Showing 182 items

matching wool production

-

National Wool Museum

National Wool MuseumBook, Cloth Sample, 1928

Production samples from Returned Soldiers and Sailors Mill, given to Mr Alexander Lau before the mill closure.varioustextile design fashion textile industry - history, alexander lau pty ltd returned soldiers and sailors mill, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Cloth Sample, 1931

Production samples from Returned Soldiers and Sailors Mill, given to Mr Alexander Lau before the mill closure.1958-59 varioustextile design fashion textile industry - history, alexander lau pty ltd returned soldiers and sailors mill, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.F H Murgatroyd/20 Kensington Rd/ Leopold 3224weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumProduction sheets

Season 1951-1952textile design fashion textile industry - history, alexander lau pty ltd, textile design, fashion, textile industry - history -

National Wool Museum

National Wool MuseumSkein

... production Astor EMPIRE / pure wool mending / MADE IN AUSTRALIA ...Skein of pure wool black mending thread, produced by Astor in Australia under the 'Empire' brand.Skein of black mending wool, produced by Astor in Australia under the 'Empire' brand, c.1930s.EMPIRE / pure wool mending / MADE IN AUSTRALIA / Astor / PRODUCTyarn production, astor -

National Wool Museum

National Wool MuseumBook, Review of Textile Progress Vol. 1

One of several books donated to the Museum from the Launceston Institute of TAFE Library, after dispersal of its collection of technical books.One of several books donated to the Museum from the Launceston Institute of TAFE Library, after dispersal of its collection of technical books.For Kelsall & Kemp (Tasmania) Limitedtextile production textile research textile testing, textile institute society of dyers and colourists, hallam, ms janet - launceston institute of tafe, textile production, textile research, textile testing -

National Wool Museum

National Wool MuseumBook, Instruction Paper No.841B :Drum and pirn winding frames, part 2, 1st Ed

"Instruction Paper No.841B :Drum and pirn winding frames, part 2, 1st Ed. - International Correspondence Schools Ltd."Instruction Paper No.841B :Drum and pirn winding frames, part 2, 1st Ed. - International Correspondence Schools Ltd.weaving textile machinery yarn production textile industry - education, international correspondence schools ltd, winding, winding machinery, weaving, textile machinery, yarn production, textile industry - education -

National Wool Museum

National Wool MuseumBook, Instruction Paper No.513: Pile Weaves, 1st Ed

"Instruction Paper No.513: Pile Weaves, 1st Ed." - International Correspondence Schools Ltd."Instruction Paper No.513: Pile Weaves, 1st Ed." - International Correspondence Schools Ltd.weaving textile machinery textile industry - history textile design textile production textile industry - education, international correspondence schools ltd, corduroy, carpet, velvet, weaving, textile machinery, textile industry - history, textile design, textile production, textile industry - education -

![Manual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065ed29821f50e3cc9ea4b/item-media/601344e16061d010347e22d5/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumManual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions

This handbook contains the setting instructions for a Standard Hattersley Loom developed by George Hattersley and Sons Ltd. The Hattersley loom was developed by George Hattersley and Sons of Keighley, West Yorkshire, England. The company had been started by Richard Hattersley after 1784, with his son, George Hattersley, later entering the business alongside him. The company developed several innovative looms, of which the Hattersley Standard Loom – developed in 1921 – was a great success. The Hattersley Standard Loom was designed and built in 1921. Thousands of models were expected to be sold, which would bring considerable financial success to the company. After the recapitalisation boom of 1919, cotton yarn production peaked in 1926 and further investment was sparse. Rayon, an artificial silk, was invented in the 1930s in nearby Silsden, and the Hattersley Silk Loom was adapted to weave this new fabric. An example of this type of loom can be seen on Vic Collections here ( https://victoriancollections.net.au/items/54065d0f9821f50e3cc9c122 ) and is also on display within the National Wool Museum in Geelong, Victoria. A copy of this manual may be available by contacting the National Wool Museum Collection Team. Book, 64pp. Red and black loose leaf, soft cover, printed black ink. "[Hattersley] Standard Loom Tuners Handbook: Setting instructions " - George Hattersley and Sons LtdTHE BRUCE WOOLLEN MANUFACTURING CO LTDtextile industry - history textile machinery weaving textile industry - education, george hattersley and sons ltd, weaving looms, weaving machinery, textile industry - history, textile machinery, weaving, textile industry - education -

