Showing 146 items

matching engine boiler

-

Federation University Historical Collection

Federation University Historical CollectionBook, A.C. Wannan et al, Wannan's engine-drivers' guide to the management, care, and working of steam boilers, engines, and pumps; and guide to examinations for certificates of competency, 1890, 1890

... Ballarat. wannans engine driver's guide steam boilers steam engines ...In 1898 Arthur Fussell did Mechanics in Mining at School of Mines Ballarat.A small red cloth bound book of 189 pages containing diagrams and illustratins. The cover title was printed in gold. On the inside cover and on the title page is written in pencil Arthur Fussell, 73 Errard St S, Ballaratwannans, engine driver's guide, steam boilers, steam engines, pumps, arthur fussell, steam -

Bendigo Historical Society Inc.

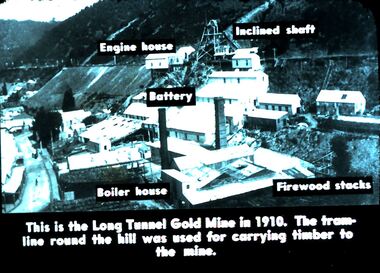

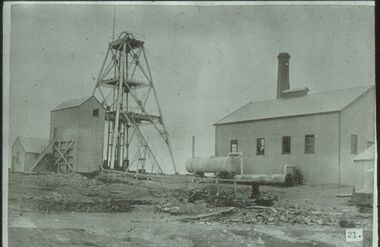

Bendigo Historical Society Inc.Slide - DIGGERS & MINING. DIGGERS AND MINERS, c1930s

Diggers & Mining. Diggers and miners. This is the Long Tunnel Gold Mine in 1910. The tram-line roamed the hill was used for carrying timber to the mine. Engine House, Inclined Shaft, Battery, Boiler House and Firewood stacks are marked on the slide. Markings: 30 994.5 WAL. Used as a teaching aid.hanimounteducation, tertiary, goldfields -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - MINE MANAGER'S REPORT TO WILLIAMS UNITED

Handwritten report from T. Banner, Mine Manager to Williams United, dated August 8, 1904, at request of Directors. Report is for the machinery at the York Shaft. Report mentions drums, ropes, length of rope on the drums, boiler which cannot work with safety up to more than 45 lbs., a good bend in the stack about 25 or 30 feet from the top and new wheels necessary. Also a report on the machinery at Central. Report mentions engine, drums, engine bed lifting a bit when bailing from the bottom, poppet legs, ropes and boiler.document, gold, mining reports, mining reports, mine manager's report to williams united, t banner, york shaft, central -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING ACCIDENTS - BOILER EXPLOSION AT LANSELL & MUELLERS COMET MINE

Handwritten extracts on a boiler explosion at Lansell & Muellers Comet Mine. 'Everything had been alright and there was plenty of water in the glass. When the boiler exploded it damaged a small part of the engine-house and tore the flue from end to end. The cause of the explosion could not be found, although it had stood the tests.'document, gold, mining accidents, mining accidents, boiler explosion at lansell & muellers comet mine, mining statistics, mines report 1884 page 43 & 44, william benson, james hall -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING ACCIDENTS - SHOCKING ACCIDENT AT WILSON'S REEF

Handwritten extract from the Bendigo Advertiser dated Friday 6th Feb. 1874 Page 2 when Thomas Bromley, engine driver at Wilson's Reef Coy, Marong was killed when he got caught in the flywheel. He had set the engine going pulling up a cage of mullock, then went away from the engine, One of the cages was pulled to the top of the poppet heads without him knowing. The wire rope broke and the cage fell down the shaft, no one was injured. The engine was still going, the braceman ran into the engine-room and told Bromley what had happened. Bromley stopped the engine to reverse the gear. He had loosened the screws and was rising from a stooping position when he was caught by the flywheel. It was thought that Bromley had started the engine, the rushed to the boiler to throw in a few pieces of wood and before he got back the cage had gone to the top of the poppet heads.document, gold, mining accidents, mining accidents, shocking accident at wilson's reef, bendigo advertiser 6/2/1874, thomas bromley -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BASIL MILLER COLLECTION: TRAMS, RAILWAY PICNICS, c1961

