Showing 678 items matching "brush"

-

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, Australian Commonwealth Engineering Standards Association, "Flame proof air break switches for Voltages Not Exceeding 600Volts"s", 1926-1932

.1 - Book - 20 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Air-break knife switches and laminated brush switches for voltages not exceeding 660Volts" - C23 - 1926, August 1926" .2 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Flame proof air break switches for Voltages Not Exceeding 600Volts", C25-1926, October 1926. .3 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Flame proof air break circuit breakers for Voltages Not Exceeding 600Volts", C26-1926, October 1926. .4 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Totally Enclosed air-break Circuit Breakers for Voltages not exceeding 660 Volts" - C27 - 1926, September 1926. .5 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Totally Enclosed air-break Switches for Voltages not exceeding 660 Volts" - C28 - 1926, December 1926. .6 - Book - 24 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard "Metallic Resistance Materials for Electrical Purposes" - C29-1926, November 1926. .7 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Face Plate controllers and resistances for use therewith Electric Motors (DC and AC Slip ring)" - C31-1926 - December 1926. .8 - Book - 28 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Australian Standard "Contactor Controllers and Resistances for use therewith Electric Motors (DC and AC Slip ring)" - C32-1926 - December 1926. .9 Book - 36 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Electrical Performance of Industrial Electric Motors and Generators with class A insulation" - C34-1927, October 1927 with a green label dated September 1932 advised that the tentative standard has been endorsed as a Standard with amendment. .10 - Book - 56 pages + grey covers, side stapled, issued by the Australian Commonwealth Engineering Standards Association, Tentative Australian Standard - "Electrical Performance of Large Electric Generators and Motors - Rating permitting overloads" - C35-1927, April 1927 with a green label dated September 1932 advised that the tentative standard has been endorsed as a Standard with amendment. On top right hand corner has the date stamp of the "The Electric Supply Co. of Victoria Ltd Ballarat" trams, tramways, power station, standards, materials, electrical systems -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumSoap, TI-TROL ANTISEPTIC AND GERMICIDAL TOILET SOAP, c. 1928-1968

TROVE : Evening News (Sydney, NSW : 1869 - 1931), Thursday 11 October 1928, page 13. NEW COMPANIES The following new companies were registered this afternoon :- Australian Essential Oils Ltd : Nominal capital. £50,000, in 93.000 ordinary and 7,000 deferred shares at 10/-. to engage in business of distillers, manufacturers of, and dealers in oils from vegetables and other sub-stances, chemists etc. First directors: N. H.B.Keynor, R.K.Allport, E.M Humphries, and H. James. Head office Sydney. TROVE : Government Gazette of the State of New South Wales (Sydney, NSW : 1901 - 2001), Friday 26 July 1968 (No.89), page 3028 IN the matter of the Companies Act, 1961-1966, and in the matter of AUSTRALIAN ESSENTIAL OILS LTD (Receiver and Manager Appointed).—Roy Leslie Pegler, Receiver and Manager of Australian Essential Oils Ltd (Receiver and Manager Appointed)„ appointed by debenture holders on the 11 th July, 1966, hereby gives notice that any debenture holders and others having any claim against or to Australian Essential Oils Ltd (Receiver and Manager Appointed) are required to send particulars of their debenture or claim to the Receiver, Roy Leslie Pegler, at c.o. Messrs Pegler, Ellis & Co., Chartered Accountants, 235-7 Elizabeth Street, Sydney, N.S.W., on or before the 27th September, 1968, at the expiration of which time the Receiver and Manager will distribute the assets of the said Company to the persons and/or companies entitled, having regard only to the claims of which he then has notice.—Dated 24th July, 1968. PEGLER, ELLIS & CO., Chartered Accountants, 235-7 Elizabeth Street, Sydney, N.S.W. 8744—$5 White cardboard box printed in dark green with a round blue and white sticker on one side, containing a cream paper leaflet printed in dark green, wrapped around a greaseproof paper wrapped rectangular cake of translucent brown soap with impressed text on one side.Impressed on one side of the cake of soap ' A PRODUCT OF AUSTRALIAN ESSENTIAL OILS LTD SYDNEY'. On reverse of soap impressed 'TI-TROL ANTISEPTIC TOU\ILET SOAP'. Printed on the box 'TI-TROL ANTISEPTIC AND GERMICIDAL TOILET SOAP. Printed Leaflet wrapped around cake of soap 'Germicide TI-TROL Antiseptic, Toilet Soap ELEVEN TIMES MORE POWERFUL THAN CARBOLIC. NON IRRITANT ………NON POISONOUS. “Ti –Trol” GERMICIDAL ANTISEPTIC SOAP is the most modern of all toilet soap …..Distilled and manufactured by Australian Essential Oils Ltd., the pioneers of Tea-Tree Oil Industry in Australia, and manufacturers of that famous antiseptic solution Melasol. It has taken years of patient research, of test, trial and experiment to reach the pinnacle of perfection which Ti-Trol Soap is now offering to the public. Ti-Trol is a hand-made glycerine base soap in which only the finest ingredients are used. One of its most attractive features is that it contains a full three per cent. of “Ti-trol”. In medical and clinical practice, both in Australia and abroad, Ti Trol has given remarkable results…particularly in its cleansing properties: its soothing HEALING action on dirty and inflamed septic wounds. By incorporating Ti-Trol in a glycerine base soap, experts are agreed that the result….. Ti-Trol soap is unequalled-anywhere- for its soft soothing healing and germicidal properties. Ti-Trol soap is non-irritant and non-poisonous and can be used on the tenderest skins…babies’ or the most delicate peach-bloom complexions, with most excellent results. . PRODUCT OF A SOAP MAKER OF INTERNATIONAL EXPERIENCE Australian Essential Oils Ltd., have been fortunate in procuring the services of a soap-maker of International experience and world-wide knowledge of Soap Production, whose genius has produced Ti-Trol, and whose uncanny sense of blending has made Ti-Trol the most famous of all Germicidal Toilet Soaps. Ti-Trol is non-irritant and non-poisonous and has been proved by medical and specialised authorities top\ possess great healing and cleansing properties. It is a powerful Germicide and antiseptic….ELEVEN TIMES QUICKER THAN PURE CARBOLIC. . DANDRUFF CAN’T LIVE WITH Ti-Trol. Dandruff ......that horrible “give away” which many men and women suffer from…..can easily be dispelled by using Ti-Trol Soap this way : Rub a little Olive Oil into the scalp before retiring at night, and the following morning wash your head thoroughly with Ti-Trol Soap, allowing the lather to remain on the scalp for about a minute and a half. Then rinse the hair thoroughly in warm water. .WASH BRUSHES AND COMBS WITH Ti-Trol SOAP When you’ve done this and dried your hair, wash all your brushes and combs in a strong, soapy solution made with Ti-Trol Soap, and then carefully sponge the inside of the hat bands with a flannel or cloth moistened with this soapy solution. Follow these directions and you’ll never need to fear dandruff. .Ti-Trol…WONDERFUL HEALER OF CUTS. SORES, WOUNDS, ETC. There never was a more patent healer of CUTS, SORES, WOUNDS, ABRASIONS AND SEPTIC SORES than Ti-Trol… Here’s how to use it : Wash the affected parts with a fairly strong Ti-Trol soapy solution made with warm water, and then apply with lint soaked with Melasol, which is the miscible form of Ti-Trol (Melasol is obtainable at all chemists and stores everywhere). . Ti-Trol SOAP……..A DEODORANT, A BEAUTIFIER……a safeguard for tender skins Ti-Trol Soap, because of its delicate, pungent, aroma and antiseptic properties, is unequalled as a deodorant, and is never failing when used for this purpose. Ti-Trol Soap can be used on the tenderest skins, and even baby’s skin, with greatest safety. It’s delightful fragrance will give added pleasure to your toilet. . DO NOT WASTE Ti-Trol Soap is too valuable to waste. Therefore, use it carefully. Do not leave it in the water. To obtain greatest economy it is preferable to use a face cloth when using Ti-Trol Soap. For health, for the most economical means of insuring against disease, use Ti-Trol Ointment…..for cuts, bruises etc. Ti-Trol….for boils, cuts, sores, abrasions and septic conditions. MELASOL…..for Tinea, Mouth Wash and as a Dentifice. . All are products containing Ti-Trol, distilled and provided by Australian Essential Oils Ltd. 18 Loftus Street, Sydney. N.S.W.'. tea tree oil, soap, glycerine, antisptic, germicide -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Eltham District Historical Society Inc