National Wool Museum

National Wool MuseumCatalogue, Hartmann Webstuhle

Hartmann catalogue of textile machinery.AUSTRALOVER MACHINERY COY PTY LTD/ 486 BOURKE ST. MELB LOOMStextile machinery textile mills yarn production, hartmann, weaving looms, weaving machinery, spinning machinery, carding, textile machinery, textile mills, yarn production -

National Wool Museum

National Wool MuseumBook, Cloth Sample

Book of fabric samples produced by Yarra Falls Pty Ltd, Melbourne.Book of fabric samples produced by Yarra Falls Pty Ltd, Melbourne. Book of fabric samples produced by Yarra Falls Pty Ltd, Melbourne.Arbuckle Waddell Pty. Ltd. Printerstextile production textile design textile mills, lable, forrest, mr craig - yarra falls pty ltd, melbourne, victoria, textile production, textile design, textile mills -

National Wool Museum

National Wool MuseumLabel, Blanket, Physician Chillproof Blanket

Woven labels for 'Physician' blankets produced by Collins Bros Pty Ltd.Woven labels for 'Physician' blankets produced by Collins Bros Pty Ltd.Physician CHILLPROOF BLANKET EXTRA SUPER FINE PURE MERINO WOOL MOTHPROOFED MADE IN AUSTRALIAtextile design textile production, collins bros mill pty ltd, textile design, textile production -

National Wool Museum

National Wool MuseumSamples, "From Sheep to Sleep"

... Only the finest and best of wool used in the production... in the production of "Physician" Products Samples of wool, fibres and cloth ...Samples of wool, fibres and cloth demonstrating the processes in the creation of blankets, from greasy wool to finished cloth, produced by Collins Bros Pty Ltd.Samples of wool, fibres and cloth demonstrating the processes in the creation of blankets, from greasy wool to finished cloth, produced by Collins Bros Pty Ltd."From Sheep to Sleep" when buying Blankets or Flannels, always look for, and insist on "PHYSICIAN' 'CHILLPROOF' Brand Only the finest and best of wool used in the production of "Physician" Productstextile industry - education, collins bros mill pty ltd, blankets -

National Wool Museum

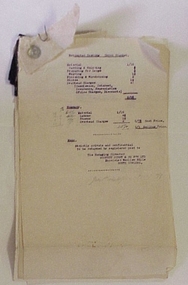

National Wool MuseumCosting estimates

Set of eight costing estimates with cloth samples, for Godfrey Hirst textiles 1924-1925.Set of eight costing estimates with cloth samples, for Godfrey Hirst textiles 1924-1925.July 1st 1924 to June 30th 1925..textile industry - history textile production, godfrey hirst and co. pty ltd excelsior woollen and worsted mills, blankets, cloth - woollen, cloth - union, textile industry - history, textile production -

National Wool Museum

National Wool MuseumBook, Yarn sample, Children's wear colour card: basic range for knitwear

"Children's wear colour card: basic range for knitwear", British Colour Council, 1960.dyeing knitting yarn production, alexander lau pty ltd british colour council, lau, mr alexander - alexander lau pty ltd, dyeing, knitting, yarn production -

National Wool Museum

National Wool MuseumBook, Record of cloth tests

Acquired when "Classewave Industries" closed down.RECORD OF /CLOTH /TESTStextile industry - history textile testing textile production world war i world war ii, federal woollen mills ltd classweave industries pty ltd, textile industry - history, textile testing, textile production, world war i, world war ii -

National Wool Museum

National Wool MuseumWool Winder, 1999

... spinning handicrafts - history yarn production Wooden wool winder ...Wool winder "perhaps designed to accept a skein prior to ball winding, or for plying 2 from 2 single plies." (ref donation form)Wooden wool winder.handicrafts - history yarn production, spinning, handicrafts - history, yarn production -

