Showing 104 items matching "victoria foundry."

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - BENDIGO FOUNDRIES

Typed notes on Bendigo Foundaries. Notes mention some of the foundries that were in Bendigo, the work they did, where they were, and where some of their work can be seen.document, bendigo foundaries, horwood & sons, girton college, the victoria foundary, andrew harkness & co, palmer river diggings, george lansell, robert harkness, abraham roberts, united iron works, laanecoorie weir, bendigo railway station, coles new world supermarket, target stores, taylor horsefield's engineering works, improved harvester, hugh victor mckay, holland bros., state rivers & water supply, civic buildings, st aiden's, bendigo hospital, carter & brown, osborn bros, bendigo building society, a'becket chambers, fortuna, george lansell, lansell mine, army survey regiment, jorgenson's, st killian's fence, redpath & brown -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - EQUIPMENT PURCHASED BY BENDIGO & DISTRICT TOURIST ASSOCIATION

Handwritten carbon copy of list of equipment purchased by the Bendigo and District Tourist Association including winding engines, cylinders, air compressor, bailing tank, safety cage and other mining equipment. Equipment came from Ron Barker, Rex Archbold and Geo. Holt. Also mentioned is Harry Archbold. Notes prepared by Albert Richardson.mine, gold, victoria hill, victoria hill, equipment purchased by bendigo and district tourist associations, walkers limited maryborough foundry qld, central nell gwynne, mr miles lewis, ron barker, rex archbold, geo holt, harry archbold, a richardson -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - BENDIGO MINING REPORTS

Albert Richardson had a life long interest in Bendigo's mining. He wrote broadly about the practical aspects of mining and the history of many of the mining companies. One handwritten and typed copies (3 of page 1, 3 of page 2, 2 of page 3 and 2 of page 4). Notes, written by Albert Richardson, include an introduction which mentions the noise of the mining activities, all the machinery being made in Bendigo by the local foundries and the end of the mining.There are explanations of poppet legs or heads, landing brace, intermediate brace, safety brace, pulley wheels, boilers, winding engine, types of engines and air compressors.document, gold, mining reports, mining reports, bendigo mining reports, a. roberts & sons, h.harkness and coy, horsfield's, south new moon, central deborah, great extended hustlers, wattle gully mine chewton, big deborah mine, royal hustlers reserve no 2 shaft, the city, johnsons reef no 2, lansell's comet, south devonshire, great southern, victoria quartz, lansell's big '180', little '180', new moon, big blue, central blue, central nell gwynne, lansell's sandhurst or 'needle' mine, eureka extended -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - ALBERT RICHARDSON COLLECTION: HISTORICAL RECORDS OF BENDIGO MINES

Copy of 3-page handwritten document by Albert Richardson. Written on top of page one: 'Mining Report Historical Society 6.7.67. Historical Records of Bendigo Mines' which outlines a project undertaken by Albert and the Historical Society to write a description of each Bendigo mine, showing location, plant, gold gained, depth of shaft etc. The objective was to publish this information in a book for 'educational and historical purpose'. The paper further describes a public meeting to outline the BHS proposal to 'preserve a gold mine with all equipment both surface and underground, a crushing battery, a windlass, a whip and a whim to be stored, as far as possible in correct position. For tourists, local residents and educational purposes this should illustrate what Bendigo workers in Bendigo foundries and Bendigo citizens generally, achieved in making this city a world-famous gold mining centre. That Victoria Hill be made available and developed for the benefit of tourists and local residents' Members of the BHS involved: J. Hattam President, E. Clarke, Neil Murray, A. LLewellyn.bendigo, mining, bendigo gold mines -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Bradford Kendall, Wodonga