Newspaper clipping. Bendigo Advertiser. Saturday October 14, 1961. Early Railway Picnics Recalled. Article includes photo of souvenir tram ticket number 3588. Springtime, 1905 was Railway picnic time. And what a time it was - with packed trains from the metropolis and country towns, and Bendigo, thronged with the crowds of gay holiday-makers. Souvenir ticket belongs to rear Mrs. A. Bolitho, 5 Webster Street, Bendigo, issued by Electric Supply Coy. Of Victoria Ltd., Bendigo Tramways. Railway Picnic September 16, 1905. The ticket belong to Mrs Bolitho's father, the late Mr J H P Ellis, who lived in McIntyre Street. Post card size, printed in sepia on cream, bears photographs of the power house, engine room, a tram (we presume one of the first models) and the boiler room. Down the sides are listed cemetery, railway station, Rodney St, Charing Cross, through to California Gully Bridge and Eaglehawk. The fare was 2d. On the back a Beehive advertisement. 'Half-Century With Trams' is a history as remembered by Mr W J Evans of Mt. Korong Road, California Gully. 'Boisterous' is a history as remembered by Mr W Bolton of the firm of Bolton Bros. recalled the early picnics as 'boisterous' affairs. 'riff-raff' used to gather at Spencer St Station, arriving in Bendigo-after having spent the night drinking. The picnicers certainly had a right royal time in those early days. Railway Picnic was also boronia time, Mr Bolton said - and bunches of fragrant West Australian borania were sold on the streets. Bolton Bros always printed the tram tickets in Bendigo in those early years. A report in the 'Bendigonian' of the 1903 Railway Picnic period told that 20 special trams came to Bendigo on Saturday morning, September 15, 1903. Railway Picnic Committee: J Southern, Mrs Tait, Mrs Hudson, Mrs Fitzpatrick, Cr J H Curnow, Sir John Quick and many members of parliament. Fare from Melbourne costing 5/ for a day return, or 7/6 for the week.organization, business, bendigo trams -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - INSTRUCTION BOOK CONCERNING THE LOCOMOTIVE AND THE WESTINGHOUSE BRAKE FOR ENGINE CLEANERS, 1937

... RAILWAYS Bendigo To Melbourne locomotive locomotive brakes boilers ...Instruction Book Concerning the Locomotive and the Westinghouse Brake for Engine Cleaners. Place of publication: Melbourne. 52 pages. Black and white illustrations.Victorian Railwaysrailways, bendigo to melbourne, locomotive, locomotive brakes boilers westinghouse engine cleaners -

Bendigo Historical Society Inc.

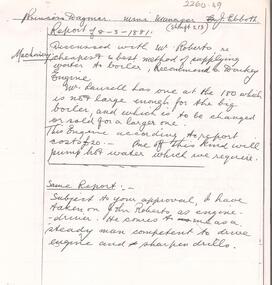

Bendigo Historical Society Inc.Document - ALBERT RICHARDSON COLLECTION: PRINCESS DAGMAR MINE, GARDEN GULLY LINE

... water to boiler, recommend a donkey engine. Mr. Lansell has one... method of supplying water to boiler, recommend a donkey engine ...4 page handwritten document, (copy) detailing some of the Mine Manager's reports for Princess Dagmar mine 1881 - 1914. Example: Reportof 8.3.1881, shaft 213, Mine Manager J. Ebboth. 'Discussed with Mr. Roberts re cheapest and bst method of supplying water to boiler, recommend a donkey engine. Mr. Lansell has one at the 180 which is not large enough for the big boiler and which is to be changed or sold for a larger one. This engine according to report costs 20 pounds. One of this kind will pump hot water which we require. Subject to your approval I have taken on John Roberts as engine driver. He comes to me as a steady man competent to drive engine and sharpen drills.'bendigo, mining, princess dagmar -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Slide - ALBERT RICHARDSON COLLECTION: VIRGINIA MINE EAGLEHAWK, 1906

