Showing 15572 items

matching valley

-

National Wool Museum

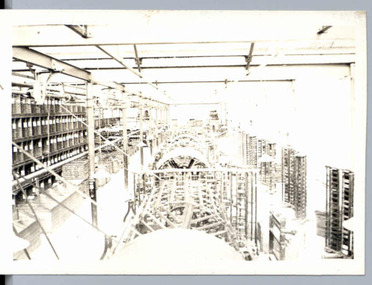

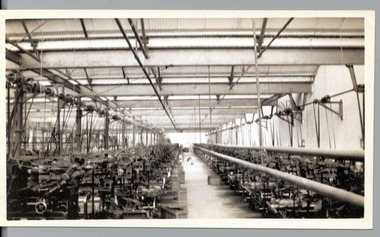

National Wool MuseumPhotograph

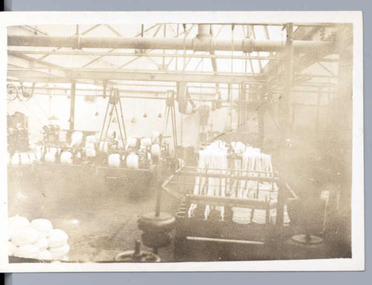

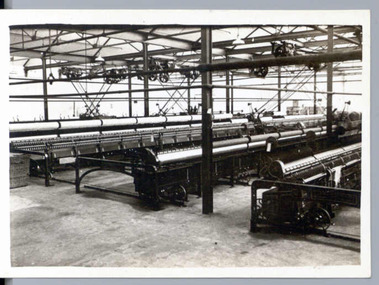

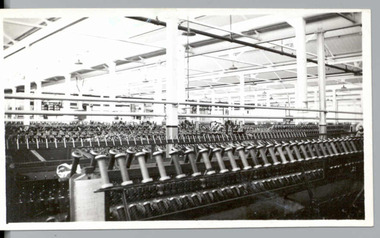

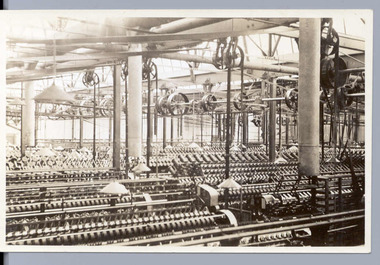

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows warping. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, warping, warping machinery -

National Wool Museum

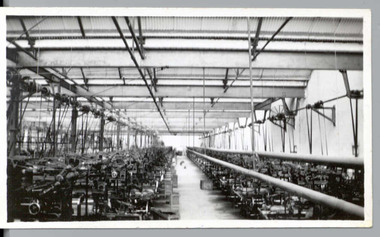

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows warping. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, warping, warping machinery -

Eltham District Historical Society Inc

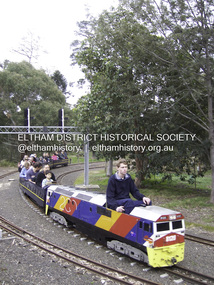

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Diamond Valley Railway, Eltham Lower Park, 7 September 2008

