Showing 13224 items

matching brown a

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook, Selections from The Poetical Works of Robert Browning

This item is from the ‘Pattison Collection’, a collection of books and records that was originally owned by the Warrnambool Mechanics’ Institute, which was founded in Warrnambool in 1853. By 1886 the Warrnambool Mechanics’ Institute (WMI) had grown to have a Library, Museum and Fine Arts Gallery, with a collection of “… choice productions of art, and valuable specimens in almost every branch and many wonderful national curiosities are now to be seen there, including historic relics of the town and district.” It later included a School of Design. Although it was very well patronised, the lack of financial support led the WMI in 1911 to ask the City Council to take it over. In 1935 Ralph Pattison was appointed as City Librarian to establish and organise the Warrnambool Library as it was then called. When the WMI building was pulled down in 1963 a new civic building was erected on the site and the new Warrnambool Library, on behalf of the City Council, took over all the holdings of the WMI. At this time some of the items were separated and identified as the ‘Pattison Collection’, named after Ralph Pattison. Eventually the components of the WMI were distributed from the Warrnambool Library to various places, including the Art Gallery, Historical Society and Flagstaff Hill. Later some were even distributed to other regional branches of Corangamite Regional Library and passed to and fro. It is difficult now to trace just where all of the items have ended up. The books at Flagstaff Hill Maritime Village generally display stamps and markings from Pattison as well as a variety of other institutions including the Mechanics’ Institute itself. RALPH ERIC PATTISON Ralph Eric Pattison was born in Rockhampton, Queensland, in 1891. He married Maude Swan from Warrnambool in 1920 and they set up home in Warrnambool. In 1935 Pattison accepted a position as City Librarian for the Warrnambool City Council. His huge challenge was to make a functional library within two rooms of the Mechanics’ Institute. He tirelessly cleaned, cleared and sorted a disarrayed collection of old books, jars of preserved specimens and other items reserved for exhibition in the city’s museum. He developed and updated the library with a wide variety of books for all tastes, including reference books for students; a difficult task to fulfil during the years following the Depression. He converted all of the lower area of the building into a library, reference room and reading room for members and the public. The books were sorted and stored using a cataloguing and card index system that he had developed himself. He also prepared the upper floor of the building and established the Art Gallery and later the Museum, a place to exhibit the many old relics that had been stored for years for this purpose. One of the treasures he found was a beautiful ancient clock, which he repaired, restored and enjoyed using in his office during the years of his service there. Ralph Pattison was described as “a meticulous gentleman whose punctuality, floorless courtesy and distinctive neat dress were hallmarks of his character, and ‘his’ clock controlled his daily routine, and his opening and closing of the library’s large heavy doors to the minute.” Pattison took leave during 1942 to 1945 to serve in the Royal Australian Navy, Volunteer Reserve as Lieutenant. A few years later he converted one of the Museum’s rooms into a Children’s Library, stocking it with suitable books for the younger generation. This was an instant success. In the 1950’s he had the honour of being appointed to the Victorian Library Board and received more inspiration from the monthly conferences in Melbourne. He was sadly retired in 1959 after over 23 years of service, due to the fact that he had gone over the working age of council officers. However he continued to take a very keen interest in the continual development of the Library until his death in 1969. The Pattison Collection, along with other items at Flagstaff Hill Maritime Village, was originally part of the Warrnambool Mechanics' Institute’s collection. The Warrnambool Mechanics’ Institute Collection is primarily significant in its totality, rather than for the individual objects it contains. Its contents are highly representative of the development of Mechanics' Institute libraries across Australia, particularly Victoria. A diversity of publications and themes has been amassed, and these provide clues to our understanding of the nature of and changes in the reading habits of Victorians from the 1850s to the middle of the 20th century. The collection also highlights the Warrnambool community’s commitment to the Mechanics’ Institute, reading, literacy and learning in the regions, and proves that access to knowledge was not impeded by distance. These items help to provide a more complete picture of our community’s ideals and aspirations. The Warrnambool Mechanics Institute book collection has historical and social significance for its strong association with the Mechanics Institute movement and the important role it played in the intellectual, cultural and social development of people throughout the latter part of the nineteenth century and the early twentieth century. The collection of books is a rare example of an early lending library and its significance is enhanced by the survival of an original collection of many volumes. The Warrnambool Mechanics' Institute’s publication collection is of both local and state significance. Selections from The Poetical Works of Robert Browning Author: Robert Browning Publisher: Smith, Elder & Co Date: 1891Label on spine cover with typed text PAT 821 BRO Pastedown front endpaper has sticker from Warrnambool Mechanics Institute and Free Library Front loose endpaper has a sticker from Corangamite Regional Library Servicewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, book, pattison collection, warrnambool library, warrnambool mechanics’ institute, ralph eric pattison, corangamite regional library service, warrnambool city librarian, mechanics’ institute library, victorian library board, warrnambool books and records, warrnambool children’s library, great ocean road, selections from the poetical works of robert browning, robert browning -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBook, Selections from The Poetical Works of Robert Browning

