Showing 95 items matching "wood working tool"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, Mid 20th Century

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the gripfid, is used for ply-split braiding. The gripfid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid’s is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Metal Fid with a wooden bulb on top metal body tapering to a point. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, Early 20th century

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the gripfid, is used for ply-split braiding. The gripfid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid's is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Fid, Metal and Wood top with brass ferrule between the two.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, Late 19th- early 20th Century

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the gripfid, is used for ply-split braiding. The gripfid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern fid's are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid's is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Wooden Fid with 3 rings around base of knob at the top of fid. Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Marlin Spike, Unknown possibly washed up from a wreck late 19th century

A marlinspike is a tool used in marine rope work it is shaped in the form of a polished metal cone tapered to a rounded or flattened point, it is used in such tasks as unlaying rope for splicing or untying knots. For drawing a marline tight and using a marlinspike hitch as well as for joining toggle ropes under tension in a belaying pin splice. Most marlin spikes are 15–30 cm long, but may reach 61 cm and more for working heavy cables and ropes. They are usually made from iron or steel, whereas fids, similar in shape and function, are formed from wood or bone. The marlinspike may be a separate tool or as an item on a pocket knife. Sailors who become proficient at knot tying, splicing, and sewing using the marlinspike are said to have mastered marlinespike seamanship, earning them the right to be known as marlin spikes or marlinspike seamen.A tool still very much in use today wherever a rope or cable requires joining, splicing etc the marlin spike tool design has not changed since first invented centuries ago as a sailors tool to splice and make repairs to ropes and cables on board a ship. This item gives a snapshot into the life sailors have on board sailing vessels past and present. Marlin Spike made of solid steel. Handle is bulbous and spike end is rounded.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, marlin spike -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Archimedean drill, Mid to late 1800s

... Wood Working Tools None Archimedean drill with wooden grip ...The Archimedes drill, also known as a fretwork drill, is an old type of drill which works on the Archimedian principle; the drill rotates quickly as the barrel on the stem is worked up and down. This tool provides a quick and easy way to bore holes through ordinary fret wood and other substances, smaller versions are used in jewellery making where precision drilling is required. There were numerous different sized Archimedes drills made from various materials, usually a combination of wood and steel, some being all steel and some including brass parts. The fancier versions of these drills included parts made from Rosewood, Ebony, Ivory and decorative brass parts. Some of the later Archimedes drills had technological improvements such as a ratchet device and the inclusion of fly-weights. The ratchet device allows the drill to revolve continuously in the cutting direction. The fly-weights give momentum to maintain the speed of the drill during the upward stroke of the hand. Most old examples such as the subject item have no makers names.A vintage drilling tool that gives a snapshot into how holes were drilled by hand into small or delicate objects during the Victorian era. Tools from this time are today regarded as collectable items eagerly sought by collectors of antique tools.Archimedean drill with wooden grip and butterfly nut on chuck.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, archimedean drill, drill, fretwork tools, wood working tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, 1940s

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the grip fid, is used for ply-split braiding. The grip fid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid’s is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Metal Fid painted brown, flattened point turned end and hole for a lanyardNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, marlinspike -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Wood Plane, Late 19th to Early 20th century

... Carpenders Tools Cabinet Makers Tools Wood Working Tools Wood Planes ...A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Ogee Complex Moulding Plane Alex Mathieson & Son. Stamped W Worrel, (owner) & No 2.flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alexander mathieson & sons, complex moulding plane, carpenders tools, cabinet makers tools, wood working tools, wood planes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Bow Saw, 1850 to 1900

... -village bow saw Carpenders Tools Cabinet Makers Tools Wood Working ...The Bow Saw is considered by many to be the most satisfactory saw for cutting shapes since the narrow blade negotiates curves easily, and is held in tension. Both the handle and knob (at the other end of the blade) can be turned so that a cut can be made more or less parallel to the required cut. Obviously the blade must be free of twist when in use. It is available with blade lengths of 25 to 40 cm (10 to 16 in). Generally both hands grips the one handle, hence the bulbous shape with narrow neck, but when thick wood has to be sawn it is helpful to have a person at each side, both sides of the wood having been marked. In this way it is much easier to keep the cut square to the sides of the timber. The rivets holding the blade to the handle can be withdrawn so that the saw can be used for an internal cut, the blade being threaded through a hole drilled through the timber.A vintage bow saw used in cabinet work by a cabinet maker in the mid to later part of the 19th century probably made in England.Bow saw wooden frame and handles. Twine attached to upper section of frame.Noneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bow saw, carpenders tools, cabinet makers tools, wood working, wood saw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Broad Axe, Mid-20th century

