Showing 239 items matching "machine factory"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, boy's first underpants, 1907

These white cotton underpants were made for Mr Geoff Maggs by his mother in 1907 as his first underwear at age 2 years old. The Maggs family were early settlers in the Moorabbin ShireThe pioneer settlers and market gardeners of Moorabbin Shire had to be self reliant and made their own clothing and utensils. This is one of many items that exhibit the skill and craftsmanship of the women in these families. White, cotton underwear for a 2 year old boy. Made at home on a sewing machine with hand feather stitching and factory-made guipure lace on leg-bands. Buttons at waist, and a tuck pleat to let down as child grows.clothing, brighton, moorabbin, pioneers, dendy henry, dressmakers, market gardners, early settlers, maggs geoff -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Wertheim Sewing Machine, c1880

Hugo Wertheim (1854–1919) arrived in Melbourne in 1875. He became a successful agent for sewing machines manufactured by his father’s cousin Joseph Wertheim in Frankfurt, Germany. Hugo married Joseph’s daughter Sophie Emilie and they settled in Melbourne. Hugo made many trips back to the main factory in Germany and, with extensive advertising, established a thriving business for sewing machines, bicycles, pianos under various ‘brand names’ - Wertheim, Electra, Planet, Griffin, Hapsburg. It has been said that Dame Nellie Melba preferred a Wertheim piano for her performances. In 1908 Hugo opened a large piano factory in Bendigo St Richmond, Victoria. His son Herbert maintained the business until the factory closed in 1935.The pioneer settlers and market gardeners of Moorabbin Shire had to be self reliant and made their own clothing and utensils. This sewing machine was one of many items they used to exhibit the skill and craftsmanship of the women in these families. A sewing machine was a necessary part of each home.A Wertheim hand–crank sewing machine c1880. The hand machine was operated by turning the handle. The hand machine could also be fitted to a stand with table and draws, the machine could then be used by hand or foot. This type of sewing machine was widely used in many homes, in an era when hand-made clothes were the “norm”, and clothes were mended, or ‘re-made’ into another garment 'WERTHEIM' across body of machinemelbourne, clothing, brighton, moorabbin, germany, piano, pioneers, richmond, bentleigh, dressmaking, market gardeners, early settlers, craftwork, sewing machines, wertheim hugo, wertheim joseph -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Manufactured Glass, bottle tomato sauce c 1910, Very early 20th Century

From the 1860s, colonists in the Moorabbin district discovered tomato growing was very successful. Tomatoes and tomato products from the Moorabbin District won prizes as far afield as NZ., London, Philadelphia, Amsterdam, India as well as in Melbourne. Two particularly successful growers were Henry Comport of Cheltenham, and Edward Zorn at Clayton. As a result of this extensive tomato growing many factories 'sprang up' in the Moorabbin district to process the produce, one of which was the "Tom Smith Pty Ltd" factory. An Advertisement on the 29th August c1912, in the Brighton Southern Cross newspaper for Tom Smith's Tomato Sauce states that it is - "Superior. From absolutely Pure Locally Grown Tomatoes. Put up in our own bottles. A High-Grade Article. Manufactured at Highett Railway Station. Smith & Lambert Manufacturers" Phone Cheltenham 206.This item is significant because it relates to the prize-winning major industry of tomato growing that the Moorabbin colonist market gardeners commenced in the 1860s. Many tomato processing factories also sprang up in the district at that time. Because the tomato industry was virtually wiped out by a virus that attacked the plants in the very early 1900s very few tangible artefacts now remain that relate to what was once an important industry.A clear glass machine-made tomato sauce bottle. The neck of the bottle indicates that the contents were originally sealed with a cork at the top. The glass appears to be of poor quality as air bubbles are evident and was moulded, not hand-blown. The bottle is embossed on the front with the manufacturer's name, and location. The glass embossing on the bottle reads Tom Smith Pty Ltd, Highett Railway Station, Moorabbin, Victoria.tomato, market gardeners, pioneers, early settlers, henry comport, edward zorn, colonists, industry, prize winning, 1860s, moorabbin district, cheltenham, clayton, glass sauce bottle, manufactured glass, bottles -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Booklet - 'Universal Knitting Book' Paton, John Paton, Son & Co. 6th Edition 1923, c1923

