Showing 773 items matching "mechanical"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Chair, Early 20th Century

The chair has been used since antiquity, although for many centuries it was a symbolic article of state and dignity rather than an article for ordinary use. "The chair" is still used as the emblem of authority in the House of Commons in the United Kingdom and Canada, and in many other settings. In keeping with this historical connotation of the "chair" as the symbol of authority, committees, boards of directors, and academic departments all have a 'chairman' or 'chair'. Endowed professorships are referred to as chairs. It was not until the 16th century that chairs became common. Until then, people sat on chests, benches, and stools, which were the ordinary seats of everyday life. The number of chairs which have survived from an earlier date is exceedingly limited; most examples are of ecclesiastical, seigneurial or feudal origin. Chairs were in existence since at least the Early Dynastic Period of Egypt (c. 3100 BC). They were covered with cloth or leather, were made of carved wood, and were much lower than today's chairs – chair seats were sometimes only 10 inches (25 cm) high. In ancient Egypt, chairs appear to have been of great richness and splendour. Fashioned of ebony and ivory, or of carved and gilded wood, they were covered with costly materials, magnificent patterns and supported upon representations of the legs of beasts or the figures of captives. Generally speaking, the higher ranked an individual was, the taller and more sumptuous was the chair he sat on and the greater the honour. On state occasions, the pharaoh sat on a throne, often with a little footstool in front of it.[ The average Egyptian family seldom had chairs, and if they did, it was usually only the master of the household who sat on a chair. Among the better off, the chairs might be painted to look like the ornate inlaid and carved chairs of the rich, but the craftsmanship was usually poor. The earliest images of chairs in China are from 6th-century Buddhist murals and stele, but the practice of sitting in chairs at that time was rare. It was not until the 12th century that chairs became widespread in China. Scholars disagree on the reasons for the adoption of the chair. The most common theories are that the chair was an outgrowth of indigenous Chinese furniture, that it evolved from a camp stool imported from Central Asia, that it was introduced to China by Christian missionaries in the 7th century, and that the chair came to China from India as a form of Buddhist monastic furniture. In modern China, unlike Korea or Japan, it is no longer common to sit at floor level. In Europe, it was owing in great measure to the Renaissance that the chair ceased to be a privilege of state and became a standard item of furniture for anyone who could afford to buy it. Once the idea of privilege faded the chair speedily came into general use. Almost at once the chair began to change every few years to reflect the fashions of the day. Thomas Edward Bowdich visited the main Palace of the Ashanti Empire in 1819, and observed chairs engrossed with gold in the empire. In the 1880s, chairs became more common in American households and usually there was a chair provided for every family member to sit down to dinner. By the 1830s, factory-manufactured “fancy chairs” like those by Sears, Roebuck, and Co. allowed families to purchase machined sets. With the Industrial Revolution, chairs became much more available. The 20th century saw an increasing use of technology in chair construction with such things as all-metal folding chairs, metal-legged chairs, the Slumber Chair,[ moulded plastic chairs and ergonomic chairs. The recliner became a popular form, at least in part due to radio and television. The modern movement of the 1960s produced new forms of chairs: the butterfly chair (originally called the Hardoy chair), bean bags, and the egg-shaped pod chair that turns. It also introduced the first mass-produced plastic chairs such as the Bofinger chair in 1966. Technological advances led to moulded plywood and wood laminate chairs, as well as chairs made of leather or polymers. Mechanical technology incorporated into the chair enabled adjustable chairs, especially for office use. Motors embedded in the chair resulted in massage chairs. https://en.wikipedia.org/wiki/ChairThe chair is one of the most commonly used items providing comfort.Chair wooden varnished dark brown. Spokes for back support, front legs and spokes joining legs are patterned turned wood. Back rest has a floral emblem with a kangaroo in the centre.Back rest has a floral emblem with a kangaroo in the centre.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chair, dining, carpentry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Chair, Early 20th Century

The chair has been used since antiquity, although for many centuries it was a symbolic article of state and dignity rather than an article for ordinary use. "The chair" is still used as the emblem of authority in the House of Commons in the United Kingdom and Canada, and in many other settings. In keeping with this historical connotation of the "chair" as the symbol of authority, committees, boards of directors, and academic departments all have a 'chairman' or 'chair'. Endowed professorships are referred to as chairs. It was not until the 16th century that chairs became common. Until then, people sat on chests, benches, and stools, which were the ordinary seats of everyday life. The number of chairs which have survived from an earlier date is exceedingly limited; most examples are of ecclesiastical, seigneurial or feudal origin. Chairs were in existence since at least the Early Dynastic Period of Egypt (c. 3100 BC). They were covered with cloth or leather, were made of carved wood, and were much lower than today's chairs – chair seats were sometimes only 10 inches (25 cm) high. In ancient Egypt, chairs appear to have been of great richness and splendour. Fashioned of ebony and ivory, or of carved and gilded wood, they were covered with costly materials, magnificent patterns and supported upon representations of the legs of beasts or the figures of captives. Generally speaking, the higher ranked an individual was, the taller and more sumptuous was the chair he sat on and the greater the honour. On state occasions, the pharaoh sat on a throne, often with a little footstool in front of it.[ The average Egyptian family seldom had chairs, and if they did, it was usually only the master of the household who sat on a chair. Among the better off, the chairs might be painted to look like the ornate inlaid and carved chairs of the rich, but the craftsmanship was usually poor. The earliest images of chairs in China are from 6th-century Buddhist murals and stele, but the practice of sitting in chairs at that time was rare. It was not until the 12th century that chairs became widespread in China. Scholars disagree on the reasons for the adoption of the chair. The most common theories are that the chair was an outgrowth of indigenous Chinese furniture, that it evolved from a camp stool imported from Central Asia, that it was introduced to China by Christian missionaries in the 7th century, and that the chair came to China from India as a form of Buddhist monastic furniture. In modern China, unlike Korea or Japan, it is no longer common to sit at floor level. In Europe, it was owing in great measure to the Renaissance that the chair ceased to be a privilege of state and became a standard item of furniture for anyone who could afford to buy it. Once the idea of privilege faded the chair speedily came into general use. Almost at once the chair began to change every few years to reflect the fashions of the day. Thomas Edward Bowdich visited the main Palace of the Ashanti Empire in 1819, and observed chairs engrossed with gold in the empire. In the 1880s, chairs became more common in American households and usually there was a chair provided for every family member to sit down to dinner. By the 1830s, factory-manufactured “fancy chairs” like those by Sears, Roebuck, and Co. allowed families to purchase machined sets. With the Industrial Revolution, chairs became much more available. The 20th century saw an increasing use of technology in chair construction with such things as all-metal folding chairs, metal-legged chairs, the Slumber Chair,[ moulded plastic chairs and ergonomic chairs. The recliner became a popular form, at least in part due to radio and television. The modern movement of the 1960s produced new forms of chairs: the butterfly chair (originally called the Hardoy chair), bean bags, and the egg-shaped pod chair that turns. It also introduced the first mass-produced plastic chairs such as the Bofinger chair in 1966. Technological advances led to moulded plywood and wood laminate chairs, as well as chairs made of leather or polymers. Mechanical technology incorporated into the chair enabled adjustable chairs, especially for office use. Motors embedded in the chair resulted in massage chairs. https://en.wikipedia.org/wiki/ChairThe chair is one of the most commonly used items providing comfort.Chair wooden varnished dark brown. Spokes for back support, front legs and spokes joining legs are patterned turned' wood. Backrest has a floral emblem with a kangaroo in the centre.Back rest has a floral emblem with a kangaroo in the centre.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chair, dining, carpentry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Chair, Early 20th Century

