Showing 96 items

matching wool processing textile industry

-

National Wool Museum

National Wool MuseumChart, Australia's Wool Industry Processing chart, 1960

... -and-the-bellarine-peninsula "Australia's Wool Industry Processing chart ..."Australia's Wool Industry Processing chart, 1960"education wool industry textile industry - education, australian wool board, galloway, mr ken, education, wool industry, textile industry - education -

National Wool Museum

National Wool MuseumDocument, The Wool Textile Industry: ten minute broadcast

... Post-war reconstruction Textile Industry Woollen Mills Wool..., and broadcast in c.1946 re: the Wool Textile Industry. The speech ...Typescript copy of a 10 minute speech given by the Hon. J.J. Dedman, Minister for Post War Reconstruction, and broadcast in c.1946 re: the Wool Textile Industry. The speech mentions W.R. Lang and a copy was presumably forwarded to him for this reason.FROM / The Hon. J.J. DEDMAN, MP / With his Compliments / No. 13post-war reconstruction textile industry woollen mills wool processing, dedman, hon. j. j. m.p. - c. of a. - ministry of post-war reconstruction, post-war reconstruction, textile industry, woollen mills, wool processing -

National Wool Museum

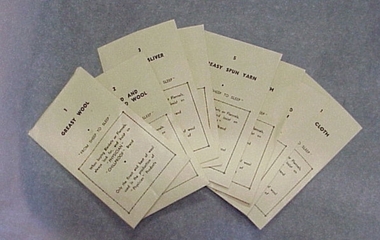

National Wool MuseumSamples, "From Sheep to Sleep"

Samples of wool, fibres and cloth demonstrating the processes in the creation of blankets, from greasy wool to finished cloth, produced by Collins Bros Pty Ltd.Samples of wool, fibres and cloth demonstrating the processes in the creation of blankets, from greasy wool to finished cloth, produced by Collins Bros Pty Ltd."From Sheep to Sleep" when buying Blankets or Flannels, always look for, and insist on "PHYSICIAN' 'CHILLPROOF' Brand Only the finest and best of wool used in the production of "Physician" Productstextile industry - education, collins bros mill pty ltd, blankets -

National Wool Museum

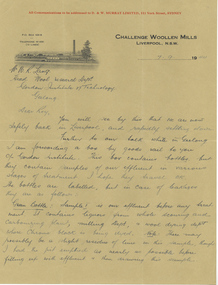

National Wool MuseumLetter

... of effluent from wool processing operations. Textile Industry ...Letters from the Challenge Woollen Mills, Liverpool, NSW in 1944 and 1949, to W.R. Lang re: treatment of effluent from wool processing operations.textile industry - pollution world war ii, challenge woollen mills, lang, dr w. roy, textile industry - pollution, world war ii -

National Wool Museum

National Wool MuseumBook, World Wool Guide 1969

... Wool Marketing Textile Industry Wool Brokering Wool... Textile Industry Wool Brokering Wool Processing Woollen Mills ..."World Wool Guide 1969 ed."wool marketing textile industry wool brokering wool processing woollen mills trade - international, world wool guide inc., wool marketing, textile industry, wool brokering, wool processing, woollen mills, trade - international -

National Wool Museum

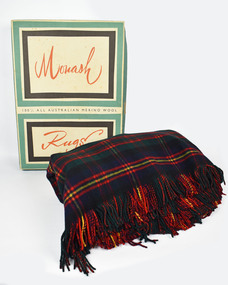

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

National Wool Museum

National Wool MuseumBook, The Sheep and Wool Industry in Australia and New Zealand

"The Sheep and Wool Industry of Australia and New Zealand: A Practical Handbook for Sheep Farmers and Wool-Classers with chapters on wool buying and selling, sheepskins and kindred products" - 3rd ed., Henry B. Smith, rev. Harold Haile, c.1926.wool growing sheep breeding - history shearing wool - characteristics woolclassing textile fibres wool - pelts wool sales wool brokering wool processing, wool press, scouring, fellmongery, mutton, wool growing, sheep breeding - history, shearing, wool - characteristics, woolclassing, textile fibres, wool - pelts, wool sales, wool brokering, wool processing -

National Wool Museum

National Wool MuseumJournal, Wool Record

... Wool Processing Wool Marketing Textile Fibres Textile... Textile Industry Textile Production Wool Processing Wool Marketing ..."Wool Record" Vol. 100, No. 2745, Bradford, Fri. Dec. 22, 1961.wool processing wool marketing textile fibres textile industry textile production, wool processing, wool marketing, textile fibres, textile industry, textile production -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.Book, front cover: "Modern Developments in the Australia Woollen Industry" c.1923; Yarra Falls Spinning Co. Pty Ltd and Australian Knitting Mills Limited.weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, logo merino: sheep in australian art and design - exhibition (29/07/2000 - 04/02/2001), weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumBook, Early stage processing of Australian wool [English and Chinese]

"Early stage processing of Australian wool [English and Chinese]" Australian Wool Corporation and Production Department of the Ministry of Textile Industry of the People's Republic of China, 1984wool processing export - wool yarn production textile production textile machinery, australian wool corporation, wool processing, export - wool, yarn production, textile production, textile machinery -