Gladys Reed was a member of the Ormond Choral Society c 1950. who performed plays and musicals the City of Moorabbin and she was skilled in hand knitting, crochet and dressmaking. Her garments were used by her family and the Ormond Choral Society . Patons' & Baldwin Ltd began as two separate companies: J & J Baldwin and Partners, founded in the late 1770s by James Baldwin of Halifax, West Yorkshire, England, and John Paton Son & Co., founded in 1814 by John Paton of Alloa, Scotland. Both men had formed their businesses using the spinning mule developed by Samuel Crompton. They mainly produced yarns for commercial knitting machines. The two companies merged in 1920 and diversified into producing wool for home knitters, as well as publishing knitting patterns under the "Patons Rose" and "Baldwins Beehive" trademark. By the mid-1930s, the company had establishments across Scotland and Northern England, Canada, New Zealand, Launceston, Tasmania, Australia. The company branched out into various related lines of business, and the development of new products such as nylon and Terylene. In 1961, the company was merged with J & P Coats Ltd. The Patons trademark is still in use today.The yarn production facility at Alloa was closed in 1999 and the large factory in Launceston, Tasmania, Australia,closed in 1997. In 1952 J. & P. Coats and the Clark Thread Co. merged.and in 1961 a merger with Patons and Baldwins created Coats Patons. In 2015 the business returned to the market as "Coats Group".Patons' knitting books have been used by hand knitters in many countries since they were published early in 20thC Gladys Reed and other residents of the City of Moorabbin used these pattern guides to make clothing for their families and community c1950A printed paper booklet with 64 pages of knitting and crochet patterns, instructions, photographs bound by 2 metal staplesFront Cover ; UNIVERSAL/ KNITTING BOOK / SIXTH / ED / ITION / PRICE / NINE / PENCE / Photo of lady knitting / Trade Mark / JOHN PATON, SON & CO. / BRANCH OF PATONS & BALDWINS LTD. / ALLOA / LONDON, MANCHESTER / MELBOURNE / MONTREAL Written top right ; G Reed Back Cover ; Trade Mark / Registered / THIS TRADE MARK / IS YOUR GUARANTEE / WHEN BUYING / PATONS' ALLOA / KNITTING WOOLS knitting, crochet, craftwork, john paton son & co., baldwin j &j ltd, aloa scotland, launceston tasmania, melbourne, knitting mills, knitting books, coates j&p ltd, early settlers, moorabbin shire, mechanics institute cheltenham, ormond choral society, postworld war 11 settlers, housing estates moorabbin 1950, bentleigh, ormond, moorabbin, cheltenham, drama societies, musical society cheltenham, clark judy, reed gladys, reed george -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Silver Plated Vase, Paramount - K. G. Luke Pty Ltd

Manufactured by K. G. Luke Pty Ltd.In 1921 Kenneth Luke became a partner in a small metal-spinning and silverware business at Carlton. By 1925 he was its proprietor and an employer of seven. These employees were still with him thirty years later, with 650 others, making an ever-increasing range of products: silverware, stainless steel surgical equipment, plated goods and glass-washing machines. In 1929 he bought a larger factory in Queen's Parade, Fitzroy (since redeveloped), doubled his staff and introduced new lines. At the outbreak of World War 2 production was again stepped up and Luke became an honorary adviser to the Department of Supply and Shipping. Luke went on to achieve many major public roles. In 1938-55 he was president of the Carlton Football Club. A delegate (from 1935) to the Victorian Football League, he was its vice president (1946-55) and president (1956-71). With post-war growth generating record crowds, he consolidated central administration and professionalised the game for players.A Silver Plated Vase manufactured by K.G. Luke Pty Ltd.A1 - Paramount Plate - Best EPNS Quality Plate 4001-0paramount, k. g. luke pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - String Dispenser, Lovell Manufacturing Company, 1900-1948