The chair has been used since antiquity, although for many centuries it was a symbolic article of state and dignity rather than an article for ordinary use. "The chair" is still used as the emblem of authority in the House of Commons in the United Kingdom and Canada, and in many other settings. In keeping with this historical connotation of the "chair" as the symbol of authority, committees, boards of directors, and academic departments all have a 'chairman' or 'chair'. Endowed professorships are referred to as chairs. It was not until the 16th century that chairs became common. Until then, people sat on chests, benches, and stools, which were the ordinary seats of everyday life. The number of chairs which have survived from an earlier date is exceedingly limited; most examples are of ecclesiastical, seigneurial or feudal origin. Chairs were in existence since at least the Early Dynastic Period of Egypt (c. 3100 BC). They were covered with cloth or leather, were made of carved wood, and were much lower than today's chairs – chair seats were sometimes only 10 inches (25 cm) high. In ancient Egypt, chairs appear to have been of great richness and splendour. Fashioned of ebony and ivory, or of carved and gilded wood, they were covered with costly materials, magnificent patterns and supported upon representations of the legs of beasts or the figures of captives. Generally speaking, the higher ranked an individual was, the taller and more sumptuous was the chair he sat on and the greater the honour. On state occasions, the pharaoh sat on a throne, often with a little footstool in front of it.[ The average Egyptian family seldom had chairs, and if they did, it was usually only the master of the household who sat on a chair. Among the better off, the chairs might be painted to look like the ornate inlaid and carved chairs of the rich, but the craftsmanship was usually poor. The earliest images of chairs in China are from 6th-century Buddhist murals and stele, but the practice of sitting in chairs at that time was rare. It was not until the 12th century that chairs became widespread in China. Scholars disagree on the reasons for the adoption of the chair. The most common theories are that the chair was an outgrowth of indigenous Chinese furniture, that it evolved from a camp stool imported from Central Asia, that it was introduced to China by Christian missionaries in the 7th century, and that the chair came to China from India as a form of Buddhist monastic furniture. In modern China, unlike Korea or Japan, it is no longer common to sit at floor level. In Europe, it was owing in great measure to the Renaissance that the chair ceased to be a privilege of state and became a standard item of furniture for anyone who could afford to buy it. Once the idea of privilege faded the chair speedily came into general use. Almost at once the chair began to change every few years to reflect the fashions of the day. Thomas Edward Bowdich visited the main Palace of the Ashanti Empire in 1819, and observed chairs engrossed with gold in the empire. In the 1880s, chairs became more common in American households and usually there was a chair provided for every family member to sit down to dinner. By the 1830s, factory-manufactured “fancy chairs” like those by Sears, Roebuck, and Co. allowed families to purchase machined sets. With the Industrial Revolution, chairs became much more available. The 20th century saw an increasing use of technology in chair construction with such things as all-metal folding chairs, metal-legged chairs, the Slumber Chair,[ moulded plastic chairs and ergonomic chairs. The recliner became a popular form, at least in part due to radio and television. The modern movement of the 1960s produced new forms of chairs: the butterfly chair (originally called the Hardoy chair), bean bags, and the egg-shaped pod chair that turns. It also introduced the first mass-produced plastic chairs such as the Bofinger chair in 1966. Technological advances led to moulded plywood and wood laminate chairs, as well as chairs made of leather or polymers. Mechanical technology incorporated into the chair enabled adjustable chairs, especially for office use. Motors embedded in the chair resulted in massage chairs. https://en.wikipedia.org/wiki/ChairThe chair is one of the most commonly used items providing comfort.Chair varnished dark brown. Spokes for back support, front legs and spokes joining legs are patterned turned wood. Back rest has a floral emblem with a kangaroo in the centre.Back rest has a floral emblem with a kangaroo in the centre.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chair, dining, carpentry -

Flagstaff Hill Maritime Museum and Village

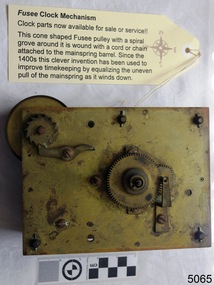

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Eltham District Historical Society Inc

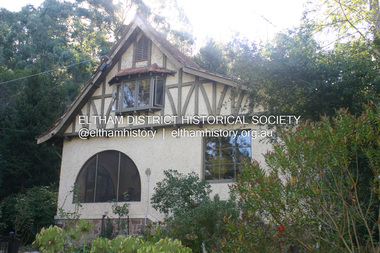

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, The Robins, 13 Kangaroo Ground-Warrandyte Road, North Warrandyte, 2 March 2008