Slide. . Virginia Gold Mine, Eaglehawk. Image taken about 1906. Poppet head and mine buildings on LH side. Large mine building,possibly engine shed with brick chimney visible behind the shed. Boiler against outside wall of shed .No. 21 printed on bottom of slide.mine, gold, virginia mine., bendigo mines-jack hattam collection -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - ALBERT RICHARDSON COLLECTION: WANNANS ENGINE DRIVERS GUIDE

... Wannan boilers mining mines engine driver engineman A.C. Wannan ...Book: red covered book, written on front in gold 'Wannan's Engine-Drivers' Guide'. Written in pencil inside front cover : H.R. Attwood, Alice St., Sunshine and in blue pen 'Hrm Grauz' On further page, Hilliaue Grauz, Gibson Street, Warrnambool. Book contains chapters relating to boilers, operation and accidents.A.C. Wannan, Consulting Engineermachinery, engines- steam, wannan's engine-drivers' guide, richardson, wannan, boilers, mining, mines, engine driver, engineman -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - ALBERT RICHARDSON COLLECTION: THE ENGINEMAN'S POCKET COMPANION

... boilers mining engine drivers engineman Michael Reynolds Book ...Book: blue covered book 'The Engineman's Pocket companion' by Michael Reynolds. A practical educator for Enginemen, boiler attendants and mechanics. Second Edition, revised. Published by Crosby Lockwood and co., Stationers' Hall Court, Ludgate hill, 1887. Written in pen inside front cover 'A.E. Richardson, 29 Harrison St., Bendigo ' Pencil equations written throughout book.Michael Reynoldsmachinery, engines- steam, engineman's pocket companion, richardson, boilers, mining, engine drivers, engineman -

