Showing 101 items

matching leather making

-

Mont De Lancey

Mont De LanceyHammer and 2 Knives/Cutters

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron hammer with a wooden handle. Larger Cutter/knife, cast iron with a wooden handle. Smaller Cutter/knife, cast-iron with a wooden handleHammer: "London" Larger knife: "Pettys Sheffield".bootmaking tools, hammers, cutting tools -

Mont De Lancey

Mont De LanceyBootmaking Equipment

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast iron Heel plate. Miscellaneous Sole plates. Hobnails and a tin of wooden sprigs.bootmaking tools, nails -

Mont De Lancey

Mont De LanceyHeel Shave and 2 Heels

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Cast Iron Heel Shave. 1 larger Leather heel piece. 1 smaller Leather heel piece.bootmaking tools, shaves -

Mont De Lancey

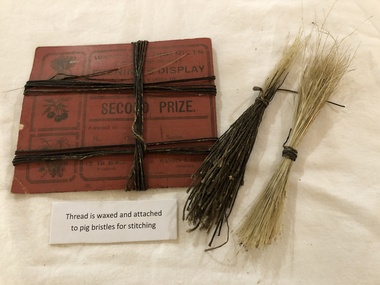

Mont De LanceyBootmaking Equipment, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.Handmade Waxed Thread attached to pig bristles, for boot stitching .bootmaking tools, thread waxers, threads -

Mont De Lancey

Mont De LanceyAwls and Awl Tips

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.5 x Cast iron Awls, all with wooden handles. 1 x container of spare Awl metal tips.bootmaking tools, awls, piercing tools -

Trafalgar Holden Museum

Trafalgar Holden MuseumTool - Eyelet tool

... Bootmakers tool used for making eyelets in leather goods... Bootmakers tool used for making eyelets in leather goods Used ...Bootmakers tool used for making eyelets in leather goodsUsed and sold by Holden ca1900Wooden handle with steel spikebootmaker, tool -

Trafalgar Holden Museum

Trafalgar Holden MuseumTool - Eyelet tool

Used circa 1900 for boot makers to put lace holes in leather boots/shoesused during the late 19th and early 20th centuries for boot makingeyelet tool with wooden and metal hook bent to 90 degrees for pressing eyelet holestool, cobbler, hole making -

Trafalgar Holden Museum

Trafalgar Holden MuseumVehicle - 1932 VY Vauxhall Coupe, 1932

1932 VY Vauxhall Coupe Bodied in Australia by Holden Motor Body Builders.The great depression hit Australia in 1932 and less than500 vehicles were bodied by Holden that year. The first British car fitted with a gear-box "embodying the now famous Synchro-Mesh principle", a system of gear change making every driver an expert. Providing a faultless shift-speed operation it was fitted to all Cadets from late 1931.[Engine in line six Cylinder 2048cc Gearbox- Three forward speed with synchromesh on 2nd and third gears. Burgundy 2 door Vauxhall coupe with black leather clad roof, Dicky seat in rear.automobile, holden, bodied -

Trafalgar Holden Museum

Trafalgar Holden MuseumFunctional object - Ammunition pouch, 1916

As used by soldiers to carry spare ammunitionAs manufactured and sold by Holden and FrostTan leather ammunition pouch, with strap riveted to rear thus making able to attach to bandolier or beltHolden and Frost Adelaide CMF SA /13military, pouch, ammunition -

Trafalgar Holden Museum

Trafalgar Holden MuseumFunctional object - Rein set for pair of horses, Ca 1900

set of reins used when driving a pair of horses to allow control of both .As manufactured and sold by Holden and FrostBlack leather strapping with brass buckles making up a set of carriage reins for a pair of horsesleather, reins, equine -

Mont De Lancey

Mont De LanceyClothing - Leather Boots, Wandin Thomas Sebire JP

Wandin Thomas Sebire JP (1867-1960) learnt boot-making as a young man. In a small workshop on his property in Sebire Avenue, Wandin he made boots for family, friends & neighbours. He also repaired boots & made other small leather articles. Bootmaking is a complex process requiring a variety of tools. The leather is cut to shape, glazed & burnished (polished) with heated irons. The pieces are stretched onto, & nailed to, a wooden last to form the boot. Once attached to the insole, the boot is finished on a metal last. Uppers are stitched with waxed thread through holes made with an awl. Heels comprise pieces nailed together & neatened with a heel shave. Metal plates, short nails or hob nails driven into the sole & heel, often in a pattern, improved durability.2 pairs of handmade, adult brown leather boots, with decorative stitching, eyelets and stitched with waxed thread. Soles covered with hob nails in a decorative pattern. 1 handmade child's brown leather boot, with decorative stitching, metal eyelets, heel has patterned nails.bootlaces, boots