Showing 1005 items matching "ready"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Lead Ingot, circa 1878

This lead ingot was donated to Flagstaff Hill Maritime Village in January 2015 by local residents who discovered the ingot in their garden after they purchased the property about 12 months ago The LOCH ARD cargo manifest lists “Pig lead 50 tons” comprising “944 pig and 37 rolls”. Subsequent classification has rendered this section of cargo as “Lead Ballast”. This could be true. The international price per ton of lead ore plunged from a high point of £17 in 1853 to a low of £8 in 1882. The cheaper price of lead at the time of the vessel’s loading in early 1878 may have meant it was considered as an alternative to other ballast material (traditionally stone) for the journey to Melbourne. Loch Line ships generally returned to Britain laden with Australian wool. Even though wool bales were “screwed in” to the hold to less than half their “pressed weight”, they still made an awkwardly light cargo for the passage around the Horn. The concentrated weight of lead pigs along the keel line would help steady and centre the ship, and perhaps the artefacts in this case were to be retained for this purpose, rather than being sold on to the ready colonial market. However this is conjecture. Demand for building materials in the gold and wool rich Colony of Victoria was high in the 1870s, and much of the LOCH ARD cargo was intended for the Melbourne International Exhibition in 1880, which was another example of buoyant economic conditions. In the nineteenth century lead was valued for its density (high ratio of weight to volume), flexibility (relative softness for working into shape), and durability (corrosion resistant and waterproofing properties). It was used for pipes and water tanks, roof flashing and guttering, window sealing and internal plumbing. Many large private residences and new public buildings were at planning or construction stage in the colony during this period. The LOCH ARD lead ingots could equally have been destined for this ready market. HISTORY OF THE LOCH ARD The LOCH ARD belonged to the famous Loch Line which sailed many ships from England to Australia. Built in Glasgow by Barclay, Curdle and Co. in 1873, the LOCH ARD was a three-masted square rigged iron sailing ship. The ship measured 262ft 7" (79.87m) in length, 38ft (11.58m) in width, 23ft (7m) in depth and had a gross tonnage of 1693 tons. The LOCH ARD's main mast measured a massive 150ft (45.7m) in height. LOCH ARD made three trips to Australia and one trip to Calcutta before its final voyage. LOCH ARD left England on March 2, 1878, under the command of Captain Gibbs, a newly married, 29 year old. She was bound for Melbourne with a crew of 37, plus 17 passengers and a load of cargo. The general cargo reflected the affluence of Melbourne at the time. On board were straw hats, umbrella, perfumes, clay pipes, pianos, clocks, confectionary, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were items included that intended for display in the Melbourne International Exhibition in 1880. The voyage to Port Phillip was long but uneventful. At 3am on June 1, 1878, Captain Gibbs was expecting to see land and the passengers were becoming excited as they prepared to view their new homeland in the early morning. But LOCH ARD was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4am the fog lifted. A man aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head on into the wind, the ship lost momentum, the sails fell limp and LOCH ARD's bow swung back. Gibbs then ordered the anchors to be released in an attempt to hold its position. The anchors sank some 50 fathoms - but did not hold. By this time LOCH ARD was among the breakers and the tall cliffs of Mutton Bird Island rose behind the ship. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves broke over the ship and the top deck was loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of LOCH ARD and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as LOCH ARD Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael had raced onto deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke open case of brandy which had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a state of exhaustion, he told the men of the tragedy. Tom returned to the gorge while the two men rode back to the station to get help. By the time they reached LOCH ARD Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland, this time by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost family in the LOCH ARD disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost all of her family in the tragedy. Ten days after the LOCH ARD tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of LOCH ARD still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some was washed up into what is now known as LOCH ARD Gorge. Cargo and artefacts have also been illegally salvaged over many years before protective legislation was introduced. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton porcelain peacock - one of only nine in the world. The peacock was destined for the Melbourne International Exhibition in 1880. It had been well packed, which gave it adequate protection during the violent storm. Today, the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck it has now become Australia's most valuable shipwreck artefact and is one of very few 'objects' on the Victorian State Heritage Register. The shipwreck of the LOCH ARD is of State significance ― Victorian Heritage Register S417 Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best known shipwrecks in Victoria’s history. Lead ingots (sometimes referred to as ‘lead ballast’ or ‘lead pigs), salvaged from the wreck of the LOCH ARD. Grey metal bars with flat base, rising in a curved moulded shape to form a smooth rounded upper face. The imprint of the maker runs along the upper surface in clearly legible capital lettering (height 3cm). Durable and heavy, with some marine staining, but in good condition. Stamped along curved surface, within oval border, "PONTIFEX & WOOD LONDON."flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, lead pigs, lead ingots, lead ballast, pontifex and wood, london, lead smelters -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Folder, Aerospace Industry, 1958-1961

honeywell, scout rocket, echo satellite, mercury rocket, centaur rocket, advent rocket, mariner satellite, dyna soar, x-15, midas rocket, tiros satellite, discoverer rocket, vanguard satellite, aerospace industry, alan gardiner collection, space industry -

Federation University Historical Collection

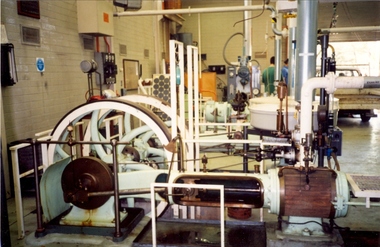

Federation University Historical CollectionPhotograph - Colour photograph, Davey Paxman Experimental Steam Engine in the Mount Helen Workshop, c1994

The Davey Paxman Experimental Steam Engine was purchased by the Ballarat School of Mines as the result of a bequest from Thomas Bath.The Davey Paxman Experimental Steam Engine was purchased as the result of a bequest from Thomas Bath. The 'substantial sum' was used to build an Engineering Laboratory. The Ballarat School of Mines Council minutes of 08 November 1901 record: - Plans for [the] proposed building were submitted ... and ... it was resolved that a temporary building for an Engineering Laboratory be put up.' This laboratory, as an existing building, is first mentioned in the Ballarat School of Mines President's Annual Report of 1901, presented on 28 February 1902, reporting 'the erection of a building 67ft long by 33 ft wide' This report also lists all the equipment that would be accommodated in the Engineering Laboratory, including the experimental steam engine and boiler. The experimental Davey-Paxman steam engine arrived in Ballarat towards the end of 1902. The Engineering Laboratory was opened on 14 August 1903 by His Excellency Sir Sydenham Clarke. This engineering laboratory remained in use till about 1945. By 1944 preparations were under way at the Ballarat School of Mines to expand existing facilities, to be ready for the influx of returned soldiers. A new Heat Engines laboratory was built, this time of brick construction, replacing the previous corrugated-iron shed. In the early stages the steam engine was used to drive an overhead transmission shaft for machinery in the adjacent workshop. Later the steam engine was moved to a space that became the Heat Thermodynamics Laboratory. At the end of 1969 the engine was relocated to the Thermodynamics Laboratory at the then Ballarat Institute of Advanced Education (BIAE) Mt Helen Campus. It was donated to Sovereign Hill in 2006. According to the research of Rohan Lamb in 2001 around five experimental steam engines were made by Davey Paxman, and three of these had similar configuration to the Ballarat School of Mines Steam Engine, however, each of these was also unique with different valve arrangements. The list, which was on a scrap of paper in a folio held in the Essex Archives, confirmed that one was sent to India. The Ballarat steam engine can be dated to late 1901 to early 1902. Zig Plavina was responsible for moving the steam engine to Mount Helen, and worked on it as a technician for many years. He observed the following: * The condenser is driven by the low pressure engine. * The following arrangements are possible: i) the high pressure engine alone, exhausting to atmosphere. Condenser not used, crankshaft flanges not coupled. ii) crankshafts coupled, mains pressure (120 psi) steam supplied to high pressure engine, partially expanded steam delivered to low pressure engine (Tandem operation). Choice available re exhaust steam: either to the condenser or to atmosphere. iii) crankshafts not coupled, reduced pressure steam supplied to low pressure engine. Exhaust steam - either to the condenser or to atmosphere. * Valve arrangement - a choice of Pickering cut-off or throttle governor. On low pressure engine - throttle governor only.davey paxman experimental steam engine, model steam engine, steam, thermodynamics laboratory, thomas bath, bequest -