Built by noted artist Theodore Penleigh Boyd, father of architect Robin Boyd. Covered under National Estate, National Trust of Australia (Victoria) Local Significance and Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p111 The Robins at Warrandyte,* was once home to a member of a famous family and is also one of the first reinforced concrete houses in Victoria. The builder, Theodore Penleigh Boyd, born in 1890, was a talented painter1 noted for his works of the Warrandyte bush. He was the father of architect Robin Boyd, author of the Australian Ugliness and the uncle of painter, Arthur Boyd. Penleigh Boyd’s great grandfather was Sir William A’Beckett, Victoria’s first Chief Justice. Penleigh Boyd is considered by some to be an ‘unsung hero’ overshadowed by more famous members of his family. Mornington Gallery Director Andrea May said many believed Boyd ‘had never received the national acclaim that he deserved’.2 Classified by the National Trust3 and part of the Australian National Heritage,4 The Robins is set well back near the end of Kangaroo Ground – Warrandyte Road, unobserved by passers-by. Built in 1913, The Robins has some Art Nouveau influences and is a descendant of the Queen Anne style. It is covered in stucco and has a prominent attic, which Boyd used as a studio. Some parts of the house are up to 33 centimetres thick and built in part with pisé (rammed earth) and in part with reinforced concrete. Amazingly, Boyd built The Robins without an accessible driveway, and only a narrow track along which he had to cart building materials. The journey was uphill and Boyd terraced the land with Warrandyte rock5 without the aid of machinery. At only 33 years, Boyd was killed in a car accident in 1923. He was buried in Brighton near the home of his parents. Several people have since owned the house, including political journalist, Owen Webster. Boyd was born at Penleigh House, Wiltshire, and studied at Haileybury College, Melbourne and The Hutchins School, Hobart. He attended the Melbourne National Gallery School and in his final year exhibited at the Victorian Artists’ Society. He arrived in London in 1911 and his painting Springtime was hung at the Royal Academy. He painted in several studios in England and then worked in Paris.6 There he met painter Phillips Fox through whom he met artists of the French modern school and also his wife-to-be, Edith Anderson, whom he married in Paris in 1912. After touring France and Italy, the couple returned to Melbourne. In 1913 Boyd held an exhibition and won second prize in the Federal Capital site competition, then the Wynne Prize for landscape in 1914. In 1915 Boyd joined the Australian Imperial Force, and became a sergeant in the Electrical and Mechanical Mining Company. However he was severely gassed at Ypres and invalided to England. In 1918 in London Boyd published Salvage, writing the text and illustrating it with 20 black-and-white ink-sketches of army scenes. Later that year he returned to Melbourne, and, despite suffering from the effects of gas, he held several successful one-man shows, quickly selling his water-colour and oil paintings. In his short career Penleigh Boyd was recognized as one of Australia’s finest landscape painters. He loved colour, having been influenced early by Turner and McCubbin. His works are in all Australian state galleries, the National Collection in Canberra as well as in regional galleries.7 His wife Edith was also an artist having studied at the Slade School, London, and in Paris with Phillips Fox. After her marriage she continued to paint and excelled in drawing. In later years she wrote several dramas, staged by repertory companies, and radio plays for the Australian Broadcasting Commission, in which she took part. She was the model for the beautiful red-haired woman in several of Phillips Fox’s paintings and the family hold three of his portraits of her. *Possibly named after the Aboriginal words warran, meaning ‘object’ and dyte, meaning ‘thrown at’.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, kangaroo ground-warrandyte road, north warrandyte, the robins -

Melbourne Tram Museum

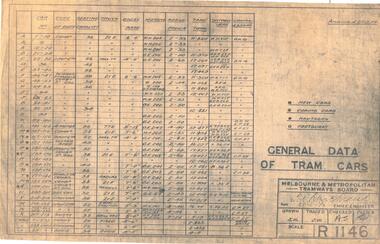

Melbourne Tram MuseumDocument - Folder, Melbourne & Metropolitan Tramways Board (MMTB), "MMTB General Data of Tramcars", compiled to c2005

Set of 60 A3 sheets, comprising a folder of GA Drawings – from Keith Kings, held with black plastic semi elastic black clip or retaining strip. All drawings have been scanned (about 50% were already scanned, e.g. the first sheet) and placed on the Depot Tramcar Mechanical component listing. Order of drawings as received has been retained and listed as follows. R1146 – General Data of Tramcars – 24-9-1924 R11-927 – SW6 and W6 – Advertising Panel Location R11-928 – W7 Advertising Panel Location R9529 – Class W7 GA List of Tramcar GA Arrangement Drawings dated 13/12/1974 Cover sheet – “Melbourne and Metropolitan Tramways Board – Electric Tramcars Index - lists Class, numbers and Drawing Nos. R1266 – Cable Train – Dummy and 4 wheel trailer R3799 – Cable train – Dummy & 4 wheel trailer R3422 – Cable train – dummy & Bogie trailer PMTT 161 – Combination Car R3076 – Class A – Combination Car Dropped ends PMTT – 163 - Bogie car with dropped centre compartment PMTT – 700 – Bogie Car with dropped centre compartment and longitudinal rattan saloon seats R3078 – Dropped Centre bogie car – Maximum Traction R4571 – Dog Transport Car – class C converted PMTT 162 – Summer car (old type) – F class PMTT 164 – Summer car – G class R3079 – Class L R7416 – Class L PMTT 160 – Bogie Closed Car – (O class) R9787 – Class G – All night tram style R3077 – Class G – All night tram style R8999 – Class A tramcar Coburg type Original – S class R5963 - Class A tramcar Coburg type Original – S class (modified) R3093A - Class T R4382 – Class T arrangement for one-man operation Car 178 R3756A – class U R2461 – class W – W class converted to W2 R2460 – class W1 R2459 – class W2 R4646 – class SW2 R9525 – class SW2 R3071 – class W3 R3812 – class W4 R4678B – class W5 R9601 – class CW5 R5818 – class SW5 R12-052 – Class W5 – sliding door conversion R4771A – class SW6 (reversible seats) R6408A – class SW6 (Tubular Fixed Seats) R8617 – class SW6 and W6 R9529 – class W7 R10-129 – Class VR car R8332 – PCC type car R2462 – class X R1811 – types of electric cars – class X Safety car R2463 – class X1 R3080 – Class X2 R2464 – class Y R2465 – class Y1 R10-946 – All electric tram – 1041 R11-333 – class Z1 and Z2 trams R11-387 – class z outside dimensions R11-563 – Class Z tram (101-115) R11-580 - class Z3 tram R12-062 – Class A tram T4000-12 – double ended 6 axle articulated LRV – a possibly arrangement R6928 – PCC Car – double end operation R9980 – Freight car 17 – former V class passenger car See Reg Item 5639 for a similar document.trams, tramways, drawings, tramcars, cable trams, tramcar design, preston workshops, mmtb -