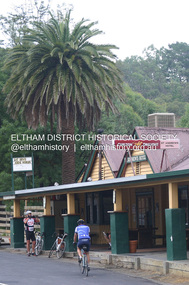

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, St Andrews Hotel, 2 February 2008

The c1860 St Andrews Hotel, with the c1930 additions, and the Canary Island Palm, and the surrounding site to the title boundaries are historically, socially and aesthetically significant to the Shire of Nillumbik. The St Andrews Hotel is historically significant because it may have given its name 'St Andrews' to the town (another suggestion is that the name came from St Andrews church) and for its connection to Ewen Hugh Cameron (1831-1915) the prosperous local farmer, member of the Eltham Roads Board/Shire Council and local MP. It is also significant as the oldest hotel building in the former Shire of Eltham, as one of the few surviving buildings connected with the Caledonian goldfields era and as one of a handful of early structures to have survived the 1960s bushfires; the additions and alterations to the hotel reflect its long life. The hotel is socially significant because it has served as an important meeting place for more than 160 years. The Canary Island Palm is historically significant as a rare example of exotic tree planting in this rural area. The tree is aesthetically and historically significant as a local landmark and for its contribution to the streetscape and landscape value. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p71 Built around 1860, St Andrews Hotel has changed little since it first welcomed thirsty gold diggers from the Caledonia Goldfields. The timber building, with gabled roof, beamed ceilings and a massive fireplace, is Nillumbik Shire’s oldest hotel and has always been an important community centre, particularly in its early days. Fortunately, the hotel and the near-by Canary Island Palm Tree, which is quite rare in this area, survived the 1960s bushfires, along with a few other early buildings. St Andrews (formerly Queenstown) was founded on gold, as were Panton Hill (formerly Kingstown), Research and Diamond Creek, from the mid-1850s to the 1860s. But by the early 20th century common use changed the name Queenstown to St Andrews, possibly after this hotel or after the church or the mining district.1 The Caledonia Diggings were probably named by Scottish settlers after the Roman name for Scotland, despite this land bearing little similarity to their homeland.2 Queenstown, which was proclaimed as a township in 1861, was the gold-mining centre on the Upper Diamond and in the 1850s had up to 600 European inhabitants and a small camp of Chinese on the flats along the creek. Queenstown was the administrative centre of the Upper Diamond with three hotels, a brewery and a slaughterhouse.3 It is unclear which hotel was the district’s first, as distinct from the earliest unlicensed grog shops, some of which operated in tents. John Corke Knell was one of eight unlicensed storekeepers supplying drink to miners at Caledonia in 1857, named by Sgt. McNamara of the Caledonia Police Station.4 In February 1859, Knell apparently bought most of the present hotel’s site at the first township land sales. As he was a local storekeeper, he might have first established a store there.5 Knell and his wife Eliza were early licensees of the St Andrews Hotel. The hotel had eight bedrooms – including three for public use – and the dining-room seated 30 people. It is thought they named the hotel St Andrews after Eliza’s hometown of St Andrews in Scotland. St Andrews Hotel was an important local centre in several ways. In the same building the Knells also operated a post office and general store. In 1867 Mrs Knell was appointed Deputy Registrar of Births and Deaths for Queenstown. The hotel was also used to hold inquests into people’s deaths when the police residence became too small.6 The hotel also became a fashionable destination at Christmas for parties from Melbourne. In 1868, possibly following her husband’s death, Mrs Knell applied for a temporary licence, which was then transferred to Robert Smith after their marriage in 1869. But then, possibly after Robert’s death, Mrs Smith operated the hotel until 1892. This contradicts a report in The Evelyn Observer 1882 that JC Knells of the St Andrews Hotel was granted a publican’s licence in the Queenstown Police Court. At that time he was supposed to have been dead for around 14 years! Although Mrs Smith was a respected citizen, known for her geniality and as an ideal hostess, she had a minor brush with the law when she was fined ten shillings for not lighting a lamp outside her licensed premises.7 From 1892 several publicans owned the hotel including W Atkins, from 1895. In 1909 the licensee was apparently Mrs Smith’s son, Walter Knell, who held the licence until at least the 1920s. Not surprisingly, this old hotel has attracted romantic stories. Mrs Smith is said to be seen roaming the pub in her nightdress – even though she was buried in the Queenstown Cemetery in 1911.8 A musical The Hero of Queenstown, set in the hotel, was written and produced by local actor Reg Evans in the 1970s.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, st andrews hotel -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - Duplicates - see Description