This item is from the ‘Pattison Collection’, a collection of books and records that was originally owned by the Warrnambool Mechanics’ Institute, which was founded in Warrnambool in 1853. By 1886 the Warrnambool Mechanics’ Institute (WMI) had grown to have a Library, Museum and Fine Arts Gallery, with a collection of “… choice productions of art, and valuable specimens in almost every branch and many wonderful national curiosities are now to be seen there, including historic relics of the town and district.” It later included a School of Design. Although it was very well patronised, the lack of financial support led the WMI in 1911 to ask the City Council to take it over. In 1935 Ralph Pattison was appointed as City Librarian to establish and organise the Warrnambool Library as it was then called. When the WMI building was pulled down in 1963 a new civic building was erected on the site and the new Warrnambool Library, on behalf of the City Council, took over all the holdings of the WMI. At this time some of the items were separated and identified as the ‘Pattison Collection’, named after Ralph Pattison. Eventually the components of the WMI were distributed from the Warrnambool Library to various places, including the Art Gallery, Historical Society and Flagstaff Hill. Later some were even distributed to other regional branches of Corangamite Regional Library and passed to and fro. It is difficult now to trace just where all of the items have ended up. The books at Flagstaff Hill Maritime Village generally display stamps and markings from Pattison as well as a variety of other institutions including the Mechanics’ Institute itself. RALPH ERIC PATTISON Ralph Eric Pattison was born in Rockhampton, Queensland, in 1891. He married Maude Swan from Warrnambool in 1920 and they set up home in Warrnambool. In 1935 Pattison accepted a position as City Librarian for the Warrnambool City Council. His huge challenge was to make a functional library within two rooms of the Mechanics’ Institute. He tirelessly cleaned, cleared and sorted a disarrayed collection of old books, jars of preserved specimens and other items reserved for exhibition in the city’s museum. He developed and updated the library with a wide variety of books for all tastes, including reference books for students; a difficult task to fulfil during the years following the Depression. He converted all of the lower area of the building into a library, reference room and reading room for members and the public. The books were sorted and stored using a cataloguing and card index system that he had developed himself. He also prepared the upper floor of the building and established the Art Gallery and later the Museum, a place to exhibit the many old relics that had been stored for years for this purpose. One of the treasures he found was a beautiful ancient clock, which he repaired, restored and enjoyed using in his office during the years of his service there. Ralph Pattison was described as “a meticulous gentleman whose punctuality, floorless courtesy and distinctive neat dress were hallmarks of his character, and ‘his’ clock controlled his daily routine, and his opening and closing of the library’s large heavy doors to the minute.” Pattison took leave during 1942 to 1945 to serve in the Royal Australian Navy, Volunteer Reserve as Lieutenant. A few years later he converted one of the Museum’s rooms into a Children’s Library, stocking it with suitable books for the younger generation. This was an instant success. In the 1950’s he had the honour of being appointed to the Victorian Library Board and received more inspiration from the monthly conferences in Melbourne. He was sadly retired in 1959 after over 23 years of service, due to the fact that he had gone over the working age of council officers. However he continued to take a very keen interest in the continual development of the Library until his death in 1969. The Pattison Collection, along with other items at Flagstaff Hill Maritime Village, was originally part of the Warrnambool Mechanics' Institute’s collection. The Warrnambool Mechanics’ Institute Collection is primarily significant in its totality, rather than for the individual objects it contains. Its contents are highly representative of the development of Mechanics' Institute libraries across Australia, particularly Victoria. A diversity of publications and themes has been amassed, and these provide clues to our understanding of the nature of and changes in the reading habits of Victorians from the 1850s to the middle of the 20th century. The collection also highlights the Warrnambool community’s commitment to the Mechanics’ Institute, reading, literacy and learning in the regions, and proves that access to knowledge was not impeded by distance. These items help to provide a more complete picture of our community’s ideals and aspirations. The Warrnambool Mechanics Institute book collection has historical and social significance for its strong association with the Mechanics Institute movement and the important role it played in the intellectual, cultural and social development of people throughout the latter part of the nineteenth century and the early twentieth century. The collection of books is a rare example of an early lending library and its significance is enhanced by the survival of an original collection of many volumes. The Warrnambool Mechanics' Institute’s publication collection is of both local and state significance. Selections from The Poetical Works of Robert Browning Author: Robert Browning Publisher: Smith, Elder & Co Date: 1891Label on spine cover with typed text PAT 821 BRO Pastedown front endpaper has sticker from Warrnambool Mechanics Institute and Free Library Front loose endpaper has a sticker from Corangamite Regional Library Servicewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, shipwrecked-artefact, book, pattison collection, warrnambool library, warrnambool mechanics’ institute, ralph eric pattison, corangamite regional library service, warrnambool city librarian, mechanics’ institute library, victorian library board, warrnambool books and records, warrnambool children’s library, great ocean road, selections from the poetical works of robert browning, robert browning -

Federation University Historical Collection

Federation University Historical CollectionDocument, Goldfields Print Award Application Form, 1988 (exact)

The Ballarat College of Advanced Education Print Award offered $1,200 as an encouragment to Australian printmakers. The exhibition was held at the Ballarat Fine Art Gallery. Four page application form for the inaugural Goldfields Print Award Exhibition printed in brown ink on light brown paper. allan mann, margaret rich, neil leveson, john crump, printmaking, ballarat college of advanced education, ballarat fine art gallery, art gallery of ballarat -

St Kilda Historical Society

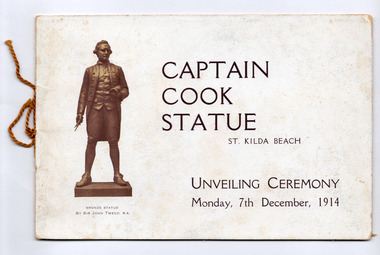

St Kilda Historical SocietyEphemera - Special event program, Osboldstone & Co. Pty. Ltd, Captain Cook Statue St Kilda Beach Unveiling Ceremony Monday, 17th December, 1914, 1914

The booklet was produced for the unveiling of the Captain Cook Statue on 7 December 1914 at the St. Kilda Foreshore. It contains details of Cook's life, the statue and the donor, Andrew Stenhouse, as well as of its unveiling. The statue was unveiled by the Governor of Victoria, Sir Arthur Stanley, watched on by Commonwealth and State dignitaries and hundreds of St Kilda residents. Sixteen page booklet of white paper printed in brown with cardboard cover of similar colours. Secured by brown cotton cord..st kilda, catani gardens, john tweed, andrew stenhouse, captain cook statue, statue, captain cook -

Hume City Civic Collection

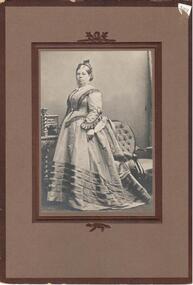

Hume City Civic CollectionPhotograph, c1880

Ann Holden married George Evans at the age of 16 in 1843. She lived at Emu Bottom and died in 1893 at the age of 67. Possibly taken between 1880 and 1890, perhaps when she was operating the Royal Oak Hotel, Latrobe Street, Melbourne.Sepia photograph of a lady standing in front of a chair and dresser. This photo is mounted on brown cardboard edged in a darker brown outline.On back: stamp: S.A.MAYOR / Morrah Street / PARKVILLE Written in ink: Mrs George Evans / nee Ann Holden / Married 1843 / died 1893 aged / 67 years.evans, george, emu bottom, oldest house, holden, anne, mayor, s. a., photographers, royal oak hotel, hotels, george evans collection -

Stawell Historical Society Inc

Stawell Historical Society IncBook, R Allan Blachford, Anecdotes of History 1985 by Alan Blachford, 1985

Reference book. Fawn card cover Sketches of various scenes in brown. the title also in brown. Sketches by John Glover (Local Artist).R A Blachfordstawell -

Whitehorse Historical Society Inc.

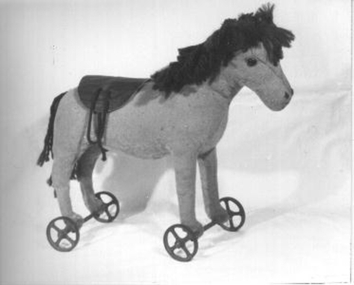

Whitehorse Historical Society Inc.Leisure object - Toy Horse

Beige cloth covered horse on wheels. Brown wool mane and tail. Brown leather saddle. Black button eye.toys, general -

Northern District School of Nursing. Managed by Bendigo Historical Society Inc.

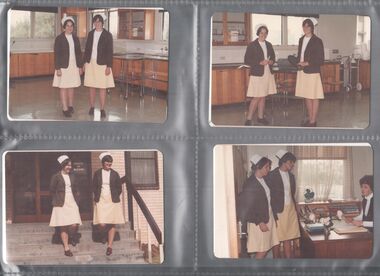

Northern District School of Nursing. Managed by Bendigo Historical Society Inc.Photograph - Models wearing new uniform

The Northern District School of Nursing opened in 1950 in to address the issues around nurse recruitment, training and education that had previously been hospital based. The residential school was to provide theoretical and in-house education and practical training over three years. The students would also receive practical hands-on training in the wards of associated hospitals. The Northern District School of Nursing operated from Lister House, Rowan Street, Bendigo. It was the first independent school of nursing in Victoria and continued until it closed in 1989.Eight colour photographs with two nurses modelling the yellow uniform with alternate brown jacket and brown shoes at Lister House.nurses uniforms, ndsn -

Ballarat Tramway Museum

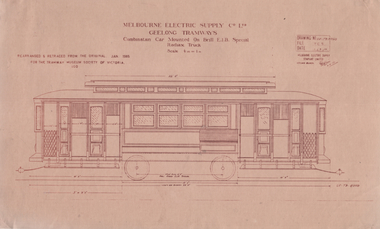

Ballarat Tramway MuseumDrawing, TMSV, "Combination Car Mounted Brill E1B Special Radiax Truck", 1/1985

Drawing of Melbourne Electric Supply Co. Ltd (MESCo) Geelong tramways - "Combination Car Mounted Brill E1B Special Radiax Truck" - trams 16 to 23, built by Pengelley & Co in Adelaide 1924-25. Details the tramcar elevation with dimensions, and shows the towbars. Drawing dated Jan 1985, prepared for the TMSV. Scale 1/4"=1' Second drawing is titled "Elevations of body Pengelley tram Nos. 20-23" - based on MESCo drawing GE-T9-8358. Drawing dated Jan 1985, prepared for the TMSV. Scale 1/4"=1' Yields information about the Pengelley built tramcars for Geelong.Set of Drawings printed on light brown paper with brown ink - Drawing GE-T9-8350 and GE-T9-8358trams, tramways, geelong, drawings, pengelley -

Mont De Lancey

Mont De LanceyBaby shoes

Worn by Dorothy WilmsA pair of brown leather baby shoes with ribbon tie. Plus one additional brown shoe - not matching, with button tie.baby shoes, shoes -

Melbourne Legacy

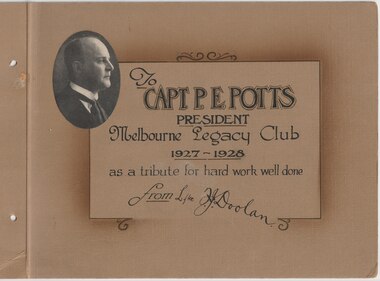

Melbourne LegacyAlbum - Photo album, One Week's Legacy Club Publicity. Tribute to Capt P E Potts, 1928

An album of newspaper clippings and photos compiled to thank Legatee Philip E Potts when he was leaving Melbourne in 1928. L/ Potts was president of Legacy in 1927-28. The album was compiled by Legatee Frank Doolan. The articles included the first annual demonstration being held on 28 March 1928 with 300 junior legatees performing. Legatee Aaron Beattie was in charge with help from Mrs Gillies and Jim Tierney. Also articles about the proposed building of the Shrine of Remembrance and the appeal for funds. One page shows pictures of a social event held on the Burns Philp ship 'Marella'. Another photo of Marella is in the collection. Legatee Potts was manager of the old-established shipping firm Burns, Philip and Co Ltd. He also was president of the Melbourne 'Highland Pipe Band, a councillor of the Melbourne Scots and English Speaking Union, and a member of the Rotary Club. A record of a tribute to a past president and outlines significant events in 1928.Brown cardboard album x 13 pages of newspaper clippings and photos from 1928 held together by brown string.shrine of remembrance, philip e potts, past presidents -

Port of Echuca

Port of EchucaDomestic object - Ceramic jug

An item from the Bridge Hotel displays that were sourced circa 1974.Large brown and cream ceramic bottle with a handle on the top of the bottle. A brown rope is tied around the spout at the top of the bottle.bridge hotel, bridge hotel restoration, echuca -

Bendigo Military Museum

Bendigo Military MuseumUniform - PUTTEES, LEG WRAPPINGS, Unknown

Wool and cotton with cotton patch sewn on the inside, 3 brown buttons, 3 brown buttons, 3 button holes.passchendaele barracks trust, puttee, army uniform -

Linton Mechanics Institute and Free Library Collection

Linton Mechanics Institute and Free Library CollectionBook - Novel, Prosper, John, Gold-Killer : a mystery of the new underworld, Copyright 1922

Murder mystery and romance283 p. : brown cover, trimmed with brown tape. Title and author's name hand printed on front cover and spine.fictionMurder mystery and romancefiction, crime fiction, romance, john prosper -

Wangaratta RSL Sub Branch

Wangaratta RSL Sub BranchPrint - Framed Print, Premier Framing Service

Landing of ANZAC's at Gallipoli April 25 1915Brown timber frame with light brown mount containing print depicting soldiers landing on shore from ships at sea.The landing of the New Zealand and Australian Expeditionary Forces,Gallipoli,April 25,1915anzac, gallipoli, 25/4/1915 -

Orbost & District Historical Society

Orbost & District Historical Societycorrespondence books, 10.12.1955 - 20.9.1977

These books were used by the Orbost Rifle Club to record correspondence. The Orbost Rifle Club existed in the early 20th century. (There are records from 1900). It folded in the late 1970's.Target shooting is one of the oldest organised sports in Australia. Records date back to the British Marines at Sydney Cove in 1788. The Victorian Rifle Association (VRA) was formed in 1860. One of the most important adjuncts to the militia system from 1903 to the re-organisation of 1912 was the role played by the Rifle Club movement in Australia. At the time, these clubs were seen as the reservoir of manpower for a potential guerrilla force should any invasion occur. For Australia, the invasion fear was uppermost in the minds of the population. So important were the rifle clubs for the defence of Australia that the Commonwealth provided the training staff, rifles and ammunition so the clubs could function. Members were drilled, wore uniforms and practised all the basic skills of soldiering as well as target shooting. The Orbost Rifle Club was active during this period.Four duplicate Correspondence books. All are brown with a brown cloth spine. 1359.1, 1359.2 and 1359.3 have marbled covers and 1359.4 has a dark brown soft cover with "TUDOR DUPLICATE BOOK" in paler print. -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Decorative object - Tapestry

Canvas Needlework also known as Needle Point. Done on canvas with the same stitch throughout so as to resemble tapestry - another name for Point Lace,Tapestry of canvas needlework in shades of creams into brown. Picture of double story house and trees. Brown velvet border. Mounted on stiff cardboard. Backed with brown cotton. Woven in wool. Crown woven in gold thread.Stitched into tapestry - 'E.E.T.'' '1860'handcrafts, tapestry -

Southern Sherbrooke Historical Society Inc.

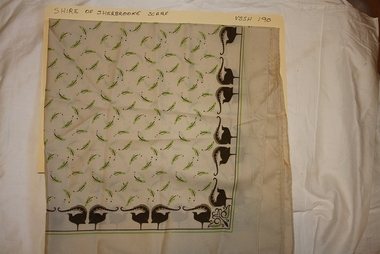

Southern Sherbrooke Historical Society Inc.Scarf, Shire Of Sherbrooke, c1960s

In a box of leftover items from when Shire Of Sherbrooke was dissolved in 1995.Scarf given as presentation gift by Shire Of Sherbrooke. Cream background with green and dark brown leaf pattern repeating, and edged with dark brown lyrebird motifs (Shire logo) surrounded by dark brown and green stripes.shire of sherbrooke -

Melbourne Legacy

Melbourne LegacyBook, Printed Forms. Junior Legacy

This portfolio of printed forms, letters and reports has been assembled to show how Melbourne Legacy, in the past, has kept in contact with Legatees, widows, their families and the records of the above mentioned. The information would be typed or handwritten, then posted and delivered to Legacy Melbourne, Legatees or widows and families. Types of form include 'First Contact Form' to record the details of the families. Also printed cards for noting dental appointments. A typical letter that is sent to the widow on Legacy receiving news of the death of an ex-serviceman. One of the proforma letters is signed by Legatee A Dore who was President in 1965 so the forms are from the 1960s.A record of work practices within Legacy.Brown patterned cardboard cover. Spine reinforced with brown tape. Cover and pages bound together by three evenly spaced brass screws. Copies of reports, letters and forms pasted onto brown paper pages.Front cover, title hand written in black on rectangular, white adhesive label, the figure 19 is circled. contact records, register, proformas -

Bendigo Military Museum

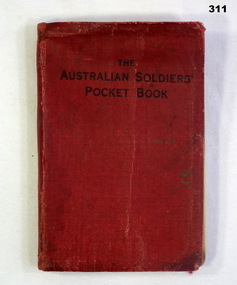

Bendigo Military MuseumBook - POCKET BOOK, The Australian Soldiers' Pocket Book, July 1941

Made for the Australian Comforts Fund and published by Brown, Prior Anderson Pty LtdPocket book with red cloth cover, title in black ink on front. Contains information of use to Australian soldiers including signalling, first aid, military terminology etc Revised 5th Edition.Page 3 personal details of owner .pocket books, soldiers, military, -

Ringwood and District Historical Society

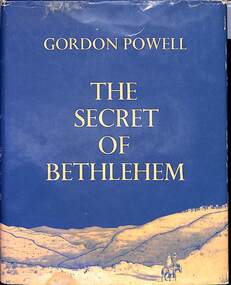

Ringwood and District Historical SocietyBook, "The Secret of Bethlehem" by Gordon Powell. Illustrated by local Ringwood resident, George Browning. Published South Australia 1963

The Illustrator of the book George Browning was a resident of Ringwood. He was a war photographer in WW2.Book illustrated by local Ringwood resident. Dust cover and book have blue covers with gold printing. 30 pages with illustrations. -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Margaret Ball, 28 Dudley Street, Eltham, June 1999, 1999

Built 1960s by J. Brown as a spec. house; Owner 1960s: Lyndsay ArdleyThe Margaret Ball (Pre 1960s Houses) Collection was a personal project initiated to mark the year 2000 and arose as a result of the disappearance of many pre-1960s parts of Eltham due to development. Approximately 200 pre-1960s style houses that were left in Eltham between Main Road and east to Bible Street, between Cecil Street to the north and south to Dalton Street were photographed in late 1999. Not all of the houses could be photographed; some because the garden or trees blocked the view of the house, others because of rubbish or cars were in the way, some because people were working on the house or in the gardens at the time.Roll of 35mm colour negative film, 5 of 6 stripsFuji 200eltham, houses, streets, margaret ball (pre 1960s houses) collection, dudley street -

Federation University Historical Collection

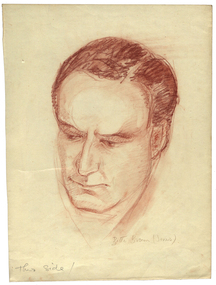

Federation University Historical CollectionArtwork - Drawing, Doctor David Alexander by Bette Brown (Jones)

Bette brown studied art at the Ballarat School of Mines Technical Art School.Conte sketched portrait of Dr David Alexander of Ballaratbette jones, jones, alexander, david alexander, artwork, portrait -

Winchelsea and District Historical Society

Winchelsea and District Historical SocietyMedal, 1897

Handed in by Trevor Brown who found it under a house at Horsham, Victoria, Australia. Shire of Winchelsea medal. Photo of Shire Hall.Round Commemorative Medal. Shire Hall Photo 1897. Queen Victoria's 60th year of reign. 1837 - 1897. Shire of Winchelsea. O.F.Armytage President.winchelsea. medal. queen victoria. -

Creswick Campus Historical Collection - University of Melbourne

Creswick Campus Historical Collection - University of MelbourneSample

A large quantity of reddish brown resin from Xanthorrhoea australis, Kangaroo IslandResinVictorian School of Forestry Reference Collection. RESIN. -

Malmsbury Historical Society

Malmsbury Historical SocietyPhotograph (Item), William Henry Lipp And Wife Laura Katherine (Brown) Lipp, Malmsbury c1940

People - "William Henry Lipp, Laura Katherine (Brown) Lipp" Associated with - Wwii -

Malmsbury Historical Society

Malmsbury Historical SocietyPhotograph (Item), "M.H.S Exhibition, Wooden Artifacts, Bottles Photos", Malmsbury 1991

Associated with - M.H.S Buildings - Town Hall People - "Brown, Jack; Slimmon, Barb" -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyAccessory - Suitcase

Lockable brown case, key attached, gold inscription on centre of case lid.Leather Lodge suitcase, empty, with leather handle -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumPhotograph

Photos from Superintendent Hannan's album. Presbyterian Training Boys Farm.|Dhurringile Mansion.|Photo 2- Charles Brown top left and right.|Photo 3- Charles Brown top left and right.|Photo 4-Tom Been right.|Douglas McHugh left.|5 Photos.photograph, people -

Creswick Campus Historical Collection - University of Melbourne

Creswick Campus Historical Collection - University of MelbourneStill Image, 1964

Subject: Lower Glenelg Plantation . 7 brown envelopes marked Run 1. No. 12 - 17of 9 prints each. Stored in a brown cardboard file box marked Lower Glenelg Plantation Run No.1. 11 - 17(x9). Photos commissioned by Forests Commission Victoria 1964.Aerial Photographs