Showing 152 items

matching testing engines

-

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Avon Fuel System And Engine Test Schedules MK1,26 & 109

... CAC Collection - Avon Fuel System And Engine Test Schedules...CAC Collection - Avon Fuel System And Engine Test Schedules... System And Engine Test Schedules MK1,26 & 109 ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC ATAR Engine Test Reports Collection

... CAC ATAR Engine Test Reports Collection... Document CAC ATAR Engine Test Reports Collection ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument - CAC Commonwealth Aircraft Corporation, Rolls Royce Gas Turbine Engines Test Results - Correction Factors

... Moorabbin melbourne Rolls Royce Gas Turbine Engines Test Results ... -

Puffing Billy Railway

Puffing Billy RailwayBlackstone Oil Engine, 6 November 1908

8HP Blackstone Lamps Start Oil Engine engine number 71076 Engine Details Maximum operating RPM of 240. Fitted with a 3'9" Flywheel Tested on the 6th of November 1908. Shipped to Cluter buck South Australia for installation on concrete base. Recovered and restored during the 80's in South Australia Purchased privately in 2013 in Tailem Bend South Australia and transported to Victoria. Currently on loan to the Puffing Billy Museum at Menzies Creek as an operating exhibit. Blackstone & Co. was a farm implement maker at Stamford, Lincolnshire, United Kingdom. In 1896 they built lamp start oil engines. The Lamp or hot-bulb engine (also hotbulb or heavy-oil engine) is a type of internal combustion engine. It is an engine in which fuel is ignited by being brought into contact with a red-hot metal surface inside a bulb, followed by the introduction of air (oxygen) compressed into the hot-bulb chamber by the rising piston. There is some ignition when the fuel is introduced, but it quickly uses up the available oxygen in the bulb. Vigorous ignition takes place only when sufficient oxygen is supplied to the hot-bulb chamber on the compression stroke of the engine. Most hot-bulb engines were produced as one-cylinder, low-speed two-stroke crankcase scavenged units Historic - Industrial - single cylinder, horizontal, 4 stroke, hot-bulb ignition oil engine Blackstone 8HP Oil Engine made from steel, wrought iron and brassOval Plate with Black Stones and Clutter Buck Brass Plaque engine number 71076blackstone, oil engine, clutter buck, black stone, puffing billy, hit and miss, engine, blackstone & co -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

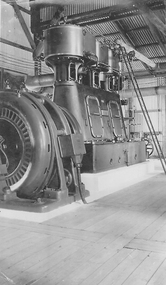

Cocks Pioneer New Engines, c. 1934. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25,000. Settling dams were built, one of which held 1,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64 397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mining, gold, tin, engine, electricity, gold mining, tin mining, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

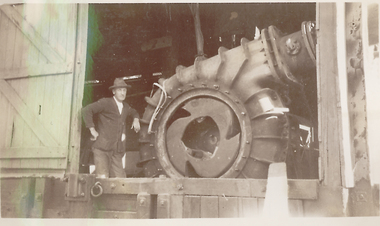

Cocks Pioneer Engine c1930s. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1,,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mining, gold, tin, gold mining, tin mining, machinery, engines, men, cocks pioneer, el dorado, eldorado -

El Dorado Museum Association Inc.

El Dorado Museum Association Inc.Photograph (item) - Digital Image

Cocks Pioneer new engines. Cocks Pioneer Electric Gold & Tin Mine Company was formed in 1899. The company's first power station, located at the eastern end of the valley began operating with its 340 Kilowatt steam-powered generator. By 1909, from 2,500,000 cubic yards worked, reported recovery was 17,284 ounces of gold and 224 tons of tin ore. By 1909, Cocks Pioneer’s power plant had become inadequate and uneconomical. The barge was floated downstream about a mile, but lost time caused the operations to cease. Following testing, a new mine was established by diverting Reid's Creek at a cost of £25 000. Settling dams were built, one of which held 1,935,900 cubic feet. Sold earth banks, built against a wall of stringy bark saplings constructed and laced with vertical props, were built. In 1914, the company was reformed as Cock’s Pioneer Gold and Tin Mines NL, another power station was constructed at the western end of the township, near the junction of Clear and Reid's Creeks. From 6,800,000 cubic yards of material processed, the returns were 64,397 ounces of gold and 855 ton of tin. Cocks Pioneer mine then moved the barge downs stream and continued sluicing. In 1929 Cocks Pioneer Electric Gold and Tin Mining Company ceased operations due to a drop in values. Cock’s Pioneer Gold and Tin Mines NL carried on large-scale hydraulic sluicing operations until 1941. mines, mining, tin, gold, tin mining, gold mining, hydraulic mining, cocks pioneer, el dorado, eldorado -