Melbourne Tram Museum

Melbourne Tram MuseumDocument - Personal Papers, Melbourne Tramways Trust (MTT), "Notice Papers for 'The Melbourne Tramways Trust' meetings", 1885 - 1886

Set of 16 Notice Papers or Meeting Agendas - sent to Trust Members and others for The Melbourne Tramways Trust for period April 1886 to November 1890 as listed below. Printed by Ferguson and Moore or Edgerton and Moore for the Trust. Signed by the Secretary. Covers construction arrangements, appointments, financial, loans, debentures, legislation, arrangements with the Melbourne Tramway and Omnibus Company and other organisations including banks. Notes are the principal items shown in the Orders of the Day. Printed by Fergusson and Moore or Edgerton and Moore - different name on the 17/1/1890 meeting. 1886 – 1887 – Thomas O’Grady and T. Hamilton remain as Chairman and Secretary respectively. Meeting No. Date Notes 5 16/4/1886 Wages, supplier payments, accept tenders for mechanical stokers, construction of Carlton line, notice to construct a siding in Wellington Parade and purchase of land for the Brunswick Engine house. 1888 – 1890 – Cr. C.H Jennings Chairman, T. Hamilton Secretary Meeting No. Date Notes 3 17/1/1890 Wages, supplier payments, accept tenders for crossings, railway crossings, cement and that the Hawthorn House is completed and ready for traffic. 4 24/1/1890 Special meeting to consider communication from MTCo re opening of the Hawthorn horse tramway. 5 14/2/1890 Wages, supplier payments. 6 14/3/1890 Wages, supplier payments, dispute with David Munro over fine for the Hawthorn bridge and Collingwood council seeking to widen approach to Victoria St bridge. 7 18/4/1890 Wages, supplier payments, wood blocking of Hawthorn and Victoria bridge lines. 8 16/5/1890 Wages, supplier payments, proceed with Victoria Bridge approaches. 9 13/6/1890 Wages, supplier payments, reappointment of C. W. Ellis as auditor, protect Trust interest in reference to the Hoddle St tramway bill. 10 11/7/1890 Wages, supplier payments including hire of horses for threading of cable. 11 8/8/1890 Wages, supplier payments, call tenders etc for St Kilda Esplanade line. 12 5/9/1890 Wages, supplier payments 13 3/10/1890 Wages, supplier payments, letting of tenders for track materials, 2nd crossover for cars in Spencer St. 14 31/10/1890 Wages, supplier payments, acceptance of tenders for Esplanade line. 1890 – 1891 – Cr. C.H Jennings Chairman, T. Hamilton Secretary Meeting No. Date Notes 1 19/12/1890 Wages, supplier payments, accept of tenders for Esplanade including engines. 15 3/11/1890 Special meeting to consider letter from St Kilda council re widening of the Esplanade. 16 28/11/1890 Wages, supplier payments, accept of tenders for Esplanade including engine house and cable. For a word version - see: \dbtext\hawthtramcoll\images\htd2003doc.doctrams, tramways, mtt, cable trams, melbourne tramways trust, construction, finances, mto co -

Eltham District Historical Society Inc

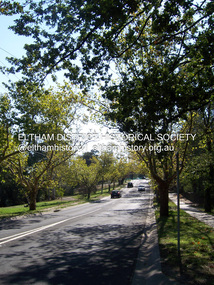

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Avenue of Honour, Main Road, Eltham, 20 April 2008

The suggestion of an Avenue of Honour may have been originally put forward by Lady Irvine who was a member of the Welcome Home Committee. The Avenue of Honour was established to memorialise all those from Eltham who enlisted (some of whom were still fighting overseas at the time), similarly as the Shire of Eltham (Soldiers) Memorial Park was in tribute to all from the Shire who enlisted. The twenty-seven names of those killed from Eltham were engraved on the Eltham War Memorial Obelisk unveiled in 1919 at the corner of Main Road and Bridge Street. From an article in the Heidelberg News and Greensborough, Eltham and Diamond Creek Chronicle, September 22, 1917, p. 2, it was reported: Some few weeks ago a public meeting was held in the Eltham Rechabite Hall for the purpose of forming a committee to make necessary arrangements for the return of our brave lads from the front, with the result that the following officers were elected, viz., Sir William Irvine. president; Cr. R. D. Taylor, vice-president; Rev. T. W. Sapsford, secretary; Mr R. E. Gilsenan, treasurer; with a very strong committee of local residents. Lady Irvine then suggested that it would be nice to plant an Avenue of Honor, which was carried out in a very cheerful and spirited manner on Saturday afternoon. Cr Taylor and Mr R. E. Gilsenan occupied themselves during the fore-forenoon in getting the lining-out and other preliminaries ready, but shortly after one o'clock the willing workers could be seen wending their way towards the township, with picks, shovels. &c., on their shoulders, and in a very short time the gang at work was in appearance a very lively and pretty sight, the only thing that was missing was the camera, to have had a few snapshots taken. A little after 3 o'clock Sir William and Lady Irvine, and Mr W. Gray and family, arrived by motor. Cr Taylor then explained that their object in gathering together so hurriedly to plant the avenue was on account of the lateness of the season, and being offered 100 trees, free of charge, by Cr. Wm. G. Gray; of Allwood Nursery, Hurst's Bridge (for which the committee are deeply grateful to him and the public highly appreciate his generous offer). Sir Wm. Irvine then spoke at some length on the ravages of this cruel war, and the good that must result therefrom in bringing all closer together; he also referred to our brave lads who were fighting for us, and thought it was for those at home to show their appreciation by planting the Avenue of Honor. Lady Irvine thou proceeded to plant the first tree, which was an English oak: Sir William following by planting a Spanish chestnut; and Mrs W. G. Gray a sycamore. After that the gathering refired to the entrance of Mr R. E. Gilsenan's green paddock to partake of refreshments, which the ladies had kindly provided for the willing band of workers. Work was again taken to in earnest, and the planting finished, all being satisfied that they had done good work. At the Eltham Shire Council’s monthly meeting held May 6, 1918, Cr. Gray promised to give Council £20 to £25 worth of trees if the Council would plant and guard them. His desire was that a tree be planted in the name of every soldier lad who has gone to the front. Each tree was later adorned with a brass plaque with the name of a soldier and a wooden tree guard placed around them. Over the years many trees died, and following roadworks were replanted on a new alignment. Nillumbik Shire Council is continuing this process of replanting trees in a new alignment to move them away from overhead power lines and to clear the VicRoads reserve. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p119This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, avenue of honour, main road, eltham -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Plane, Mid to Late 19th Century