National Wool Museum

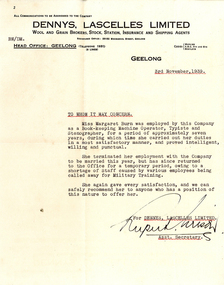

National Wool MuseumLetter - Letter of reference for Margaret Burn, 03/11/1939

Letter of Reference for Miss Margaret Burn detailing her work as a bookkeeper, machine operator, typist, and stenographer over seven years at Dennys Lascelles Limited. The letter details her leaving the company as she married in 1939. In the same year, Ms Burn returned to the office owing to the shortage of staff caused by various employees being called away for Military Training. Included in the staff called away for military training was her newlywed husband, Mr Jack Ganly. A fellow employee of Dennys, the Ganly name was well known within the company, with three generations of the Ganly family working at Dennys. Margaret worked at Dennys for 7 years during the 1930s. The Letter of Reference is accompanied with a story written by Margaret about her time working at the company. WORKING CONDITIONS & OFFICE WORK DUTIES. Written by Margaret Burn in 2021. Worked at Dennys Lascelles in the 1930s. In the 1930s coming out of the Depression, jobs were hard to come by and had to be clung to by efficiency and subserviency. There was no union to protect workers – bosses could be tough and rough. Dennys Lascelles revolved around fortnightly wool sales in the “season” – September to May. Sale day was always a day of suppressed excitement. Preparation from a clerical point of view was complete and we now awaited the aftermath of the actual wool auction. The building teemed with people. There were country people down to see their wool sold, buyers of many nationalities, or from the big cities, who were coming in and out of the building all day. Their role was to inspect the acres of wool bales displayed on the show floors; however, caterers were present to feed clients, and there was plenty of social interactions on top of business. The office staff did not go home but waited until the first figures came back from the wool sales and the machines went in to action, both human and mechanical, preparing the invoices for the buyers’ firms. This comprised of lists of lot numbers, weights, prices per lb., and the total prices paid. A lot of this was done by old-school typewriters, making this work a big, heavy, tiring job. Before the finished lists could be dispatched, they were collated on an “abstract”. The lists had to balance with the catalogue from which the invoices had been prepared. This never happened automatically. All the paperwork had to be split up amongst pairs of workers and checked until discrepancies were found. This would happen until midnight but occasionally went until 2 or 3 am. Once complete, the invoices could then be rushed off to the buyers’ firms usually in Melbourne, and hire cars took the staff home. It was back on the job the next morning, usually around 8.30. The office hours varied according to the size of the sale and work involved. Some days started as early as 8 and could finish around 5.30. The second phase of work began with the account sales to be prepared for the sellers of the wool. These detailed all the weights, descriptions of wool, brands, and prices. One Sales account could have multitudes of lot numbers, all needing to be individually described. Various charges needed to be deducted such as finance for woolpacks, extra stock, or farmers who were given a loan to live on during the season. Details of how payment was to be made was also noted, whether the seller was to be paid by cheque, to a bank, or credited to their account with the company (which often left the seller still in debt). For a couple of months in the winter, things were quieter when staff took holidays and were sometimes given afternoons off. But there were still weekly skin sales and stock sales around the state. The annual end of June figures to be prepared for a big company like Dennys with branches all around the state also kept the staff busy. In good years there was sometimes a bonus. On sale days there was a bar open for the clients and wool buyers. This added to the excitement for the young girls, who were strictly barred from using it, but somehow managed to sneak a gin and tonic. This is how I had my first ever, before the evening meal. There was also the romantic notion in some minds, with all the influx of males, that some of us might end up on a wealthy station, or be noticed by an exotic buyer. To my knowledge, this never happened at Dennys Lascelles Limited. Group staff photo at Dennys Lascelles Limited. Margaret Burn. Age 18 or 19. Jack Ganly (Margaret’s future husband). 22. Sheet of paper shorter in length than A4 size, creamed with age. Paper has a header for Dennys, Lascelles Limited’s Head Office at 32 Moorabool Street, Geelong. Body of paper is made up of 3 paragraphs in a typewritten message of black ink with subheadings highlighted with a red underline. The text is finished with a signature at the bottom of the paper. Paper is accompanied by its original envelope. Envelope has typewritten text in black ink with a red underline located at the centre. It also has return to sender instructions to Dennys, Lascelles Limited in the lower left-hand corner.Typewritten text, black and red ink. Multiple. See multimediadennys lascelles ltd, worker conditions 1930s, letter of reference -

Melton City Libraries

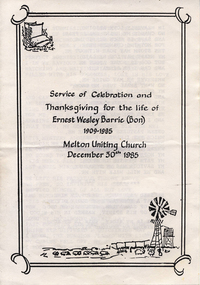

Melton City LibrariesDocument, Service of Celebration and Thanksgiving for the life of Ernest Wesley Barrie (Bon) 1909-1985, 1985

SUMMARY - Ernest W (Bon) Barrie, 1909 – 1985 Profile Melton Mechanics Institute Member 1935 - 1982i Trustee 1952 - 1982 Life Member 1968 Years of service – 47 years He constructed and provided a public address system which was used at Melton and district halls and sports grounds for a wide variety of community events including school sports, gymkhanas, theatrical productions and processions. Fire Brigade Melton Fire Brigade (and predecessor Bush Fire Brigade) Apparatus Officer, 1945 - 1953 Captain, 1951 - 1965 Mt Cotterill Fire Brigades’ Group Elected Group Officer, on the formation of the Group, 1967. As Group Communications Officer he operated the VL3 LY base radio station from home on a 24 hour basis for fire brigades of Melton, Rockbank, Sydenham, Diggers Rest, Toolern Vale, Truganina and Werribee. With his brother Edgar, he built the first Melton Fire Truck. It was housed on the family property until a fire station was constructed in the Melton township. Recipient of the Queens Medal, 1979 Recognised for 44 years of service on the Melton Fire Brigade Memorial Wall Plaque, dedicated May 2013 Melton State School, no 430 Committee – School Correspondent (secretarial and financial role) 34 years of Service Provided his Amplifier Equipment for events and the annual district School Sports from 1939-1973. Donated the House Athletic Shield Melton and District Historical Society 1968 – 1985 President and foundation member Willows Historical Park – supported the establishment of the park and contributed many volunteers hours in the construction and landscaping of the precinct Member, Western Metropolitan Groups of Historical Societies, 1980s Shire of Melton Councillor South Riding, 1969-1971 Member of the Water Trust Melton Uniting Church Melton Uniting Church (and its predecessors the Methodist, Methodist-Presbyterian churches). A lifetime association which extended from childhood when he attended Sunday school until his death in 1985. Member of the Presbyterian Board of Management for more than 25 years in which he held positions of Honorary Secretary and Treasurer, Board member of the Parish Council and Member of the Committee of Management. He was a Sunday school teacher 1933. Community development With Mr RC Butler met with Shire Council in 1937 to canvass residents to ascertain prospective Electric consumers in the district. Electricity was subsequently turned on at dusk on 20th December 1939. Melton Progress Association, including Melton Musical, Elocutionary and Vocal Competitions, Vice President 1939 1940 Melton Development Association, 1960s Volunteer Air Observers Corps (VAOC)ii Carried out plane spotting at Shire Office and spotting tower in Melton and later from home until 1944/45. Agriculture and farming Progress and Better Farming Association, Melton. Honorary Secretary, 1935 Member, Agricultural Engineering Society Australia c1960-1985 A successful grower of wheat, oats and barley, he planted experiment plots and held Field Days on the “Darlingsford” property. He later diversified into other grains and sheep (wool and meat). He took a enthusiastic interest in agricultural engineering and was keen to introduce innovative ideas that improved the productivity of farms and farming practices. In the mid 1950 he conducted trials during harvest on the family property of the original mechanical hay fork built on a British Bedford truck by Bill Gillespie. This design was further refined in collaboration with the Gillespie brothers and resulted in the construction the hydraulically operated tractor mounted hay fork. The innovative design of the hay fork created interest from far and wide and was quickly taken up by farmers because it significantly reduced hand labouring of loading sheaves of hay with a pitch fork. His father established chaff mills in Melton, Rockbank, Parwan, Diggers Rest in the first decade of 1900 and in 1915 went into partnership with JR Schutt to establish the Schutt & Barrie Pty. Ltd. Chaff Cutting and Flour Mill in West Footscray. When it ceased trading in 1968 the directors were: Ernest W Barrie and Thomas L Barrie, R, A, and M Schutt. Awards Queens Medal, 1979 Rotary Award for Community Service, 1980 Victoria 150th Anniversary Celebrations contributions, 1985 Service held at Melton Uniting Church local identities -