-

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Colour Print, Nathan Islip, Eltham Library under construction, c.1993

Photo taken by Nathan Islip who at the time was studying Architecture at the University of Melbourne. During his experience year he worked as a builder's labourer on the new Eltham Library construction project. Eltham Library Service 1930s - 1994 Originally collated by Harry Gilham, President, Eltham District Historical Society Inc (1993-2009) (edited 2022) In the Eltham township area, in the early 1930s, library books for adults were available from E J Andrew's newsagency in Main Road. In the newsagency cum haberdashery, some shelves were set aside for a lending library of adults' books. In 1935, Mr & Mrs JC Rains purchased the newsagency and continued the lending service until the late 1940s. At this time the business was extended from haberdashery to sell ladies' and men's clothing. The library section was discontinued. In the 1930s a mobile book library was also run by a Mr Foster of Bible Street, Eltham. In the 1950s adult books were available from racks in the foyer of the Eltham Shire Offices which was then located beside the Eltham Hall on the comer of Arthur Street and Main Road. In the early 1950s a referendum of ratepayers was called to seek public opinion on the issue of raising money for a public library for which the rates would have to be increased - the motion was defeated. On 11 November 1965 Eltham Shire Council, in conjunction with the City of Heidelberg and the Shire of Diamond Valley, met to form the Heidelberg Regional Library Service. Eltham was represented by Councillors Charis Pelling and John Lewis. The first library service for the Shire of Eltham from this group came in the shape of a bookmobile van which had, amongst others, a central stopover near the Shillinglaw trees outside the newly opened Shire offices at 895 Main Road, the original site of Shillinglaw Cottage and the former Shillinglaw farm. Present-day Wingrove Park was another stopover and the many recorded requests for this service can be read as denoting the areas of population or gathering points at that period throughout the Shire. 1968 saw the Shire convert the ‘Brinkkotter’ house in Dudley Street to house both adult and children's books. This library was originally staffed from the City of Heidelberg Library and records of committee meetings range from borrowing Heidelberg's old library shelving to trying to increase the Government's subsidy to a dollar for dollar basis. Book loans in the period 1966-67 totalled 30,400 and the following year ran to 52,113. With 2 books plus 1 paperback the limit per person, it was overcrowded and unable to house the range of other services which had become common library stock. Planning to extend the Shire Offices by the addition of the south wing was an opportunity to re-house the Shire's Library. The opening of the library in the extension was carried out on 17th August 1971 by the Hon R J Hamer ED, MP, Chief Secretary of Victoria. Cr Geoffrey Dreverman officiated as the Shire President. The Heidelberg Regional Library Service continued until September 1985 when it disbanded. On 21 November 1985 the Yarra Plenty Regional Library Service was established. At that time Eltham was represented by Councillors Mary Grant and Robert Manuell. By 1987, over-crowding of the Eltham Library and an inability to house the range of other services yet again rose to prominence. At a Council meeting held on 1 June 1987, the Councillors supported a resolution which threatened to close the library on 30 September 1987. Council's frustration arose from yet another re-run of the annual State Government versus Council Library funding and records show first arose in Eltham Council in 1967 with the Government of 1he day. After prolonged public anger and petitions the motion to close the library was rescinded in August 1987. Council, considering the community's concern, set up a ‘Library Review Working Party’ which a year later became the Library Occasional Committee with direct access to Council. This Committee investigated the workings of the 386 square metre library and found inadequate space for storage and display, lack of equipment, out-of-date furniture together with an increasing patronage which resulted in queues of borrowers becoming longer no matter when the library was open. Community consultation took the form of 1,000 questionnaires sent to users and non-users along with noticeboard reminders of what was planned. Council developed a strategy to set aside capital funds from 1988 on an annual basis so that preliminary planning and consultative expenses could be met, and construction could be completed early 1997. The Committee visited metropolitan libraries which were catering for a similar population as was projected for Eltham. Australia-wide Federal Government funding grants under the Local Capital Works Program became available from October 1992 for community projects endorsed by local Councils. The Eltham Council submitted a proposal, based on library findings and requirements accumulated by the Library Occasional Committee, to the Federal Grants Committee to build a new Eltham Library. The Federal Grants Committee supported the funding request allowing commencement of the library project three years earlier than planned. With finance finalised, the Council set up its Eltham Library Re-development Special Committee which was given the task of overseeing what could be the last major expansion of the Shire's Library Service as Eltham's population nears its projected maximum. The new library was designed by Gregory Burgess and Peter Ryan of Gregory Burgess Pty Ltd. Construction of the library commenced in 1993 and was officially opened May 22nd, 1994. The library building was designed to reflect its parkland setting. External features include: the roof which includes interesting aspects when viewed from Main Road; verandahs which provide ramp access and give a sheltered entrance to the building; walls which feature locally made mudbricks, conventional bricks and copper panels; and space for an outdoor courtyard/reading area which will be developed later. Internally there are several features. The building includes a foyer with a fireplace suitable for displays including artwork, a community multi-purpose room suitable for meetings or functions and an outdoor cafeteria. The ceilings are lined with Victorian Ash. The shapes for the ceiling give a free-flowing form to the building. Brush Box has been used for the circulation and information desks. The tree trunk columns are Grey lronbark from New South Wales. Arches and various-shaped windows add interest to the internal structure. The carpet design reflects the Eltham environment and compliments the natural colours and timbers used in the building. Tiles by artist Felix Bosari feature in the building and additional art by local artists added externally and internally to the building. Since 1994 the library has undergone a major extension to cater for children’s services and others. See also EDHS_02111 construction, eltham library -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Colour Print, Nathan Islip, Eltham Library under construction, c.1994