The string has long been a household and office utility, but an easily tangled one. generations of manufactures have devised cast-iron string holders and string reels in an attempt to distribute this material more efficiently. Many different designs of cast-iron string holders exist some nickel, others painted many had an open pattern so clerks behind the counter of the general store could see at a glance if he or she was about to run out of string. In the 20th century, string holders became more decorative, morphing into novelty items for the home. History: Starting from 1869, the young carpenter by trade, Melvin Newton Lovell (1844-1895) from Erie, Pennsylvania, later a manufacturer and successful businessman, was granted numerous patents for various devices, between them several patents for adding machines and cash registers in 1891. The Lovell Manufacturing Company was founded by Melvin Newton Lovell who was born in Allegheny, Venango county, Pennsylvania, on 31 August 1844, to Darius T. Lovell (1815-1855) and Susan B. (Conover) Lovell (1827-1883). When Melvin Lovell was a boy, the family moved to Kerrtown, a village located in the vicinity of Titusville, Pennsylvania. There Melvin served an apprenticeship as a carpenter's and his natural mechanical talent, soon enabled him to become a skilled workman. In 1861, at seventeen years of age, Melvin left home, without parental authority, and joined the Union Army soon after the outbreak of the Civil war, in August 1862, he enlisted as a private in the 127th Pennsylvania Volunteer Infantry, and was discharged the end of May 1863. In 1865 he took up residence in Erie, where he worked as a carpenter for some years. In 1869 Melvin Lovell invented and patented several useful articles for household use, and in that year he began the manufacturing certain of these inventions, in partnership with Franklin Farrar Adams, another inventor. The company's principal products were washing machines and step-ladders but also made many other cast iron household items known as the “Anchor Brand” when manufacturing began in earnest in 1881. As a result, the Lovell Manufacturing Company grew to be one of the largest industrial concerns of its kind in the country, recognized as being the most extensive manufacturer of clothes-wringers in the entire world. Lovell established sales agencies for his products in all parts of the country, and these branches were known as the Lovell stores. These goods were sold on the instalment plan, an innervation at the time for which Lovell was credited as the originator. Lovell invented and patented the famous wringer which bears his name, and in later years he confined his operations largely to the manufacture and improvement of this invention. Lovell was also one of the organisers and stockholders of the Combination Roll & Rubber Manufacturing Co, of New York, which was formed to manufacture his patents. With headquarters in New York and a factory at Bloomfield, New Jersey. Unfortunately, during a trip to Atlanta, while representing the state of Pennsylvania at a trade exposition, he passed away in his prime, on 21 November 1895, and was buried in Erie Cemetery, Erie, PA. Today the Lovell Manufacturing Company and foundry is preserved and situated at Lovell Place 1301 French Street Erie Pennsylvania, the site is regarded as a historic complex and national historic district. It includes nine contributing buildings built between 1883 and 1946 and has now been converted to luxury apartments.An item used in shops, offices etc to dispense string although the item was commonly found in many areas of general commerce. It was made by a factory and patented in the USA by Melvin Lovell who had invented the first adding machine and the original mangle or wringer washing machine used in every house throughout the world from 1891 and the forerunner to our modern day washing machines. Its age and connection to this once notable maker and his company and it's age makes it an interesting item from a historical view point.Dispenser,cast iron for string with a central rod & 2 curved handing hooks. Marked Anchor Brand & blue in colour.flagstaff hill, warrnambool, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, melvin newton lovell, string dispenser, string, packaging, anchor brand -

Bendigo Historical Society Inc.

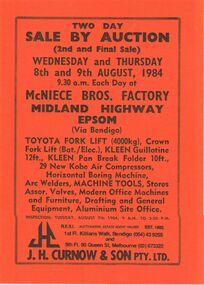

Bendigo Historical Society Inc.Document - IAN DYETT COLLECTION: AUCTION CATALOGUE - MCNIECE BROS FACTORY - EPSOM

Three orange covered auction catalogues with black printing for a sale on the 8th and 9th August, 1984 at McNiece Bros. Factory Midland Highway, Epsom, Via Bendigo. For sale were Fork Lifts, Guillotine, Pan Break Folder, Air Compressors, Horizontal Boring Machine, Arc Welders, Machine Tools, Stores Assort. Valves, Modern Office Machines and Furniture, Drafting and General Equipment and Aluminium Site Office. Some lots in the catalogue are underlined. J. H. Curnow & Son Pty. Ltd. Were the auctioneers.business, auctioneers, j h curnow & son pty ltd, ian dyett collection - auction catalogue - mcniece bros factory - epsom, j h curnow & son pty ltd, mr bill doxford, f c dyett, i m dyett, n f dyett, bolton bros pty ltd print -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO MACHINE