A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more maneuverable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a smooth finish to timber. The tool was used when timber items needed to have a smooth finish these types of planes were used in conjunction with profiled planes that provided a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Smoothing Plane coffin design Maker J Moseley & Son London & 2 1/4"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageOar, early 20th century

This oar is from the Lifeboat Warrnambool, which is on sit at Flagstaff Hill Maritime Village. The construction of the lifeboat ‘Warrnambool’ began 15th September 1909 and was completed almost 12 months later, 1st September 1910. It was built at the Government Dockyard in Williamstown, Victoria, along the lines designed by the Great Britain’s Royal Lifeboat Institution, and included whaleback decks fore and aft, mast and centreboard, and rudder and tiller hung from the sternpost. It could be propelled by both sail and oar. At that time Captain Ferguson was Chief Harbour Master and Mr Beagley was foreman boat builder. Mr Beagley built the lifeboat with his fellow workmen. The boat was described as “… a fine piece of workmanship and does credit to her builders and designers…” It had all the latest improvements in shape, disposition of weight and watertight compartments, and it had space for a large number of people in addition to the crew. It appears that 'H Meiers' whose signature was on the plaque that was found concealed in the hull, was involved with the building of the lifeboat. His signature and the dates of the start and finish of the boat’s construction are pencilled on the raw timber 'plaque' found in the hull in the early 1990’s when the lifeboat was being restored. It is interesting that the ‘Melbourne Directory’ of 1911, published by Sands and MacDougal, lists McAuley and Meiers, boat builders, Nelson Place foreshore, between Pasco and Parker Streets, Williamstown, (Victorian Heritage Database, ‘Contextual History, Maritime Facilities’), It is quite possibly the business of the person whose name is inscribed on the lifeboat plaque. Flagstaff Hill’s documentation also mentions that the keel was laid at ‘Harry Myers, boat builders, Williamstown, Melbourne’ – the name ‘Myers’ can also be spelled ‘Meiers’, which could be the same person as the Meiers in “McAuley and Meiers” (as mentioned in genealogy lines of Myers). The new lifeboat, to be named ‘Warrnambool’ was brought to town by train and launched at the breakwater on 1st March 1911 using the Titan crane (the old lifeboat built in 1858, was then returned to Melbourne in 1911). This new lifeboat was stationed at Warrnambool in a shed located at the base of the Breakwater, adjacent to the slipway. A winch was used to bring it in and out of the water. The lifeboat ‘Warrnambool’ was similar in size to the old lifeboat but far superior in design, build and sea-going qualities such as greater manoeuvrability. The ‘self-righting, self-draining’ design was “practically non-capsizeable” and even if the boat overturned it would right itself to an even keel and the water would drain away. The hull was built of New Zealand Kauri, using double diagonal planking, laid in two layers at right angles, with a layer of canvas and red lead paint between the timbers to help seal the planking. It has “… plenty of freeboard, high watertight spaces between the deck and bottom… through which pipes lead…” The backbone timbers were made of Jarrah. The lifeboat Warrnambool was one of several rescue boats used at Port Fairy and Warrnambool in early 1900's. In late 1914 the Warrnambool lifeboat and crew were used to help find what was left of the tragic wreckage of the Antares, and were able to discover the body of one of the crewmen, which they brought back to Warrnambool. Between 1951 and 1954 the lifeboat was manned under the guidance of Captain Carrington. He held lifeboat practice each month on a Sunday morning, to comply with the Ports and Harbour’s request that lifeboats be manned by a strong and competent crew, ready for action in case of emergency. In the early 1960’s it ended its service as a lifeboat and was used in Port Fairy as a barge to help dredge the Moyne River, bolted to the Port Fairy lifeboat. Flagstaff Hill obtained the Warrnambool in 1975. In 1984 it was on display at Flagstaff Hill Maritime Village, Warrnambool. On 23rd May 1990 she was lifted from the water and placed in a cradle for restoration. The name ‘WARRNAMBOOL could be seen faintly on the lifeboat before it was restored. It was during the restoration that Flagstaff Hill's boat builder discovered the 'plaque' inside the hull. A copy of the blueprint plans has the name “V.E.E. Gotch” printed on it. His advertisement in Footscray’s ‘Independent’ newspaper of Saturday 11th May 1901 states he is “Principal and Skilled member (Naval Architect) to the Court of Marine Inquiry of Victoria and holds classes for naval architectural drawing and arithmetic.” The oar is significant for its association with the lifeboat WARRNAMBOOL, which is significant for its half century service to the local community as a lifesaving vessel. She was also used to help retrieve the body of a shipwrecked crew member of the ANTARES. Large wooden oar, shaped two handgrip with tapering shaft to large flattened blade, (2) copper reinforcing strips on blade. Sweep oar is from the Lifeboat Warrnambool. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, oar, lifeboat warrnambool, sweep oar -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Caldwell’s Ink Factory, Late 19th to early 20th centuries

This design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a three-piece mould, a method often used in the late 19th and early 20th centuries, with the maker's name engraved into the mould section for the base. The glass blower would cut the bottle off the end of his blowpipe with a tool and join a mouth onto the top, rolling the lip. The bottle was then filled with ink and sealed with a cork. This method of manufacture was more time-consuming and costly to produce than those made in a simple two-piece mould and 'cracked' off the blowpipe. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. This particular bottle is unusual as it has four sloping indents at the corners of the shoulder, most likely for resting a pen with its nib upwards and the handle resting on a flat surface. Most of the bottles made during this era had horizontal pen rests that were indented into both of the long sides of the shoulder. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. This only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This hand-blown bottle is significant for being the only bottle in our collection with the unusual sloping pen rests on its shoulder. It is also significant for being made in a less common three-piece mould. The method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle is of state significance for being produced by an early Melbourne industry and exported overseas. This ink bottle is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottle; rectangular base, hand-blown clear glass bottle with its own cork. The bottle has side seams from the base to the mouth, an indented base and an applied lip. The corners of the shoulder sides have unusual diagonal grooves that slope down and outwards that may have been used as pen rests. Inside the bottle are remnants of dried blue-black ink. The glass has imperfections and some ripples on the surface. The bottle has an attached oval black label label with gold-brown printed text and border. The base has an embossed inscription. The bottles once contained Caldwell’s blend of blue black ink.Printed on label; “CALDWELL's BLUE BLACK INK” Embossed on the base "CALDWELLS"flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture, three part mould, cauldwells, cauldwell's -

