Showing 2813 items

matching chinese

-

Queenscliffe Maritime Museum

Queenscliffe Maritime MuseumCeramic - Saucer

Mark verified from Staffordshire Potteries websiteOwned by Bay steamers Ltd who operated in Port PhillipSaucer, vitreous china, white glaze; 1/4 broken offBay Steamers Ltd Melbourne - black crest John Maddock and Sons Ltd Englandchina, bayside steamers -

Friends of Westgarthtown

Friends of WestgarthtownOrnament, Kookaburra

China Kookaburra ornament sitting on a tree branch. Painted in browns and greens.No visible markingsornament, ceramics, kookaburra, brown and green, ceramic, china, tree branch. -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia

China Cheese Dish with Lid. Cream & Pink colour. Gilding on handle.stawell -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia

Wedge shaped China Cheese Dish with Lid. Painted Daisy design.stawell -

Stawell Historical Society Inc

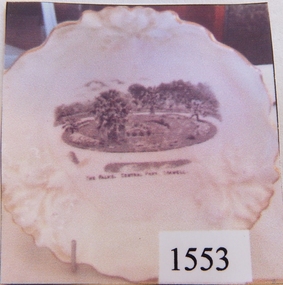

Stawell Historical Society IncSouvenir

White China Tuscan Bowl Printed with The Palms, Central Park Stawellstawell -

Stawell Historical Society Inc

Stawell Historical Society IncMemorabilia - Realia

Vase – Small Mauve/Pink china Vase with Violets at Handle & Leavesstawell -

Mont De Lancey

Mont De LanceyCarving Dish, 1890's

Part of a Wedding present Dinner Service. Used in Australia.Large china carving dish, patterned blue and white, with a scalloped edge.dishes -

Mont De Lancey

Mont De LanceyCarving Dish, Wedgewood & Co. Ltd, Circa 1900

Gift to Wandin Museum by Mrs. K. Bourke of Hawthorn.Wedgewood china, white carving dish, with black decoration around the rim."Wedgewood & Co. Ltd. England"dishes -

Mont De Lancey

Mont De LanceyMoustache cup

Late 19th centuryPainted floral china moustache cup and saucer with handle and gold edging.P9129 in ink on base of cup and saucercup, saucer and plate sets, cups and saucers, drinking cups -

Mont De Lancey

Mont De LanceyBowl, Burlington Ware

Used by Edna Andrews for storing dripping.Oval cream china bowl with orange and gold flowers and a green rim.Burlington Ware Made in Englandbowls -

Mont De Lancey

Mont De LanceyDish, Circa 1910

White China triangular cheese dish with gold, and pink 'flash' design. -

Mont De Lancey

Mont De LanceySugar Bowl, Circa 1900

Blue China sugar bowl with white raised figures and matching lid. -

Mont De Lancey

Mont De LanceyCloisonne - Vase

Purchased by Mr. & Mrs. H.N. Lord in 1970. Purchased by Mr. & Mrs. H. N. Lord in 1970. Cloisonné, a French word meaning "enclosed", is a metal-working technique. It is an ancient technique for decorating metalwork objects. The resulting objects can also be called cloisonné. The decoration is formed by first adding compartments or cells to the metal object. This is done by soldering or sticking silver or gold wires or thin strips placed on edge. These are visible in the finished piece, separating the different compartments. Coloured enamel is the usual filling for the cells. Cloisonné enamel objects are worked on with enamel powder made into a paste, which then is fired in a kiln. In older times inlays of cut gemstones were often used. They were decorated with geometric or schematic designs, with thick cloison walls. IOrnamental miniature Chinese cloisonne vase. Has floral patterned design.vases -

Mont De Lancey

Mont De LanceyVase

Wedding present to Mr. & Mrs. W.J. Sebire in 1897.Tall white china vase, with green flowers and yellow leaves painted on.vases -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreBox wooden containing a set of 12 coloured china carpet bowls, Mid 1940s

Harcourt Methodist Church was instrumental in forming the Harcourt Carpet Bowls Association with many members common to both organisations. This commenced about 1948 and is still in existence in 2017. The bowls were used at some church social evenings in addition to being used in the Harcourt Carpet Bowls competition. Mr. William A. Carr was the prime mover in this activity. Reminds us of the rise of post-World War II community organisations to fill the social gap left by the winding up of wartime patriotic associations. Box wooden containing a set of 12 coloured china carpet bowls - -