... Inside of a factory with some large machines. Two(2) men... BUSINESS Retail gas and fuel Kodak Inside of a factory with some ...Inside of a factory with some large machines. Two(2) men in overallsKodakbusiness, retail, gas and fuel -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - CASTLEMAINE GAS COMPANY COLLECTION: PHOTO MACHINE

Photo of a big piece of machinery inside a factory. Huge shaft with different size inpeller blades.Kodakbusiness, retail, gas and fuel -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO BUTTER FACTORY : DISPLAY NOTES

Explanatory notes for a display of photographs of the Bendigo Butter Factory. Date given on the reverse of the Title photograph is 1950-1955. In another photograph there is a calendar with the date March 1957. These notes, mounted on cardboard relate to the photograph 11011.09. The notes as written - this machine automatically cuts and wraps bulk butter into neat pounds.bendigo, industry, bendigo butter factory. -

Bendigo Historical Society Inc.

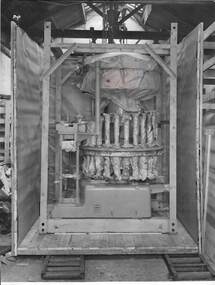

Bendigo Historical Society Inc.Photograph - MACHINERY IN BOX IN FACTORY

Black and white photograph. Machinery in box in factory. Partially unpacked machinery in wooden crate (top and front removed). Inscriptions: 'MP 207', 'B 226, 50, 4' on back. 'Cohn Bros No. 1, 24 head filler' typed on back. 'Received 14 Sep. 1950' (rectangular rubber purple stamp), 'Butlers (Australia) Pty Ltd, 18-24 Allen Street, Pyrmont, Sydney' (oval rubber red stamp). 'MP 207', T&B L corners.topic, objects, machine, 2000.525.01, 2000.524.01, 2000.532.01. 2000., 526.01, 2000.530.01, 2000.533.01, 2000.527.01, 2000.531.01 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - Lydia Chancellor collection: McKay of Drummartin

William McKay came to Australia in 1851 with three sons and four daughters. He selected land at Drummartin and the family farmed extensively. Williams grandson, Hugh Victor, was only sixteen and helping his father with the wheat harvest, when he had the idea to make a machine that would both strip and winnow the wheat, thus saving time and effort. His first machine was ready by February 1884. Hugh Victor subsequently started a small factory in Ballarat before moving to the Melbourne suburb of Sunshine. Thus became what is known as the Sunshine combine harvester.Bendigo Advertiser from Saturday May 9, 1970. The article is titled: "McKay of Drummartin, he began a new era for the world". Several photographs complement the article.drummartin, mckay -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO BUSINESSES COLLECTION: ORDNANCE FACTORY

Ona page typewritten short history of the Ordnance factory plus a ten pages document with 1) General information: location, site details, prime purpose, major capabilities and staffing levels. 2) Production in 1980-81 and 3) Major equipment items and capacities: cranes, treatment facilities, machining capacity, N.C. machines, fabricating capacity, welding and other equipment, testing facilities.bendigo, business, ordnance factory -

Bendigo Historical Society Inc.

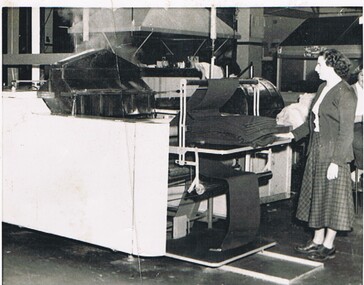

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: INTERIOR OF FACTORY

Black and white photograph of a section of the interior of the Handschin and Ronus factory in Switzerland (the parent company of Hanro), depicting a woman working at a machine that is winding a large number of bobbins from large skeins of yarn that are fitted onto frames above the bobbinsorganization, business, hanro, clothing manufacturing, hanro , handschin and ronus -

Bendigo Historical Society Inc.