A double-bevelled broad axe can be used for chopping or notching and hewing. When used for hewing, a notch is chopped in the side of the log down to a marked line, called scoring. The pieces of wood between these notches are removed with an axe, called juggling, and then the remaining wood is chopped away to the line. Broad axe head; handmade. A metal, T-shaped axe head, double-bevelled, with a formed slot for adding a wooden handle. The shape is common; a Canadian pattern. warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, hewing axe, timber working tool, forestry, axe head, braod axe, lumber, building, handmade, forged, iron, steel -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Spokeshave, Mathieson and Son, 1860 to 1910

A spokeshave is a hand tool used to shape and smooth woods in woodworking jobs such as making cart wheel spokes, chair legs, paddles, bows, and arrows. The tool consists of a blade fixed into the body of the tool, which has a handle for each hand. Historically, a spokeshave was made with a wooden body and metal cutting blade. With industrialization metal bodies displaced wood in mass-produced tools. Being a small tool, spokeshaves are not suited to working large surfaces. The name spokeshave dates back to at least the 16th century, though the early history of the tool is not well documented. The name spokeshave reflects the early use of the tool by wheel wrights. The first spokeshaves were made of wood usually beech with steel blades, before being largely superseded by the development of metal-bodied spokeshaves in the latter half of the 19th century, though many woodworkers still use wooden spokeshaves. Due to their widespread use and versatility vintage wooden spokeshaves remain commonly available and relatively low in price. Spokeshaves consist of a blade or iron secured to the body or stock of the tool, which has two handles – one for each hand. The bottom surface of the tool is called the sole. The blade can be removed for sharpening, and adjusted to vary the depth of the cut. An early design consisted of a metal blade with a pair of tangs to which the wooden handles were attached, as with a draw knife. Unlike a draw knife, but like a plane, spokeshaves typically have a sole plate that fixes the angle of the blade relative to the surface being worked. There are a wide variety of different types of spokeshave, suited to different trades and applications. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tin men's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm.A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used to shape various items mainly in use by wheel wrights. A significant vintage item from the mid to late 19th century that today is quite sought after by collectors. It gives us a snapshot of how trade people predominately worked materials such as wood by hand and with tools that were themselves hand made shows the craftsman's art of the time. Spokeshave with blade 4 inches wide.Mathieson and Son Glasgow. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, spokeshave, mathieson and son, carpentry tools, wheel wright tools -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Brace & Bit, John S Fray, 1883 - 1906

Context: A brace is a hand tool used with a bit (drill bit or auger) to drill holes, usually in wood. The pressure is applied to the top and the tool is rotated with a U-shaped grip. Bits used to come in a variety of types but today the more commonly used Ridgeway and Irwin pattern bits also rely on a snail point (called the snail), which is a tapered screw point shaped the same as a wood screw thread, which helps to pull the bit into the wood as the user turns the brace handle and applies pressure. The designs used today come from an original idea and pattern invented by John S Fray. Company History: John S. Fray (1833 ) immigrated to Bridgeport Connecticut USA from England in the 1850s and established a working relationship with Nelson Spofford, who held an 1858 patent for a bit brace (the tool could be augured in a continuous circular motion by hand). He established the John S. Fray Co. around the same time and immediately began producing the Spofford bit brace. Fray himself held at least two patents: one awarded in 1869 for a boring brace attachment, and another awarded in 1883 for a tool handle. By 1889, the firm was located at the industrial complex that sits between the former International Silver Company and the former Bridgeport Chain Company on Crescent Avenue and is identified on the Sanborn Insurance Atlas as a manufacturer of Spofford bit braces, hollow handle awl, and toolsets. The company was in competition with Peck Stow and Wilcox Co. of Southington, and in 1898 was enjoined from making a ratchet bit brace for which the latter company held a patent. By the 1920s, the factory had been purchased by the Stanley Company of New Britain and leased to the American Tube and Stamping Company, a manufacturer of brass, copper, seamless, and bicycle tubing, which also ran a rolling mill to the south on Stafford Avenue (now demolished). The Stanley Company bought both mills in 1926, perhaps as a strategic move to be located along the Bridgeport Harbour, through which much of the raw material used in its operations throughout the state came. By the 1950s, the Crescent Avenue operations had been moved to other sites in Connecticut, and Stanley again leased the building to a company called Cornwall and Patterson, a manufacturer of piano hardware. Today the building appears to be vacant. An early carpenters tool made by a well known early manufacturer from America who instigated many innovations to the making of tools. His early pattern for the improvement of a tool that could be used for the boring of holes in wood was a significant step forward. His design for a boring brace attachment and later a specific handle is still in use today and his original brace and bit is now sought after by collectors of antique tools. Spofford Carpenter's Bit Brace metal has bit attached. Wing nut holds bit in place but nut missing. holds bit in place. 285mm long x 160mm Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageMallet

John Heath tool boxSmall wood working mallet. 210mmL x 75mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Federation University Historical Collection

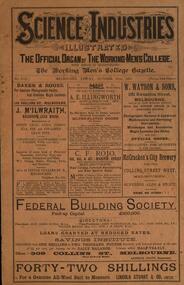

Federation University Historical CollectionBook - Magazine, Science and Industries Illustrated: The Official Organ of the Working Men's College, 30 October 1891, 30/10/1891

12 page magazine of the Working Men's College. Includes advertisements for Brooks, Robinson and Co; Australian Mercantile Loan and guarantee Co. Ltd;W. Watson and Sons; McCracken's City Brewery; Federal Building Society working men's college, rmit, brennan torpedo, edward s. prior, planet mars, wood workers' tools, brooks, robinson and co, australian mercantile loan and guarantee co. ltd, w. watson and sons, mccracken's city brewery, federal building society, c.f. rojo, a.e. illingworth, j. mcilwraith, baker and rouse, remington, w. detmold, g. stuckey, walter j. turner, g. james, hammond typewriter, havelock tobacco, tangyes limited, arnall and jackson, h.p. gregory and co, foster's lager beer, james mcewan and co, phoenix spouting, ridging and curving works, joh ndanks and son, walter j. anderson, herbery v. hampton, alcock and co -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Tools, steel 'C' or 'G' clamp, c1900

A clamp is a fastening device to hold or secure objects tightly together to prevent movement or separation through the application of inward pressure. The tool is for temporary use for positioning components during construction and wood working. There are many types of clamps available for many different purposes. Some are temporary, as used to position components while fixing them together, others are intended to be permanent. A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal work piece, and often used in carpentry and welding. C-clamps or G-clamps are typically made of steel or cast iron, though smaller clamps may be made of pot metal. At the top of the "C" is usually a small flat edge. At the bottom is a threaded hole through which a large threaded screw protrudes. One end of this screw contains a flat edge of similar size to the one at the top of the frame, and the other end usually a small metal bar, perpendicular to the screw itself, which is used to gain leverage when tightening the clamp. When the clamp is completely closed, the flat end of the screw is in contact with the flat end on the frame. When the clamp is actually used, it is very rare that this occurs. Generally some other object or objects will be contained between the top and bottom flat edges. A steel ‘C’ or ‘G’ Clamp used to hold a wood or metal work piece, used in carpentry and welding.L.W.BANKtools, woodwork, metalwork, welding, carpentry, pioneers, market gardeners, early settlers, bank w.l., moorabbin, cheltenham, bentleigh, ormond -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc.Draw knife with metal blade and two wooden handlesNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc.Draw knife with metal blade and two wooden handlesMarkings on blade unreadable flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc. However this item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Draw knife with metal blade and two wooden handlesNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc. However this item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Draw knife with metal curved blade and two wooden handlesNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Draw Knife, Prior to 1950

A draw knife or drawing knife, draw shave, shaving knife is a traditional woodworking hand tool used to shape wood by removing shavings. It consists of a blade with a handle at each end. The blade is much longer along the cutting edge than it is deep (from cutting edge to back edge). It is pulled or "drawn" toward the user. A draw knife is commonly used to remove large slices of wood for flat faceted work, to debark trees, or to create roughly rounded or cylindrical billets for further work on a lathe, or it can shave like a spokeshave plane, where finer finishing is less of concern than a rapid result. The thin blade lends itself to create complex concave or convex curves such as in making staves for barrels.A specialised tool used in many different types of wood working and in the making of barrels, this type of tool has been used for many hundreds of years by coopers and other woodworking craftsmen all around the world. It is a tool that has not changed in design during this time and is still used today by craftsmen in the making of wooden barrels for the storage of wines etc. However this item at this time cannot be associated with an historical event, person or place, provenance is unknown, item assessed as a collection asset as it is believed to have been produced before 1950.Draw Knife bent blade, metal with two wooden handlesNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, draw knife, coopers tools, woodworking tools, knife, cooperage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fid, 1940s