National Wool Museum

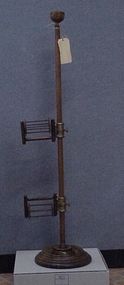

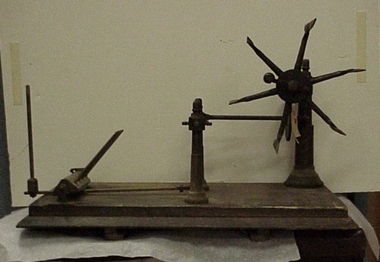

National Wool MuseumMachine - Wrap Reel

Wrap reel manufactured at Valley Worsted Mill and possibly used in the laboratory. "Wrap reels were used to check the yarn count in a spinning mill. A set length of yarn was wound off several test bobbins and weighed, if the weight was not the correct amount expected the spinning machines draft could be re calculated and the machine draft wheel ( cog ) changed to achieve the required count". - Greg AldridgeA small hand operated wrap reel. The reel is on a wooden base, the winding mechanism is metal and turned by a wooden handle. There is a metal plaque on the base inscribed MAKERS VWM. A wood and metal yarn feeder has broken off its mount.MAKERS/ VWMtextile machinery textile production weaving, valley worsted mill valley worsted mill, warping machinery, textile machinery, textile production, weaving, wrap reel, skein winder -

National Wool Museum

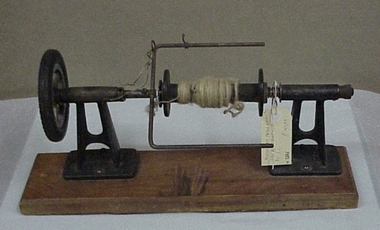

National Wool MuseumBobbin Winder

A small, manual bobbin winder on wooden baseA small, manual bobbin winder on wooden base.yarn production handicrafts, yarn production, handicrafts -

National Wool Museum

National Wool MuseumStamp Set, Bicentenary of the Arrival of Merino Sheep in Australia 7th August 1997

National Wool Museum collaborated in the production work. The two sheep images are from the NWM collection.First Day of Isssue 7 August 1997/ Deniliquin NSW 2710 H L S POTTER/ PHOTO STORES/...wool - history merino sheep - history textile mills textile mills, deniliquin, new south wales, wool - history, merino sheep - history, textile mills -

Stawell Historical Society Inc

Stawell Historical Society IncBook - Laboratory Reference Book, Wool an Introduction to its properties, Varieties, uses and production, W.J. Onions

Textbook. Lab Reference - Norwellan & AUNDE North Western Woolen Mills became Norwellan Textiles then AUNDELight Brown hardcover with Gold title on spineJohn T Bennett, Lyddon Hall Leeds 17/10/1968manufacturing -

National Wool Museum

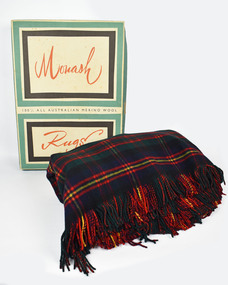

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

National Wool Museum

National Wool MuseumTool - Numnuts Prototypes, Numnuts

Worldwide, more than 100 million lambs are castrated, and their tails are docked each year. Numnuts is a technological innovation to improve animal welfare. It combines traditions with innovation. In the mid-1990s it was scientifically shown that the immense pain felt during castration and tail docking could be significantly reduced with the use of anaesthetic. For the next 15 years, the industry said the cost the welfare devices and development were too high. But todays ethical consumer has demanded that sheep have no more pain. Initiated in Glasgow in 2009, Numnuts took nearly a decade to develop. Here you can see five stages of development, from an early prototype to the Numnuts device farmers use today. Each phase of development took years of on-farm trails to achieve the final product. Today there is even NumOcaine, an approved local anaesthetic used by Numnuts. Using the simple elastrator ring and adding an anaesthetic injector, Numnuts delivers pain relief during tail docking and castration. In the world’s first rubber ring applicator with a pain relief delivery mechanism. Through innovation and consumer pressure the wool industry is going through a moment of rapid change.Four prototype numnuts tools made from white plastic and stainless steel, each in varying stages of production. FInalised version made with black, orange and clear plastics.8097.2 - Mk4 8097.3 - Numnuts Tool V7; 20 10 0 8097.4 - On label - Numnuts NumOcaine 100ml 65 proceeduressheep, tools, castration, innovation, docking -