Bay Steamers Maritime Museum

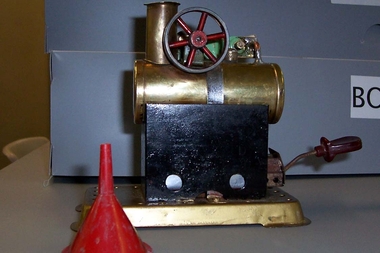

Bay Steamers Maritime Museummodel steam engine

This model was found in the collection of Bay Steamers Maritime Museum. It is not knowt who created it but it is supposed that it was constructed to educate the many masters of the Wattle in the operation of a steam engine - a not so common mode of power these days. A Bay Steamers Maritime Museum examined the model in March 2012 and discovered that is was in poor repair. Using his existing knowledge, and with reference to some historic texts, he made some repairs and returned the model to working order. Here is his anaylsis of the situation as an excerpt from the Bay Steamers Maritime Museum newsletter Steamlines May 2012 "I was confronted with a model of a steam engine used years ago as a training aid for hopeful steam engineers. Already having a knowledge of steam operations, I considered a museum write-up for that model a ‘piece of cake’. However, on turning the model’s crankshaft, the valve timing seemed ‘out of kilter’ with the movement of the piston. Problem was that the two eccentrics on the crankshaft were not properly secured to it. Eventually I fastened the two eccentrics to the crankshaft where I felt that they should be and then realized that one of them had a chain-driven valve-timing device attached. This would be adjusted while an engine was running to achieve best performance and fuel economy whilst in operation by accurately controlling the period of time during which steam under pressure from the boiler would be admitted to the cylinder and give greater time for the steam to expand in the cylinder, move the piston and turn the crankshaft and thus, drive the attached apparatus. When the valves were correctly set up it was then possible to get the model to function properly.The model comprises a green section, which is the actual the model mounted on a brown painted board. There are two parts of the model, painted white representing the steam passages, and black representing the cast- iron portions of the cylinder-block casting, and of the main valve sliding between the cylinder a second sliding valve. Of the black portions, one slides back and forth being connected to a rod which is connected to an eccentric clamped to the crankshaft and is the nearer to the flywheel of two eccentrics. This eccentric is attached to the crankshaft at an angle of 90 degrees to the crank-pin attached to the flywheel. To operate the model simply turn the flywheel by means of the handle attached to its crank-pin. A second eccentric is also attached to the crankshaft, further away from the first eccentric, and it is adjusted to operate 90 degrees from the first eccentric (that is, 180 degrees from the crank-pin) A piston (painted silver) is located in a plastic cylinder and has a piston rod which passes through one end of the cylinder, (in actual practice a steam-proof gland seals the cylinder against loss of steam) terminating in a cross-head slide between four rails guiding it. From this cross-head, a connecting rod joins the piston-rod to the flywheel via the crank-pin attached to the flywheel which is part of the crankshaft. (In actual practice, a flywheel may not be used, particularly in a multi-cylinder engine.) The white portions of the model painted nearest to the cylinder represent the two steam ports cast into the main cylinder block, whilst one section painted in between those two represents the exhaust outlet (which may be connected to a condenser to conserve water, or to the open air). The main slide valve has three white-painted portions painted thereon. It has two white-painted marks representing the steam passages to the steam ports into the cylinder, and a third section in between the other two, being that part of the valve through which exhaust steam passes in line with the ports in the cylinder block. By rotating the flywheel, the operations of an engine will be observed as steam is admitted to the main valve via the gap between the two jaws of two moveable portions of a second sliding valve which is operated by the second eccentric attached to the crank-shaft. This eccentric is used to finely tune the valve timing of this model to obtain best running results of an engine. There are various methods used for reversing a steam engine. model compound steam engine, steam engine, model, crankshaft, valve, flywheel, wattle, engineer, eccentrics -

Bay Steamers Maritime Museum

Bay Steamers Maritime MuseumBook, Newnes Marine Engineering Volume 1 Marine Steam Engines and Turbines Marine Steam Boilers

Black leather look hard cover book of 588 pagesHand wirtten in blue pen "The property of / Law Praid / S. Townhead Rd / Cotehill" Hand written in pencil ET $15 / 2 vols" -

Bay Steamers Maritime Museum

Bay Steamers Maritime MuseumBook, W.C. MacGibbon, Board of Trade Orals and Marine Knowledge Steam and Motor

... steam engines turbines boilers ships trade Sticker on inside ...Red cloth hard cover book of 1166 pagesSticker on inside front cover ÄDMIRALTY CHART AGENTS / BOOKSELLERS & STATIONERS / J. DONNE & SON / 349 POST OFFICE PLACE / MELBOURNE" Handwritten in pencil on first page "A.C. DUNSMUIR / 98 BRAUND RD / PROSPECT" non-fiction, marine engineering, shipbuilding, electricity, steam engines, turbines, boilers, ships, trade -

Puffing Billy Railway

Puffing Billy RailwayGeorge and George multi tube under fired boiler, 1929

Boiler purchased by Malvern city council to supply steam to a stationary vertical engine that drove a stone crusher. Built by George and George Pty. Ltd., Melbourne in 1929, it is an external under-fired return-flue type 18 tube boiler capable of supplying steam at 100 pounds per square inch (600 kPa). This boiler can be occasionally seen in steam at the Museum supplying steam for the operation of stationary engines on display near by. Donated by Malvern City Council in 1969. Historic - Industrial Steam Boiler EquipmentSteel, Cast IronGeorge and George Pty Ltd, Melbourne 1929george and george, malvern, steam, boiler, stone crusher, puffing billy -

