Showing 100 items

matching conveyor

-

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - digital, LJ Gervasoni, Murtoa Stick Shed 00031, 13/08/2011

From the Victorian Heritage Register statement of significance H0791 The Marmalake/Murtoa Grain Store, originally the No.1 Murtoa Shed, is located within the Murtoa Grain Terminal, adjacent to the grain elevator tower and railway line. The shed is 280m long, 60m wide and 19m high at the ridge with a capacity of 3.4 million bushels. The hipped corrugated iron roof of the shed is supported on approximately 600 unmilled hardwood poles set in a concrete slab floor and braced with iron tie rods. These poles are the reason for use of the term "stick shed". With its vast gabled interior and the long rows of poles the space has been likened to the nave of a cathedral. An elevator at one end took wheat from railway trucks to ridge level where it was distributed by conveyor along the length of the shed, creating a huge single mound of grain. Braced internal timber bulkheads on either side took the lateral thrust of the wheat, and conveyors at ground level outside the bulkheads took wheat back to the elevator for transport elsewhere. Wheat had been handled in jute bags from the start of the Victorian wheat industry in the mid nineteenth century. Bulk storage had been developed in North America from the early 1900s. NSW began building substantial concrete silos from 1920-21. In Western Australia, farmers' co-operatives, who had to supply their own bulk storage from 1934-5, pioneered the use of low-cost horizontal sheds of timber and corrugated iron for bulk storage. Following its establishment in 1935 the Victorian Grain Elevators Board (GEB) planned a network of 160 concrete silos in country locations, connected by rail to the shipping terminal at Geelong. By the outbreak of the Second World War there was a worldwide glut of wheat, and Australia soon had a massive surplus which it was unable to export. Only 48 silos had been established under the Victorian Silo Scheme so far, and wartime material and labour restrictions prevented progress with this scheme. The storage deficit had become an emergency by 1941 as Britain obtained its imports from North America, rather than over the lengthy and difficult shipping route from Australia. In 1941 the GEB, under chairman and general manager Harold Glowrey, proposed large temporary versions of the horizontal bulk storage sheds already in use in Western Australia. The proposal was approved by the Victorian Wheat and Woolgrowers Association, who considered the use of shed storages as a longer term proposition. After initial resistance from the Australian Wheat Board, some of whose members represented wheat bagging interests, the Commonwealth and Victorian governments agreed to split the costs, and Murtoa was chosen as a suitable site for the first emergency storage. The main contractor, Green Bros, commenced work on the No.1 Murtoa Shed in September 1941, deliveries of bulk wheat began in January 1942, and the store was full by June of the same year. In the following years the Council for Scientific and Industrial Research (later CSIRO) conducted valuable research and experiment on the impacts and control of insect pests at the Murtoa No.1 shed. With these discoveries, and the development of more effective pesticides, use of the No.1 shed and the larger No.2 shed, erected in 1942/43, continued for many years. The No.2 shed was demolished in 1975. By the 1990s, pest resistance to pesticides and requirements for both pest free and insecticide free grain rendered open storage of this type unviable. The No. 1 store was also becoming increasingly expensive to maintain, and its use was phased out from 1989.Image of the Marmalake/Murtoa Grain Store which is of historical, architectural, scientific (technical) and social significance to the State of VictoriaDigital colour image of the interior of the Marmaduke . Murtoa grain storage facility better known as the Stick Shed. The shed was constructed in World War Two to store grain. The supporting columns are trees.marmalake, murtoa grain store, wheat store, stick shed, murtoa -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Mincer, late 19th or early 20th Century

A meat grinder, commonly known as the meat mincer, is used for chopping meat into fine pieces. Alternatively, it can be used for the mixing of raw or cooked meat, fish and vegetables. It is the best way to process meat, and is a widely used piece of equipment by butchers and in the home.. Butchers have been known to use either mincing knives or meat cleavers in the kitchen for years to produce a quantity of minced meat. This was a slow and laborious process. The advent of the meat mincer has not only made the mincing process easier but also faster. The meat mincer has slowly evolved over the years into what it is today. The first meat mixer or meat mincer was invented in the 19th century by a German inventor named Baron Karl Drais. Although some versions of the device date back to much earlier. The oldest form of meat mincer was hand cranked which forced meat through a metal plate with several small holes in it, which resulted in long and thin strands of the meat. The meat was fed into the funnel that was placed at the top of the mixer. This meat would pass through a hand cranked screw conveyor that would squash and mix the meat before passing it through the metal plate. Needless to say, this was again a slow and laborious procedure to follow to produce large quantity of meat. With passage of time, this hand cracked machine became powered by electricity. The meat mincer has a great adaptability and efficiency now. The huge variety in mincer plates allows a butcher to produce different types of minced meat in any shape desired. However, traditional manual meat mincers have not really changed a lot. They are manually operated and made of cast iron, as earlier. They are similar to the original mincer designs, dating back to the early 1900s. Some butchers still prefer using a variety of mincer knives. Adapted from: https://brennan-group.com/blogs/news/history-of-the-meat-mincerThe development of the meat mincer enabled both butchers and home cooks to process and grind meat effectively.Clamp on meat mincer with handle for rotating the mincing apparatus inside.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, meat mincer -

Wodonga & District Historical Society Inc

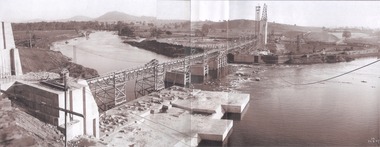

Wodonga & District Historical Society IncAlbum - Hume Reservoir Australia Album - General View of Works from New South Wales end, Looking Upstream, August 1927, 1927