Melton City Libraries

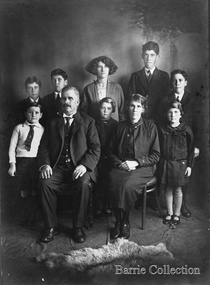

Melton City LibrariesPhotograph, Bon Barrie, c.1940, Unknown

SUMMARY - Ernest W (Bon) Barrie, 1909 – 1985 Profile Melton Mechanics Institute Member 1935 - 1982i Trustee 1952 - 1982 Life Member 1968 Years of service – 47 years He constructed and provided a public address system which was used at Melton and district halls and sports grounds for a wide variety of community events including school sports, gymkhanas, theatrical productions and processions. Fire Brigade Melton Fire Brigade (and predecessor Bush Fire Brigade) Apparatus Officer, 1945 - 1953 Captain, 1951 - 1965 Mt Cotterill Fire Brigades’ Group Elected Group Officer, on the formation of the Group, 1967. As Group Communications Officer he operated the VL3 LY base radio station from home on a 24 hour basis for fire brigades of Melton, Rockbank, Sydenham, Diggers Rest, Toolern Vale, Truganina and Werribee. With his brother Edgar, he built the first Melton Fire Truck. It was housed on the family property until a fire station was constructed in the Melton township. Recipient of the Queens Medal, 1979 Recognised for 44 years of service on the Melton Fire Brigade Memorial Wall Plaque, dedicated May 2013 Melton State School, no 430 Committee – School Correspondent (secretarial and financial role) 34 years of Service Provided his Amplifier Equipment for events and the annual district School Sports from 1939-1973. Donated the House Athletic Shield Melton and District Historical Society 1968 – 1985 President and foundation member Willows Historical Park – supported the establishment of the park and contributed many volunteers hours in the construction and landscaping of the precinct Member, Western Metropolitan Groups of Historical Societies, 1980s Shire of Melton Councillor South Riding, 1969-1971 Member of the Water Trust Melton Uniting Church Melton Uniting Church (and its predecessors the Methodist, Methodist-Presbyterian churches). A lifetime association which extended from childhood when he attended Sunday school until his death in 1985. Member of the Presbyterian Board of Management for more than 25 years in which he held positions of Honorary Secretary and Treasurer, Board member of the Parish Council and Member of the Committee of Management. He was a Sunday school teacher 1933. Community development With Mr RC Butler met with Shire Council in 1937 to canvass residents to ascertain prospective Electric consumers in the district. Electricity was subsequently turned on at dusk on 20th December 1939. Melton Progress Association, including Melton Musical, Elocutionary and Vocal Competitions, Vice President 1939 1940 Melton Development Association, 1960s Volunteer Air Observers Corps (VAOC)ii Carried out plane spotting at Shire Office and spotting tower in Melton and later from home until 1944/45. Agriculture and farming Progress and Better Farming Association, Melton. Honorary Secretary, 1935 Member, Agricultural Engineering Society Australia c1960-1985 A successful grower of wheat, oats and barley, he planted experiment plots and held Field Days on the “Darlingsford” property. He later diversified into other grains and sheep (wool and meat). He took a enthusiastic interest in agricultural engineering and was keen to introduce innovative ideas that improved the productivity of farms and farming practices. In the mid 1950 he conducted trials during harvest on the family property of the original mechanical hay fork built on a British Bedford truck by Bill Gillespie. This design was further refined in collaboration with the Gillespie brothers and resulted in the construction the hydraulically operated tractor mounted hay fork. The innovative design of the hay fork created interest from far and wide and was quickly taken up by farmers because it significantly reduced hand labouring of loading sheaves of hay with a pitch fork. His father established chaff mills in Melton, Rockbank, Parwan, Diggers Rest in the first decade of 1900 and in 1915 went into partnership with JR Schutt to establish the Schutt & Barrie Pty. Ltd. Chaff Cutting and Flour Mill in West Footscray. When it ceased trading in 1968 the directors were: Ernest W Barrie and Thomas L Barrie, R, A, and M Schutt. Awards Queens Medal, 1979 Rotary Award for Community Service, 1980 Victoria 150th Anniversary Celebrations contributions, 1985 Photographs of Bon Barrielocal identities, pioneer families -

Melbourne Tram Museum

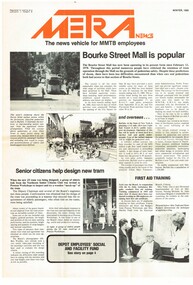

Melbourne Tram MuseumMagazine, Melbourne & Metropolitan Tramways Board (MMTB), "Metra News", 1980 to 1982