Kids of all ages enjoy the Miniature Railway. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p163 On Sundays in Eltham thousands of children, mums, dads and grandparents can be seen travelling around Lower Eltham Park in tiny trains. They are among the two and half million passengers who have travelled on the Diamond Valley Railway since it officially began in 1961. The miniature railway originally operated from the 1940s at Chelsworth Park, Ivanhoe, until flooding caused it to be moved to the Eltham Lower Park in 1959. The railway is modelled on the 1920s era – the heyday of passenger rail travel – and the trains are built on a scale of two inches to the foot (1/6). Although not exact replicas, trains include models of the Spirit of Progress, Puffing Billy, The Overland, Dog Boxes, Vic Rail S class, G class and a NSW 81 Class. The three and a half kilometres of track is set amongst native plants and picnic areas. A friendly hoot or the clang of a bell occasionally punctuates the tranquillity as a train emerges from a treed bend with passengers excitedly waving to onlookers. For $3 the train takes you on a 13-minute two-kilometre ride. Passengers sit in single file in the narrow train, which clatters along tracks built to the scale of the Australian narrow gauge of three feet six inches (1.1m). These are used in Queensland, South Australia, Tasmania and Western Australia. Safety standards are stringently kept. Even before you buy a ticket notices tell you that you must wear closed shoes. You can even borrow these, and you are given a pair of socks for the ride! Blue-overalled volunteers check tickets, see you aboard, and drive the train. They are mainly retired men who can at last devote their time to what little boys dream of – playing with trains. Passengers are instructed in safe behaviour, then the station master waves a white flag and off we go. The guard sits at the back with his whistle and green flag at the ready. The winding track, fringed by native trees and bushes planted by volunteers, stands on crown land managed by Nillumbik Council. The train clatters along the track and crosses a bridge over a drain elevated by name to The Blow Fly Creek. We pass by Meadmore Junction at a speed of three kilometres an hour. Then on through a tunnel, accompanied by squeals of delight, and after a few moments of blackness, light glimmers at the end. On we go, past the original platform, along another route past busy Main Road through Pine Creek Station, over a bridge and through another tunnel with more screams of delight.Then a signal stops us before the ‘all clear’ to return to our original point of departure. The railway services its passengers – the largest number of any miniature railway in Australia – with a fleet including: six diesel locomotives, three steam locomotives, eight sets of passenger cars and one battery electric Dog Box set. Members also privately own 20 locomotives and powered carriage sets as well as four carriage sets.1 All the trains are stored on-site in workshops, sheds and a tunnel. The railway is entirely run by volunteers, so that all ticket money is used for maintenance and extensions, and some goes to local charities. Since 1991, the entire railway has been rebuilt, including an upgraded signalling system. About half of the 120 volunteer members are active with about 35 working each Sunday, and a dozen or so working every Wednesday. Members are trained to positions of station assistant, booking officer, train guard, train driver or signalman. Members construct new carriages and locomotives as well as maintaining track, signalling and rolling stock.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, diamond valley railway, eltham lower park -

National Wool Museum

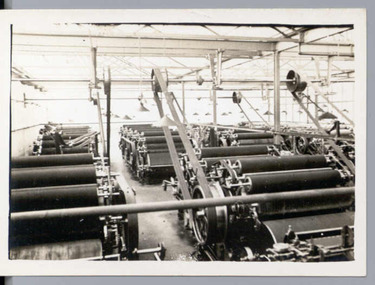

National Wool MuseumPhotograph

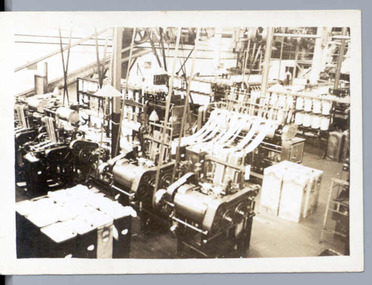

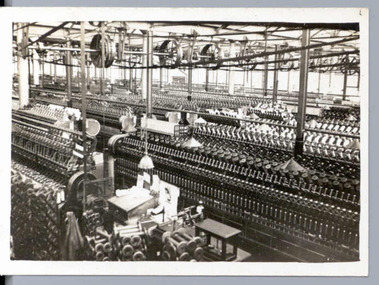

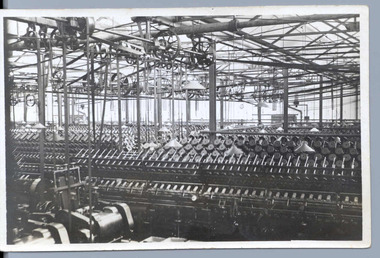

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the carding machine. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, carding -