Photo taken by Nathan Islip who at the time was studying Architecture at the University of Melbourne. During his experience year he worked as a builder's labourer on the new Eltham Library construction project. Eltham Library Service 1930s - 1994 Originally collated by Harry Gilham, President, Eltham District Historical Society Inc (1993-2009) (edited 2022) In the Eltham township area, in the early 1930s, library books for adults were available from E J Andrew's newsagency in Main Road. In the newsagency cum haberdashery, some shelves were set aside for a lending library of adults' books. In 1935, Mr & Mrs JC Rains purchased the newsagency and continued the lending service until the late 1940s. At this time the business was extended from haberdashery to sell ladies' and men's clothing. The library section was discontinued. In the 1930s a mobile book library was also run by a Mr Foster of Bible Street, Eltham. In the 1950s adult books were available from racks in the foyer of the Eltham Shire Offices which was then located beside the Eltham Hall on the comer of Arthur Street and Main Road. In the early 1950s a referendum of ratepayers was called to seek public opinion on the issue of raising money for a public library for which the rates would have to be increased - the motion was defeated. On 11 November 1965 Eltham Shire Council, in conjunction with the City of Heidelberg and the Shire of Diamond Valley, met to form the Heidelberg Regional Library Service. Eltham was represented by Councillors Charis Pelling and John Lewis. The first library service for the Shire of Eltham from this group came in the shape of a bookmobile van which had, amongst others, a central stopover near the Shillinglaw trees outside the newly opened Shire offices at 895 Main Road, the original site of Shillinglaw Cottage and the former Shillinglaw farm. Present-day Wingrove Park was another stopover and the many recorded requests for this service can be read as denoting the areas of population or gathering points at that period throughout the Shire. 1968 saw the Shire convert the ‘Brinkkotter’ house in Dudley Street to house both adult and children's books. This library was originally staffed from the City of Heidelberg Library and records of committee meetings range from borrowing Heidelberg's old library shelving to trying to increase the Government's subsidy to a dollar for dollar basis. Book loans in the period 1966-67 totalled 30,400 and the following year ran to 52,113. With 2 books plus 1 paperback the limit per person, it was overcrowded and unable to house the range of other services which had become common library stock. Planning to extend the Shire Offices by the addition of the south wing was an opportunity to re-house the Shire's Library. The opening of the library in the extension was carried out on 17th August 1971 by the Hon R J Hamer ED, MP, Chief Secretary of Victoria. Cr Geoffrey Dreverman officiated as the Shire President. The Heidelberg Regional Library Service continued until September 1985 when it disbanded. On 21 November 1985 the Yarra Plenty Regional Library Service was established. At that time Eltham was represented by Councillors Mary Grant and Robert Manuell. By 1987, over-crowding of the Eltham Library and an inability to house the range of other services yet again rose to prominence. At a Council meeting held on 1 June 1987, the Councillors supported a resolution which threatened to close the library on 30 September 1987. Council's frustration arose from yet another re-run of the annual State Government versus Council Library funding and records show first arose in Eltham Council in 1967 with the Government of 1he day. After prolonged public anger and petitions the motion to close the library was rescinded in August 1987. Council, considering the community's concern, set up a ‘Library Review Working Party’ which a year later became the Library Occasional Committee with direct access to Council. This Committee investigated the workings of the 386 square metre library and found inadequate space for storage and display, lack of equipment, out-of-date furniture together with an increasing patronage which resulted in queues of borrowers becoming longer no matter when the library was open. Community consultation took the form of 1,000 questionnaires sent to users and non-users along with noticeboard reminders of what was planned. Council developed a strategy to set aside capital funds from 1988 on an annual basis so that preliminary planning and consultative expenses could be met, and construction could be completed early 1997. The Committee visited metropolitan libraries which were catering for a similar population as was projected for Eltham. Australia-wide Federal Government funding grants under the Local Capital Works Program became available from October 1992 for community projects endorsed by local Councils. The Eltham Council submitted a proposal, based on library findings and requirements accumulated by the Library Occasional Committee, to the Federal Grants Committee to build a new Eltham Library. The Federal Grants Committee supported the funding request allowing commencement of the library project three years earlier than planned. With finance finalised, the Council set up its Eltham Library Re-development Special Committee which was given the task of overseeing what could be the last major expansion of the Shire's Library Service as Eltham's population nears its projected maximum. The new library was designed by Gregory Burgess and Peter Ryan of Gregory Burgess Pty Ltd. Construction of the library commenced in 1993 and was officially opened May 22nd, 1994. The library building was designed to reflect its parkland setting. External features include: the roof which includes interesting aspects when viewed from Main Road; verandahs which provide ramp access and give a sheltered entrance to the building; walls which feature locally made mudbricks, conventional bricks and copper panels; and space for an outdoor courtyard/reading area which will be developed later. Internally there are several features. The building includes a foyer with a fireplace suitable for displays including artwork, a community multi-purpose room suitable for meetings or functions and an outdoor cafeteria. The ceilings are lined with Victorian Ash. The shapes for the ceiling give a free-flowing form to the building. Brush Box has been used for the circulation and information desks. The tree trunk columns are Grey lronbark from New South Wales. Arches and various-shaped windows add interest to the internal structure. The carpet design reflects the Eltham environment and compliments the natural colours and timbers used in the building. Tiles by artist Felix Bosari feature in the building and additional art by local artists added externally and internally to the building. Since 1994 the library has undergone a major extension to cater for children’s services and others. See also EDHS_02111 construction, eltham library -

Eltham District Historical Society Inc

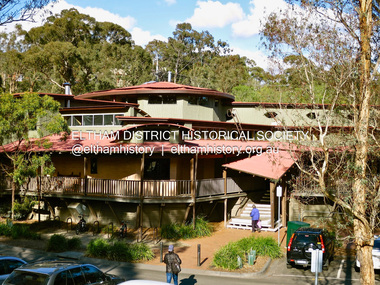

Eltham District Historical Society IncPhotograph - Digital Photograph, Jim Connor, Eltham Library, 11 August 2015

