Showing 92 items

matching twine

-

Eltham District Historical Society Inc

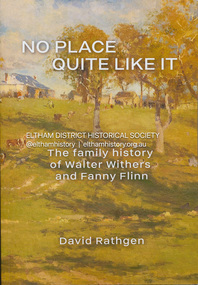

Eltham District Historical Society IncBook, David Rathgen, No Place Quite Like It; The family history of Walter Withers and Fanny Flinn, 2023

Summary For over 250 years the Withers family of Birmingham worked as tailors, sometimes also as butchers. During the Georgian era, English society changed and the Withers family with it. First came a gentleman amateur artist in the form of Edward Weston Withers, grandfather of Walter Withers. Then Edwin Withers, Walter Withers' father, took to tobacco, rope and twine manufacturing which put an end to the traditions of butchery and tailoring.The origins of Walter's painterly ambitions are explored. There was a physical altercation between Walter and his father, Edwin. That fight emerged out of contradictory expectations between Walter's father, Edwin and his grandfather Edward. Those expectations and the societies which kindled them contributed to Walter's character and art. Up until now there has been no family history about Walter Herbert Withers (1854-1914) a notable Australian landscape artist of the Heidelberg school and friend to Tom Roberts, Frederick McCubbin, Arthur Streeton and Clara Southern. Walter, the son of a rich Victorian businessman, married Fanny Flinn, the daughter of a commercial salesman who also owned part of a Birmingham brewery. In No Place Quite Like It, Walter, his wife Fanny and his family are depicted against the social contexts in which they each grew up. Our appreciation of Walter Withers' art is expanded: by knowing those forces which helped shape his early years and how he responded to them; by gaining new insights into his origins and how he grew into the man he was. We also gain a fresh appreciation of his wife Fanny, and the influence she had upon him, their children, and upon the society in which she lived. Includes 200 pages of text, Prefaces by Andrew Mackenzie OAM (art historian), and Eileen Mackley AM (President, Victorian Artists Society), Bibliography and an Index, extensive images, maps, charts and family trees, provide a visual porthole through which an insight might be had into the lives and times of Walter Withers and his family history.walter withers, fanny withers (nee flinn), family history -

Melton City Libraries

Melton City LibrariesPhotograph, Harvesting, 1950

1950 decade HAY FORK - A local invention. Bill and Arthur Gillespie and Bon Barrie In the early 1950’s Bill Gillespie of Bulmans Lane had been experimenting in developing a machine to improve the collection of hay sheaves at harvesting and stack building time. The ripened crop was cut by a reaper and binder which bundled the storks into sheaves tied with binder twine. The reaper and binder was towed by a tractor by the mid 1940s previously teams of draught horses were used to pull the reaper and binder. A photograph taken at the Barrie farm shows three binders the first being towed with a tractor and the others with horse teams. Two workmen were needed to operate the binder when cutting a crop. The sheaves collected on the binder and released onto the ground and were scattered across the paddocks. Using a conventional two pronged pitch fork the harvest hands collected the sheaves and placed each one cut edge on the ground in an upright position and layered with about 15 sheaves into an apex shape to form was is known as a stook. The shape of the stook allowed for drying and draining of water if rain had occurred. Prior to the invention of the mechanical hayfork this was a laborious task requiring each sheaf to be pitched onto a tray truck and moved to the location of the haystack. The mechanised HAYFORK was operated by one person on tractor greatly reducing the need for gangs of labourers. At harvest time farmers had relied on itinerant teams of workers descending on the district looking for work. The three Barrie brothers on their adjoining farms combined forces to cut their crop at its optimum time while the weather was in their favour. Up to many 20 workers at times formed a team in earlier times. Agricultural university students were also keen to gain practical experience in the field. Each of the brothers had a particular skill, and Tom Barrie was the expert on stack building. The district haystacks had a distinctive shape and could be recognised by their builder. Bill Gillespie’s first operational HAY FORK consisted of a large 13 pronged fork situated forward of the truck cabin. It was attached with iron girders and mounted on the rear of the cabin to the tray of his British Bedford truck. It was constructed in metal and iron and welded in the farmers work sheds. The mechanism was raised and lowered by the driver scooping along the ground to pick up a complete stook to raise high enough to deposit all the sheaves in one stook onto the stack or truck tray. The fork section was released by a rope and operated by the driver in the cabin. This model was trialled on the Barrie farm at Ferris Lane. It proved to be very successful and the Barrie/ Gillespie brothers went on to develop a HAYFORK which attached to a tractor and was operated with a series of levers and was raised and lowered hydraulically. It was detached from the tractor when stacking was completed. In its early days farmers travelling along the Western Highway called at the Barrie farm at Ferris Lane to inspect its construction and operation of the invention. It became a widely adopted by farmers throughout the State. It was being used on Wattie Palmer’s farm on Bridge Road Melton South in 1997. Farming in Melton, hay growing and stack building. agriculture, local identities