Puffing Billy Railway

Puffing Billy RailwaySteam Engine - Tangye single cylinder vertical, Circa 1920

Used by the Malvern city council until 1969 to drive a rock crushing plant. While large horizontal steam engines predominated in major factories, small vertical steam engines like this were the workhorses of industries that had modest power requirements. This reliable little engine, made by leading UK manufacturer Tangye Bros of Birmingham Steam engines had the advantage that any fuel could be used to fire their boilers, but they were less convenient and efficient than internal combustion engines, required operators with higher skill levels, and had lower power to weight ratios. Tangye Limited was founded in 1857 in Birmingham by businessman Richard Tangye (1833-1906) and his mechanic brothers James and Joseph; brothers Edward and George joined them later. Richard was born near Redruth in Cornwall and educated at the Friends School at Sidcot, Somerset, where he became a pupil-teacher. From there he moved to Birmingham to work as a clerk for an engineering firm. In 1856 he started a hardware factor and commission agent business in Birmingham whose customers were mainly Cornish mine-owners in the Redruth district. From 1858 Tangyes concentrated on the manufacture of machinery and secured the sole right to manufacture Weston's differential pulley block (object 2003/45/1). They established their Cornwall Works in the Birmingham suburb of Smethwick in 1864 and soon developed a huge range of products. It was stated that 'there are perhaps no other works in the kingdom so largely employed upon so great a variety of specialities as the Cornwall Works of Messrs Tangye Bros.' The Tangyes attracted creative people to work for them. They wrote: 'We are in a position to offer unusual facilities to Inventors for carrying out their patents.' Info about Tangye Bros of Birmingham from Powerhouse Museum https://ma.as/207954 Donated by Malvern City Council in 1969 Of Interest : The Vertical and Horizontal Tangye engines on display are of the design that won a Gold Medallion at the Paris Industrial Exhibition of 1878.Historic - Industrial Steam Engine Equipmentsingle cylinder vertical Steam Engine made of Cast Iron, (Painted)Tangye Birmingham Builder's number 2462tangye, vertical steam engine, steam engine, puffing billy, stone crushing, george and george, malvern -

Puffing Billy Railway

Puffing Billy RailwayPortable Compound Steam Engine, Marshall & Son's - Builders Number 48317, circa 1908 / 1909

Portable Compound Engine - Marshall & Son's. Builders Number 48317 Built by Marshall Sons & Co., Ltd., Gainsborough, England (Builder’s Number 48317 of approximately 1908/1909), to the order of Robison Brothers, Engineers, South Melbourne. It was used for operating a pump to supply irrigation water at Robinvale in Northern Victoria. Robison Bros & Co. P/L was founded by James McFarlane Robison and his brothers in 1854, initially as plumbers and coppersmiths, the firm expanded into general engineering, boiler-making and brass, iron and steel founders and became one of Melbourne's most important engineering firms. They constructed railway bridges, gold mining equipment, railway locomotives, pumping stations, brewing vessels, abattoir machinery, amongst much else and including the first turnstiles at the Melbourne Cricket Ground. A portable engine is either a steam engine or an internal combustion engine, that remains in one place while operating (providing power to machinery), and can be easily moved from one work site to another. Mounted on wheels or sometimes skids, it is required to be towed between work sites.Historic - Industrial Portable Compound Engine - steam engine - Marshall & Son's. Marshall & Son's Portable Compound Engine - Builders Number 48317 made of steel Marshall & Son's. Builders Number 48317puffing billy, state rivers and water supply commission of victoria, portable compound engine - marshall & son's., portable compound engine, marshall sons & co., ltd., robison bros & co. p/l -

Puffing Billy Railway

Puffing Billy Railwaysingle cylinder Blackham stationary engine, circa 1900

Engine (power producing equipment) A single cylinder Blackham stationary engine. This engine required steam from a separate boiler to operate. Maker : W.H Blackham King Street, Melbourne, Victoria c. 1900 Historic - Industrial - Single cylinder Stationary engine - W. H. Blackham - Kings St. Melbourne, Victoria, Australia A single cylinder Blackham stationary engine. - Made from Iron, wrought Iron & brassW.H Blackham King st. Melbournepuffing billy, blackham, single cylinder stationary engine -

