Showing 102 items

matching vintage hand tools

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Circular moulding Rabbet Plane Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, circular rabbet plane, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it.A vintage tool made by an unknown company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane H Heathflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1832-1864 made in London

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane J Budd London & No 4 opposite end flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, j budd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, 1832-1864

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about J Budd is that he was a tool maker and retailer that operated a business in London between 1832 to 1864. There are many of his tools including decorative moulding planes of all sizes and designs for sale around the world and that his tools in particular moulding planes are well sought after by collectors of vintage tools. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the early to mid 18th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item.Plane Moulding type maker J Budd London also stamped J Heath (owner) & No 2 opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Marking Gauge

This mortice marking gauge has an adjustable sliding arm. The gauge is used for scribing two lines on a flat surface such as timber for measuring and cutting. It is a hand-powered tool that would have been used by a tradesperson such as a cabinet maker, woodworker or carpenter. The hand tool shows signs of much use. The ‘W. Maples & Sons, Hibernia’s catalogue of 1867 had a very similar tool, called a Mortice Gauge, column 2, page 15. W. MARPLES & SONS- William Marples Snr. had a business on the Sheffield Moor in 1773/74. In 1821 his son William Jnr. At 12 years old began in his father’s joinery business. 1833 the firm was known as a tool manufacturer. In 1838 Marples called his business Hibernian Works and moved to 67-69 Spring Lane, Sheffield. When he moved to Westfield Terrace in 1856, he called his business Hibernia Works (no ‘n’ on the end). The business remained at this address for 116 years. In about 1859 the firm began using the Lyre (Irish harp) mark. In 1860 or so the two brothers, Edwin and William Marples, became partners and the firm became William Marples and Sons. The firm introduced the single shamrock symbol in 1860-61. The boys’ brother Albert joins the firm in 1863. In 1875 the company registered both the name ‘Hibernia’ and the trade mark symbol of a Triple Shamrock and the use of these trademarks continued for many decades, into the 1940 and the firm, with many changes, was still in business in the early 21st century. About Shamrock and Hibernia, both are related to Ireland and W. Marples named his products the Shamrock brand.The marking gauge is an example of a hand powered woodworking tool used over the past few centuries. Its maker was well known for his good quality tools and his business grew because of his reputation.Mortice marking gauge: wooden staff with block and green, adjustable sliding arm within the staff. The end of the staff has a facility for holding the scribe marker. The block has a hole into which a peg or wedge would be inserted to hold the sliding arm in place. Inscription with maker's name and almost indecipherable mark is stamped onto one side of the block. Made by W Marples & Sons, Sheffield.Stamped into block “W. MARPLES & SONS / HIBERNIA WORKS” above Logo of ‘Trefoil’ image [three, three-leafed clovers on the same stem]flagstaff hill, warrnambool, maritime museum, maritime village, shipwreck coast, hand tool, woodwork, marking gauge, measuring tool, mortice gauge, mortice marking gauge, william marples, w marples & sons, hibernia, shamrock, trifoil, tripple shamrock, carpenter's tool, cabinet maker, woodworking tool, drawing, planning, tool, wooden scribe, vintage, carpenter, marking tool, antique, marking out, joiner -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fuller, Grooving iron

This hand groover is sometimes called a seamer, grooving iron, punch or fuller. It would have been used by a metal smith, such as a blacksmith, tinsmith or sheet metal worker. It is used to join two edges of metal. The smith overlaps the edges of the metal, then places the tool on top and beats it with a hammer on the top, forcing the metal into the tool's groove, which joins the metal. The device would be moved along the edges to complete the seam. The same tool could give a decorative finish to an artisan's work.This handmade tool was made for the particular purpose of joining sheets of metal together. The metal formed in this way could be used for water tanks, boilers and other similar items. It is an example of the equipment made and used in the trades of a metalsmith and blacksmith in the 19th and early 20th centuries.Tool: a fuller, used to form a groove in heated iron. It is also referred to as a groover, seamer or fuller punch. Hand tool with round handle, flat round top and indented rectangular base. Base has grooves on long edges. flagstaff hill maritime museum, maritime museum, shipwreck coast, great ocean road, blacksmith tool, vintage tool, sheet metal fabrication, groover, seamer, hand tool, tinsmth, metalsmith, seaming tool, sheet metal worker, manual tool, smith's tool, fuller, grooving iron, punch -

Maldon Vintage Machinery Museum Inc

Maldon Vintage Machinery Museum IncRope Making Machine

Hand operated rope making machine with hooks for 5 strands. Mounted on a steel angle bracket bolted to a piece of timber. Handle painted green, remainder unpainted.Nonemachine tool; metalcraft; rope -

Mont De Lancey

Mont De LanceyFunctional object - Dressmaking Shears, 1900's

These vintage steel sewing shears were used at 'Belle's Bonnets' Milliners in Flinders lane Melbourne in the 1950's. Mrs Belle Phillpi was the Proprietor. Mrs Jill Sebire's wedding head piece was made at Belle's Bonnets.A pair of heavy vintage large hand forged steel dressmaking, tailors shears. They are joined with a pivot point screw. One finger hole is larger than the other.steel, scissors, cutting tools, dressmaking equipment, dressmaking shears, dressmaking scissors -

