Showing 108 items

matching iron foundry

-

Bendigo Historical Society Inc.

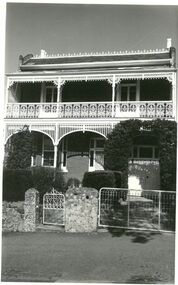

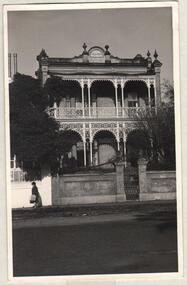

Bendigo Historical Society Inc.Photograph - Corner McKenzie Short

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.Black and White photos by A Doney of House on corner of Mc Kenzie and Short Street Bendigo showing lace ironwork on the balustrade.Photo A Doneyiron lace work, a doney, historical home bendigo -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Forest next Wesley Church

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and poured into molds made of sand. The alloys needed a minimum of 2% carbon.Black and White Photo by A Doney Bendigo of balustrade in Forest Street next to Wesley ChurchA. Doney Bendigoa doney, forest street -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Cathedral Short Street Bendigo

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of Caretakers Residence Cathedral Short Street Bendigo showing detail of the wrought iron on the verandah. A Doney Bendigoalan doney, bendigo, wrought iron, balustrade -

Bendigo Historical Society Inc.

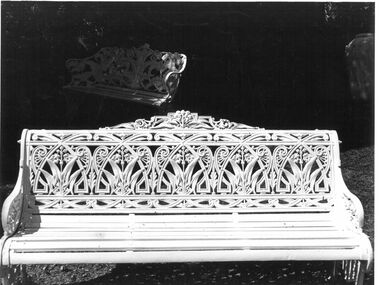

Bendigo Historical Society Inc.Photograph - Bench Seat Iron Lacework

Cast iron lace was made in foundries in most cities. There were 42 such factories in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.Black and White photos by A Doney of bench seats one showing fern detail and the other leaves and flowers.Photo A Doneyiron lace work, a doney, bench seats -

Bendigo Historical Society Inc.

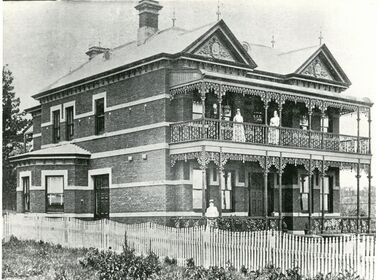

Bendigo Historical Society Inc.Photograph - Early Nurses Home BBH

CAst iron lace was made in foundries in most cities. There were 42 such factories in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys a nd then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon.A black and white photograph by Alan Doney of Early Nurses House Lucan Street (Bendigo Base Hospital). Now incorporated in portion of present Nurses home A Doney Bendigo - Copyalan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Cnr Forest Barnard Streets Bendigo

CAst iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron"' iron ore, was melted in a blast furnace, mixed with alloys and poured into moulds usually made with sand. The alloys needed a minimum of 2% carbon.Black and White photo by A Doney of Balustrade on property on the corner of Forest and Barnard Streets Bendigo.A Doney Bendigoalan doney, bendigo, wrought iron, forest street bendigo, barnard street bendigo -

Bendigo Historical Society Inc.

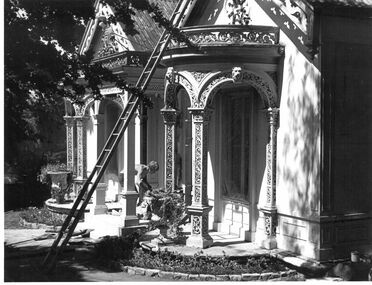

Bendigo Historical Society Inc.Photograph - Lace Iron Work

Cast iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore, was melted in a blast furnace, mixed with alloys and poured into moulds usually med from sand. The alloys needed a minimum of 2% carbon.Black and White photo by A Doney of sandblasting iron lace work on unknown property in Bendigo. Two internal photos of door and arch ways. Larger photo of balustrade with verandah pillars in backgroundA Doney Bendigoalan doney, bendigo, wrought iron -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Spastic Centre, Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore was melted in a blast furnace, mixed with alloys and then poured into moulds usually made of sand. The alloys needed a minimum of 2% carbon. Two black and white photographs by Alan Doney of the Spastic Centre in Don Street, Bendigo. Both photos shows detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron, spastic children's society -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - "Illira" Bendigo