Flagstaff Hill Maritime Museum and Village

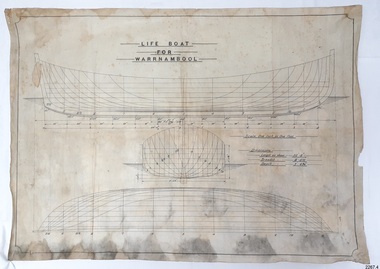

Flagstaff Hill Maritime Museum and VillagePlan - Vessel Line Drawing, Life Boat for Warrnambool, ca. 1900-1909

The plans were used for the construction of the lifeboat ‘Warrnambool’, which began 15th September 1909 and was completed almost 12 months later 1st September 1910. It was built at the Government Dockyard in Williamstown, Victoria, along the lines designed by Great Britain’s Royal Lifeboat Institution, and included whaleback decks fore and aft, mast and centreboard, and rudder and tiller hung from the sternpost. It could be propelled by both sail and oar. At that time Captain Ferguson was Chief Harbour Master and Mr Beagley was the foreman boat builder. Mr Beagley built the lifeboat with his fellow workmen. The boat was described as “… a fine piece of workmanship and does credit to her builders and designers…” It had all the latest improvements in shape, disposition of weight and watertight compartments, and it had space for a large number of people in addition to the crew. It appears that 'H Meiers' whose signature was on the plaque that was found concealed in the hull, was involved with the building of the lifeboat. His signature and the dates of the start and finish of the boat’s construction are pencilled on the raw timber 'plaque' found in the hull in the early 1990s when the lifeboat was being restored. It is interesting that the ‘Melbourne Directory’ of 1911, published by Sands and MacDougal, lists McAuley and Meiers, boat builders, Nelson Place foreshore, between Pasco and Parker Streets, Williamstown, (Victorian Heritage Database, ‘Contextual History, Maritime Facilities’), It is quite possibly the business of the person whose name is inscribed on the lifeboat plaque. Flagstaff Hill’s documentation also mentions that the keel was laid at ‘Harry Myers, boat builders, Williamstown, Melbourne’ – the name ‘Myers’ can also be spelled ‘Meiers’, which could be the same person as the Meiers in “McAuley and Meiers” (as mentioned in genealogy lines of Myers). The new lifeboat, to be named ‘Warrnambool’ was brought to town by train and launched at the breakwater on 1st March 1911 using the Titan crane (the old lifeboat built in 1858, was then returned to Melbourne in 1911). This new lifeboat was stationed at Warrnambool in a shed located at the base of the Breakwater, adjacent to the slipway. A winch was used to bring it in and out of the water. The lifeboat ‘Warrnambool’ was similar in size to the old lifeboat but far superior in design, build and sea-going qualities such as greater manoeuvrability. The ‘self-righting, self-draining design was “practically non-capsizeable” and even if the boat overturned it would right itself to an even keel and the water would drain away. The hull was built of New Zealand Kauri, using double diagonal planking, laid in two layers at right angles, with a layer of canvas and red lead paint between the timbers to help seal the planking. It has “… plenty of freeboard area, high watertight spaces between the deck and bottom… through which pipes lead…” The backbone timbers were made of Jarrah. The lifeboat Warrnambool was one of several rescue boats used at Port Fairy and Warrnambool in the early 1900s. In late 1914 the Warrnambool lifeboat and crew were used to help find what was left of the tragic wreckage of the Antares and were able to discover the body of one of the crewmen, which they brought back to Warrnambool. Between 1951 and 1954 the lifeboat was manned under the guidance of Captain Carrington. He held lifeboat practice each month on a Sunday morning, to comply with the Ports and Harbour’s request that lifeboats be manned by a strong and competent crew, ready for action in case of emergency. In the early 1960’s it ended its service as a lifeboat and was used in Port Fairy as a barge to help dredge the Moyne River, bolted to the Port Fairy lifeboat. Flagstaff Hill obtained the Warrnambool in 1975. In 1984 it was on display at Flagstaff Hill Maritime Village, Warrnambool. On 23rd May 1990, she was lifted from the water and placed in a cradle for restoration. The name ‘WARRNAMBOOL could be seen faintly on the lifeboat before it was restored. It was during the restoration that Flagstaff Hill's boat builder discovered the 'plaque' inside the hull. A copy of the blueprint plans has the name “V.E.E. Gotch” printed on it. His advertisement in Footscray’s ‘Independent’ newspaper of Saturday 11th May 1901 states he is “Principal and Skilled member (Naval Architect) to the Court of Marine Inquiry of Victoria and holds classes for naval architectural drawing and arithmetic.” The line drawing is significant for its connection with the lifeboat WARRNAMBOOL. The lifeboat is very significant to local and state history for its use in the lifesaving rescues of seafarers, particularly in Lady Bay. It was part of the local rescue equipment. It gave a half-century of service to the local community as a lifesaving vessel, including its involvement in retrieving the body of a shipwrecked crew member of the ANTARES. Line drawing in black ink and pencil on rectangular parchment or waxed linen. Drawing has diagrams of three profiles of a vessel, with measurements and connecting pencil lines on the left quarter. The plan is for the lifeboat named “Warrnambool”, which was built in Melbourne and completed in 1910. Old blue copies of the Lifeboat plan are archived also.“LIFE BOAT / FOR / WARRNAMBOOL” “Scale, One Inch to One Foot” “ “Length as shown 30’ – 8” “ “Breadth “ “ 8’ – 6 ½ “ “ “Depth “ “ 3’ – 4 ¾” “flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lifeboat, warrnambool lifeboat, boat plans, lifeboat plans, boat construction, boat building, line drawing, plan for lifeboat, life boat, life boat 'warrnambool', clinker design, 1910 lifeboat, life saving equipment, shipbuilding -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRowlock, early 20th century