National Wool Museum

National Wool MuseumBook, World Wool Guide, 27th ed., 1965

... Wool Marketing Textile Industry Wool Brokering Wool... Guide Inc, Philadelphia. Wool Marketing Textile Industry Wool ..."World wool guide, 27th ed.,1965" - World Wool Guide Inc, Philadelphia.wool marketing textile industry wool brokering wool processing woollen mills trade - international, world wool guide inc., wool marketing, textile industry, wool brokering, wool processing, woollen mills, trade - international -

National Wool Museum

National Wool MuseumBook, The World Book of Wool

"The World Book of Wool" Dept. of Education, International Wool Secretariat, c.1947.textile production textile industry - history wool - history wool growing wool processing, international wool secretariat, textile production, textile industry - history, wool - history, wool growing, wool processing -

National Wool Museum

National Wool MuseumBook, CSIRO Wool Technology: research for a great Australian industry

"CSIRO Wool Technology: research for a great Australian industry", 1992. Brochure promoting the work done by the Division of Wool Technology at CSIRO in Geelong. It provides an overview of its history and explains some of the breakthroughs made by the division.wool processing textile finishing, csiro division of wool technology, wool processing, textile finishing -

National Wool Museum

National Wool MuseumBook, Background Paper on Opportunities and Impediments to Adding Value to Wool

"TCF Information Paper no. 1: Background paper on opportunities and impediments to adding value to wool" - Textiles, Clothing and Footwear Section, Department of Industry, Technology and Commerce, Canberra, May 1987. Examines ways in which wool could be processed in Australia, rather than being exported raw.c. of a. - department of industry, technology and commerce - textiles, clothing and footwear section -

National Wool Museum

National Wool MuseumBook, Recent Developments in Wool and Wool Blend Processing

... Finishing Wool Processing CSIRO Division of Textile Industry Dyeing ..."Recent Developments in Wool and Wool Blend Processing" CSIRO Division of Textile Industry, 1983.textile finishing wool processing, csiro division of textile industry, dyeing, spinning, textile finishing, wool processing -

National Wool Museum

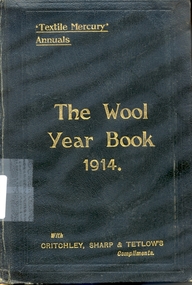

National Wool MuseumBook, The Wool Year Book 1914, 1914

"Textile Mercury Annuals:The Wool year book and diary 1914".Book, 592 pages. Dark green hard backed book, green cord bookmark, thumb cutouts designating the sections. Includes statistics, supplier lists, descriptions and specifications of processes, diary in blue paper.Cover: 'Textile Mercury' / Annuals / The Wool / Year Book / 1914. / With / CRITOHLEY, SHARP & TETLOW'S / Complimentstextile industry textile machinery textile history, textile mercury ltd, textile industry, textile machinery, textile history -

National Wool Museum

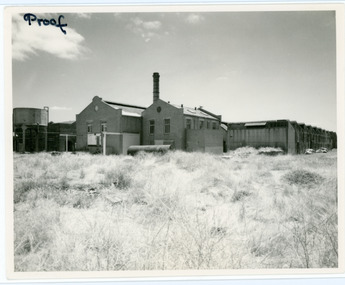

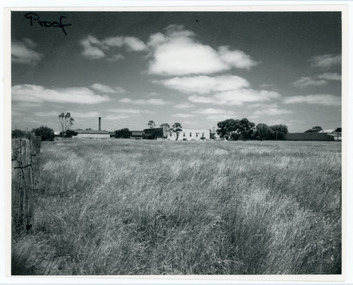

National Wool MuseumPhotograph

Exterior view of the engine room and boiler house of the Barwon Mill (built 1874; taken over by Godfrey Hirst and renamed Excelsior One in 1890) in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

National Wool MuseumPhotograph

Exterior view of the main office of Godfrey Hirst and Co. Pty Ltd mills. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd -

National Wool Museum

National Wool MuseumPhotograph

Exterior view of the main office of Godfrey Hirst and Co. Pty Ltd mills. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd -

National Wool Museum

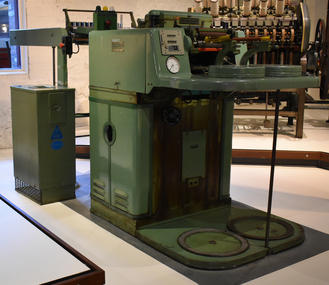

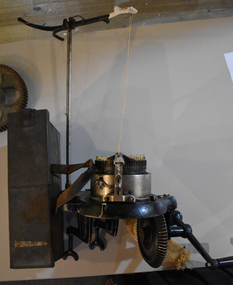

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

... with the Australian Wool Processing Industry by contributing the funds ...This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