National Wool Museum

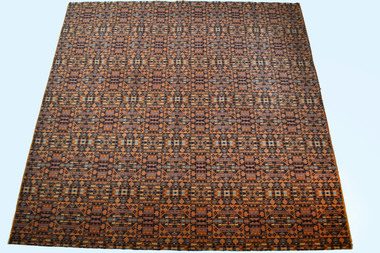

National Wool MuseumRug, Tascot Templeton Carpet (TTC), c.1990

This rug was woven in the mid-1990s at the Tascot Templeton Carpet (TTC) mills in Devonport, Tasmania. It was an in-house design. The rug was woven as a one-off design exercise and was given a Golden Thread Award by the Australian Wool Corporation. The design never went into standard stock production and was never released for public sale. This rug has been woven with 100% wool on a 1 metre wide loom. The loom was purchased by TTC from United Carpet Mills of Preston and the rug was woven to demonstrate the capabilities of these looms. This rug is an example of Wilton weaving. Wilton differs from Axminster in that it is usually Loop Pile and 100% wool whereas Axminster is Plush (cut) pile and normally 80/20 wool nylon blend. TTC manufactured primarily high-quality narrow and broad loom, Axminster and Wilton carpets for the domestic and commercial market. They operated from the early 1960s until their closure in 2011. This rug was also on display in the Tascot Templeton head offices before being donated to the National Wool Museum in 2021 by Roger Warn. 3 x 3-meter carpet rug woven in 1-meter wide sections. The pattern repeats 3 times both in the width and the length. Starting from the bottom left corner, a square can be seen within a larger circular shape. These circular shapes connect end on end across the width and length of the rug. 5 Circles make up the length of the rug while 6 circles make up the width. Numerous small shapes encompass the entirety of the rug. These small shapes work together to form many interconnected repeating forms that draw your eye in a new direction every time you look at the rug. The predominant colour of the rug is a purple background with blue, cream and orange colours making up the foreground colours.carpet rugs, woollen rugs, tascot templeton carpets, axminster carpet loom -

National Wool Museum

National Wool MuseumFunctional object - Spinning Wheel, Philip Elford, 1976-7

Jackie Kerin's (donor's) story. In 1973, I was in my late teens and while I’d moved to Sydney from Melbourne, to begin my first year of drama studies at the National Institute of Dramatic Art. My parents had moved to Lake Bunga, a few kilometers north of Lakes Entrance (Victoria). On my first holiday visit to Bunga, I called into the Jolly Jumbuck Country Craft Centre in Bairnsdale http://jumbukwool.com.au/history. I was entranced by the place and spent the following weeks learning to spin lumpy wool on an Ashford Wheel. By the end of the holidays, I had my own Ashford and it travelled with me back to Sydney. After graduation, I returned to Melbourne and the hippy “back to nature” movement was in full swing; there were many shops and galleries selling handmade woollen items and pottery etc. So I found an outlet for my pieces. Sometime in 1976-77, I met a spinner and weaver of Swiss origin (I think) – her name was Ingeborg Guber (not sure of the spelling). She had a small gallery/shop at Brighton Beach where she worked, with her pet duck for company. Ingeborg had an upright Philip Elford wheel; an Australian wheel crafted from Acacia melanoxylon (blackwood). I was smitten and ordered one. I have a memory of Philip driving to Hampton from Ballarat to make the delivery. I used this wheel for years but as time and enthusiasm for spinning waned, the wheel became a decorative item in the house. Then in the 90s, and with my drama training, I set myself up travelling to schools and festivals, museums and galleries as a storyteller. The spinning wheel had a new life accompanying me on my adventures. For many children, familiar with references to spinning in fairy tales, seeing the little Philip Elford upright was magical. The wheel was donated to the National Wool Museum in 2021.Vertical tripod leg spinning wheel. 6 spoke wheel with three bobbins. Inscription “Philip Elford Ballart” can be read in gold text stamped to the base of the wheel. Wording, stamped, gold. Philip / Elford / Ballartspinning wheel, textile production, hobby textiles, aciacia melanoxylon (blackwood) -

National Wool Museum

National Wool MuseumTool - Drum Carder, Kacoonda, c.1980

... Production Carding Wool Kacoonda Wording, green, printed. Sticker ...This drum carder was purchase by Gill Stange at the Whittlesea Show in the late 1980s. The carder allowed Gill to spin fleece from her own Merino sheep. Merino is a difficult wool to spin when compared to other popular varieties, such as Corriedale or crossbred wool. The carder helped her to tease out the fleece, slightly separating the fibres before spinning. It also allowed for easier removal of foreign matters, such as seeds and mud. Little is known about the Kacoonda brand who produced the carder. They were Australian based and appear to have only operated throughout the 1980s.The carder has one large central roller with two smaller rollers on either side. The larger roller rotates in the inverse direction of the two smaller rollers. The carding cloth is a mint green in which closely spaced wire pins are embedded. The shape, length, diameter, and spacing of these wire pins is that of a standard carder. On one side of the carder a handle is found that is used to spin the three rollers. Additionally on this side is a sticker which reads “The Kacoonda Carder. Subject to Patent Action”. A Silver grip for the easy movement of the carder can also be found high on this side. On the opposite side of the carder, many nuts and plates can be found which hold the rollers in place. This is opposed to the other side of the carder, which has a brown plastic cover plate attached underneath the handle. The walls providing a path for the carded wool to follow when being carded, are made of wood. The carder comes complete with a teasing tool. This tool has the same mint green carding cloth as the carder’s rollers. It is attached to a simple wood handle for ease of use.Wording, green, printed. Sticker on side of carder. “The Kacoonda Carder / SUBJECT TO PATENT ACTION”whittlesea show, drum carder, textile production, carding wool, kacoonda -

National Wool Museum

National Wool MuseumTool - Spinning Wheel, c.1980

This spinning wheel originates from New Zealand; however, it has no distinguishing features relating to its creator such as an inscription, so its exact maker is not known. Gill Stange remembers buying the wheel on Bridge Road in Richmond, approximately 30 years ago. Gill had joined her local Spinners and Weavers Guild after the Ash Wednesday bushfires of 1983. She was a then resident of Mount Macedon and lost everything in the fires. Moving to Melbourne to get away from the scene of much pain, Gill was also in need of a new hobby to help occupy her mind. That is when spinning and weaving entered her life. The local Spinners and Weavers Guild was a great support network for her and with their recommendation, she purchased her own spinning wheel. Her passion was started, and the wheel was to become a treasured item in Gill’s home. She had several spinning wheels within her possession over the years, however, this wheel was her first and always her favourite. When the time came for Gill to downsize, there was simply no longer room for her spinning wheel. This is when she decided to donate the wheel to the National Wool Museum. Gill remembers one highlight was weaving a tablecloth from a traditional German design. It took her two years to complete, with Gill spinning all the wool herself on this wheel. The tablecloth won the first prize in the Melbourne Show in 1987. Gill also used the wheel to teach programs to school children on how to spin and knit wool. She would take the easily transported little wheel, and its accompanying seat, with her to schools. Its small size enabled her to teach children to knit and spin, bringing others the joy that spinning had brought her. Not just limited to schools, Gill also taught programs with the wheel here at the National Wool Museum. It is a fitting home for the wheel, which Gill donated to the National Wool Museum in 2021.Dark varnished wood in a Castle style spinning wheel. The wheel has 8 small spokes which meet a thick outside rim. The outside rim has four golden disc weights on the bottom edge, to aid in the turning of the wheel. The spinning wheel has four legs of turned wood giving a sculptural form, a design pattern which is continued throughout. The wheel has a single medium sized foot pedal. This pedal is well worn with varnish missing from years of use. The wheel is completed with its accompanying chair. Made of the same dark varnished wood, its legs are also of turned wood, continuing the design pattern and uniting the two objects. The chair is very simple outside of the legs, with a medium size base and a thin backrest ending in a rounded head. The chair’s varnish is also starting to fade from years of use. The chair is small, designed to keep the spinning wheel operator at the appropriate height when spinning on the equally small and compact Castle style spinning wheel. Additional parts were donated with the Spinning Wheel. - 3 x Lazy Kates - Spare Maiden. - 450mm Niddy Noddy - Steel teeth brushspinning wool, spinning wheel, ash wednesday, mount macedon, textile production -