Rowlock from the Lifeboat Warrnambool, which is on site at Flagstaff Hill Maritime Village. The construction of the lifeboat ‘Warrnambool’ began 15th September 1909 and was completed almost 12 months later, 1st September 1910. It was built at the Government Dockyard in Williamstown, Victoria, along the lines designed by the Great Britain’s Royal Lifeboat Institution, and included whaleback decks fore and aft, mast and centreboard, and rudder and tiller hung from the sternpost. It could be propelled by both sail and oar. At that time Captain Ferguson was Chief Harbour Master and Mr Beagley was foreman boat builder. Mr Beagley built the lifeboat with his fellow workmen. The boat was described as “… a fine piece of workmanship and does credit to her builders and designers…” It had all the latest improvements in shape, disposition of weight and watertight compartments, and it had space for a large number of people in addition to the crew. It appears that 'H Meiers' whose signature was on the plaque that was found concealed in the hull, was involved with the building of the lifeboat. His signature and the dates of the start and finish of the boat’s construction are pencilled on the raw timber 'plaque' found in the hull in the early 1990’s when the lifeboat was being restored. It is interesting that the ‘Melbourne Directory’ of 1911, published by Sands and MacDougal, lists McAuley and Meiers, boat builders, Nelson Place foreshore, between Pasco and Parker Streets, Williamstown, (Victorian Heritage Database, ‘Contextual History, Maritime Facilities’), It is quite possibly the business of the person whose name is inscribed on the lifeboat plaque. Flagstaff Hill’s documentation also mentions that the keel was laid at ‘Harry Myers, boat builders, Williamstown, Melbourne’ – the name ‘Myers’ can also be spelled ‘Meiers’, which could be the same person as the Meiers in “McAuley and Meiers” (as mentioned in genealogy lines of Myers). The new lifeboat, to be named ‘Warrnambool’ was brought to town by train and launched at the breakwater on 1st March 1911 using the Titan crane (the old lifeboat built in 1858, was then returned to Melbourne in 1911). This new lifeboat was stationed at Warrnambool in a shed located at the base of the Breakwater, adjacent to the slipway. A winch was used to bring it in and out of the water. The lifeboat ‘Warrnambool’ was similar in size to the old lifeboat but far superior in design, build and sea-going qualities such as greater manoeuvrability. The ‘self-righting, self-draining’ design was “practically non-capsizeable” and even if the boat overturned it would right itself to an even keel and the water would drain away. The hull was built of New Zealand Kauri, using double diagonal planking, laid in two layers at right angles, with a layer of canvas and red lead paint between the timbers to help seal the planking. It has “… plenty of freeboard, high watertight spaces between the deck and bottom… through which pipes lead…” The backbone timbers were made of Jarrah. The lifeboat Warrnambool was one of several rescue boats used at Port Fairy and Warrnambool in early 1900's. In late 1914 the Warrnambool lifeboat and crew were used to help find what was left of the tragic wreckage of the Antares, and were able to discover the body of one of the crewmen, which they brought back to Warrnambool. Between 1951 and 1954 the lifeboat was manned under the guidance of Captain Carrington. He held lifeboat practice each month on a Sunday morning, to comply with the Ports and Harbour’s request that lifeboats be manned by a strong and competent crew, ready for action in case of emergency. In the early 1960’s it ended its service as a lifeboat and was used in Port Fairy as a barge to help dredge the Moyne River, bolted to the Port Fairy lifeboat. Flagstaff Hill obtained the Warrnambool in 1975. In 1984 it was on display at Flagstaff Hill Maritime Village, Warrnambool. On 23rd May 1990 she was lifted from the water and placed in a cradle for restoration. The name ‘WARRNAMBOOL could be seen faintly on the lifeboat before it was restored. It was during the restoration that Flagstaff Hill's boat builder discovered the 'plaque' inside the hull. A copy of the blueprint plans has the name “V.E.E. Gotch” printed on it. His advertisement in Footscray’s ‘Independent’ newspaper of Saturday 11th May 1901 states he is “Principal and Skilled member (Naval Architect) to the Court of Marine Inquiry of Victoria and holds classes for naval architectural drawing and arithmetic.” The rowlock is significant for its association with the lifeboat WARRNAMBOOL, which is significant for its half century service to the local community as a lifesaving vessel. She was also used to help retrieve the body of a shipwrecked crew member of the ANTARES. Rowlock, iron, upper ends scroll over, from the Lifeboat Warrnambool.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, life boat, life saving vessel, 1910 vessel, port fairy, boat builder plaque, rescue boat, beagley, government dockyard, williamstown, v.e.e. gotch, royal lifeboat institution, captain ferguson, non-capsizeable lifeboat, self-righting lifeboat, antares shipwreck, double diagonal planking, captain carrington, rowlock, lifeboat rowlock, lifeboat warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Vessel, Lifeboat Warrnambool, 01/09/1910

The construction of the lifeboat ‘Warrnambool’ began 15th September 1909 and was completed almost 12 months later, 1st September 1910. It was built at the Government Dockyard in Williamstown, Victoria, along the lines designed by the Great Britain’s Royal Lifeboat Institution, and included whaleback decks fore and aft, mast and centreboard, and rudder and tiller hung from the sternpost. It could be propelled by both sail and oar. At that time Captain Ferguson was Chief Harbour Master and Mr Beagley was foreman boat builder when he and his fellow workmen built the boat. The boat was described as “… a fine piece of workmanship and does credit to her builders and designers…” It had all the latest improvements in shape, disposition of weight and watertight compartments, and it had space for a large number of people in addition to the crew. It appears that 'H Meiers' whose signature, along with building dates, is pencilled on a concealed timber 'plaque' in the hull, was involved with the building of the lifeboat. It is interesting that the ‘Melbourne Directory’ of 1911, published by Sands and MacDougal, lists McAuley and Meiers, boat builders, Nelson Place foreshore, between Pasco and Parker Streets, Williamstown, (Victorian Heritage Database, ‘Contextual History, Maritime Facilities’), It is probably the company of the person whose name is inscribed on the lifeboat plaque. Flagstaff Hill’s documentation also mentions that the keel was laid at ‘Harry Myers, boat builders, Williamstown, Melbourne’ – the name ‘Myers’ can also be spelled ‘Meiers’, which could be the same person as the Meiers in “McAuley and Meiers” (as mentioned in genealogy lines of Myers). The new lifeboat, to be named ‘Warrnambool’ was brought to town by train and launched at the breakwater on 1st March 1911 using the Titan crane (the old lifeboat built in 1858, was then returned to Melbourne in 1911). This new lifeboat was stationed at Warrnambool in a shed located at the base of the Breakwater, adjacent to the slipway. A winch was used to bring it in and out of the water. The lifeboat ‘Warrnambool’ was similar in size to the old lifeboat but far superior in design, build and sea-going qualities such as greater manoeuvrability. The ‘self-righting, self-draining’ design was “practically non-capsizeable” and even if the boat overturned it would right itself to an even keel and the water would drain away. The hull was built of New Zealand Kauri, using double diagonal planking, laid in two layers at right angles, with a layer of canvas and red lead paint between the timbers to help seal the planking. It has “… plenty of freeboard, high watertight spaces between the deck and bottom… through which pipes lead…” The backbone timbers were made of Jarrah. The lifeboat Warrnambool was one of several rescue boats used at Port Fairy and Warrnambool in early 1900's. In late 1914 the Warrnambool lifeboat and crew were used to help find what was left of the tragic wreckage of the Antares, and were able to discover the body of one of the crewmen, which they brought back to Warrnambool. Between 1951 and 1954 the lifeboat was manned under the guidance of Captain Carrington. He held lifeboat practice each month on a Sunday morning, to comply with the Ports and Harbour’s request that lifeboats be manned by a strong and competent crew, ready for action in case of emergency. In the early 1960’s it ended its service as a lifeboat and was used in Port Fairy as a barge to help dredge the Moyne River, bolted to the Port Fairy lifeboat. Flagstaff Hill obtained the Warrnambool in 1975. In 1984 it was on display at Flagstaff Hill Maritime Village, Warrnambool. On 23rd May 1990 she was lifted from the water and placed in a cradle for restoration. The name ‘WARRNAMBOOL could be seen faintly on the lifeboat before it was restored. It was during the restoration that Flagstaff Hill's boat builder discovered the 'plaque' inside the hull. A copy of the blueprint plans has the name “V.E.E. Gotch” printed on it. His advertisement in Footscray’s ‘Independent’ newspaper of Saturday 11th May 1901 states he is “Principal and Skilled member (Naval Architect) to the Court of Marine Inquiry of Victoria and holds classes for naval architectural drawing and arithmetic.”The lifeboat WARRNAMBOOL is significant for its half century service to the local community as a lifesaving vessel. She was also used to help retrieve the body of a shipwrecked crew member of the ANTARES. Lifeboat "Warrnambool", a wooden, clinker hull, 'self-righting, self-draining design, single mast, pivoting centreboard. Complete with sail and yardarm. A 'plaque' was found inside the hull of the lifeboat, made of untreated wood, disc-shaped with one straight edge (Diam 15.5cm), inscribed by one of the boat builders in pencil script "Life Boat Start building / 15/9/09 - complete 1/9/10 / (signature looks like H Meiers) / Boat Builder)."'Plaque' inside body of boat is inscribed in pencil, script writing "Life Boat Start building / 15/9/09 - complete 1/9/10 / (signature looks like H Meiels) / Boat Builder)." flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lifeboat, life boat, vessel, life saving, 1910 vessel, port fairy, boat builder plaque, rescue boat, beagley, williamstown, government dockyard, v.e.e. gotch, royal lifeboat institution, captain ferguson, meiers, nelson place, non-capsizeable, self-righting, titan crane, double diagonal planking, captain carrington, barge, antares, self righting, crew of twelve, capacity of 30 survivors -