Parks Victoria - Mount Buffalo Chalet

Parks Victoria - Mount Buffalo ChaletCrockery

The jug and cup were purchased from a second - hand shop in Bairnsdale. Jug is older than cup as the chalet is represented as a single storey structure. The cup is later as the second storey appears in the illustration. 'Souvenirs in relation to the Chalet and Mount Buffalo wee first mention in December 1912... A large range of souvenirs has since been associated with the Chalet and Mount Buffalo from crafted wooden items, silver spoons, cups etc... The collection includes a broad selection of products that have been sold throughout much of the Chalet's history, each representative of the transient fashions of their period.' (Pg. 114. Historica) 'A group of tableware items is notable for its black transfer printed decoration, which features the Chalet building. Interestingly, the printed designs represent the Chalet at two different stages in its building history under the Victorian Railways, in 1926 after completion of the north wing, and 1937-39, after the second storey is added to the front.. manufactured in England by A.B. Jones and sons, a Stoke on Trent pottery firm which operated under the trade name of Grafton China between 1900-1972.' (Pg. 114. Historica)Listed in Draft Inventory of Significant Collection Items . Appendix A.3. Souvenirs. (Pg 168. Historica)..1] Ceramic jug. Souvenir of Mt Buffalo. White ceramic squat milk jug with a black transfer illustration/drawing on front side. Picture is of the MtBuffalo Chalet from the front. Some worn gold glaze detail. It appears to be a single story building with a planted garden at the front with a fence. Trees to one side and people walking up steps. "THE CHALET, MT BUFFALO NATIONAL PARK, VICTORIA." is written under the illustration. Jug has a faint crack. .2] White ceramic cup with gold edging around top of cup. Black transfer drawing of the chalet with a second storey. Rocks and tree in foreground and "THE CHALET. MT BUFFALO." underneath transfer. .1] "THE CHALET, MT BUFFALO NATIONAL PARK, VICTORIA." is written under the illustration. On the base of the jug, with sun motif, "ENGLAND / GRAFTON CHINA /A / B J / & SONS / LOFTUS MORA / PTY. LTD" .2] "THE CHALET. MT BUFFALO." underneath transfer. Under cup, "A.B.J. / GRAFTON / CHINA / MADE IN / ENGLAND" -

Bendigo Historical Society Inc.

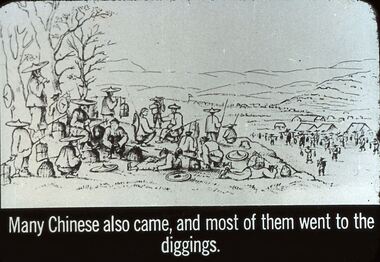

Bendigo Historical Society Inc.Slide - DIGGERS & MINING. THE GOLD ERA, c1850s

BHS CollectionDiggers & mining. The gold era. Many Chinese also came, and most of them went to the diggings. Slide shows the Chinese on the way to the diggings. Markings 10 994.031 GOL:5. Used as a teaching aid.hanimounteducation, tertiary, goldfields -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessels - Sail and Steam, A.V. Gregory, Australian Rivals - Past and Present, 1899-1932

These photographs are copies of original paintings by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. These mounted photographs, by A.V. Gregory, show both steam and sailing ships sailing in the Tea Race from China to London in 1872. The information included with the photographs has the following text: “Tea Clippers “ Well done Cutty Sark, by Bobbie Burns The CUTTY SARK and THERMOPYLAE. The start of the 1872 Tea Race from China to London. The “Cutty Sark” first away, followed closely by the “Thermopylae”, finally parting after several days’ company. On this race the “Cutty Sark” lost her rudder in the Indian Ocean, putting her hopelessly out of the race, and enabling the “Thermopylae” to pass her and reach London on 11th October, 115 days out, the “Cutty Sark” limping home seven days later. The credit of the race was given to the “Cutty Sark” by the shipping world. Copies of the pictures may be had from A.V. Gregory, 326 Albert Road, South Melbourne."The detailed images of the vessels depicted in this photographs shows some of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors. The pictures and document are significant for their association with the Tea Clippers, famous for racing across the world to arrive in Australia with the fastest time.Photographs of paintings of sail and steamships, three photographs mounted together side by side, titled "Australian Rivals - Past and Present". The centre shows the sailing ships Thermopylae and Cutty Sark. It is flanked on each side by a photograph of a steamship. The document with the photographs gives the history of the famous Tea Race from China to London in 1872.Title: "Australian Rivals - Past and Present". Handwritten on Left photograph "A.V. GREGORY - SS KATOOMBA" Handwritten on Centre photograph; "THERMOPLAE - A.V. GREGORY - CUTTY SARK - FIRST AWAY" Handwritten on Right photograph; "CANBERRA - A/V/ GREGORY" Handwritten on accompanying card is the story of the Tea Clippers.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, ss katoomba, thermopylae, cutty sark, tea race, tea race china to london 1872, canberra, tea clippers, a v gregory -

Federation University Art Collection

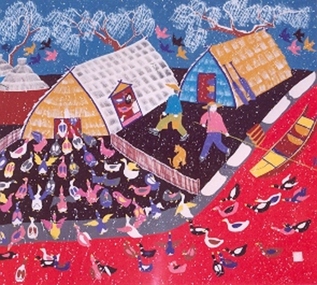

Federation University Art CollectionWork on paper - Printmaking, Returning Ducks, 1999