Cast Iron lace was made in foundries in most cities. There were 42 such foundries in Melbourne alone. It was cheaper to make than wrought iron. "Pig iron", iron ore was melted in a blast furnace, mixed with alloys and then poured into molds usually made of sand. The alloys needed a minimum of 2% carbon. Three black and white photographs by Alan Doney of the residence 'Illira' at 57 Forest St, Bendigo. The first photo shows the front of the residence. The other two photos show detail of the wrought iron on the verandah. alan doney, bendigo, wrought iron, illira bendigo -

Hymettus Cottage & Garden Ballarat

Hymettus Cottage & Garden BallaratIron Lace Frieze

This Daisy Pattern iron lace frieze was registered by the Cochrane foundry North Melbourne and exhibited at the Great Exhibition Melbourne in 1880. One of the most popular patterns used in Eastern Australia the actual foundry where this was cast is unknown but this example adorns the return verandah of Hymettus cottage in Ballarat. -

Bendigo Historical Society Inc.

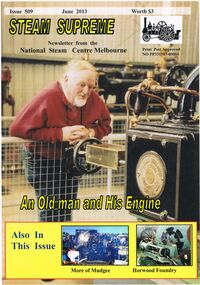

Bendigo Historical Society Inc.Magazine - HORWOOD COLLECTION: STEAM SUPREME MAGAZINE, June 2013

Magazine 'Steam Supreme', National Steam Centre, Melbourne. Article on Joel Horwood 'Horwood's Foundry' written by John Horwood, descendant. Joel Horwood JP 1832 - 1900, the pioneer foundry man of the Sandhurst Goldfields. National Steam Centre Melbournemagazine, organization, steam engines, horwood foundry, steam engines at mudgee, joel horwood, bendigo iron works -

Bendigo Historical Society Inc.

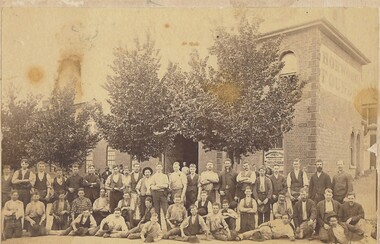

Bendigo Historical Society Inc.Photograph - HORWOOD AND SONS ENGINEERS: MILLWRIGHTS, IRON AND BRASS FOUNDERS, 1900

Sepia photo with approx 50 workmen outside Horwood's Foundry, on window 'Horwood and Son, Engineers, Millwrights, Iron and Brass Founders. Vine Street sign on building. Blue line drawn around image.R. Dermer Smith, Bull street, Sandhurstorganization, business, horwood and sons engineers, horwood and son, engineers, millwrights, iron and brass founders at the corner of vine and mackenzie streets. began as the bendigo iron works in 1856. this photograph of some of the staff was taken by r. dermer smith of bull street, sandhurst abo -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - ABRAHAM ROBERTS FAMILY

Abraham Roberts Family, the Roberts family in Australia, from Cornwall UK to Bendigo Vic, a collection of family history starting with Abraham Roberts who arrived in Australia in 1853, written by Diane.L.Penberthy, nee Roberts. Abraham Roberts founded United Iron Works and then A.Roberts and Sons foundry Wills St Bendigo. Contains black and white and colour photographs in a spring bound cover.Diane.Penberthygenealogy, family, roberts -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO FOUNDRIES