National Wool Museum

National Wool MuseumClothing - Jacket, Mrs Jean Inglis, 1988

This jacket is by the prolific spinner and weaver Jean Inglis. It has been woven with a warp of commercially brought wool & a weft of hand spun Corriedale. It is completed in a Swedish lace style of weaving. The highlight of the jacket is the blue section of fabric on the top left shoulder of the wearer, which works down to the bottom right hip. This pattern looks like long thin individual separate sections of fabric stitched to the jacket; however, only one section of fabric has been added. A dying technique has been utilised to give the appearance of multiple sections. This Japanese dyeing technique is called Shibori, “to wring, squeeze or press". It is a manual tie-dyeing technique, which produces several different patterns on fabric. The specific pattern on this fabric is known as Kumo Shibori. It utilises bound resistance. This technique involves folding sections of the cloth very finely and evenly. Then the cloth is bound in very close sections. The result is a very specific spider-like design. This design requires very precise technique. Specific to this jacket, the fabric for the dyed section was made with the same fabric as the rest of the jacket. A section of the excess fabric was concertina wrapped around a 100mm pipe and tied up before dying. This gives the consistent straight blue lines, with no bleed from the dye. The sections were then sewed into the jacket with the occasional sequin added for additional decoration and glamour. The jacket won 1st prize at the 1988 Geelong Show. Jean was assisted by the dress maker Ruth Randell with some of the design and sewing. Jean always found sewing “a bit of a bore”. The jacket also has an attached swing tag. It was added to provide information to the judges at the Melbourne Show on how the jacket was created. It comes complete with Jean’s self-proclaimed terrible handwriting. It was donated to the National Wool Museum in 2021.Cream singled breasted jacket with no overlap. The jacket has no column of buttons for fastening, or lapels. It is designed to be plain, to not draw attention. The jacket is highlighted by the Shibori dyed waves on the top left shoulder of the wearer, which works down to the bottom right hip. This blue dyed section of fabric is dotted with the occasional blue sequin. Internally, the jacket features a white silk lining for comfort. The jacket ends in a straight cut hem, including at the cuffs. The jacket has an attached swing tag. The swing tag is cream with a printed thin black boarder. Within the boarder, handwriting in black ink is found. It has a hole punch in the top left corner of the swing tag for attaching to the jacket.hand spun, hand weaving, textile design, textile production, shibori, kumo shibori -

National Wool Museum

National Wool MuseumAlbum - Photo Album, Grazcos, c.1999

Photo album detailing the process involved in the Jumbo Wool Auction Service. This process was developed by Grazcos, a company who advanced innovations for shearers and wool farmers before amalgamating with Dalgety in the early 1990s. Grazcos was a well-known name to source a competent shearing team, or as a destination for wool in need of bulk classing. The Jumbo Wool Auction service was designed to process wool more efficiently through volume. 63 traditionally dumped farm bales of wool would fill a typical shipping container. The Jumbo Wool Auction Service enabled 108 farm bales to fit into the same container. This brought reductions in the costs of handling, selling, storing, and shipping of wool. This photo album details this process; from classing to shipping. This photo album was a draft copy produced for review before the production of mass-produced advertising flyers. 12-page hard cover photo album. Internally colour images and printed text have been stuck behind a protective plastic onto paper. The backing paper has many distinctive orange and grey horizontal lines. Printed text is in black ink. Colour images are 2 x 3 inches with rounded corners. Images and text are numbered 1 to 16 detailing the process of the Jumbo Wool Auction Service developed by Grazcos.wool auction, wool processing, grazcos -

National Wool Museum

National Wool MuseumTextile - Blanket, Godfrey Hirst and CO. Pty Ltd, The Atlantic Rug, 1930s

The Excelsior Woollen and Worsted Mills were controlled by Godfrey Hirst & Co. Pty. Ltd. The Excelsior name originated from the union in the one enterprise of two of the earliest mills established in Victoria, the Old Victorian Mill, and the Old Barwon Mill. Godfrey Hirst combined his expertise with the capital of Charles Shannon to purchase the Barwon Mill in 1890 and the Victorian Mill in 1899. They commenced production of high-quality flannels in readiness for an anticipated lifting of tariff barriers in 1901, the year of federation. These were the first flannels to be produced in Australia rather than imported from England. In April 1912 the No.2 Excelsior Mill burnt down during the installation of electricity and was rebuilt. The No.1 Excelsior Mill was closed in 1930, with most hands moving to the No.2 Mill. In 1966 the firm changed ownership and became a subsidiary of the McKendrick family and commenced manufacturing of tufted carpets. Godfrey Hirst has since emerged as Australia’s leading manufacturer of tufted carpets. It has also expanded into hard flooring, including timber, laminate, and other surfaces. In 2018, the Godfrey Hirst business was acquired by Mohawk Industries, the world’s largest flooring company. Brown blanket featuring a design of four lines of cream, and a single line of orange, spanning the blanket vertically and horizontally, to form a plaid pattern. At the vertical ends, the blanket ends in a fringe.Label. Stitched. "The Atlantic Rug / Excelsior/ Guaranteed Product / Australian Manufacture"godfrey hirst & co. pty. ltd., excelsior mill, the atlantic rug