... chinese ...Yang Deliang was from the Jinshan Peasant Painting Academy where Chinese folk art of southeastern Yangtze River area of Shanghai is undertaken. The paintings integrate the folk arts of printing and dyeing, embroidery, paper cutting, wood carving, and cook stove painting, and depict the peasant's colorful customs and daily life. This style of folk art was born in 1972, under the guidance of a professional painter Wu Tongzhang. Jinshan Peasant Painting made its international debut in the Expo 1980 in Brussels, Belgium. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.Framed silkcreen An artist's 'chop' is evident on the lower right cornerart, artwork, yang deliang, chinese, silkscreen, jinshan peasant painting academy, j -

South Gippsland Shire Council

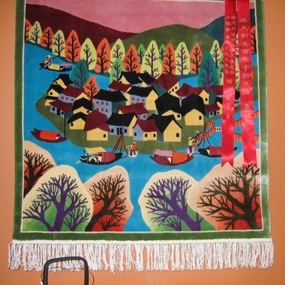

South Gippsland Shire CouncilWall hanging, Landscape on carpet

Wallhanging, Lanscape on carpet featuring a Chinese scene with buildings, trees and boats. Fixed on wooden rod. White fringe and two red satin ribbons fixed to right edge of rod. Chinese writing in gold on ribbons. -

South Gippsland Shire Council

South Gippsland Shire CouncilDolls, Painted, 1990s

Set of two decorated Chinese doll ornaments. Male and female Chinese characters featuring painted ceramic faces with rounded bodies. Dressed in cotton satin clothes and trimmed in coloured fabric and white cord with tassel. -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionFunctional object - Saucer, n.d

Displayed in History HouseWhite saucer with gold edgingFront: Base: Royal/Standard/Bone China/Englanddecorative item, bone china, saucer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Federation University Historical Collection

Federation University Historical CollectionObject, Glass Shelf Ornament: Shunde Polytechnic

Shunde Polytechnic is in district of Guangdong, Chine. District has an age-old tradition of being the centre of trade, textile industry.Glass object with etching of a building and name of institution.Chinese writing: Shunde Polytechnic in English. Symbol of institution.shunde polytechnic, china, guangdong sheng, trade, textile industry, ornament, etched glass -

Maffra Sugarbeet Museum

Maffra Sugarbeet MuseumSouvenir Plate

A tangible reminder of how important the sugar beet factory and the sugar beet industry was to Maffra, is the production of souvenir-ware with images of the factory. The Sugar Beet industry was highly significant in the Maffra area for just under 50 years, and led to the construction of the Glenmaggie Weir and the consequent Macalister Irrigation District. The item lacks detailed provenance, but is obviously local.Oblong cream and tan souvenir plate with photograph of "Sugar Factory, Maffra" printed in centre. The ends are extended to form handles, each pierced with two holes.Sugar Factory Maffra [crown] / Victoria / China / Czechoslovakiasugarbeet -

Stanley Athenaeum & Public Room

Stanley Athenaeum & Public RoomLeisure object - Euchre cards

757 Deer brand playing cards 757 Deer brand Playing cards - Made in China -

Stanley Athenaeum & Public Room

Stanley Athenaeum & Public RoomLeisure object - Euchre cards

757 Deer brand playing cards 757 Deer brand Playing cards - Made in China -

Ambulance Victoria Museum

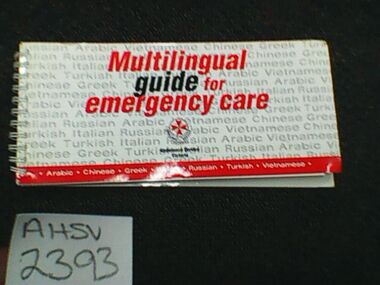

Ambulance Victoria MuseumBook, Multilingual guide for emergency care, Circa 2000

created by ambulance officer Lindsay O'Brien to help communicate with non English speaking patientsSpiral bound booklet with Ambulance Service Victoria logo in centreArabic Chinese Greek Italian Russian Turkish Vietnameselindsay o'brien -

Kew Historical Society Inc

Kew Historical Society IncHeadwear - High Crowned, Wide Brimmed Hat, Caterina Lucci, 1980s

The Kew Historical Society’s fashion and design collection is comprised of costumes, hats, shoes and personal accessories. Many of these items were purchased or handmade in Victoria; some locally in Kew. The extensive hat collection comprises items dating from the 1860s to the 1970s. While most of the hats in the collection were created by milliners for women, there are a number of early and important men’s hats in the collection. The headwear collection is particularly significant in that it includes the work of notable Australian and international milliners.Broad-rimmed soft, black polyester velvet woman’s hat designed by Caterina Lucci and imported to Australia by Crochetta.Label: Caterina Lucci [A Crochetta import]. Made in Chinawomen's clothing -- hats, headwear, caterina lucci -

School of Health and Biomedical Sciences, RMIT University

School of Health and Biomedical Sciences, RMIT UniversitySculpture - Bust, Confucius

Large bronze bust of Confucius sitting on top of a purpose built black painted wood plinth with red painted wood topper. Bronze plaque at front.Confucious (551Bc - 479BC) [Chinese script] (Kong Zi)confucius, chinese medicine, rmit chinese medicine collection