Designed by multi-award-winning architect, Gregory Burgess, for which he won the 1995 Royal Australian Institute of architects (Vic.) Merit Award in the New Institutional category. Eltham Library Service 1930s - 1994 Originally collated by Harry Gilham, President, Eltham District Historical Society Inc (1993-2009) (edited 2022) In the Eltham township area, in the early 1930s, library books for adults were available from E J Andrew's newsagency in Main Road. In the newsagency cum haberdashery, some shelves were set aside for a lending library of adults' books. In 1935, Mr & Mrs JC Rains purchased the newsagency and continued the lending service until the late 1940s. At this time the business was extended from haberdashery to sell ladies' and men's clothing. The library section was discontinued. In the 1930s a mobile book library was also run by a Mr Foster of Bible Street, Eltham. In the 1950s adult books were available from racks in the foyer of the Eltham Shire Offices which was then located beside the Eltham Hall on the comer of Arthur Street and Main Road. In the early 1950s a referendum of ratepayers was called to seek public opinion on the issue of raising money for a public library for which the rates would have to be increased - the motion was defeated. On 11 November 1965 Eltham Shire Council, in conjunction with the City of Heidelberg and the Shire of Diamond Valley, met to form the Heidelberg Regional Library Service. Eltham was represented by Councillors Charis Pelling and John Lewis. The first library service for the Shire of Eltham from this group came in the shape of a bookmobile van which had, amongst others, a central stopover near the Shillinglaw trees outside the newly opened Shire offices at 895 Main Road, the original site of Shillinglaw Cottage and the former Shillinglaw farm. Present-day Wingrove Park was another stopover and the many recorded requests for this service can be read as denoting the areas of population or gathering points at that period throughout the Shire. 1968 saw the Shire convert the ‘Brinkkotter’ house in Dudley Street to house both adult and children's books. This library was originally staffed from the City of Heidelberg Library and records of committee meetings range from borrowing Heidelberg's old library shelving to trying to increase the Government's subsidy to a dollar for dollar basis. Book loans in the period 1966-67 totalled 30,400 and the following year ran to 52,113. With 2 books plus 1 paperback the limit per person, it was overcrowded and unable to house the range of other services which had become common library stock. Planning to extend the Shire Offices by the addition of the south wing was an opportunity to re-house the Shire's Library. The opening of the library in the extension was carried out on 17th August 1971 by the Hon R J Hamer ED, MP, Chief Secretary of Victoria. Cr Geoffrey Dreverman officiated as the Shire President. The Heidelberg Regional Library Service continued until September 1985 when it disbanded. On 21 November 1985 the Yarra Plenty Regional Library Service was established. At that time Eltham was represented by Councillors Mary Grant and Robert Manuell. By 1987, over-crowding of the Eltham Library and an inability to house the range of other services yet again rose to prominence. At a Council meeting held on 1 June 1987, the Councillors supported a resolution which threatened to close the library on 30 September 1987. Council's frustration arose from yet another re-run of the annual State Government versus Council Library funding and records show first arose in Eltham Council in 1967 with the Government of 1he day. After prolonged public anger and petitions the motion to close the library was rescinded in August 1987. Council, considering the community's concern, set up a ‘Library Review Working Party’ which a year later became the Library Occasional Committee with direct access to Council. This Committee investigated the workings of the 386 square metre library and found inadequate space for storage and display, lack of equipment, out-of-date furniture together with an increasing patronage which resulted in queues of borrowers becoming longer no matter when the library was open. Community consultation took the form of 1,000 questionnaires sent to users and non-users along with noticeboard reminders of what was planned. Council developed a strategy to set aside capital funds from 1988 on an annual basis so that preliminary planning and consultative expenses could be met, and construction could be completed early 1997. The Committee visited metropolitan libraries which were catering for a similar population as was projected for Eltham. Australia-wide Federal Government funding grants under the Local Capital Works Program became available from October 1992 for community projects endorsed by local Councils. The Eltham Council submitted a proposal, based on library findings and requirements accumulated by the Library Occasional Committee, to the Federal Grants Committee to build a new Eltham Library. The Federal Grants Committee supported the funding request allowing commencement of the library project three years earlier than planned. With finance finalised, the Council set up its Eltham Library Re-development Special Committee which was given the task of overseeing what could be the last major expansion of the Shire's Library Service as Eltham's population nears its projected maximum. The new library was designed by Gregory Burgess and Peter Ryan of Gregory Burgess Pty Ltd. Construction of the library commenced in 1993 and was officially opened May 22nd, 1994. The library building was designed to reflect its parkland setting. External features include: the roof which includes interesting aspects when viewed from Main Road; verandahs which provide ramp access and give a sheltered entrance to the building; walls which feature locally made mudbricks, conventional bricks and copper panels; and space for an outdoor courtyard/reading area which will be developed later. Internally there are several features. The building includes a foyer with a fireplace suitable for displays including artwork, a community multi-purpose room suitable for meetings or functions and an outdoor cafeteria. The ceilings are lined with Victorian Ash. The shapes for the ceiling give a free-flowing form to the building. Brush Box has been used for the circulation and information desks. The tree trunk columns are Grey lronbark from New South Wales. Arches and various-shaped windows add interest to the internal structure. The carpet design reflects the Eltham environment and compliments the natural colours and timbers used in the building. Tiles by artist Felix Bosari feature in the building and additional art by local artists added externally and internally to the building. Since 1994 the library has undergone a major extension to cater for children’s services and others. See also EDHS_02111jim connor collection, eltham, eltham library, panther place -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Jim Connor, Eltham Library, 7 May 2016