Clunes Museum

Clunes MuseumCertificate, 1919

CERTIFICATE OF COMPETENCY AS ENGINE DRIVER FOR MINING PURPOSES, PRESENTED TO ARTHUR ALLEN. WE CERTIFY THAT YOU HAVE THIS DAY PASSED THE EXAMINATION TO QUALIFY TO FULFIL THE DUTIES OF SECOND CLASS ENGINEER DRIVER ON THE PURSANCE OF MINES ACTS. GRANT YOU THIS CERTIFICATE.OF COMPETANCY WHICH ENTITLES YOUTO DRIVE ANY ENGINE WITHOUT A CONDENSER FOR MINING PURPOSE EXCEPT A WINDING ENGINE AND TO TAKE CHARGE OF ANY STEAM BOILERCERTIFICATE OF COMPETENCY AS ENGINE DRIVER FOR MINING PURPOSES, PRESENTED TO ARTHUR ALLEN BY BOARD OF EXAMINERS FOR ENGINE DRIVERS.local history, document, certificates, mining -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Donkey Engine

Brass & steel steam engine. Fuelled by Methylated Spirits into a tray under the boiler. All mounted onto a Meccano Base with red plastic funnel for use with methylated spirit. The donkey engine is a toy.toys, mechanical -

City of Ballarat Libraries

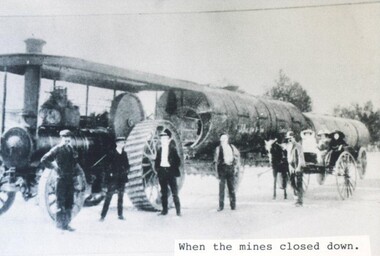

City of Ballarat LibrariesPhotograph - Card Box Photographs, Traction engines moving boilers when the mines closed down, Sebastopol circa 1916

... Sebastopol Boilers Traction engines moving boilers when the mines ...traction engine, mining, vehicles, persons, sebastopol, boilers -

Otway Districts Historical Society

Otway Districts Historical SocietyPhotograph, Victorian Railways, Derailment at Beech Forest, 1904, 4 October 1904

On Tuesday, 4 October 1904, the first serious railway accident occurred on the Colac-Beech Forest line near Beech Forest. As no train was scheduled that day in the afternoon the crew decided to fetch some wood from down the line. They fired the boiler on locomotive 3A, attached two trucks to the locomotive and moved out of the station. When they arrived opposite the Ditchley Park Hotel they stopped the engine and adjourned to the bar for some refreshments before beginning work. While they were engaged some local children boarded the unattended engine, started it, panicked when it began moving and jumped out leaving in to speed away and tip on a curve in a cutting at Ditchley. The engine was severely damaged. However, its cause remained an Otways secret. The official reason given for the accident is that the driver had fallen out of the engine while engaged in shunting allowing it to run away out of control.Locomotive No. 3A and goods wagons following their derailment at Beech Forest, 4 October 1904.beech forest; railways; narrow gauge; derailment; -

Bendigo Historical Society Inc.

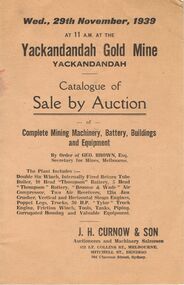

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - YACKANDANDAH GOLD MINE

Light tan coloured auction catalogue for a sale at the Yackandandah Gold Mine, Yackandandah on 29th November, 1939 of Complete Mining Machinery, Battery, Buildings and Equipment, By Order of Geo. Brown, Esq, Secretary for Mines, Melbourne. The Plant Includes:- Double 8in Winch, Internally Fired Return Tube Boiler, 10 Head Thompson Battery, 5 Head Thompson Battery, 'Broome & Wade' air Compressor, two Air Receivers, 12in Jaw Crusher, Vertical and Horizontal Steam Engines, Poppet Legs, Trucks, 30 H.P. 'Tylor' Truck Engine, Friction Winch, Tools, Tanks, Piping, Corrugated Housing and Valuable Equipment.J.; H. Curnow & Son were the auctioneers. Catalogue printed by The Cambridge Press.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - yackandandah gold mine, geo brown esq, j h curnow & son, the cambridge press -