Bradford Kendall was established in 1922 by Lesley Bradford and Jim Kendall, investing their winnings on a race horse. They both previously worked at the BHP Steel Works. They gained contracts with the railways and mining industry. During World War II they also manufactured armaments. During the boom of the 1950s they established several foundries in South Australia, Western Australia, Queensland and Victoria. Bradford Kendall Ltd Wodonga foundry was established in 1954. It melted down old railway wheels, rails and redundant machinery to produce a range of low-alloy steel products, especially for earth-moving vehicles, railways, oil rigs and sugar factories. Wodonga was ideally placed as a change point between the different rail gauges of Victoria and New South Wales, close to the Hume Highway and the Snowy Mountain Scheme. The first sod for the site was turned on 2nd June 1954 and the first melt and pour of molten metal at Wodonga took place on 7th July 1954. Bradford Kendall Plant No.5 in Wodonga became one of the most profitable foundries in the Bradford Kendall group. Bill Black became the first plant Manager, a position he held for 30 years. Another long term employee was Pat Gooding who began work at a 15 year old and retired for the position of Bradken foundry Manufacturing Manager 51 years later. In the early 1980s, Australian National Industries Ltd bought Bradford Kendall and other heavy engineering companies. The Wodonga foundry with its (then) 170 or so staff became part of Bradken Consolidated along with nine other foundries in Australia and New Zealand. In 1989, Kerry Packer’s Consolidated Press Holdings Ltd took control of ANI. In January 1999, Smorgon Steel Group acquired ANI, which included the Bradken business. The company changed hands again in 2001 when Smorgon Steel Group sold Bradken to Castle Harlan Australian Mezzanine Partners (CHAMP). In 2016 negotiations began for Bradken to be taken over by Hitachi Construction for A$689 million. In April 2017 Bradken became a wholly owned subsidiary of Hitachi Construction Machinery Co. Limited.A collection of black and white images and advertising for Bradford Kendall (Bradken) Wodonga.bradford kendall, wodonga industries, wodonga businesses -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - VICTORIA HILL - MISCELLANEOUS NOTES ON VICTORIA HILL

Handwritten notes mentioning sign posts at Victoria Hill, Mine Workers' Wages, a note asking Father Stockdale if it would be possible to type a copy of the 'History of the Victoria Hill' for Rotary Club of Bendigo South', Notes on the Sacred Heart Cathedral and mentions The Wesley Methodist and St Johns Presbyterian Churches and All Saints Pro Cathedral, Bradmill, Bendigo Creek, Shamrock Shaft, Central Deborah Gold Mine, Girton College, Horwood's Foundry and the History We Have.document, gold, victoria hill, victoria hill, miscellaneous notes on victoria hill, old chum shaft, ballerstedts first open cut, mine workers' wages, father stockdale, rotary club of bendigo south, bradmill, bendigo creek, shamrock shaft, central deborah, gold mine, girton college, horwood's foundry, sacred heart cathedral, lansell's big 180, flying fox at cent blue, len bennet, wesley methodist church, st johns presbyterian church, all saints pro cathedral, mr derham, national trust day, bendigo potery, h biggs, clark jeffrey, city council b & d t a -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - NEW CHUM & VICTORIA LINES OF REEF - VICTORIA REEF GOLD MINES COMPANY

Photocopied handwritten notes about the Victoria Reef Gold Mines Company. Extracts from Dickers M. Record Vol. 1 23/11/1861 Ps 2 &3. Extracts include Capital, Shares, Names of Directors and Manager, Workings, Main shaft size and depth, Cost of work and labour, Drainage, Pumping Plant and Engine House.document, gold, new chum & victoria lines of reef, victoria reef gold mines company, ballerstedt & co l l, edward cook esq, thomas burrows, henry jackson, alexander rose, david chaplin sterry, theodore ballerstedt, h b nicholas, canal basin foundry glasgow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ship Tank, Early 20th century