Flagstaff Hill Maritime Museum and Village

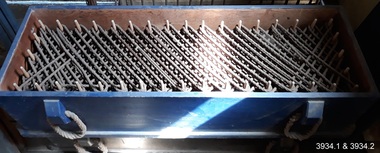

Flagstaff Hill Maritime Museum and VillageEquipment - Line faking box, Government of Victoria, 1860s

The rocket line faking box with lid has a frame inside with a specifically designed perimeter of faking pegs. The rocket shot line has been faked, or skilful wound, around these pegs to prevent it from tangling. The line is stored in the box, ready for attaching to the line throwing rocket. Some line faking boxes have a false base that is removed before firing the line-throwing pistol, leaving the line to feed out from the box when the rocket is fired. After the line is attached to the rocket the box tilted slightly and faced towards the wreck to allow it to be freely dispatched. The equipment often includes more that one faking box to make allowance for possible errors, broken lines or the need for a heavier line. Saving lives in Warrnambool – The coastline of South West Victoria is the site of over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built to house it. In 1858 the provision of rocket and mortar apparatus was approved for lifeboat stations in Victoria, and in 1864 a rocket house was built to safely store the rocket rescue equipment. In 1878 the buildings were moved to the Breakwater area, and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost a hundred years the lifeboat and rocket crews, mostly local volunteers, trained regularly to maintain their rescue skills. They were summoned when needed by alarms, gunshots, ringing bells and foghorns. Some became local heroes but all served an important role. By the end of the 1950s the lifeboat and rescue equipment had become obsolete. Rocket Rescue Method - The Government of Victoria adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain. It authorised the first line-throwing rescue system in 1858. Captain Manby’s mortar powered a projectile connected to rope, invented in 1808. The equipment was updated to John Dennett’s 8-foot shaft and rocket method that had a longer range of about 250 yards. From the 1860s the breeches buoy and traveller block rocket rescue apparatus was in use. It was suspended on a hawser line and manually pulled to and from the distressed vessel carrying passengers and items. In the early 1870s Colonel Boxer’s rocket rescue method became the standard in Victoria. His two-stage rockets, charged by a gunpowder composition, could fire the line up to 500-600 yards, although 1000 yards range was possible. Boxer’s rocket carried the light line, which was faked, or coiled, in a particular way between pegs in a faking box to prevent twists and tangles when fired. The angle of firing the rocket to the vessel in distress was measured by a quadrant-type instrument on the side of the rocket machine. Decades later, in about 1920, Schermuly invented the line-throwing pistol that used a small cartridge to fire the rocket. The British Board of Trade published instructions for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle measured by the quadrant, inserting a rocket that had a light-weight line threaded through its shaft, and then firing it across the stranded vessel, the line issuing freely from the faking board. A tally board was then sent out to the ship with instructions in four languages. The ship’s crew would haul on the line to bring out the heavier, continuous whip line, then secure the attached whip block to the mast or other sturdy part the ship. The rescue crew on shore then hauled out a stronger hawser line, which the ship’s crew fixed above the whip block. The hawser was then tightened using the block on the shore end of the whip. The breeches buoy and endless whip are then attached to the traveller block on the hawser, allowing the shore crew to haul the breeches buoy to and from the vessel, rescuing the stranded crew one at a time. This rocket line faking box is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.Rocket line faking box with loose fitting lid, painted blue on the outside. Rectangular box has two rope handles within wooden rope holders fixed onto each long side and one at each end. The box has a hook and ring at the base each end for releasing the top from the inserted faking frame. The line faking frame is inside the box. It has seventeen wooden pegs along each long side of the frame and three pegs along each short side. A continuous length of rocket line has been faked around the pegs in a specific pattern.flagstaff hill maritime museum & village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, maritime accidents, rocket crew, beach rescue, line rescue, rescue equipment, rocket firing equipment, rocket rescue equipment, rocket apparatus, beach apparatus, petticoat breeches, breeches buoy, rocket house, rocket shed, lifeboat men, rocket equipment, rocket machine, rocket head, rocket launcher, rocket line, marine technology, line-firing pistol, line throwing gun, beach rescue set, traveller, hawser, faking, faking box, faked line, lady bay, warrnambool harbour, port of warrnambool, volunteer lifesavers, volunteer crew, breakwater, lifeboat warrnambool, rocket rescue method, rocket rescue apparatus, shore to ship, italian hemp, line-throwing pistol, line throwing cartridge, rocket apparatus rescue, stranded vessel, tally board, light line, whip line, endless whip, petticoat buoy, traveller chair, traveller block, her majesty’s coast guard, harbour board, line thrower, line throwing, beach cart, hand barrow, sand anchor, hawser cutter, life jacket, faking board, welsh hand barrow, rocket set, rocket line faking box, faking frame -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Line faking box, Government of Victoria, 1860s