A Fid is a conical tapered wooden tool used for separating the strands of rope for splicing. They were a tool traditionally made of wood or bone used to work with rope and canvas in marlinespike seamanship. A Fid differs from a marlinspike in material and purposes. A marlinspike is used in working with wire rope, natural and synthetic lines also may be used to open shackles, and is made of metal. A Fid is used to hold open knots and holes in the canvas, and to separate the "lays" (or strands) of synthetic or natural rope for splicing. A variation of the Fid, the grip fid, is used for ply-split braiding. The grip fid has a jamming cleat to pull a cord back through the cord split by the fid's point. Modern Fids are typically made of aluminium, steel, or plastic. In addition to holding rope open to assist the creation of a rope splice, modern push fid's have markings for precise measurements in a variety of sizes of rope. The length of these fid’s is typically 21 or 22 times the diameter of rope to be spliced. Fids have been used since sailing vessels were first used to travel the worlds seas the tool was invented to be used to splice rope and with working with canvas sails. A Fid is a sailors tool that has maintained its general design for hundreds of years and gives a snapshot into what the working life was like for sailors on board sailing ships for hundreds of years. The tool in its original design is still in regular use today by recreational sailors all over the world to splice and join lengths of rope.Metal Fid painted half green, flattened end with a lanyard holeNoneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, marlinspike -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph - copy, 1988 copy

... made reinhard beilharz handcrafts wood working tools pow camp ...Photographed at Exhibition of Camp memorabilia displayed at Temper Home for Aged, Bayswater, Victoria, 1981.Colour photograph of handmade wooden articles. Tools and planes made by Master Carpenter Reinhard Beilharz and a jewel box and inlay brooches he made for his wife Therla. Negative no. 19.hand made, reinhard beilharz, handcrafts, wood working tools, pow, camp internees, temple society -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPlane - Wooden, 1940's

Made by internee at Camp 3 Tatura. Used there as a wood working handtoolHandmade varnished, polished wooden plane with curved, turned handle. Metal washers support centre metal barHaeringplane, wood, haering, m, camp 3, tatura, ww2 camp 3, trades, tools -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Wood Plane, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Wood Plane, for wood working. Has a handle at the front for pushing it through wood. Also has metal blade kazenwadel, blacksmith, wood, tools camp 3, metal, woodworking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Wood Plane, 1940's

Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Wood Plane, for wood working. Has a handle at the front for pushing it through wood. Also has metal blade kazenwadel, blacksmith, wood, tools camp 3, metal, woodworking -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Chisel, 1940's

... kazenwadel blacksmith wood tools camp 3 metal wood working Metal ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingMetal chisel on a wooden handle, with a metal ferrule at each end of the handle. kazenwadel, blacksmith, wood, tools camp 3, metal, wood working -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Chisel Small, 1940's

... from under the barracks ie : stumps. Used for wood working ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingChisel with small thin blade, wood shaped handle with metal ferrule at each end of handlekazenwadel, blacksmith, wood, tools camp 3, chisels -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Chisel Medium, 1940's

... from under the barracks ie : stumps. Used for wood working ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingChisel, wood shaped handle with metal ferrule at blade end end of handle, partly covered with cream paintkazenwadel, blacksmith, wood, tools camp 3, chisels -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Wooden Mallet, 1940's

... from under the barracks ie : stumps. Used for wood working ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingWooden mallet made in one piece with a curve halfway along it`s length, handle at one endkazenwadel, blacksmith, wood, tools camp 3, chisels, mallets -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Metal Wedge, 1940's

... from under the barracks ie : stumps. Used for wood working ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingMetal Wedge long and tapered at one end, worn and flattened at top end ( maybe from being struck with a hammer )kazenwadel, blacksmith, wood, tools camp 3, chisels, mallets -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumTool - Metal Wedge, 1940's

... from under the barracks ie : stumps. Used for wood working ...Made by internees at camp 3, using wood sourced from under the barracks ie : stumps. Used for wood workingMetal Wedge long and tapered at one end, worn and flattened at top end ( maybe from being struck with a hammer )kazenwadel, blacksmith, wood, tools camp 3, chisels, mallets