National Wool Museum

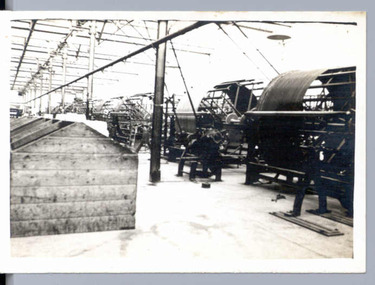

National Wool MuseumPhotograph

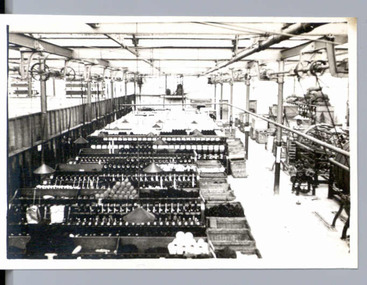

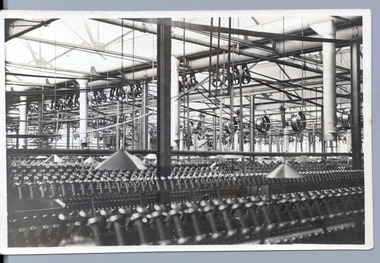

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, combing, noble comb -

National Wool Museum

National Wool MuseumPhotograph

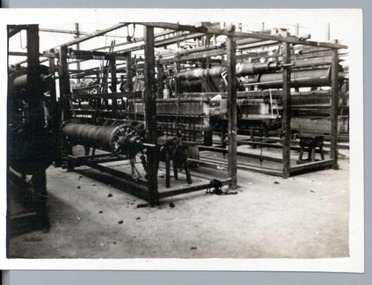

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

National Wool MuseumPhotograph

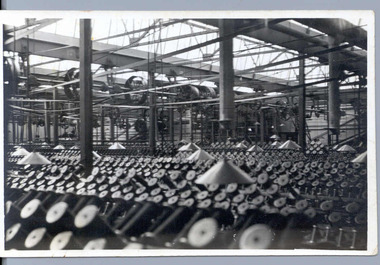

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the winding of the warp. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, winding, winding machinery -

National Wool Museum

National Wool MuseumPhotograph

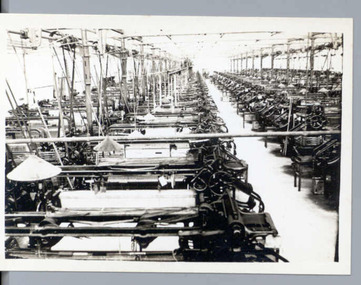

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows rows of weaving looms. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, weaving looms, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning mule for woollen threads. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - woollen -

National Wool Museum

National Wool MuseumPhotograph

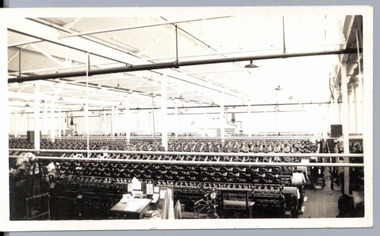

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the dyeing room with the dyeing vats. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, dyeing -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the dyeing room with the dyeing vats. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, dyeing -

National Wool Museum

National Wool MuseumPhotograph

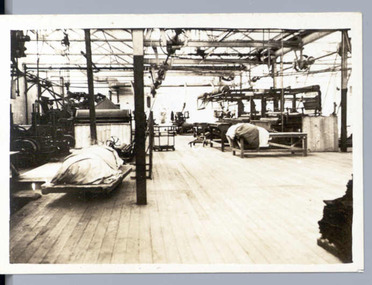

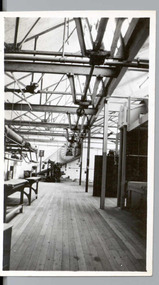

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTobacco Grading Dividers x 6, 1962

Tobacco farming began circa 1960 in the Kiewa Valley and consequently became one of its major industries. Many of the Italian families were involved in tobacco farming.Historical: This equipment was used on one of the first tobacco farms in the Kiewa Valley at Mongans Bridge. The dividers were home-made showing the resourcefulness of farmers living in the Kiewa Valley. Provenance: This tobacco farmer came from Italy and was sponsored to visit a tobacco farmer in Myrtleford to learn how to grow tobacco so that he could transfer those skills to his own farm in the Kiewa Valley.Wood plank with wire attached through a hole at each end in from side edge to create a stand. Another piece of wire stands vertically and is folded over to create blunt edge at the top. At the bottom it goes through the wood and along a bit to hold the wire in place. There are 6 dividers and because they are handmade the measurements vary slightly. tobacco. kiewa valley. mongans bridge. parmeson. rossaro, lorenzi brothers. grading dividers. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTobacco Picking Bag