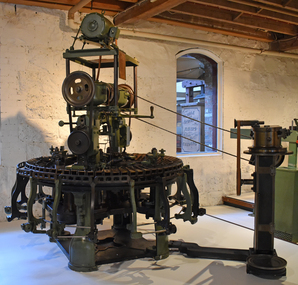

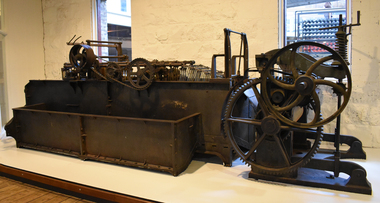

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

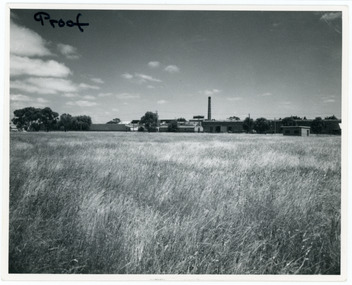

National Wool MuseumPhotograph

Exterior view of the Barwon Mill (built 1874; taken over by Godfrey Hirst and renamed Excelsior One in 1890) in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

National Wool MuseumPhotograph

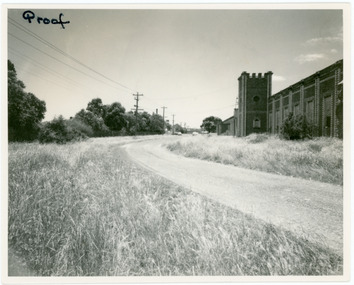

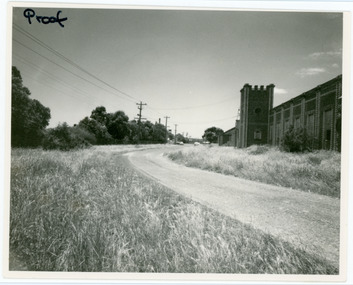

Depicts the west wall of the Barwon Mill, looking north in Factory Road. The Barwon Mill was built in 1874 and taken over by Godfrey Hirst and renamed Excelsior One in 1890. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

National Wool MuseumPhotograph

Depicts the west wall of the Barwon Mill, looking north in Factory Road. The Barwon Mill was built in 1874 and taken over by Godfrey Hirst and renamed Excelsior One in 1890. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill -

National Wool Museum

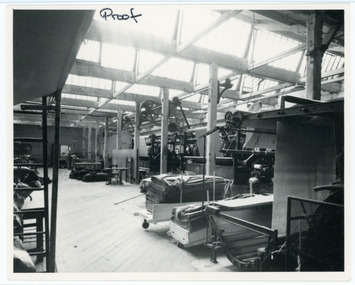

National Wool MuseumPhotograph

Depicts the dry finishing room from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile finishing, godfrey hirst and co. pty ltd, dry finishing, raising machinery -

National Wool Museum

National Wool MuseumPhotograph

Depicts the warehouse from one of the Godfrey Hirst mills in 1966, where the finished goods were stored awaiting despatch. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills - warehouses, godfrey hirst and co. pty ltd -

National Wool Museum

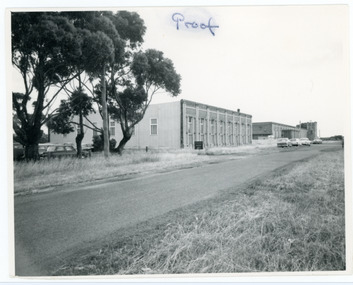

National Wool MuseumPhotograph

Depicts the north-west walls of the warehouse from one of the Godfrey Hirst mills in 1966, where the finished goods were stored awaiting despatch (the Barwon Mill can be seen alongside). In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills warehouses, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill, textile mills - warehouses -

National Wool Museum

National Wool MuseumPhotograph

Depicts the warehouse of the Barwon Mill of the Godfrey Hirst operation in 1966, where the finished goods were stored awaiting despatch. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096textile mills warehouses, godfrey hirst and co. pty ltd, barwon woollen mill, excelsior one mill, textile mills - warehouses -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine

Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Griswold bench-type sock knitting machine hand operated by turning the handle.sock knitting machine, textile industry, wool, fashion, clothing -

National Wool Museum

National Wool MuseumMachine - Scouring Bowl, J Dyson & Sons Pty Ltd, c.1890

... processing E. P. Robinson Textile Industry Factory Mill J. Dyson ...Scouring is the process that removes wool wax and other unwanted products from wool. Wool is washed in a hot detergent solution. It moves through a series of scouring bowls and is then rinsed and dried. Careful handling and washing preserves the strength and softness of wool. If the wool contains lots of seeds and other vegetable matter, it must be cabonized. This means it is treated with a solution of sulpheric acid and then baked at high temperature to remove impurities. The disused scouring water left-over from this process was often let drain into rivers and watercourses causing pollution. Many of Geelong's wool scours along the Barwon River were closed due to environmental damage. The race system on this bowl is not the original it has been modified with a variation of the harrow system. Used at E.P. Robinson South Geelong from c.1890-1970.Scouring bowl.J. Dyson & Sons Pty Ltd, Geelongsouring bowl, j dyson & sons, geelong, wool processing, e. p. robinson, textile industry, factory, mill