel head tightening -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Mortice Machine, Mathieson and Son, 1910-1940

In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. In the 1851 census, Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870, and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as a tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886 Prize medal. See note section for Thomas McPherson Australian Retailer information: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools and later woodworking machines in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages, and other industries, both locally and throughout the world. McPherson's started as an Australian retailer of hardware products in Melbourne going on to become a company that supplied machinery and other items for the establishment of major infrastructure projects in Australia during the early days of the colony that assisted in linking the various states and territories which became a precursor of Federation. From a humble beginning McPherson's became one of Australia's leading retail, and later manufacturing businesses that is still in existence today.Mortice machine metal with long metal lever handle with counter weight & 3 adjustment wheels & metal crank with wood end. Has 4 feet that can be bolted to floor & vertical moving piece that a cutting bit would fit into.Imprinted Alex Mathieson & Son Trademark Saracen Tool works Glasgow' also a brass plate "Thomas McPherson & Son Machinery Importer Melbourne"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSpirit level

Spirit level, small, wood with metal around the ends and the glass levels. Comprises both verticle and horizontal levels. Horisontal level is divided into 2 by metal surround. Imperial measurements are impressed into wood on both sides of the ruler.Impreial measurements are impressed into the wood on both sides.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spirit level, cabinet making, wood working, wood working tool, building tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Box plane, Stewart Spiers, mid-1900s

This small metal plane was manufactured in 1909 by Spiers-Stewart, Ayr, Ayrshire, Scotland. Stewart Spiers began making planes in Ayr in around 1840. The business continued successfully as a small operation until the mid-1930s.This plane is an example of tools made overseas and used in the 1900's. Box plane; hand operated small metal plane with round wooden knob. Plane has separate blade and blade cap. Inscription on blade cap is indecipherable. Originally marked as made by Spiers."SPIERS"flagstaff hill, warrnambool, maritime-museum, maritime village, shipwreck coast, tradesman's tool, plane, box plane, tool, spiers-stewart, early 20th century, scotland, hand tool, stewart spiers, spiers, woodworking -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMachine - Diving Compressor, Siebe Gorman & Co. Ltd, 1880-1890

This compressor was part of the E.G. Ward Collection. It is connected to the diving suit and boots also in our collection. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water-pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12 bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunneling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr. E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The compressor is a very significant item as it gives a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. Siebe & Gorman the company that made the equipment was a leading inventor, developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job during the early days of marine exploration.A single cylinder divers' pump by Siebe Gorman & Co Ltd, London, eccentric hand cranked in brass mounted mahogany case with instructions to the underside of the lid, brass covered pressure gauge and air outlet, brass makers plaque to the front, water inlet and outlet to the rear, green painted lifting rings. Machinery has some blue painted areas on the metal.Plate on the back 'WATER SUPPLY" "WATER OVERFLOW" "WATER DRAIN-IN" Pressure gauge dial "BOURDON'S PRESSURE GAUGE" STEBE GORMAN & CO. LONDON", "LBS PRESSURE" "FEET OF SALT WATER" Plate on the front " PATENT, Siebe Gorman & Co Ltd Submarine Engineers" below emblem (Lion, Crown, Horse)flagstaff hill, warrnambool, flagstaff-hill, maritime-museum, diving compressor, london, siebe gorman & co ltd, marine technology, life saving, deep sea diving, maritime museum, maritime village, manine history -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageShotgun, Early 20th Century