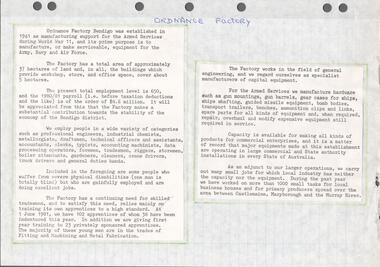

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: SPECIAL SEWING

Black and white photograph of a young women seated at a circular sewing machine?, Knitting machine ? . The photo was taken in the Handschin and Ronus factory in Switzerlandorganization, business, hanro, clothing manufacture, hanro, handschin and ronus -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: WINDING BOBBINS

Black and white photograph of a women working on a machine that is winding bobbins of yarn from large hanks. Photo taken in the Handschin and Ronus factory in Switzerlandorganization, business, hanro, clothing manufacture, hanro, handschin and ronus -

Bendigo Historical Society Inc.

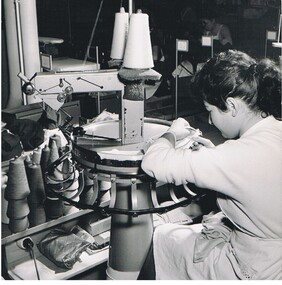

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: SEWING MACHINES

Black and white photograph of women using industrial sewing machines, taken in the Hanro factory in Switzerlandorganization, business, hanro, hanro, clothing manufacture, sewing machines -

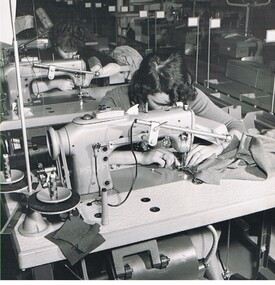

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: INTERIOR OF FACTORY, GARMENT PROCESSING MACHINE, ? 1950's

... HANRO COLLECTION: INTERIOR OF FACTORY, GARMENT PROCESSING... factory, processing material over a series of rollers. Female ...Photo: black and white photo showing machinery inside factory, processing material over a series of rollers. Female operator standing on Rh side of photo, dressed in plaid skirt, white top and long line cardigan, wearing flat shoes.no knownorganization, business, hanro, hanro, bendigo, manufacturing, machinery -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Sketch or engraving, workers, Swallow & Ariell, Australasian Sketcher, 11 Feb 1882

Sketch/Engraving of workers at Swallow & Ariell Factory, showing kneading the dough and taking the biscuits out of the machine. Australasian Sketcher 11-02-1882On rear: 24. S&A Australasian Sketcher 11 Feb 1882. P44industry - manufacturing, industry - food, swallow & ariell ltd -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - Interior, J Kitchen & Sons, Port Melbourne, Max Jeppesen, 21 Mar 2014

Five black and white photographs of the interior of J Kitchen & Sons Pty Ltd factory, Port Melbourne. .01- Tankis, Pan Room .02 - machinery for making boxes .03 - Girls possibly making boxes .04 - girls at work benches, milling, Velvet Soap plodding and wrapping dept .05 - candle factory, candles on trolley and machineMax Jeppesen, commercial photographer, 65 Hardware St, Melbourneindustry - manufacturing, workers, j kitchen & sons pty ltd -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HARRY BIGGS COLLECTION: CHAFF CUTTER

Two photographs (proofs 64 and 65) No. 64, A traction Engine driving a chaff cutter?, threshing machine? Via a very long flat belt. Behind the machine is a large pile of hay with several men standing on the heap. To the right of the machine there is another group of men and bags of grain and several bag trucks are visible. Under this photo in very faded writing is: Threshing, Chaff Cutter, Chaff Factory Collingwood, Mrs. J. Collins. 65. A working Traction Engine, cutting or threshing, there are groups of men standing on a pile of hay and also near the machine. A sign on the roof of the machine reads 'Marshalls Gainsborough'topic, farming, threshing, chaff cutter, thresher, chaff factory collingwood, mrs. j collins, marshalls, gainsborough -

Bendigo Historical Society Inc.