National Wool Museum

National Wool MuseumMachine - Shearing Motor, Sunbeam, 1960-69

With more and more woolsheds being connected to power lines, the need for electric shearing gear markedly increased from the 1960s onwards. The greater economy made electric gear an attractive proposition to many graziers. Requiring only an electric shearing motor, for small and medium scale operations, electric shearing motors were a more economical way of shearing a wool clip. The other option for graziers was Overhead shearing gear, which also required an Engine to provide shared power to a row of shearing stations. Still working, this Sunbeam Electric Shearing Motor – Heavy Duty Model, features a slow speed motor totally enclosed for protection against dust and insects. The full bearing down tube is easily removed and stored to be out of the way when not in use (not pictured). Providing 0.5 hp, which is twice the power ever needed for shearing sheep, this buffer allows for fluctuations in voltages that can occur in rural districts. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered into a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. This 0.5 horsepower vertical brushed motor air-cooled engine was designed to drive a single shearing plant. From the central cylinder which features a yellow “Sunbeam” sticker, a grey 240v power lead can be found on the left-hand side. A blue capacitor is located next to this power lead. Below, two legs extend and meet to form a foot which is fastened to a wall. On the right-hand side of the engine, a specification plate is located on the central cylinder. A yellow directional arrow sticker is located on the rotating section of the engine below the specification plate (location for photography, this section is designed to rotate and hence this sticker is not fixed in this location). At the rear of the cylinder, a plastic cap with small air cut outs protects the air-cooled engine from contaminants. At the front of the engine, the location for securing the bearing down tube is located. On the right-hand side of the lock for the bearing down tube is the handle, to which a string is often attached for switching the motor on and off by a shearer bent at the waist (not pictured). Sticker. Gold writing. Front of shearing motor “Sunbeam” Plate. Inscribed. Side of shearing motor. “Sunbeam / SHEARING MOTOR / MADE IN AUSTRALIA / 0.5 H.P. / 220/240 V / 1 PHASE A.C. / 4.0 AMPS / 50 C/S. / CONT. RTG. / 1425 R.P.M. / CLASS A INSUL / NO. J244560 / TYPE: NSB5C2/49." sheep sheering, shearing equipment, sunbeam, electric shearing motor -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Ballarat Heritage Services

Ballarat Heritage ServicesImage - Black and White, Qantas Engine-test bed control panel

... Qantas Engine-test bed control panel... Office goldfields flight aeroplane qantas Qantas Engine-test bed ...flight, aeroplane, qantas -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Atar Engine Stall Testing, Atar Stall Tests

... Tests Manual Atar Engine Stall Testing ...Commonwealth Aircraft Corporation -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Atar Engine Pre Heat Testing, Atar Pre-Heat Test

... Test Manual Atar Engine Pre Heat Testing ...Commonwealth Aircraft Corporation -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 42 FR1025

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 144 FR983

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 13517 FR982

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 160 FR984

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 13525 FR985

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 127 FR986

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 13530 FR987

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 84 FR988

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 13513 FR9889

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 155 FR990

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 100 FR991

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 108 FR992

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 28 FR993

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 123 FR994

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 13519 FR 995

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 56 FR 996

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 133 FR 997

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ... -

Moorabbin Air Museum

Moorabbin Air MuseumDocument (item) - CAC Collection - Gas Turbine Engine Test Report ATAR 09C5 No.CAC 13010 FR 998

... CAC Collection - Gas Turbine Engine Test Report ATAR 09C5...CAC Collection - Gas Turbine Engine Test Report ATAR 09C5... Moorabbin melbourne CAC Collection - Gas Turbine Engine Test Report ...