The rocket line faking box has a frame inside with a specifically designed perimeter of faking pegs. The rocket shot line has been faked, or skilful wound, around these pegs to prevent it from tangling. The line is stored in the box, ready for attaching to the line throwing rocket. Some line faking boxes have a false base that is removed before firing the line-throwing pistol, leaving the line to feed out from the box when the rocket is fired. After the line is attached to the rocket the box tilted slightly and faced towards the wreck to allow it to be freely dispatched. The equipment often includes more that one faking box to make allowance for possible errors, broken lines or the need for a heavier line. Saving lives in Warrnambool – The coastline of South West Victoria is the site of over 600 shipwrecks and many lost lives; even in Warrnambool’s Lady Bay there were around 16 known shipwrecks between 1850 and 1905, with eight lives lost. In 1859 the first Government-built lifeboat arrived at Warrnambool Harbour and a shed was soon built to house it. In 1858 the provision of rocket and mortar apparatus was approved for lifeboat stations in Victoria, and in 1864 a rocket house was built to safely store the rocket rescue equipment. In 1878 the buildings were moved to the Breakwater area, and in 1910 the new Lifeboat Warrnambool arrived with its ‘self-righting’ design. For almost a hundred years the lifeboat and rocket crews, mostly local volunteers, trained regularly to maintain their rescue skills. They were summoned when needed by alarms, gunshots, ringing bells and foghorns. Some became local heroes but all served an important role. By the end of the 1950s the lifeboat and rescue equipment had become obsolete. Rocket Rescue Method - The Government of Victoria adopted lifesaving methods based on Her Majesty’s Coast Guard in Great Britain. It authorised the first line-throwing rescue system in 1858. Captain Manby’s mortar powered a projectile connected to rope, invented in 1808. The equipment was updated to John Dennett’s 8-foot shaft and rocket method that had a longer range of about 250 yards. From the 1860s the breeches buoy and traveller block rocket rescue apparatus was in use. It was suspended on a hawser line and manually pulled to and from the distressed vessel carrying passengers and items. In the early 1870s Colonel Boxer’s rocket rescue method became the standard in Victoria. His two-stage rockets, charged by a gunpowder composition, could fire the line up to 500-600 yards, although 1000 yards range was possible. Boxer’s rocket carried the light line, which was faked, or coiled, in a particular way between pegs in a faking box to prevent twists and tangles when fired. The angle of firing the rocket to the vessel in distress was measured by a quadrant-type instrument on the side of the rocket machine. Decades later, in about 1920, Schermuly invented the line-throwing pistol that used a small cartridge to fire the rocket. The British Board of Trade published instructions for both the beach rescue crew and ship’s crew. It involved setting up the rocket launcher on shore at a particular angle measured by the quadrant, inserting a rocket that had a light-weight line threaded through its shaft, and then firing it across the stranded vessel, the line issuing freely from the faking board. A tally board was then sent out to the ship with instructions in four languages. The ship’s crew would haul on the line to bring out the heavier, continuous whip line, then secure the attached whip block to the mast or other sturdy part the ship. The rescue crew on shore then hauled out a stronger hawser line, which the ship’s crew fixed above the whip block. The hawser was then tightened using the block on the shore end of the whip. The breeches buoy and endless whip are then attached to the traveller block on the hawser, allowing the shore crew to haul the breeches buoy to and from the vessel, rescuing the stranded crew one at a time. This rocket line faking box is significant for its connection with local history, maritime history and marine technology. Lifesaving has been an important part of the services performed from Warrnambool's very early days, supported by State and Local Government, and based on the methods and experience of Great Britain. Hundreds of shipwrecks along the coast are evidence of the rough weather and rugged coastline. Ordinary citizens, the Harbour employees, and the volunteer boat and rescue crew, saved lives in adverse circumstances. Some were recognised as heroes, others went unrecognised. In Lady Bay, Warrnambool, there were around 16 known shipwrecks between 1850 and 1905. Many lives were saved but tragically, eight lives were lost.Rocket line faking box with loose fitting lid, painted black on the outside. Rectangular box has two rope handles within wooden rope holders fixed onto each long side and one at each end. The box has a hook and ring at the base each end for releasing the top from the inserted faking frame. The line faking frame is inside the box. It has seventeen wooden pegs along each long side of the frame and three pegs along each short side. A continuous length of rocket line has been faked around the pegs in a specific pattern.flagstaff hill maritime museum & village, flagstaff hill, maritime museum, maritime village, warrnambool, great ocean road, shipwreck, life-saving, lifesaving, rescue crew, rescue, rocket rescue, maritime accidents, rocket crew, beach rescue, line rescue, rescue equipment, rocket firing equipment, rocket rescue equipment, rocket apparatus, beach apparatus, petticoat breeches, breeches buoy, rocket house, rocket shed, lifeboat men, rocket equipment, rocket machine, rocket head, rocket launcher, rocket line, marine technology, line-firing pistol, line throwing gun, beach rescue set, traveller, hawser, faking, faking box, faked line, lady bay, warrnambool harbour, port of warrnambool, volunteer lifesavers, volunteer crew, breakwater, lifeboat warrnambool, rocket rescue method, rocket rescue apparatus, shore to ship, italian hemp, line-throwing pistol, line throwing cartridge, rocket apparatus rescue, stranded vessel, tally board, light line, whip line, endless whip, petticoat buoy, traveller chair, traveller block, her majesty’s coast guard, harbour board, line thrower, line throwing, beach cart, hand barrow, sand anchor, hawser cutter, life jacket, faking board, welsh hand barrow, rocket set, rocket line faking box, faking frame -

Melton City Libraries

Melton City LibrariesPhotograph, Charles Ernest Barrie with daughter Mary Ena Barrie, 1930

Mary Ena married Keith John Robinson son of Isaac and Henrietta nee Raleigh of Creighton Melton. Mary and her father are photographed beside the Darlingsford house prior to her wedding in February 1930. Mary their first child was born in 1907. In circa 1980 she wrote about her parents and her early life. Page 1 of part of the original hand written script - Mother and father were married at the Methodist Church Melton by the Rev B E Williams on Aug 23rd 1906 and lived in the house beside the chaff mill for some years. [The family left Melton South in 1910. In 1911 they moved to the farm “Darlingsford” near the town of Melton home for their nine children born between 1907 - 1922 They had three daughters and six sons, the second boy died of diphtheria 1916 aged 5 years.] Page 2 Mary writes… Each winter Father would send a 20 ton truck to the Collingwood Central Methodist Mission to be distributed to the needy people in the area. Sr. Faith who was at the mission for many years became a very much loved friend of my parents and the family. I remember her as a prolific writer of childrens stories in the Methodist paper the “Spectator”. I still treasure a book sister Faith gave me for my birthday. Father and Mother gave the first donation of 10 pounds to open the fund to start “Yooralla” for crippled children all because a small boy asked for a bag of sweets for his brother who was crippled and not able to attend kindergarten. Sister Faith who was a small fragile woman with a tremendous spirit was a frequent visitor at our home where she loved the warmth, good food and the loving companionship of the family for many years. Later she ran the Chaucer Library in Collins just below Georges near the Athenaeum Theatre. Mother was an avid reader and many of the books she read came from this library. Page 4 – Mary writes….. Dad was always involved in district affairs ever ready to help someone in need, especially as a J. P. helping young people who may have been in trouble. He was always involved in the care of his [eight] brothers who were in need at times. He was an elder at the Scots Church Melton and Sunday School Superintendant when the Sunday School thrived. The anniversary became a special event with good singing supplemented by good music by Dad’s friends from Footscray saxophone and violin. The church would be packed both Sundays. The family home was open to all and sundry from the little Salvation Army lass from Bacchus Marsh driving a horse and jinker (without any experience) round the district. collecting, came looking for a bed for the night (and later crept into bed with me because she was terrified). The Methodist local preachers regularly spent several night and breakfast while visiting people in the Melton area. They were stationed at Bacchus Marsh and again drove a horse and jinker. One preacher I remember with gratitude was Mr Webster a retired school master and a fine man. Another was Pastor Tuttlebee again with no experience driving a horse and jinker. The first time he called Mother found him taking the winkers off the horse whilst it was still harnessed to the jinker. Another regular visitor was Mr Lister the federal member for Corio, he always stayed with us when he had meeting in this area. Another evening just as dusk another minister and his dear little wife were driving the horse and buggy to a new parish at Ballarat. They had asked at the Mac’s Hotel for accommodation, and their reply was we have no accommodation, go down to Mr and Mrs Barrie they will put you up for the night. They were most grateful to be taken in and cared for, somehow it seemed the most natural thing in the world that they would be welcome. A copy of Mary’s writing was given to her niece Wendy in 1990. Mary Ena Barrie's wedding daylocal identities -