Mont De Lancey

Mont De LanceyTool - Nail Puller, N. Buchanan, Early 20th Century

Early 20th CenturyA vintage cast iron tool used to pull nails out of timber. It has a long handle with a curve at the end where there is a screw on lever to adjust around the nail being pulled.On the handle - No1. N. Buchanan Maker Melbournecast iron, hardware, nails, nail puller, hand tools -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncTool - L-30 Chain saw, Lombard, 1962 - 1964

... by a prominent Wodonga business. Hand tools Vintage chainsaws David Mann ...This chainsaw was one of the earliest models sold in Australia. It was manufactured by the Lombard company which was established in 1894 when Nathaniel Lombard developed the first practical water wheel governor in Roxbury, Massachusetts, USA. In 1904, the company moved to Ashland, Massachusetts. During the first World War, Lombard Governor produced hydraulic lathes for the manufacture of artillery shells At the conclusion of the war, Lombard expanded into the areas of chain saws and plastic molding injection machines. This model, the L-30 was only produced for 2 years from 1962 - 1964, primarily due to safety concerns and the fact that it did not have any way to sharpen or tighten the chain. This chainsaw was sold by Mann of Wodonga and donated to the Wodonga and District Historical society by David Mann, owner and manager of Mann Wodonga.This item is significant as it was produced for a limited time. It was also sold by a prominent Wodonga business.A single operator chain saw from Lombard, Ashland, Massachusetts, USA. The chainsaw was relatively lightweight but had no safety features such as a chain brake. It was made primarily of sand cast magnesium. The main cylinder was constructed of aluminium with a cast iron sleeve. It had a manual oil pump, the crankshaft operated on ball bearings and it had a maximum rpm of 4,500. See the Model profile in the accompanying Media item for details.On side of fuel tank: "ONE HALF PINT/SAE-30 OIL/ FOR EACH/ GALLON GASOLINE/ MIX WELL IN SEPARATE CONTAINER/BEFORE FILLING" On opposite side: "STARTING INSTRUCTIONS 1: FILL FUEL TANK WITH PROPER FUEL MIXTURE ( AS NOTED ON TANK) 2. FILL OIL RESERVOIR WITH #30 MOTOR OIL 3. CLOSE CHOKE, MOVE LEVER BACK TOWARDS AIR FILTER 4. HOLD THROTTLE WIDE OPEN 5. PULL STARTER HANDLE SLOWLY UNTIL STARTER ENGAGES, THEN GIVE IT A SHARP YANK 6. AS ENGINE WARMS UP, EASE CHOKE LEVER TO OPEN POSITION"hand tools, vintage chainsaws, david mann, mann wodonga -

Arapiles Historical Society

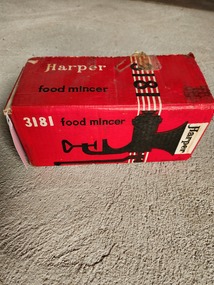

Arapiles Historical SocietyDomestic object - Greta HOGART Collection - 3181 Harper Food Mincer

The Harper 3181 Food Mincer was manufactured in England and designed for domestic kitchens in the mid-20th century. These devices allowed users to manually mince meats, vegetables, and other foods before the widespread use of electric appliances. Harper was a well-known British manufacturer of kitchen tools, and their tinned food mincers were valued for their durability and effectiveness. The mincer represents an era of hands-on food preparation and is an example of practical kitchen technology from the time.This item is a vintage Harper Food Mincer, Model No. 3181, housed in its original red and black branded cardboard box. The food mincer itself is made of heavy-duty metal with a polished finish. It features a wide hopper at the top for feeding meat or vegetables, a robust handle for manual turning, and a clamp mechanism for securing it to a countertop or table. The box displays the Harper logo and an illustration of the mincer, advertising its use for home food preparation.Box: Printed with “Harper Food Mincer No. 3181,” “Made in England,” and “Fully Tinned.” Mincer: Stamped with “3181 HARPER” on the body, and likely additional markings on handle or clamp sections (not fully visible in photo).household item, food, mincer, kitchen -

Arapiles Historical Society

Arapiles Historical SocietyTool - Roy SCHMIDT Collection - Handmade Garden Forks (2)

These hand tools are examples of early to mid-20th century garden cultivators, designed for home gardening, small-scale agriculture, or kitchen gardens. Their full-metal construction suggests they were built for durability and could be used in tough soils where wooden-handled tools might break. The minimalist yet practical design would have made them ideal for weeding, soil aeration, or root work in garden beds. Such tools were commonly found in household sheds and were often homemade or locally manufactured by blacksmiths or rural toolmakers. – Roy SCHMIDT resided with his siblings Mabel and Jack at ‘Parklands’ 85 Lake Avenue Natimuk home of Heinrich Friederick ‘Heiny’ & Minna Christina SUDHOLZ nee LANGE and their children Louis, Sophie, Alma, Lena (Roy's Mother), Florence 'Florrie' and Edward ‘Ted’.The image shows two vintage hand garden forks or cultivators, each constructed entirely from metal, including coiled wire handles. The implements are similar in size and style, but differ in tine configuration: [1] Handmade Garden Fork Straight Prongs: Has five straight, flatter tines, more like a rake, and is better suited for fine cultivation, weeding, or breaking up soil clods. [2] Handmade Garden Fork Claw Prongs: Features three thick, curved tines arranged in a spiral and claw-like fashion. These tines are more widely spaced and likely used for loosening tough or compacted soil, or for aerating.gardening