This set of photos is from a leather bound album bearing the inscription "HUME RESERVOIR AUSTRALIA" plus 'The Rt. Hon. L. C. M. S. Amery, P. C., M .P.' all inscribed in gold. It was presented to The Rt. Hon. L. C. M. S. Amery, P. C., M. P, Secretary of State for Dominion Affairs on the occasion of his visit to the Hume Reservoir on 2nd November 1927. This album is of local and national significance as it documents the planning and development of the Hume Reservoir up to 1927. It was the largest water reservoir in the British Empire. The album records the pioneering engineering work that went into its construction.DEPARTMENT OF PUBLIC WORKS, N.S.W. RIVER MURRAY WATERS SCHEME. HUME RESERVOIR. 22. General View of Works from New South Wales end, Looking Upstream. Features: At the left, part of the North Wing Wall, the highest part of which is 26 feet below its ultimate height. Below in the foreground is the portion of the dam where provision is to be made for hydro-electric generation. The tubes, three in number, 13 feet in diameter, will be laid on the level shown and an early start will be made in laying them. The level for the other four regulating outlets, 9 feet in diameter, together with a part of the spillway section of the dam, is underwater at this stage and it may be remarked that at one point, about half way across the channel where the water is now flowing, the concrete foundations are about 80 feet below the level of the water. The broken surface of the water is due to the large “plums” in the concrete. The still water in the right foreground is the stilling pool over the concrete floor of which there is now more than 20 feet of water and by means of which the discharge from the outlet pipes will be quelled. The trestlework on the upstream side of the dam carries the concrete belt conveyor. It extends from the concrete mixer house, which is out of the picture, behind the wing wall, along almost the entire length of the concrete portion of the dam. The concrete is discharged from the belt at any desired point by means of trippers, one of which may be seen over the second trestle. On the other side of the flowing water is the coffer dam. A channel 300 feet wide involving about 140,000 cubic yards of excavation and dug for the temporary diversion of the river as it is flowing now. To the right top of the view beyond the Coffer Dam is the earth embankment being thrown across the major part of the valley by the Victorian Constructing Authority. The Mitta Mitta River flows into the Murray at the far end of the reach of water on the left. August 1927.hume reservoir australia, river murray waters scheme, hume reservoir construction -

Federation University Historical Collection

Federation University Historical CollectionBook - Catalogue, McPherson's Engineering Catalogue, c1905

240 page catalgue from teh Chain Belt Engineering Company. Includes numerous line and photographic illustrations.non-fictionelevators, coal handling appliances, sheffield gas works, coke storage plants, colliery truck hauling gear, incline mineral conveyor, log hauling gear, sprocket wheels, ewart's chain, gray's chain, delivery elevator buckets, j.w. glover, chain belt engineering company, catalogue, mining -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionPhotograph - Photograph - contact prints showing silo conveyor construction, Portland, 1964

Port of Portland Authority ArchivesFront: 87. 23-9-64 88. 23-9-64 89. 23-9-64 90. 23-9-64 91. 23-9-64 92. 23-9-64 (Beneath each print, in white.) Back: 87 pencilport of portland archives, grain silos, k s anderson wharf -

Federation University Historical Collection

Federation University Historical CollectionBook, Papers Presented at the "Conveyors in Mining" Inaugural Ballarat C.A.E. Mining Symposium, 1978, 1978

Black soft covered book with conference papers presented at the Ballarat College of Advanced Education.ballarat, j. short, a.j. whittle, b.w. tweedley, d.s. sleight, j. blackwell, d. kramer, m.n.g. macrae, c.l. swindells, k.f. routley, j.a. flanagan, j. dennehy, d.j. watkins, c. stewart, k.j. o'grady, jim r. short, alan whittle, mining symposium, ballarat college of advanced education, library borrowing cards and date stamp -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Books being transports an a brick converyor belt to the new E.J. Tippett Library

Photographs of books being transported from a first floor building at the Ballarat School of Mines to the ground. The books were being transported into the newly constructed E.J. Tippett Library.e.j. tippett library, library, book transport, brick conveyor belt -

Monbulk RSL Sub Branch

Monbulk RSL Sub BranchBook, Routledge, A history of the world from the 20th century to the 21st century, 2004

The 20th century is the century of communism and fascism, of debt and prosperity, of the United Nations and nationalistic fervour, of mass demonstrations and individual defiance; and also of the aircraft and the submarine, of the conveyor belt and the computer, of miracle cures and new diseases, and of radio and television.Index, bib, ill, maps, p.888.non-fictionThe 20th century is the century of communism and fascism, of debt and prosperity, of the United Nations and nationalistic fervour, of mass demonstrations and individual defiance; and also of the aircraft and the submarine, of the conveyor belt and the computer, of miracle cures and new diseases, and of radio and television. history - modern - 20th century, history - modern - 21st century -

Puffing Billy Railway

Puffing Billy RailwayMachine - Conveyor / Loader, Munro Engineers Pty Ltd, 1955

Munro Engineers Pty Ltd, Handilift Stacker & Loader' The Land on which the Menzies Creek railway station and Museum are built on was once apart of James Hermon's & his son William Hermon's property on which this Munro Handilift Stacker & Loader was used. Historic -Industrial Tool - Handilift Stacker & Loader - used on Jame's Hermon's property on which the Menzies Creek Railway is built on Munro Engineers Pty Ltd, Handilift Stacker & Loader made of steel and wood and wrought ironMunro Engineers Pty ( symbol map of Australia ) Ltd, Ballarat Vic. On side - No. 3147 On wheel - no, 2052puffing billy, munro engineers, handilift stacker & loader, hermon, menzies creek -

Moorabbin Air Museum

Moorabbin Air MuseumManual (item) - CAC tractors vehicles hangar design code NFPA 409 catering dolly conveyors, CAC ground support equipment