.0 - Autumn 1980 - Passenger counting, Survey provides data, We lead the way with Z3, Wattle Park, transport in Moscow, Spike Milligan, Melbourne's decorated trams, transporting art, sports, training, and Raymond Stock, Assistant Traffic Manager Revenue .1 - Winter 1980 - Bourke St Mall is popular, Senior citizens help design new tram (Z3), A bus-only lane in Johnstone St., Depot Employees' Social and facility Melbourne. Has a profile on Mr R. C. Drummond, Traffic Manager. .2 - Spring 1980 - Christmas Message, supporting those children with polio in 1938, Trolley buses, Z3 trams being built, use of parafil in overhead, cleaning truck. Has a profile on Ken Hall, Assistant Chief Engineer - Mechanical and Reg Robinson who was the organiser for the 1938 polio event - bus driver / instructor. .3 - Summer 1981 - MMTB involvement with Australia Day pageant, note involvement of TMSV, Bendigo, BTPS 27 (26 Jan. 1981), film on apprentices, tram stop shelters, resilient track work, trolley buses, the supply and systems department including Hawthorn clothing workroom and printing department (photos) and profile on Mr Jerry Compton, Supply and systems department. (Two copies held) .4 - Autumn 1981 - new buildings at Footscray, South Melbourne, trolley buses for Melbourne?, building MAN buses, why join the Tramways Benefit Society, article that looks at the Engineering Branch and profile of John Grigg, Chief Engineer. (Two copies held) .5 - Winter 1981 - New passenger shelters, image of the Elizabeth St shelter proposal, where do old trams go?, "Around the Clock" Emergency Service (item on R10) (See Reg item 1004 for photo), formation of Tramway's Sporting Associations, retirement of Board's driver Peter Savage, bus driving school transferred to Hawthorn, Apprentices and Profile on Bill Sibbison, Depot Manager North Fitzroy. .6 - Spring 1981 - 8 pages - Making of Squizzy Taylor film - Flinders St station, Engineering Amenities at South Melbourne opened, traverser at Preston Workshops, track work - pressing curves at South Melbourne, Conductresses re-union, model tramway at the Royal Show, retirements, sporting association, tramway band, AVM, reducing noise levels, lists Editorial committee. .7 - Summer 1982 - 8 pages - Its Christmas Party time, want to charter a tram or bus?, portable radios, MMTB role in Paraplegic Games, MMTB Architect Gene Marshall retires, photo of WW2 most popular conductresses ball, MMTB Highlights, O-Bahn. Has a profile on Rob Downing - Deputy Chairman. Also Dick Newnham - lift operator at head office, Bob Moffatt - driver turned actor. Also has a follow up on the making of the Squizzy Taylor film "What's wrong with Squizzy" and a photo of the Editorial team and their names. .8 - Autumn 1982 - 8 pages - item on "Taking Melbourne by Storm", photo of Austerity bus 500, Radio Centre, Clifton Pugh tram 504, Essendon Depot (see Reg Item 1005) includes of photos of managers, revenue etc, story on the most popular conductress photo by Win Gibson (see Reg item 180 and 181), new apprentices, John Murdoch model train (Diamond Valley) builder, Sunday vintage tram service (V214) and L class to the zoo. Has a profile on Mr. Peter Saul, Architect. (two copies held) (see image 1178i5 for cover) .9 - Winter 1982 - 8 pages - changes to Doncaster bus - Eastern Free extension, changes to Ministry will affect Board - Steve Crabb, new uniforms, Footscray Depot, apprentice awards, follow up on Austerity buses, Norm Cross and Destination City, Profile on Alan Nolan Runningsheds Engineer, and Mike McLeod MMTB Photographer. (two copies held) .10 - Spring 1982 - book - see Melbourne by tram, Bundoora tramway work, new articulated vehicles (B class trams), Elizabeth St modal interchange shelter, Brunswick depot, demise of the F class bus (Mark VI), profile of Daryl Meade bus engineer, Joe Saccasan carpenter building branch and a list of Jargon. (two copies held).Demonstrates a MMTB employee newsletter, early 1980sMagazine, two colour printed on A2 sheet, folded to A3, "METRA News", published by the MMTB. Each issue unless noted otherwise four pages. Major items listed. Each issue has personnel news, including new staff, promotions, overseas items;trams, tramways, mmtb, z3 class, bourke st, track equipment, overhead, most popular conductress competition, hawthorn depot, clothing, trolley buses, fund raising, footscray, welfare, sale of trams, recovery, r10 vehicle, flinders st, films, radio centre, essendon depot, theatre, transporting art, austerity buses, footscray depot, doncaster, minister for transport, shelters, bundoora, brunswick depot, buses, mont albert, route 42 -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Len Parker's Bedford truck at the Tosch home in Panton Hill, c.1952

Len Parker's Bedford truck is featured in one of the public art mosaics in Were Street, Montmorency. Mr Parker by Grace de Visser (EDHS Newsletter No. 249, December 2019) Len Parker was a regular sight around the district for almost 40 years, selling fruit and veggies from the back of his truck to his regular customers between 1939 and 1978, first in a 1927 Chevy then a 1949 Bedford truck. Len’s connection to the Eltham district started long before he was born. His father Fred first came through the district in the early 1900s. With horse and cart buying and selling what was available at the markets using his mothers’ home in North Melbourne as his base. Fred settled and developed a market garden in the rich soil along the creek at Watsons Creek, Christmas Hills in 1903. Ada Watson was almost five years old and one of eight siblings aged two to sixteen, when her Grandfather and Father both named Christopher Watson brought the Eltham Hotel and they moved from Richmond. Ada’s mother was formerly Emily Silk whose parents Martha and John Silk had been farming in Eltham around 1858 and much later a dairy farmer in Fitzroy. In 1917 at St Margaret’s Church Eltham, Fred aged 44 married Ada aged 35 who was still living and working at the Eltham Hotel. Six years later Ada died from cancer leaving Fred with two small children, Rose five and Len three. Len as a young boy, like his father before him worked the land with horses, growing vegetables, mainly potatoes, cabbages, pumpkins, beans, and tomatoes, selling the excess at the market. Len took over from his ageing father Fred, who had established similar rounds selling door to door with a horse and cart. Len preferred mechanical horsepower to the real kind! In 1939 at the age of eighteen Len brought an old 1927 Chevy Truck. He was taught how to drive it and two weeks later got his driver’s Licence. The Chevy truck had an old wagon on the back with no doors, only hessian bags to keep the wind out! Len had paid 75 pounds for it, kept it for ten years and sold it for the same price! Len’s blue 1949 Bedford was brought new in 1950 for 900 pounds with only a tray back on it. Straight away Len had a wooden frame covered with canvas added, with a roll up front and back. In later years, more solid sides replaced the canvas. Benches were added to hold the boxes of fruit and vegetables, with room to move in the middle, a fruit shop on wheels. Len had large scales attached to a box for weighing the fruit and veggies and many a district baby was also weighed on them. Len would stop at customer’s homes, take their orders and with his big cane basket on his arm deliver their order to their door. On his rounds he always wore a big soft back leather apron and a black or navy beret. If it was cold, he wore a ‘bluey’ jacket on his tall slender frame. Len would go to the markets early Thursday morning, only buying what was not grown at home or brought from his brother in law’s orchard. On his way home Len would start his ‘rounds’ in Lower Plenty and then Montmorency and parts of Eltham. Friday’s regulars were in Research, Kangaroo Ground and Panton Hill. Saturdays were Panton Hill and Christmas Hills. When Len retired in 1978, due to changing social times, women were working more and supermarkets starting to take over; his ageing truck was retired too. In 1999 his son Jim had the Bedford restored, Len was very happy to see ‘Beddy’ all shiny and new once again with just a tray back, like when it was new. Jim still drives the ‘Beddy’ to Heritage Truck shows twenty years on. Len married, had five children and lived most of his life, (except during World War 2 when he served in New Guinea), at Watsons Creek, Christmas Hills dying there in 2006 and is buried at the Kangaroo Ground cemetery with his wife of 64 years, Stella nee Tosch 1917 - 2007. Grace de Visser, the author of this article, is the daughter of Len Parker and a descendant of the two former owners of the Eltham Hotel, both named Christopher Watson. bedford truck, len parker, panton hill, tosch property -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Len Parker's Bedford truck, c.1962

Len Parker's Bedford truck is featured in one of the public art mosaics in Were Street, Montmorency. The little girl is Grace de Visser's sister. Mr Parker by Grace de Visser (EDHS Newsletter No. 249, December 2019) Len Parker was a regular sight around the district for almost 40 years, selling fruit and veggies from the back of his truck to his regular customers between 1939 and 1978, first in a 1927 Chevy then a 1949 Bedford truck. Len’s connection to the Eltham district started long before he was born. His father Fred first came through the district in the early 1900s. With horse and cart buying and selling what was available at the markets using his mothers’ home in North Melbourne as his base. Fred settled and developed a market garden in the rich soil along the creek at Watsons Creek, Christmas Hills in 1903. Ada Watson was almost five years old and one of eight siblings aged two to sixteen, when her Grandfather and Father both named Christopher Watson brought the Eltham Hotel and they moved from Richmond. Ada’s mother was formerly Emily Silk whose parents Martha and John Silk had been farming in Eltham around 1858 and much later a dairy farmer in Fitzroy. In 1917 at St Margaret’s Church Eltham, Fred aged 44 married Ada aged 35 who was still living and working at the Eltham Hotel. Six years later Ada died from cancer leaving Fred with two small children, Rose five and Len three. Len as a young boy, like his father before him worked the land with horses, growing vegetables, mainly potatoes, cabbages, pumpkins, beans, and tomatoes, selling the excess at the market. Len took over from his ageing father Fred, who had established similar rounds selling door to door with a horse and cart. Len preferred mechanical horsepower to the real kind! In 1939 at the age of eighteen Len brought an old 1927 Chevy Truck. He was taught how to drive it and two weeks later got his driver’s Licence. The Chevy truck had an old wagon on the back with no doors, only hessian bags to keep the wind out! Len had paid 75 pounds for it, kept it for ten years and sold it for the same price! Len’s blue 1949 Bedford was brought new in 1950 for 900 pounds with only a tray back on it. Straight away Len had a wooden frame covered with canvas added, with a roll up front and back. In later years, more solid sides replaced the canvas. Benches were added to hold the boxes of fruit and vegetables, with room to move in the middle, a fruit shop on wheels. Len had large scales attached to a box for weighing the fruit and veggies and many a district baby was also weighed on them. Len would stop at customer’s homes, take their orders and with his big cane basket on his arm deliver their order to their door. On his rounds he always wore a big soft back leather apron and a black or navy beret. If it was cold, he wore a ‘bluey’ jacket on his tall slender frame. Len would go to the markets early Thursday morning, only buying what was not grown at home or brought from his brother in law’s orchard. On his way home Len would start his ‘rounds’ in Lower Plenty and then Montmorency and parts of Eltham. Friday’s regulars were in Research, Kangaroo Ground and Panton Hill. Saturdays were Panton Hill and Christmas Hills. When Len retired in 1978, due to changing social times, women were working more and supermarkets starting to take over; his ageing truck was retired too. In 1999 his son Jim had the Bedford restored, Len was very happy to see ‘Beddy’ all shiny and new once again with just a tray back, like when it was new. Jim still drives the ‘Beddy’ to Heritage Truck shows twenty years on. Len married, had five children and lived most of his life, (except during World War 2 when he served in New Guinea), at Watsons Creek, Christmas Hills dying there in 2006 and is buried at the Kangaroo Ground cemetery with his wife of 64 years, Stella nee Tosch 1917 - 2007. Grace de Visser, the author of this article, is the daughter of Len Parker and a descendant of the two former owners of the Eltham Hotel, both named Christopher Watson. bedford truck, len parker -

Eltham District Historical Society Inc

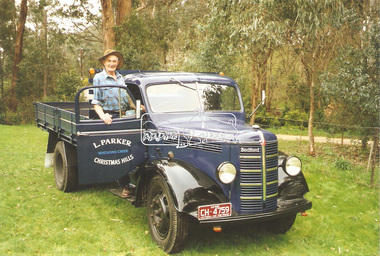

Eltham District Historical Society IncPhotograph, Len Parker with his restored Bedford truck, 1999

Len's Bedford truk is featured in one of the Montmorency Were Street shopping precinct mosaics. Mr Parker by Grace de Visser (EDHS Newsletter No. 249, December 2019) Len Parker was a regular sight around the district for almost 40 years, selling fruit and veggies from the back of his truck to his regular customers between 1939 and 1978, first in a 1927 Chevy then a 1949 Bedford truck. Len’s connection to the Eltham district started long before he was born. His father Fred first came through the district in the early 1900s. With horse and cart buying and selling what was available at the markets using his mothers’ home in North Melbourne as his base. Fred settled and developed a market garden in the rich soil along the creek at Watsons Creek, Christmas Hills in 1903. Ada Watson was almost five years old and one of eight siblings aged two to sixteen, when her Grandfather and Father both named Christopher Watson brought the Eltham Hotel and they moved from Richmond. Ada’s mother was formerly Emily Silk whose parents Martha and John Silk had been farming in Eltham around 1858 and much later a dairy farmer in Fitzroy. In 1917 at St Margaret’s Church Eltham, Fred aged 44 married Ada aged 35 who was still living and working at the Eltham Hotel. Six years later Ada died from cancer leaving Fred with two small children, Rose five and Len three. Len as a young boy, like his father before him worked the land with horses, growing vegetables, mainly potatoes, cabbages, pumpkins, beans, and tomatoes, selling the excess at the market. Len took over from his ageing father Fred, who had established similar rounds selling door to door with a horse and cart. Len preferred mechanical horsepower to the real kind! In 1939 at the age of eighteen Len brought an old 1927 Chevy Truck. He was taught how to drive it and two weeks later got his driver’s Licence. The Chevy truck had an old wagon on the back with no doors, only hessian bags to keep the wind out! Len had paid 75 pounds for it, kept it for ten years and sold it for the same price! Len’s blue 1949 Bedford was brought new in 1950 for 900 pounds with only a tray back on it. Straight away Len had a wooden frame covered with canvas added, with a roll up front and back. In later years, more solid sides replaced the canvas. Benches were added to hold the boxes of fruit and vegetables, with room to move in the middle, a fruit shop on wheels. Len had large scales attached to a box for weighing the fruit and veggies and many a district baby was also weighed on them. Len would stop at customer’s homes, take their orders and with his big cane basket on his arm deliver their order to their door. On his rounds he always wore a big soft back leather apron and a black or navy beret. If it was cold, he wore a ‘bluey’ jacket on his tall slender frame. Len would go to the markets early Thursday morning, only buying what was not grown at home or brought from his brother in law’s orchard. On his way home Len would start his ‘rounds’ in Lower Plenty and then Montmorency and parts of Eltham. Friday’s regulars were in Research, Kangaroo Ground and Panton Hill. Saturdays were Panton Hill and Christmas Hills. When Len retired in 1978, due to changing social times, women were working more and supermarkets starting to take over; his ageing truck was retired too. In 1999 his son Jim had the Bedford restored, Len was very happy to see ‘Beddy’ all shiny and new once again with just a tray back, like when it was new. Jim still drives the ‘Beddy’ to Heritage Truck shows twenty years on. Len married, had five children and lived most of his life, (except during World War 2 when he served in New Guinea), at Watsons Creek, Christmas Hills dying there in 2006 and is buried at the Kangaroo Ground cemetery with his wife of 64 years, Stella nee Tosch 1917 - 2007. Grace de Visser, the author of this article, is the daughter of Len Parker and a descendant of the two former owners of the Eltham Hotel, both named Christopher Watson. bedford truck, len parker -

National Wool Museum

National Wool MuseumFunctional object - Typewriter, Remington Typewriter Company, c.1925

This Remington No.12 typewriter is of the typebar, front-strike class. It was made by the Remington Typewriter Company of Ilion, New York, U.S.A. in about 1925. The Model No. 12 was introduced in 1922 and was one of the first 'visible writer' machines, in which the typed characters were visible to the operator. Previous models were of the upstrike class in which the characters were typed on the underside of the platen. To see what had been typed the operator had to raise the platen, meaning the typist was typing blind much of the time. This machine was used by Margaret Ganly née Burn in the 1930s. It was purchased for her by one of the sons of William Pride, a famous saddle maker in Geelong, William was Margaret’s grandfather. The typewriter was donated with original sales receipt and servicing tools. Margaret worked at Dennys for 7 years during the 1930s. The typewriter is accompanied with a story written by Margaret about her time working at the company. Margret married Jack Ganly, a fellow employee of Dennys. The Ganly name was well known within Dennys, with three generations of the Ganly family working at the company. WORKING CONDITIONS & OFFICE WORK DUTIES. Written by Margaret Burn in 2021. Worked at Dennys Lascelles in the 1930s. In the 1930s coming out of the Depression, jobs were hard to come by and had to be clung to by efficiency and subserviency. There was no union to protect workers – bosses could be tough and rough. Dennys Lascelles revolved around fortnightly wool sales in the “season” – September to May. Sale day was always a day of suppressed excitement. Preparation from a clerical point of view was complete and we now awaited the aftermath of the actual wool auction. The building teemed with people. There were country people down to see their wool sold, buyers of many nationalities, or from the big cities, who were coming in and out of the building all day. Their role was to inspect the acres of wool bales displayed on the show floors; however, caterers were present to feed clients, and there was plenty of social interactions on top of business. The office staff did not go home but waited until the first figures came back from the wool sales and the machines went in to action, both human and mechanical, preparing the invoices for the buyers’ firms. This comprised of lists of lot numbers, weights, prices per lb., and the total prices paid. A lot of this was done by old-school typewriters, making this work a big, heavy, tiring job. Before the finished lists could be dispatched, they were collated on an “abstract”. The lists had to balance with the catalogue from which the invoices had been prepared. This never happened automatically. All the paperwork had to be split up amongst pairs of workers and checked until discrepancies were found. This would happen until midnight but occasionally went until 2 or 3 am. Once complete, the invoices could then be rushed off to the buyers’ firms usually in Melbourne, and hire cars took the staff home. It was back on the job the next morning, usually around 8.30. The office hours varied according to the size of the sale and work involved. Some days started as early as 8 and could finish around 5.30. The second phase of work began with the account sales to be prepared for the sellers of the wool. These detailed all the weights, descriptions of wool, brands, and prices. One Sales account could have multitudes of lot numbers, all needing to be individually described. Various charges needed to be deducted such as finance for woolpacks, extra stock, or farmers who were given a loan to live on during the season. Details of how payment was to be made was also noted, whether the seller was to be paid by cheque, to a bank, or credited to their account with the company (which often left the seller still in debt). For a couple of months in the winter, things were quieter when staff took holidays and were sometimes given afternoons off. But there were still weekly skin sales and stock sales around the state. The annual end of June figures to be prepared for a big company like Dennys with branches all around the state also kept the staff busy. In good years there was sometimes a bonus. On sale days there was a bar open for the clients and wool buyers. This added to the excitement for the young girls, who were strictly barred from using it, but somehow managed to sneak a gin and tonic. This is how I had my first ever, before the evening meal. There was also the romantic notion in some minds, with all the influx of males, that some of us might end up on a wealthy station, or be noticed by an exotic buyer. To my knowledge, this never happened at Dennys Lascelles Limited. Group staff photo at Dennys Lascelles Limited. Margaret Burn. Age 18 or 19. Jack Ganly (Margaret’s future husband). 22.The typewriter has a black painted metal frame. The top section of the typewriter consists of a cylindrical platen on a carriage featuring plated metal fittings. A curved folding paper guide sits behind the platen and moves on the horizontal axis when the user types on the keyboard. A horizontal semicircular type basket with typebar links the top section to the lower keyboard. The ink ribbon is carried between two spools on a horizontal axis, one on each side of the type-basket. At the rear, a paper tray features gold lettering which reads ‘Remington’. At the front, a four-row QWERTY keyboard is found with 42-character keys total. 'SHIFT LOCK' and 'SHIFT KEY' are to the left of the keyboard, 'BACK SPACER' and 'SHIFT KEY' to the right. All keys are circular, white with black lettering. At the top of the keyboard are five circular red keys with the numbers 1-5 displayed behind their respective keys. A Spacebar is found along the front of the keyboard. The typewriter is accompanied by a cardboard box. This box contains the original sales receipt, on blue paper with grey lead handwriting. It also contains spare parts, a spare ribbon stretched between two spools, and cleaning tools such as brushes of differing sizes. Serial Number. Engraved. "LX45395" Gold lettering. Paper tray. “Remington” Gold Lettering. Behind keyboard. “Made in Ilion, New York, U.S.A. Gold Lettering. Mirrored both sides of type-basket. “12”remington, dennys lascelles ltd, worker conditions 1930s -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Date Stamp, Mid 20th century

This hand held, mechanical date stamp, made in mid-20th century by English Numbering Machines Ltd (ENM) in Enfield, England and is part of the stationary items once used by Dr. W.R. Angus in his medical service. ENM was a well know manufacturer of mechanical counters and hand numbering machines, both printing and non-printing, for the stationery industry, offices, sales control and the legal profession. The company was amongst the exhibitors at the Birmingham section of the British Industries Fair, (stand number D 539). This Fair operated annually from the 1920 – 1960 and was attended by royalty and dignitaries as well as the general public. At its peak there were over 1000 exhibitors. This date stamp was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served with the Australian Department of Defence as a Surgeon Captain during WWII 1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The W.R. Angus Collection is significant for still being located at the site it is connected with, Doctor Angus being the last Port Medical Officer in Warrnambool. The collection of medical instruments and other equipment is culturally significant, being an historical example of medicine from late 19th to mid-20th century. Dr Angus assisted Dr Tom Ryan, a pioneer in the use of X-rays and in ocular surgery. Metal date stamp with Bakelite handle, made in Britain by English Numbering Machines. Model No. 4531; part of the W.R. Angus Collection. Stamped on metal: “ENM / British made / Model 4531” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, dr w r angus, dr ryan, surgical instrument, t.s.s. largs bay, warrnambool base hospital, nhill base hospital, mira hospital, flying doctor, date stamp, office stationery, mechanical date stamp, enm date stamp, english numbering machines, enm model 4531 -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Jelbart home, 93 Arthur Street, Eltham, 11 November 2006