Cubed iron ship tanks were invented by Richard Trevithich in 1808, in partnership with Robert Dickson, and the design was patented that year. The invention eventually replaced the wooden casks or barrels used at the time, as the ship tanks were more secure and their shape was much more economical in storage space. The robust metal tanks were originally made to transport water, but their preserving quality enabled them to transport perishable dry goods such as grain on long voyages, as well as other forms of liquid and solid cargo. The first ship tanks were made from sheets of iron, and later mild steel sheets, with double riveted edges and corners. A round cast iron lid with handle grips was fitted snugly into the top opening, providing an air-tight and water-tight seal. Brass taps were often fitted into the base, which could have been the case with this tank, but it now has a wooden bung in the hole. Sailing ships began using the new ship tanks on Australian voyages from around the 1830s, storing food and water for those on board, and filling them with other cargo. A large number of the ship tanks were repurposed in 1838 for the Victoria Settlement at Port Essington, N.T., as they were able to protect the food, clothing and other stores from termite and insect damage. Other ‘recycled’ ship tanks were cut in half and used as washing tubs or cookers. A 1929 catalogue from Hudson’s Tank Stores advertised square tanks that contained around 600 litres – 160 gallons – which equals an internal measurement of 33.25 inches – 84.5 centimetres – per side ship tanks are still made and sold in 1952 by the Globe Tank and Foundry in Wolverhampton, England, which was incorporated in 1922. Today, ship tanks can be seen around Australia. Wilsonson’s Promontory Lightstation has the lid from a ship tank that was used on site for the storage of water. Some have been repurposed as domestic water tanks and dog kennels, others for eucalyptus distilleries. Flagstaff Hill has two ship tanks. The Campaspe Port at Echuca, once a bustling river port, has a ship tank beside the locomotive yard. The lids of ship tanks are collectible items. Richard Trevithick (1771-1833): - Trevithick was born in 1771 in Cornwall, England. He was a famous British engineer and inventor during the Industrial Revolution, known for his invention of the first full-scale working railway, the high-pressure steam locomotive, which he demonstrated hauling a railway train in 1804. He set up a small workshop in 1808 at 72 Fore Street, Limehouse, London, to make iron ship tanks, and this invention was instrumental in replacing the wooden casks formerly used for storage on ships. He was involved with mining technology, iron foundry and ship equipment. Ship tanks changed the way that cargo was transported on ships and other vehicles from the 1830s and were used into the mid-20th century. The ship tanks’ advantages were that they could store more content, lasted longer, were waterproof and airtight, stackable and could be repurposed for many uses other than water, such as fuel, dry goods and domestic cargo. They have even been used aa dog kennels and cookers. Ship tanks were part of the evolving methos to transport water, food and cargo, which changed in 1956 when Malcolm McLean invented the large, rectangular shipping containers that are in use today; they speed up the process of loading on and off the ships, saving time and money. Ship tank: a cubed iron container with an offset hole on one side. The hole has cutouts for securely attaching a lid. This tank is on its side on the ground with the opening facing sideways. The side facing upwards has a wooden bung in a round hole. The ship tank is made from six square, thick iron sheets, rolled and riveted along the edges. The inside has a black sticky coating, possibly bitumen, and a strong creosote odour. There are small remnants of green paint on the outer surface.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, iron cube, water tank, shipping container, ship tank, ship's tank, ship tanks, marine container, richard trevithich, 1808, robert dickson, water transport, water storage, iron foundry, steel sheets, iron sheets, revets, victoria settlement, port essington, globe tank and foundry, wolverhampton, british engineer, british inventor, wooden casks -

Lakes Entrance Historical Society

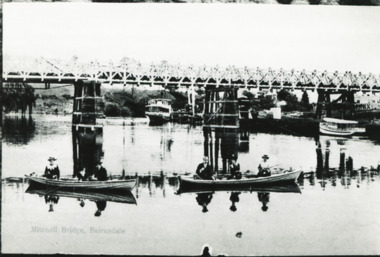

Lakes Entrance Historical SocietyPhotograph - Mitchell River bridge Bairnsdale Victoria, 1895

Downstream from bridge a steamer shown at the Bairnsdale wharf and Phoenix Foundry among wharf buildingsBlack and white photograph showing two rowing boats each containing three people, above Mitchell River bridge Bairnsdale Victoriabridges, waterways -

Stawell Historical Society Inc

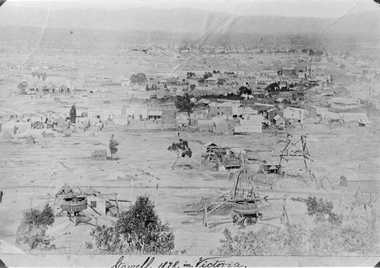

Stawell Historical Society IncPhotograph, Panorama of Stawell from Big Hill 1878, North Scotchmans No6 and No7 and South Cross Mine whims and Poppet Heads

Scene from Big Hill. Shows Stawell looking to West c 1878 Patrick Streets and Sloane Street intersection. Back of Royal Exchange Hotel Kays Foundry in Wimmera Street. Coffee Palace formerly Castlemaine Hotel at right of photo. Mining poppet heads in foreground Three Whims in the foreground are North Scotchmans No 6 & 7 and South Cross in CentreSepia toned print & also a Black & White print (these photos are similar to 29.9). Photos show Western view of mining activity in Stawell c 1878. Kays Foundry on upper left and Upper Main Street on very right of photo.Stawell 1878 in Victoria.stawell, mining, panorama, streatscape -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Tap, mid-late 19th century

This type of large, brass tap is typical of the plumbing fittings manufactured in the late 19th and early 20th centuries. The tap has encrustations and concretion inside, showing that it had been in the sea for quite some time. The pipe leading to the spout is squashed, nicked and appears to have been sawn or broken off. It could have once been part of the plumbing from a ship, perhaps from one of the boilers used in the kitchen, for bathing or for laundry or cleaning. The name “BEST” on the tap signifies that it could have been made by Robert Best who began his Birmingham brass foundry c. 1840, and even though The information from the donor is that tap was given to her father (1906-1982) who lived in the Warrnambool district. It was likely given by a cray fisherman or diver, who said that the tap came from the Loch Ard shipwreck, wrecked on Mutton Bird Island, east of Port Campbell, Victoria, on 1st June 1878. This could easily be the case but there is no provenance for it. ROBERT BEST, BRASS FOUNDRY Circa 1840 Robert Best founded his brass foundry business and was referred to as a Brass Chandelier of Birmingham”. In 1864 an advertisement in the Journal of Gas Lighting, Water Supply, & Sanitary Improvement announces Best and Hobson, late Robert Best, 100 Charlotte Street Birmingham, manufacturers of Chandeliers, Brass and iron fittings, Steam and Water-cocks etc. gas apparatus of every description, Plumber's brass foundry, with works at Birmingham and Great Bridge, Staffordshire. In 1867 Best & Lloyd was formed, after Best and Hobson went into liquidation, manufacturing at the Cambray Works of Wattville Road, Handsworth. It was a light industrial engineering works and one of the owners was Robert Dudley Best’s father. Robert Dudley Best (1892-1984) later took over the business of Best & Lloyd. The company is still in business at Downing Street, Smethwick, Birmingham. In 1878, brass ship furniture and bell fittings stamped “BEST” was made by William Udal & Co., who advertised as manufacturers of BEST cast and stamped brass foundry goods. This large brass tap is typical of industrial tapware of the mid-late 19th and 20th centuries. The location of the tap, when found, is associated with the Warrnambool district and could have easily been from a shipwreck due to the encrustation found inside the tap. Due to its design and manufacturer, the tap is associated with the mid-late 19th and early 20th-century manufacture of plumbing fittings. Tap, brass, heavy-duty, with butterfly handle. The design and style are typical of the plumbing of the late 1800s. Inscription pressed into the handle, within rectangular border "BEST". Encrustation and concretion are inside the tap spout. “BEST” on one side of the tap handle (Also, a label from the donor attached to the tap “from the wreckage of the LOCH ARD")flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, robert best brass foundry, best and hobson, best & llyod, birmingham brass foundry, brass tap, best brand tap, heavy duty brass tap, industrial brass tap, boiler tap, 19th century plumbing, 19th century tapware, 19th century plumbing fitting, tap with butterfly handle, tap salvaged from shipwreck, brass fittings, steam engine fittings, water-cock fitting -

Bendigo Historical Society Inc.

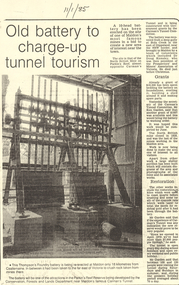

Bendigo Historical Society Inc.Document - LONG GULLY HISTORY GROUP COLLECTION:OLD BATTERY TO CHARGE-UP TUNNEL TOURISM

BHS CollectionPhotocopy of a newspaper article titled Old battery to charge-up tunnel tourism. There is a photo of a Thompson's Foundry battery which is being re-erected at the site of the North British mine on Parkin's Reef, near Carman's tunnel. The battery was recovered from a deep gully at Bola Creek. Other works include restoration of quartz roasting kilns and cyanide vats. Written at the top of the article is a date 11/1/85.bendigo, history, long gully history group, the long gully history group - old battery to charge-up tunnel tourism, thompson's foundry, parkin's reef reserve, conservation forests and lands department, carman's tunnel, north british mine, carman's tunnel committee, dr doug kemsley, the prospectors' and miners' association of victoria, mr ken garden