Tobacco farming began circa 1960 in the Kiewa Valley and consequently became one of its major industries. Many of the Italian families were involved in tobacco farming.Historical: This equipment was used on one of the first tobacco farms in the Kiewa Valley at Mongans Bridge. The picking bag was home-made showing the resourcefulness of farmers living in the Kiewa Valley. Provenance: This tobacco farmer came from Italy and was sponsored to visit a tobacco farmer in Myrtleford to learn how to grow tobacco so that he could transfer those skills to his own farm in the Kiewa Valley.Picking bag known as 'Sacco'. The bag was used as a liner to the collecting bin in front of each of the 4 pickers on the picking machine. The bag was then hooked closed and held the leaf together for transport to the shed. Brown hessian woven length with 2 thick wires at 1 end hooked through 'bag' 100 mm from each side and hook on other end. Shaped in 1 rectangle rather than like a bag.Edges rough with wear and tear. A couple of holes where weave in 1 direction has torn.tobacco. picking bag. mongans bridge. kiewa valley. sacco. parmesan. rossaro. lorenzi brothers. -

Kiewa Valley Historical Society

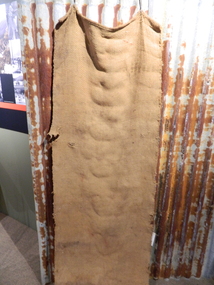

Kiewa Valley Historical SocietyTobacco Picking Apron

Tobacco farming began circa 1960 in the Kiewa Valley and consequently became one of its major industries. Many of the Italian families were involved in tobacco farming.Historical: This equipment was used on one of the first tobacco farms in the Kiewa Valley at Mongans Bridge. The picking apron was home-made showing the resourcefulness of farmers living in the Kiewa Valley. Picking machines replaced the picking apron. Provenance: This tobacco farmer came from Italy and was sponsored to visit a tobacco farmer in Myrtleford to learn how to grow tobacco so that he could transfer those skills to his own farm in the Kiewa Valley.The apron was used to gather green leaf before picking machines were made. Thick cotton cream apron, hemmed around the outside. Widest at the waist which has 2 rings each side where string is attached with a knot to tie around the waist. From the ring, material tapers inwards to form a bib. The corners of the bib have rings from which white rope is attached to hang around the neck. Similariy material tapers to the bottom where rings in the corners have rope attached - also to hang around the neck. Half way between the waist and neck, the material is double stitched and overlapped. grubbytobacco. mongans bridge, kiewa valley, parmesan, rossaro . picking apron. -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyTobacco 'Stretcher'

Tobacco farming began circa 1960 in the Kiewa Valley and consequently became one of its major industries. Many of the Italian families were involved in tobacco farming.Historical: This equipment was used on one of the first tobacco farms in the Kiewa Valley at Mongans Bridge. The tobacco 'stretcher' was home-made showing the resourcefulness of farmers living in the Kiewa Valley. Provenance: This tobacco farmer came from Italy and was sponsored to visit a tobacco farmer in Myrtleford to learn how to grow tobacco so that he could transfer those skills to his own farm in the Kiewa Valley.The 'stretcher' was used for carrying dry tobacco from kiln to stacking shed and later from stacking shed to the grading benches. 2 tree logs parallel to each other with 2 hessian bags cut into a piece each to overlap down the middle and starched between and held by a plank of wood nailed along at each end. The tree logs are held in position across the middle and behind the hessian by a thick plank of wood.Holes. One piece of hessian has painted in green:- Albury NSW and 5 green rectangles printed on it at the top partly covered by wooden plank.tobacco. mongans bridge. kiewa valley. kiln. shed. parmesan. rossaro. lorenzi brothers.