Flagstaff Hill Maritime Museum and Village

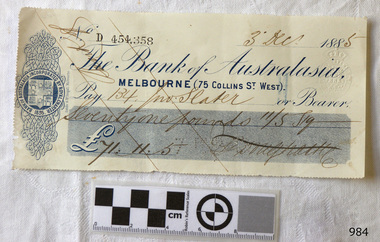

Flagstaff Hill Maritime Museum and VillageCurrency - Bank cheque, Sands & McDougall Limited, 03-12-1885

This bank cheque originated from the Bank of Australasia, Melbourne branch. It was issued on 3rd December 1885 to a person surnamed Slater for £71.11.5 (seventy-one pounds, eleven shillings and five pence). The parallel lines are called Cheque Crossed and mean that only Slater and no one else could receive the payment and that it would have been paid into Slater's bank account, not exchanged for cash. The embossed dots signify that the cheque amount was also paid to be the bearer of the cheque. Slater would have visited the bank to deposit the money into his or her own account. The cheque was printed by Sands & McDougall, a long-standing Melbourne printing and stationery company. It was then Stamped at the bank with its own unique number before it was issued to the customer. From its previously perforated edges, it is presumed that the cheque was part of a page of cheques, likely to be contained within a book of similar cheques ready for use. The Bank of Australia was incorporated by Royal Charter of England in March 1834. It had its Australian beginnings on 14th December 1835, opening in Sydney. The Acting Superintendent of the bank at that time was David Charters McArthur. He was Superintendent from 1867-to 1876. The Melbourne branch opened on 28th August 1838 in a two-roomed brick cottage on the north side of Little Collins Street, where two huge mastiff dogs were used at night to guard the bank. The government also provided an armed military sentinel. Due to the bank's rapid growth, a new building for the Melbourne branch was opened in 1840 at 75 Collins Street West. By 1879 the bank had been upgraded to a magnificent two-storey building on the corners of Collins and Queens Streets, with the entry on Collins Street. In 1951 the Bank of Australasia amalgamated with the Union Bank to form the Australia and New Zealand Bank, now known as the ANZ. Then in 1970, the ANZ merged with both the ES&A and the London Bank of Australia to form the ANZ Banking Group Limited. The ANZ Banking Group Ltd kindly donated a variety of historic items from the Bank of Australasia. BANK of AUSTRALASIA, WARRNAMBOOL – In 1854 Warrnambool had two banks, the Union Bank and the Bank of Australasia. Later, completely different bank businesses opened; in 1867 the National Bank of Australasia, then in 1875 the Colonial Bank of Australasia. The original Warrnambool branch of the Bank of Australasia was established in July 1854, and operated from a leased cottage on Merri Street, close to Liebig Street. The bank next bought a stone building previously erected by drapers Cramond & Dickson on the corner of Timor and Gibson Streets. Samuel Hannaford was a teller and then Manager at the Warrnambool branch from 1855 to 1856 and the Warrnambool Council chose that bank for its dealings during 1856-57. In 1859 Roberts & Co. was awarded the contract to build the new Bank of Australasia branch for the sum of £3,000. The land was on a sand hill on the northeast corner of Timor and Kepler Streets and had been bought in 1855 from investor James Cust. The new building opened on May 21, 1860. The bank continued to operate there until 1951 when it merged with the Union Bank to form the ANZ Bank, which continued operating from its Liebig Street building. Warrnambool City Council purchased the former Bank of Australasia building in 1971 and renovated it, then on 3rd December 1973 it was officially opened as the Art Gallery by Cr. Harold Stephenson and Gallery Director John Welsh. The Gallery transferred to the purpose-built building in Liebig Street in 1986 and the old bank building is now the Gallery club. Staff at the Bank of Australasia in Warrnambool included the following men but others were also involved: Samuel Hannaford, Teller then Manager from 1855-1856; W H Palmer, Manager from January 1857 until November 1869 when the Teller Basil Spence was promoted to Manager; H B Chomley, Manager from April 1873 and still there in 1886; A Butt, Manager in 1895-1904; J R McCleary Accountant and Acting Manager for 12 months, until 1900; A Kirk, Manager 1904; J Moore, staff until his transfer to Bendigo in December 1908; J S Bath was Manager until 1915; C C Cox, Manager until April 1923; Richard C Stanley, Manager 1923 to April 1928. The bank cheque has significance through its association with the Bank of Australasia. The early Australian bank was established in 1834 by Royal Charter and opened in Sydney, Australia, in Sydney in 1835. The bank had many Australian offices in November 1877, particularly on the east and south coasts. Victoria had 45 percent of all Offices. The bank cheque is significant as an early example of financial management of money and money exchange or transfer.Bank cheque of the Bank of Australasia, Melbourne branch. The rectangular paper has three sides that have been perforated. It is printed in blue with bank's Insignia of a heraldic shield of sheep hung by their waists and ships in full sail. Embossed Stamp Duty mark. Embossed dots. Handwritten black ink details Dated 3rd Dec 1885. Printed in Melbourne by Sands & McDougall. Diagonal parallel lines are across the cheque. Printed: "Bank of Australasia, MELBOURNE (75 COLLINS ST. WEST)." "454,358" "Sands & McDougall, Melbourne" Embossed stamp: Symbol of Crown above double oval lines " - STAMP DUTY" "ONE PENNY" Embossed dots forming test "7 PAID T2" Handwritten: "3rd Dec. [188] 5" "134 - Slater" "Seventy one pounds 11/S 5p" "£71.11.5" Signature: (undecipherable) flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, bank cheque, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, bank of australasia, boa, union bank, australia & new zealand bank, anz bank, bank note, melbourne, slater, sands & mcdougall, chrssed cheque, embossed dots, paid cheque -

Bendigo Military Museum

Bendigo Military MuseumPhotograph - 4th Field Survey Squadron – Operation ARIGHT 93, Queensland, 1993