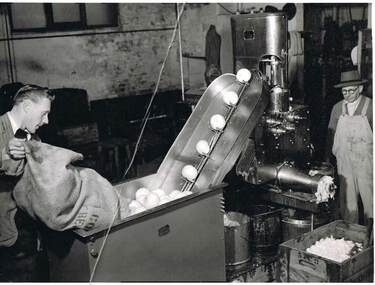

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: WORKERS

Photograph of 2 men inside the factory. The young man on the left is loading what may be oranges into a machine that crushes them, he is wearing a dust coat. The older man on the right is wearing a hat glasses and bib and brace overalls. By his feet is a large wooden box nearly full of the pulp (waste?). On the back is written in pencil ML45/.1 , there is also a purple stamp from the Australian news and Information Bureau requesting that the photo be acknowledgedAustralian News and Information Bureau.organization, business, factory workers, cohn brothers . -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - COHN BROTHERS COLLECTION: REAR VIEW OF THE FACTORY

Small sepia tone photograph: a large tin shed. There is a water tank on the far left, on the far left side of the photo there is a weatherboard house, on the far right there are double gates. There are two men working on different machines. There are lots of bits of wood lying on the ground in the bottom right corner of the photo. Written on the back in black ink is 'Back view of the Factory'buildings, commercial, cohn brothers, cohn brothers -

NMIT (Northern Melbourne Institute of TAFE)

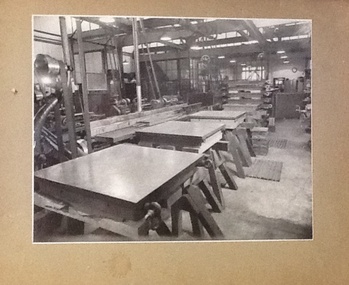

NMIT (Northern Melbourne Institute of TAFE)Photographs - CTS 1940-1943, Collingwood Technical School. Defence Training Scheme, 1940-1943

Collingwood Technical School trained apprentices in many trades. CTS was also invlved in Training Schemes during the late 1930s and during World War II. These photographs depict some of the machines and machine parts built in class. These are high quality professional photographs taken circa 1940-1943. At this time , CTS was part of the Defence Training scheme. These photographs are a visual record of this scheme.6 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work undertaken during the Defence Training Scheme, 1940-43. Also a smaller photograph of a Moultar Thread Milling Machine 1941.Each photograph has a hand written caption on the back. Captions: 1. Finished surface plates for R.A.A.F. / standing on trestle after scraping. Stack of / others in background waiting for scraping. 2. Lathe bodies in foreground, with machined / parts of lathes in middle distance, and milling / cutters, gauges and bearings in background. 3. Frames of glass splitting machines, thread / rectifying machines, and two types of milling / machine vises made in technical schools. 4.View of engineering machine shop. Carbon dioxide / freezing box in foreground, and stack of / surface plates for RAAF in middle / distance. 5.Fan geared lathes, 6 inch centres, with / self-contained motor drives, made for / cartridge factory. To be used for making / this 6.Freezing of cast iron surface plates / in layers of solid carbon dioxide / blocks. Smaller photograph has a handwritten note on the reverse: 'this photograph shows how, with the aid of a 3ft. extension mounted in front of the tool box, on which Mr. Grubb sen. is seated, these large milling machine bases ... machinists at Collingwood Technical School. A Strang, Principal 21.4.1941'. collingwood technical school, cts, apprentices, students, defence training scheme, lathes, machinery, machine parts, nmit, -

Bendigo Historical Society Inc.

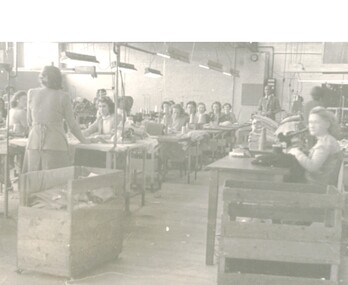

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: HANRO

Photograph. Black and White Photo of Women working at sewing machines within the Hanro Knitting Mills Factory, in Hargreaves Street, Bendigo.organization, business, hanro knitting mills, hanro -

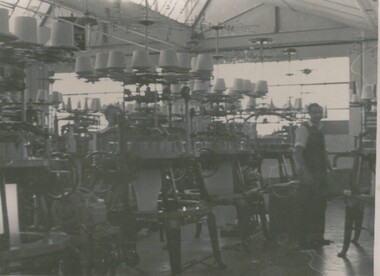

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: HANRO FACTORY

Photograph.Black and White Photo of the interior of the Hanro Knitting Mills, within the photos is a number of spooling machines and a man.organization, business, hanro knitting mills, hanro