Philip Webley was born in 1813, he was the younger brother of James Webley who was born in 1807. Both were born in Birmingham. Towards the end of the 1800s, the firm claimed establishment in 1790, this must have been the date James and Philip's father or grandfather originally established a bullet or gun implement making business. It was not, as is often stated, the date William Davis established his business. Philip Webley was apprenticed in 1827 to Benjamin Watson. James Webley also seems to have been apprenticed but to who is not known. In 1834 James and Philip established their partnership as percussioners, lock filers and gun makers at 7 Weaman Street,Birmingham which was William Davis' old premises Davis, a gun implement maker, mould and toolmaker, died in 1831 and his wife Sarah inherited the business at 84 Weaman Street which she ran with her daughter, Caroline. On 5 January 1838 Philip Webley married Caroline. Philip was recorded at 84 Weaman Street from 1838 as a gun percussioner, lock filer and gun maker and this is when the partnership was last recorded, but the brothers apparently continued to co-operate until 1845 when Philip reportedly sold his interest to James and used the money to purchase Sarah Davis' business. Even then, they worked together particularly about the design and manufacture of percussion revolvers. Philip Webley was recorded in the 1851 census as a 38-year-old gun and pistol implement manufacturer living at 84 Weaman Street with his wife Caroline they had four sons and one daughter Thomas William, Emma, and Philip Jnr, and two other sons, James, and Henry and Philip's cousin, also lived with the family probably as a nurse, Sarah Haywood. On 4 February 1853 Philip Webley registered patent No. 335 for a hinged revolver and on 14 September 1853 he registered patent No. 2127 for improvement for the first muzzle-loading percussion cap and ball revolver which became known as the "Longspur". In 1859 Philips son Thomas William, aged 21, was made a partner in the firm, which then changed its name to P Webley & Son and described itself as "Gun and Pistol Makers and Patent Revolving Pistol Makers", probably exploiting Philip Webley's patent No. 305 of February 1853 for a revolver frame and lock, and its improvement under patent No. 2127 of September 1853. Thomas later went on to managed the shotgun side of the business. From about 1863 up to the First World War, the firm made rook rifles for Holland & Holland. From the 1890s they supplied magazine rifles. In 1863 and 1864 the firm's address was given as 83-84 Weaman Street, but from late 1864 to 1875 their address was 84 Weaman Street. By 1874 the firm had a showroom in London at an unknown address. In 1875 the firm expanded into 82-84 and 88-89 Weaman Street. The shotgun is not in very good condition is unusable as a firearm and is not very significant historically or valuable, although made by a well known and respected manufacturer of firearms there are many better examples of shotguns made by P Webley and Son in collections and for sale. This particular example is of a standard pattern for utilitarian use of which many were made. Pin fire double barrel cartridge loading shotgun, the stock is of varnished walnut, the shotgun is in a wooden box, box has hinged lid and dovetail joints. Raised inscription on butt has an image of "dog carrying a bird in his mouth" and another image of a "anchor and chain". Inscribed to both sides of the locks "P Webley and Son", Maker's mark and proof marks for black powder shotguns on undersides of both barrels. Proof marks used are for Birmingham. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shotgun double barrel, double barrel, bird dog and bird, anchor and chain, webley & scott, pin fire, cartridge, philip webley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1869-1920

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Hollow type Marked Routledge No.8 Blade Stamped JAS Burden (owner). flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Between 1869 early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Plane, Moulding, Hollow Size No 18 Routledge Maker (Owner "J.A.S.Burden")flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Richard Routledge, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc, or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Rebate Moulding plane Size 1/2"Maker R Routledge Birmingham also marked Owner Jas Burdenflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Richard Routledge, Late 19th to early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use to produce a decorative moulding for a piece of furniture, door trims etc. or other timber items that had to be accomplished by using hand tools and in particular one of these types of planes. Profiled planes came in various shapes and sizes to achieve the required decorative finish. A significant tool from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Plane Moulding type size 1/8" Maker stamped R Routledge & JAS Burden (owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about Richard Routledge is that he was a tool maker and retailer that operated a business at either 23 or 64 Bull St Birmingham between 1869 to sometime in the early 20th century. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture was done by hand using one of these types of plane. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane. Stamped JAS Burden (owner) also No 2flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFootwear - Boots, Rossiters Ltd, 1908-1920

Rossi Boots started in 1910 when Arthur Edward Rossiter resigned from his position as a supervisor at the Adelaide Boot Company and started Rossiters Ltd in a small tin shed in his backyard. A larger factory was needed so the first of three stages of a factory was built. During the Second World War Rossi Boots was a major supplier to the military making hundreds of thousands of boots that saw service in various theatres including New Guinea. The war years saw the number of employees peak at around five hundred. As methods of manufacturing footwear changed as petroleum-based products such as glues, rubbers and plastics have replaced the traditional ones of leather, nails, and threads. More modern machinery was introduced to directly mould soles to the bottom of the boot. At the end of 1987, the company moved from Unley to Hilton this move allowed production to be carried out in a more modern, fit-for-purpose factory. Since then the company has continued to change; introducing computer-controlled machines for cutting, sewing, and attaching soles. These changes occurred whilst many of Rossi's competitors moved offshore. Whilst the introduction of these machines reduced the number of local staff, it has enabled Rossi Boots to continue to manufacture in Australia. In March 2019 Rossi Boots relocated the factory, warehouse, and headquarters from Hilton to Kilburn, South Australia. This move to a new, expansive location allows Rossi Boots to continue manufacturing in South Australia housing all operations under one roof. The items are significant as they show the beginnings of an important manufacturer and innovator that is still in the original founding family's ownership and is producing boots today with exports to many countries. Boots leather lace up brownNonewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Food Safe, Willow Ware Pty Ltd, 1920-1950

Willow started business in 1887 as a metal working company based in Melbourne Australia, making tinned biscuit and tea canisters. The outbreak of the First World War saw their manufacturing change to making armaments and essential packaging for the war effort. In the early 1920’s, the Willow brand was established. Making tin plated canisters and baking pans with the well-known Willow pattern, imprinted on them. Some other items in production at this time include billies, boilers, basins and Coolgardie safes. In the late 1950’s, the company ventured into plastics production. Stepping away from its very successful tin plating industry of more than 50 years. In 1965, the company name changed to Willow Ware Pty Ltd, to be more closely linked to its Willow brand. Willow Ware is still in business today. A food safe known as a “Coolgardie” meat storage made by an emerging Australian company no longer in bushiness. This item gives a snapshot into early Australian manufacturing specifically aimed at the Australian market. Safe metal kitchen safe with two shelves, a hinged door and latch and a small swivel wire handle at the top. cream colour . "Made in Australia" "Willow" warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, willow ware, domestic item, coolgardie meat safe, meat safe, food safe, food preservation -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Diving Suit, boots and weight, 1900

This diving suit with helmet, boots and weight is part of the E.G.Ward collection, along with the diving compressor and a photograph of a diver in this equipment. Siebe Gorman & Company Ltd was a British company that developed diving equipment and breathing equipment and worked on commercial diving and marine salvage projects. The company advertised itself as 'Submarine Engineers'. It was founded by Augustus Siebe, a German-born British engineer chiefly known for his contributions to diving equipment. Siebe Gorman traded as an engineering firm for over 180 years from 1819 to 1999. The early success of the business was due to its founder, the Prussian immigrant Christian 'Augustus' Siebe (1788-1872). For business reasons, he applied for and was granted British citizenship in 1856. He was a gifted engineer who was able to translate theoretical problems into practical, working products. During the industrial Victorian period, the business traded as 'A. Siebe' at 145 High Street Holborn London, but in 1828 new premises were acquired at 5 Denmark Street, Soho. The family firm produced a wide range of manufactured goods including paper-making machinery, measuring machinery, water pumps, refrigeration equipment and diving apparatus. Augustus Siebe specialised in submarine engineering early on and the company gained a reputation for the manufacture of safe, reliable diving apparatus. Augustus Siebe is best remembered for the development and manufacture of the ‘closed’ Diving Dress based on the ideas of Charles and John Deane, George Edwards and Charles Pasley. Apart from some small modifications to valves and diver communications, the basic 12-bolt ‘closed’ diving dress remained relatively unchanged after the 1870s. Later company successes were also based on innovation, with new products that could be successfully developed and manufactured to high standards. This was largely attributed to the inventive nature, foresight, engineering and entrepreneurial skills of Robert Henry Davis (1870-1965). In 1882, RH Davis joined the company of 'Siebe & Gorman' as a young 11-year-old office boy and he was to remain with the company until he died in 1965. Augustus Siebe retired in 1869 and handed over the company to a new partnership of Henry H. Siebe (1830-1885) and William A. O'Gorman (1834-1904). The new firm traded as 'Siebe & Gorman' (1870-1879) from premises in and around Mason Street, Westminster Bridge Road, Lambeth, London. The two partners soon recognised the potential of R.H. Davis and in 1894, aged 24, he became General Manager of Siebe & Gorman. Davis increasingly ran the company until the surviving partner (W.A. Gorman) died in 1904. The firm was disposed of to the Vickers (armaments) family and a new company 'Siebe Gorman & Co. Ltd.' (1905-1998) was formed. Under the chairmanship of Albert Vickers, R.H. Davis was kept on as Managing Director, and the company forged ahead. However, after WW1, the Great Depression caused manufacturing output and share prices to slump. In 1924 Robert Davis made a deal with the Vickers Board and acquired control of the company through majority shares. Under his leadership, the Siebe Gorman Company flourished and within time, four of his sons also joined the firm. The company gained a worldwide reputation for the manufacture of diving apparatus, decompression and observation chambers, and safety breathing apparatus of all types for use on the land, in the air and under the sea (including mine rescue, tunnelling, aircraft, diving, submarine escape and in other hazardous environments). Close research and development links with the MOD (especially the Admiralty), also provided a lucrative outlet for the company products. In 1932, Robert Davis was knighted by King George V, principally for his invention of the ‘Davis Submerged Escape Apparatus’ (D.S.E.A.). Siebe Gorman essentially remained a family firm from the beginning (under A.Siebe) until it became a public company for the first time in 1952. However, following WW2, British manufacturing stagnated through stifled investment and post-war austerity, and there was little innovation. Siebe Gorman fortunes began to decline as an ageing Sir Robert Davis failed to invest, or change the company business and management practices. In 1959, Siebe Gorman was acquired by the “Fairy Group” and the ailing Sir Robert was made Life President. Consequently, nothing changed and the slow decline continued until Sir Robert's death in March 1965. Around 1960, Siebe Gorman acquired the diving apparatus manufacturer C E Heinke, and for a brief period, it manufactured some diving equipment under the combined name of Siebe Heinke. Around 1964, Mr E. 'Barry' Stephens was appointed as the new Managing Director to modernise Siebe Gorman. Changes were made, including a move to a new factory in Wales in 1975. The new company concentrated on fire-fighting breathing apparatus and escape equipment, and the move coincided with the loss of many of the older, traditional craft skills. Between 1985 and 1998, Siebe expanded through acquisitions, and several other companies were acquired. The Siebe Gorman (diving apparatus) company has therefore traded as A. Siebe (1819-1870); Siebe & Gorman (1870-1879); Siebe Gorman & Co (1880-1904); Siebe Gorman & Co. Ltd (1905-1998).The items are very significant as a snapshot into marine history and the development of diving equipment generally especially that used for salvage operations before and during WW2. The company that made the equipment was a leading inventor,developer and innovator of marine equipment with its early helmets and other items eagerly sought after today for collections around the world. The items in the Flagstaff Hill collection give us an insight as to how divers operated and the dangers they faced doing a very necessary and dangerous job.Diving suit including helmet, boots and a weight. Diving suit is made of canvas with knitted cuffs. The helmet is metal. The boots have a thick sole and thick leather upper that is held on with leather straps and buckles. The toe of the boot is heavy metal. The weight is worn next to the trunk of the diver and it has an inscription to mark the front. It is worn with straps and buckles holding it in place. Royal Navy Admiralty Pattern 6 bolt No 3 light Siebe Gorman light diving helmet circa 1960 used by the Royal Navy before and after World War 2"Siebe Gorman & Co Ltd Marine Engineers London. Patent" with "E G Ward" on front and back plate. On weight "FRONT"flagstaff hill, warrnambool, diving suit, siebe gorman and co ltd., siebe gorman and co ltd marine engineers london, marine engineers, diving helmet, diving boots, diving weight, marine diving, maritimemuseum, maritime village, maritime history, marine technology, life saving, deep sea diving -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Churn, Malleys Ltd, 1930-1950

This is a steel, bench-mounted, hand-operated (60 rpm) butter churn for making small amounts of butter from cream in the home. It was made by the Sydney firm of Malleys Ltd from the 1930s until the 1950s and came in 3 and 5 quart sizes. Malleys Ltd was established in about 1890 by Francis Malley (1863-1932). This firm was located in the Sydney suburb of Alexandria, in McEvoy Street. They manufactured items for use in the dairy industry, as well as for hardware related to building and plumbing. Many of the Malley dairy products were sold under the "Sunrise" name. Malley retired in 1912. In 1931 there were branches at Parramatta, Hurstville & North Sydney. Butter churns were machines used to produce butter by the violent agitation of separated cream. Depending on the design of the churn, the agitation would be variously achieved by a repetitive thrashing, centrifugal motion or internal paddles. Churns were typically constructed from wood, glass and cast-iron; with tin or steel commonly used for some fixtures. The subject item gives an insight into domestic life where butter was made in the home.Heavy red cast iron base, with a long handle, wooden grip, connected to a shaft along the base, thence, to a cog wheel, and gear, to a second shaft and paddle in a metal basin. Basin has lid, and hole in base with a screw cap to allow the draining of the butter milk. Designed to be placed on a bench, with the handle over the edge. Malleys is written in raised letters on the base, and on the handle, '60 rev. pr. min.'warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, malleys, butter churn, domestic object, dairy machine