Typed notes on Bendigo Foundaries. Notes mention some of the foundries that were in Bendigo, the work they did, where they were, and where some of their work can be seen.document, bendigo foundaries, horwood & sons, girton college, the victoria foundary, andrew harkness & co, palmer river diggings, george lansell, robert harkness, abraham roberts, united iron works, laanecoorie weir, bendigo railway station, coles new world supermarket, target stores, taylor horsefield's engineering works, improved harvester, hugh victor mckay, holland bros., state rivers & water supply, civic buildings, st aiden's, bendigo hospital, carter & brown, osborn bros, bendigo building society, a'becket chambers, fortuna, george lansell, lansell mine, army survey regiment, jorgenson's, st killian's fence, redpath & brown -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncFunctional object - Foot Bellows, Fletcher Russell & Co. Ltd, c1895

FLETCHER RUSSELL & CO. LTD/ WARRINGTON MANCHESTER & LONDON Thomas Fletcher (1840-1903) had established a gas appliance manufactory in Thynne Street, Warrington by the 1880s. By 1895 the company had become Fletcher Russell and Co Gas Engineers, his firm having merged with Alexander and William Russell of Pendleton Iron Works. In 1950, the firm merged into Radiation Ltd which was later acquired by 'TI New World. In the early 1880s Thomas Fletcher was a registered dentist who went on to found a dental apparatus manufacturing business. He later diversified into producing equipment for blacksmiths, foundries, forging and other sectors. The company had grown to 900 employees in 1914. These foot-operated bellows were for pumping gas to keep the patient relaxed while the dentist worked on their teeth. They were later modified for a variety of uses where a continual flow of air was needed.These bellows are representative of a range of devices developed in the late 19th Century to assist in manufacturing. They were donated to our collection by a Wodonga resident.A set of foot bellows made from timber, metal and leather. The bellows were activated by pressing up and down on the metal step-shaped lever at the front. The air outlet on one side would have a hose attached to it to direct the air current to wherever it was needed. The bellows are made from leather. The manufacturers mark is attached to the top within a metal circle.On top of Bellows in a circle: "FLETCHER RUSSELL & CO./ WARRINGTON/ MANCHESTER / LONDON"foot bellows, fletcher russell & co. ltd. -

City of Greater Bendigo - Civic Collection

City of Greater Bendigo - Civic CollectionCeremonial object - Common Seal, F M Brown & Co Foundry

F. M. Brown & Co were a foundry located (in 1892) on the corners of Creek and High Street in Bendigo. This embosser was manufactured by them for the City of Bendigo. Large, decorated, hand operated cast iron embosser with an top iron winder. Winder has a large knob on each end and when turned lowers and raises the seal. Embosser is decorated with a layer of plaster with is black with gold hand painted decorations including scrolls and flowers. Object is extremely heavy. Seal head is still attached and holds the embossing stamp for the City of Bendigo. 'F.M Brown Bendigo' on both sides of the embosser 'City of Bendigo' on seal head.city of bendigo commerce -

Sunbury Family History and Heritage Society Inc.

Sunbury Family History and Heritage Society Inc.Photograph, Rosa McCall, St. Andrews Uniting Church, April 2017

In the foreground of this photograph are the original wrought iron gates which served as the entrance to St. Andrews Uniting Church, formerly St.Andrews Presbyterian Church. They were erected there in 1922 and were made at H.V.McKay's Sunshine Harvester foundry, at Sunshine. H.V McKay was a member of the Presbyterian Church in Sunbury. Originally the gates opened onto Stawell Street, which ran at an angle between O'Shanassy and Barkly Streets. Apart from a small area leading to the Memorial Hall the rest of Stawell Street has been incorporated in the Village Green in Sunbury.The gates fell into disrepair but in 2000 they were restored and erected on their original site. A coloured photograph of white painted wrought iron double gates with two smaller gates on either side and supported by stone pillars. A red brick church is in the background beyond a grassed area. st. andrews uniting church, h.v.mckay, stawell street, churches, st.andrews presbyterian church, sunbury