Designed by multi-award winning architect, Gregory Burgess, for which he won the 1995 Royal Australian Insitute of architects (Vic.) Merit Award in the New Institutional category. Eltham Library Service 1930s - 1994 Originally collated by Harry Gilham, President, Eltham District Historical Society Inc (1993-2009) (edited 2022) In the Eltham township area, in the early 1930s, library books for adults were available from E J Andrew's newsagency in Main Road. In the newsagency cum haberdashery, some shelves were set aside for a lending library of adults' books. In 1935, Mr & Mrs JC Rains purchased the newsagency and continued the lending service until the late 1940s. At this time the business was extended from haberdashery to sell ladies' and men's clothing. The library section was discontinued. In the 1930s a mobile book library was also run by a Mr Foster of Bible Street, Eltham. In the 1950s adult books were available from racks in the foyer of the Eltham Shire Offices which was then located beside the Eltham Hall on the comer of Arthur Street and Main Road. In the early 1950s a referendum of ratepayers was called to seek public opinion on the issue of raising money for a public library for which the rates would have to be increased - the motion was defeated. On 11 November 1965 Eltham Shire Council, in conjunction with the City of Heidelberg and the Shire of Diamond Valley, met to form the Heidelberg Regional Library Service. Eltham was represented by Councillors Charis Pelling and John Lewis. The first library service for the Shire of Eltham from this group came in the shape of a bookmobile van which had, amongst others, a central stopover near the Shillinglaw trees outside the newly opened Shire offices at 895 Main Road, the original site of Shillinglaw Cottage and the former Shillinglaw farm. Present-day Wingrove Park was another stopover and the many recorded requests for this service can be read as denoting the areas of population or gathering points at that period throughout the Shire. 1968 saw the Shire convert the ‘Brinkkotter’ house in Dudley Street to house both adult and children's books. This library was originally staffed from the City of Heidelberg Library and records of committee meetings range from borrowing Heidelberg's old library shelving to trying to increase the Government's subsidy to a dollar for dollar basis. Book loans in the period 1966-67 totalled 30,400 and the following year ran to 52,113. With 2 books plus 1 paperback the limit per person, it was overcrowded and unable to house the range of other services which had become common library stock. Planning to extend the Shire Offices by the addition of the south wing was an opportunity to re-house the Shire's Library. The opening of the library in the extension was carried out on 17th August 1971 by the Hon R J Hamer ED, MP, Chief Secretary of Victoria. Cr Geoffrey Dreverman officiated as the Shire President. The Heidelberg Regional Library Service continued until September 1985 when it disbanded. On 21 November 1985 the Yarra Plenty Regional Library Service was established. At that time Eltham was represented by Councillors Mary Grant and Robert Manuell. By 1987, over-crowding of the Eltham Library and an inability to house the range of other services yet again rose to prominence. At a Council meeting held on 1 June 1987, the Councillors supported a resolution which threatened to close the library on 30 September 1987. Council's frustration arose from yet another re-run of the annual State Government versus Council Library funding and records show first arose in Eltham Council in 1967 with the Government of 1he day. After prolonged public anger and petitions the motion to close the library was rescinded in August 1987. Council, considering the community's concern, set up a ‘Library Review Working Party’ which a year later became the Library Occasional Committee with direct access to Council. This Committee investigated the workings of the 386 square metre library and found inadequate space for storage and display, lack of equipment, out-of-date furniture together with an increasing patronage which resulted in queues of borrowers becoming longer no matter when the library was open. Community consultation took the form of 1,000 questionnaires sent to users and non-users along with noticeboard reminders of what was planned. Council developed a strategy to set aside capital funds from 1988 on an annual basis so that preliminary planning and consultative expenses could be met, and construction could be completed early 1997. The Committee visited metropolitan libraries which were catering for a similar population as was projected for Eltham. Australia-wide Federal Government funding grants under the Local Capital Works Program became available from October 1992 for community projects endorsed by local Councils. The Eltham Council submitted a proposal, based on library findings and requirements accumulated by the Library Occasional Committee, to the Federal Grants Committee to build a new Eltham Library. The Federal Grants Committee supported the funding request allowing commencement of the library project three years earlier than planned. With finance finalised, the Council set up its Eltham Library Re-development Special Committee which was given the task of overseeing what could be the last major expansion of the Shire's Library Service as Eltham's population nears its projected maximum. The new library was designed by Gregory Burgess and Peter Ryan of Gregory Burgess Pty Ltd. Construction of the library commenced in 1993 and was officially opened May 22nd, 1994. The library building was designed to reflect its parkland setting. External features include: the roof which includes interesting aspects when viewed from Main Road; verandahs which provide ramp access and give a sheltered entrance to the building; walls which feature locally made mudbricks, conventional bricks and copper panels; and space for an outdoor courtyard/reading area which will be developed later. Internally there are several features. The building includes a foyer with a fireplace suitable for displays including artwork, a community multi-purpose room suitable for meetings or functions and an outdoor cafeteria. The ceilings are lined with Victorian Ash. The shapes for the ceiling give a free-flowing form to the building. Brush Box has been used for the circulation and information desks. The tree trunk columns are Grey lronbark from New South Wales. Arches and various-shaped windows add interest to the internal structure. The carpet design reflects the Eltham environment and compliments the natural colours and timbers used in the building. Tiles by artist Felix Bosari feature in the building and additional art by local artists added externally and internally to the building. Since 1994 the library has undergone a major extension to cater for children’s services and others. See also EDHS_02111jim connor collection, eltham, eltham library, panther place -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Jim Connor, Eltham Library, 25 December 2017

Designed by multi-award winning architect, Gregory Burgess, for which he won the 1995 Royal Australian Insitute of architects (Vic.) Merit Award in the New Institutional category. Eltham Library Service 1930s - 1994 Originally collated by Harry Gilham, President, Eltham District Historical Society Inc (1993-2009) (edited 2022) In the Eltham township area, in the early 1930s, library books for adults were available from E J Andrew's newsagency in Main Road. In the newsagency cum haberdashery, some shelves were set aside for a lending library of adults' books. In 1935, Mr & Mrs JC Rains purchased the newsagency and continued the lending service until the late 1940s. At this time the business was extended from haberdashery to sell ladies' and men's clothing. The library section was discontinued. In the 1930s a mobile book library was also run by a Mr Foster of Bible Street, Eltham. In the 1950s adult books were available from racks in the foyer of the Eltham Shire Offices which was then located beside the Eltham Hall on the comer of Arthur Street and Main Road. In the early 1950s a referendum of ratepayers was called to seek public opinion on the issue of raising money for a public library for which the rates would have to be increased - the motion was defeated. On 11 November 1965 Eltham Shire Council, in conjunction with the City of Heidelberg and the Shire of Diamond Valley, met to form the Heidelberg Regional Library Service. Eltham was represented by Councillors Charis Pelling and John Lewis. The first library service for the Shire of Eltham from this group came in the shape of a bookmobile van which had, amongst others, a central stopover near the Shillinglaw trees outside the newly opened Shire offices at 895 Main Road, the original site of Shillinglaw Cottage and the former Shillinglaw farm. Present-day Wingrove Park was another stopover and the many recorded requests for this service can be read as denoting the areas of population or gathering points at that period throughout the Shire. 1968 saw the Shire convert the ‘Brinkkotter’ house in Dudley Street to house both adult and children's books. This library was originally staffed from the City of Heidelberg Library and records of committee meetings range from borrowing Heidelberg's old library shelving to trying to increase the Government's subsidy to a dollar for dollar basis. Book loans in the period 1966-67 totalled 30,400 and the following year ran to 52,113. With 2 books plus 1 paperback the limit per person, it was overcrowded and unable to house the range of other services which had become common library stock. Planning to extend the Shire Offices by the addition of the south wing was an opportunity to re-house the Shire's Library. The opening of the library in the extension was carried out on 17th August 1971 by the Hon R J Hamer ED, MP, Chief Secretary of Victoria. Cr Geoffrey Dreverman officiated as the Shire President. The Heidelberg Regional Library Service continued until September 1985 when it disbanded. On 21 November 1985 the Yarra Plenty Regional Library Service was established. At that time Eltham was represented by Councillors Mary Grant and Robert Manuell. By 1987, over-crowding of the Eltham Library and an inability to house the range of other services yet again rose to prominence. At a Council meeting held on 1 June 1987, the Councillors supported a resolution which threatened to close the library on 30 September 1987. Council's frustration arose from yet another re-run of the annual State Government versus Council Library funding and records show first arose in Eltham Council in 1967 with the Government of 1he day. After prolonged public anger and petitions the motion to close the library was rescinded in August 1987. Council, considering the community's concern, set up a ‘Library Review Working Party’ which a year later became the Library Occasional Committee with direct access to Council. This Committee investigated the workings of the 386 square metre library and found inadequate space for storage and display, lack of equipment, out-of-date furniture together with an increasing patronage which resulted in queues of borrowers becoming longer no matter when the library was open. Community consultation took the form of 1,000 questionnaires sent to users and non-users along with noticeboard reminders of what was planned. Council developed a strategy to set aside capital funds from 1988 on an annual basis so that preliminary planning and consultative expenses could be met, and construction could be completed early 1997. The Committee visited metropolitan libraries which were catering for a similar population as was projected for Eltham. Australia-wide Federal Government funding grants under the Local Capital Works Program became available from October 1992 for community projects endorsed by local Councils. The Eltham Council submitted a proposal, based on library findings and requirements accumulated by the Library Occasional Committee, to the Federal Grants Committee to build a new Eltham Library. The Federal Grants Committee supported the funding request allowing commencement of the library project three years earlier than planned. With finance finalised, the Council set up its Eltham Library Re-development Special Committee which was given the task of overseeing what could be the last major expansion of the Shire's Library Service as Eltham's population nears its projected maximum. The new library was designed by Gregory Burgess and Peter Ryan of Gregory Burgess Pty Ltd. Construction of the library commenced in 1993 and was officially opened May 22nd, 1994. The library building was designed to reflect its parkland setting. External features include: the roof which includes interesting aspects when viewed from Main Road; verandahs which provide ramp access and give a sheltered entrance to the building; walls which feature locally made mudbricks, conventional bricks and copper panels; and space for an outdoor courtyard/reading area which will be developed later. Internally there are several features. The building includes a foyer with a fireplace suitable for displays including artwork, a community multi-purpose room suitable for meetings or functions and an outdoor cafeteria. The ceilings are lined with Victorian Ash. The shapes for the ceiling give a free-flowing form to the building. Brush Box has been used for the circulation and information desks. The tree trunk columns are Grey lronbark from New South Wales. Arches and various-shaped windows add interest to the internal structure. The carpet design reflects the Eltham environment and compliments the natural colours and timbers used in the building. Tiles by artist Felix Bosari feature in the building and additional art by local artists added externally and internally to the building. Since 1994 the library has undergone a major extension to cater for children’s services and others. See also EDHS_02111jim connor collection, eltham, eltham library, panther place -

Eltham District Historical Society Inc

Eltham District Historical Society IncAudio - Audio Compact Cassette Tape, Harry Gilham, Audio Recording; Eltham Library History presented by Harry Gilham, 1994

The new Eltham Library was opened 22 May 1994 and celebrates its 30th anniversay in 2024. This audio recording, presented by Harry Gilham, President of Eltham District Historical Society at the time of the opening is a summarised history of the Eltham Library service to 1994. Eltham Library Service 1930s - 1994 Originally collated by Harry Gilham, President, Eltham District Historical Society Inc (1993-2009) (edited 2022) In the Eltham township area, in the early 1930s, library books for adults were available from E J Andrew's newsagency in Main Road. In the newsagency come haberdashery, some shelves were set aside for a lending library of adults' books. In 1935, Mr & Mrs JC Rains purchased the newsagency and continued the lending service until the late 1940s. At this time the business was extended from haberdashery to sell ladies' and men's clothing. The library section was discontinued. In the 1930s a mobile book library was also run by a Mr Foster of Bible Street, Eltham. In the 1950s adult books were available from racks in the foyer of the Eltham Shire Offices which was then located beside the Eltham Hall on the comer of Arthur Street and Main Road. In the early 1950s a referendum of ratepayers was called to seek public opinion on the issue of raising money for a public library for which the rates would have to be increased - the motion was defeated. On 11 November 1965 Eltham Shire Council, in conjunction with the City of Heidelberg and the Shire of Diamond Valley, met to form the Heidelberg Regional Library Service. Eltham was represented by Councillors Charis Pelling and John Lewis. The first library service for the Shire of Eltham from this group came in the shape of a bookmobile van which had, amongst others, a central stopover near the Shillinglaw trees outside the newly opened Shire offices at 895 Main Road, the original site of Shillinglaw Cottage and the former Shillinglaw farm. Present-day Wingrove Park was another stopover and the many recorded requests for this service can be read as denoting the areas of population or gathering points at that period throughout the Shire. 1968 saw the Shire convert the ‘Brinkkotter’ house in Dudley Street to house both adult and children's books. This library was originally staffed from the City of Heidelberg Library and records of committee meetings range from borrowing Heidelberg's old library shelving to trying to increase the Government's subsidy to a dollar for dollar basis. Book loans in the period 1966-67 totalled 30,400 and the following year ran to 52,113. With 2 books plus 1 paperback the limit per person, it was overcrowded and unable to house the range of other services which had become common library stock. Planning to extend the Shire Offices by the addition of the south wing was an opportunity to re-house the Shire's Library. The opening of the library in the extension was carried out on 17th August 1971 by the Hon R J Hamer ED, MP, Chief Secretary of Victoria. Cr Geoffrey Dreverman officiated as the Shire President. The Heidelberg Regional Library Service continued until September 1985 when it disbanded. On 21 November 1985 the Yarra Plenty Regional Library Service was established. At that time Eltham was represented by Councillors Mary Grant and Robert Manuell. By 1987, over-crowding of the Eltham Library and an inability to house the range of other services yet again rose to prominence. At a Council meeting held on 1 June 1987, the Councillors supported a resolution which threatened to close the library on 30 September 1987. Council's frustration arose from yet another re-run of the annual State Government versus Council Library funding and records show first arose in Eltham Council in 1967 with the Government of 1he day. After prolonged public anger and petitions the motion to close the library was rescinded in August 1987. Council, considering the community's concern, set up a ‘Library Review Working Party’ which a year later became the Library Occasional Committee with direct access to Council. This Committee investigated the workings of the 386 square metre library and found inadequate space for storage and display, lack of equipment, out-of-date furniture together with an increasing patronage which resulted in queues of borrowers becoming longer no matter when the library was open. Community consultation took the form of 1,000 questionnaires sent to users and non-users along with noticeboard reminders of what was planned. Council developed a strategy to set aside capital funds from 1988 on an annual basis so that preliminary planning and consultative expenses could be met, and construction could be completed early 1997. The Committee visited metropolitan libraries which were catering for a similar population as was projected for Eltham. Australia-wide Federal Government funding grants under the Local Capital Works Program became available from October 1992 for community projects endorsed by local Councils. The Eltham Council submitted a proposal, based on library findings and requirements accumulated by the Library Occasional Committee, to the Federal Grants Committee to build a new Eltham Library. The Federal Grants Committee supported the funding request allowing commencement of the library project three years earlier than planned. With finance finalised, the Council set up its Eltham Library Re-development Special Committee which was given the task of overseeing what could be the last major expansion of the Shire's Library Service as Eltham's population nears its projected maximum. The new library was designed by Gregory Burgess and Peter Ryan of Gregory Burgess Pty Ltd. Construction of the library commenced in 1993 and was officially opened May 22nd, 1994. The library building was designed to reflect its parkland setting. External features include: the roof which includes interesting aspects when viewed from Main Road; verandahs which provide ramp access and give a sheltered entrance to the building; walls which feature locally made mudbricks, conventional bricks and copper panels; and space for an outdoor courtyard/reading area which will be developed later. Internally there are several features. The building includes a foyer with a fireplace suitable for displays including artwork, a community multi-purpose room suitable for meetings or functions and an outdoor cafeteria. The ceilings are lined with Victorian Ash. The shapes for the ceiling give a free-flowing form to the building. Brush Box has been used for the circulation and information desks. The tree trunk columns are Grey lronbark from New South Wales. Arches and various-shaped windows add interest to the internal structure. The carpet design reflects the Eltham environment and compliments the natural colours and timbers used in the building. Tiles by artist Felix Bosari feature in the building and additional art by local artists added externally and internally to the building. Since 1994 the library has undergone a major extension to cater for children’s services and others. See also EDHS_02111Digital file only recorded from Audio Cassette tape on loan Converted to MP3 file; 11.1MB, 0:08:49eltham library, opening, harry gilham, harry gilham collection, 1994, audio cassette, audio recording -

University of Melbourne, Burnley Campus Archives

University of Melbourne, Burnley Campus ArchivesPhotograph - Black and white prints, Publicity Branch Victorian Department of Agriculture et al, Plants, 1957-1963

Black and white photographs, many labelled. Flowers, trees, propagation, signs, etc. Some for Journal articles. Publicity Branch Victorian Department of Agriculture: (1) 2 copies, C.1768A "Camellias Geraniums." (2) c.1262D "Anemone japonica." ((4) c.1262K "Hibiscus Wilder's White." (5) "Peace." (7) D521A Fruit tree. (8) c.1262E "Helenium autumnale." (9) c.1262I "Gerri Hock?" (12) c.1262F "Golden Ash. " (13) Struck cuttings 05 7.6.57. (14) "Kumquat." (15) Path to Principal's Residence. (16) A479 "Thujopsis dolobrata. Make an excellent tub specimen of the spreading type." (17) A477 "Aucuba japonica variegata. A very good foliage shrub for tubs. Sept '63 Jnl." (18) Struck cutting. (19-22) Arum, different views. (23) 2 copies ? (24) "June garden notes," small tree with roots. (25, 26) Different views ? (27)Pittosporum crassifolium. (28) "For Dec article (This is the one to use) Polyanthus are attractive & easily managed pot plants. (29) 2 copies ? (30) ? (31) Tubers. (32) "Oct Jnl" "Dividing the tubers. This is necessary to ensure that one eye is left etc." (33) Divided tuber. (34) Aucuba in pot. (35) ? (36) "Thuja plicata aurea a good tub plant of pyramid form." (37) "Buxus sempervirens. he English Box makes a neat, compact, low hedge." (38) "Cupressus torulosa is useful for a high narrow hedge for screening." (39) Sign giving information about different fertilizer treatments. (40) Sign comparing yield of Jonathons & Democrats with fertilzers. (41) "Russell Lupins." (42, 43) Different views ? (44) Soil profile in hole. (45) "Cyclamen is a good subject flowering over winter period." (46) "Cyclamen." (47) "Chabbads? & Malmaisons are suitable for bedding & make good cut flowers." (48) A478 "Seedlings." (49) A487 2 copies Roses in vase. (50) C.1767.E "Angophora 5-6 years." (51) C.1769.C "Jan '60 Jul. Ginko biloba Maidenhair Tree." (52) C.1768.C "Thuja plicata aurea, Golden Willow, Pinus radiata." (53) C.1762.I Vegetables. (54) A512 ?. (55) C.1767.C 2 copies "Eucalyptus torquata." (56) C.1769C 2 copies "Eucalyptus ficifolia." (57) C.1769.C 2 copies "Callistemon lanceolata( Bottle Brush.) (59) C.1769.B 2 copies "Pepperomias." (58) C.1769.F 2 copies "Melaleuca styphelioides (Paper Bark Tree.) (60) C.1769.D 2 copies "African Violets." (61) C.1768.F 2 copies "Pelargonium." (62) C.1768.B 2 copies "Tilia europea (Linden Tree.) Department of Agriculture Biology Branch: (6) Neg No 06 24.11.59 "A struck cutting of Rhododendron var. Alice. For a rhododendron this popular & beautiful variety strikes readily." (13) 05 5.6.57 Struck cuttings. No provenance: (3) "Araucaria excelsa, ?, ?, Metrosideros tomentosa." (10) "Thuja rheingold." (11) "Border of Geraniums (zonal Pelargoniums." (14) "Kumquat." (15) Path to Principal's Residence." (18) Struck cuttings. (19-22) Different views of Arum. (23) 2 copies ? (24-26) "June garden notes." Small tree with roots. (27) "Pittosporum crassifolium." (28) "For Dec article (This is the one to use) Polyanthus are attractive & easily managed pot plants." (29) 2 copies ? (30) ? (31) Tubers. (32) "Oct Jnl Dividing the the tubers. This is necessary to ensure that one eye is left etc." (33) Divided tuber. (34) Aucuba in pot. (35) ? (36) "Thuja plicata aurea a good tub plant of pyramid form. (37) "Buxus sempervirens. The English Box makes a neat, compact, low hedge." (38) Cupressus torulosa is useful for a high narrow hedge for screening." (39) Sign in Orchard giving information about different fertilizer treatments. (40) Sign in Orchard comparing yield of Jonathans and Democrats with fertilizers used. (41) "Russell lupins. (42-43) Different views ? (44) Soil profile in hole. (45) "Cyclamen is a good subject flowering over Winter period." (46) Cyclamen. (47) "Chabbads? & Malmaisons are suitable for bedding & make good cut flowers." flowers, trees, propagation, signs, camellias, geraniums, anemone japonica, hibiscus, fruit trees, principal's residence -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSouvenir - Rope Sample, before September 1891