Buninyong & District Historical Society

Buninyong & District Historical SocietyPhotograph - Photo of Original Photograph, Merryweather Fire Engine, Warrenheip Street, 1930's

Merryweather manual fire engine, acquired by Buninyong Fire Brigade in 1882, in the last years of its working life. Engine now restored and homed in Buninyong Fire Station.Coloured photograph (and b/w print) of detail, interior of Boiler House, Whykes & Sons' Slaughter House and yards, showing railing and washing area for carcasses, functioned for Whykes Butchers from 1863-1994, situated at Slaughterhouse Rd. Durham Leadbuninyong, fire brigade, fire engine, merryweather, horse -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, Estimated late 19th century

Large 4 wheeled single cylinder (horizontal) steam engine designed to be towed. Fire box painted black, boiler and steam cylinder green, wheels red. Boiler is not sound so engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Brass water drain tap on firebox. Also other brass fittings on firebox. Cast brass disc with red background fixed high on firebox :- "Marshal Sons & Co. / Made expressly / to the order / Shut, No. 45781, Open / of / Robison Bros / South Melbourne." "10017" raised in relief on firebox door. machinery; engines; steam power source -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncSteam Engine, 1877

Restored by Maldon Flywheelers Association. Originally owned and used by Zemster Brothers of "Brook Mount" Shellbourne.Known as "Aunty Jack"Large 4 wheeled 9 HP single cylinder (horizontal) steam engine, designed to be towed. Front wheels smaller than rear. Folding smoke stack with spark arrestor. Fire box and smoke stack painted black, boiler and steam cylinder green, wheels grey. In working order but engine is connected to an independent steam/air source to be operated for display purposes. 150 cm flywheel on LHS looking forward toward the front. Timber front turntable and back brake pad assembly. Brass water drain tap on firebox. Also other brass fittings on firebox.On brass ring near top of firebox:- "Serial No. 5672, Marshal Sons & Co. / Limited / Engineers / Gainsborough England". Metal plate on front turntable:- "Restoration of the Front Undercarriage / and retubing of the boiler by / Castlemaine Technical School / 1979". Cast in relief on wheel hubs:- "Marshal Sons & Co. Gainsborough".machinery - engines - steam -

Port Fairy Historical Society Museum and Archives

Port Fairy Historical Society Museum and ArchivesPhotograph, S.S.Eumeralla

EUMERALLA 906 gross tons, 489 net. Lbd: 190' x 30'1" x 12'5". Steel steamship built by Scott of Kinghorn Ltd, Kinghorn for the Western District Steam Ship Co Ltd., Melbourne. This concern may have been a subsidiary of Howard Smith Ltd, at least held some connection. Powered by a triple expansion engine producing 97 horsepower and of 2 single ended boilers, coal fired. Employed on the Western districts of Victora - Melbourne in passenger-cargo capacity. World War 1 disrupted trade and she spent much time 'laid up'. 1920 owned by Australian Steamships Pty Ltd (Howard Smith). 1928 again laid up, 1934 sold to Young & Co., Sydney who probably acted as agents for Asian interests when she was renamed Mow Li No. 2 in 1934-5. Under that name she sunk at Tinghai on the 12th July 1935 This photograph was almost certainly not taken at Port Fairy but it did work through the Port Fairy Port. sepia photographs.s.eumeralla, ship, boat, sea, moyne river -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Workers at Tarnagulla Flour Mill, c. 1873-1920, probably around 1900

Williams Family Collection. A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years.Monochrome photograph depicting workers at Tarnagulla Flour Mill, some loading or unloading a horse-drawn cart. An original photograph, mounted on card. Handwritten on back: 'L.Williams Tarnagulla' and 'Leo Fitzgerald' and full recipe for a red currant dessert.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla