Showing 1174 items matching "solids"

-

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionLucas Morse Code Key

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Morse Code Key - 10 Voltbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionAWA Teleradio 80

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Mobile vehicle radio with handsetbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionForest Phone, AWA FP 1

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Introduced to the FCV in the mid 1960sRadio Transceiver Forest Phone FP-1 with handsetbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionForest Phone, AWA FP 1

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Introduced to the FCV in the mid 1960sRadio Transceiver Forest Phone FP-1 with handsetbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionHarbros Radio

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Radio with handsetModel 11/53M Serial 649 Manufactured by Harding Bros Horshambushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPYE Desk Microphone handset

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Desk microphone for use with base radio stationPTCA 4001bushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionCodan selective call controller

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Radio telephone.8422bushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionDesk Microphone

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Desk microphone for use with base radio stationbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionWeston FM radiotelephone

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Radio telephone.bushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionSSB Long Range Transceiver

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. SSB Long Range Transceiver including aerial wire and operation card (1992)Codan SSB transceiver 6924Bbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionSawtron portable radio

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Portable radio with aerial and handsetKG109 - 40DO 5KWbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionSawtron portable radio

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Portable radio with aerialKG109 - 40DO 5KWbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPortable STC Radiophone - c 1970s

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. This contraption is thought to have been developed in the FCV radio workshops at Surrey Hills. It's basically a STC vehicle radio which has been mounted on a backpack frame and powered by a heavy lead-acid battery. The backpack frame was manufactured at the Altona fire equipment development centre. A considerable number of these radio units were made and distributed to the field.bushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPortable radio Philips BC34

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Portable radio with handset, aerial and chargerAir Operations Ballarat Vickers stbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPCM Portable aerial radio FM322

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Portable radio with charger and handsetbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionTait portable mini phone

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Portable mini phone in leather casebushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPortable radio aerial

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Radio Aerial for use with aircraftbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionField telephone - Fire Tower

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Used to communicate to remote fire towers Single wire often run through the bush from FCV district officesFire tower telephone with winderChristmas Hills South Instructions for use around winderbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionField telephone - Fire Tower

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Used to communicate to remote fire towers Single wire often run through the bush from FCV district officesFire tower telephone with winderChristmas Hills South Instructions for use around winderbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRemote telephone - Fire Tower

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Used to communicate to remote fire towers Single wire often run through the bush from FCV district officesFire tower telephone with winderWattle Glen Diamond Creekbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionRemote telephone - Fire Tower

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. Used to communicate to remote fire towers Single wire often run through the bush from FCV district officesFire tower telephone with winderWattle Glen Diamond Creekbushfire, radios, forests commission victoria (fcv) -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionAWA Superheterodyne receiver

After the 1939 bushfires, the Forests Commission Victoria invested heavily in a radically new communications network. After suffering some inevitable delays due to the war, radio VL3AA switched into full operation in October 1945 proudly beaming out 200 watts across the State. But by today’s standards, the technology was primitive and the reception poor unless the user was on a high point somewhere. The radio signal was "line-of-sight" and bounced between fire towers and relay transmitters across the mountains back to the District offices. The advent of solid-state electronics in the 1960s replaced the more delicate valve sets which enabled greater use of vehicle mounted radios. The Commission continued to research, develop and build new radios at its many workshops around Victoria. The network was supported by a large team of skilled radio technicians. The more secure and versatile State Mobile Radio (SMR) digital trunk system came into operation in about 1995. Upgraded Tait Radios were purchased in 2014 after recommendations of the 2009 Bushfires Royal Commission. But it was the convergence of separate technologies such as 5G mobile phones, high-capacity and light-weight lithium batteries, Wi-Fi, the ever-expanding internet, cloud data storage, digital cameras, GPS, personal organisers and hundreds of supporting Apps into powerful smartphones and tablets which revolutionised bushfire communications from the mid-2000s. AWA ReceiverType IC 9640bushfire, radios, forests commission victoria (fcv) -

Mission to Seafarers Victoria

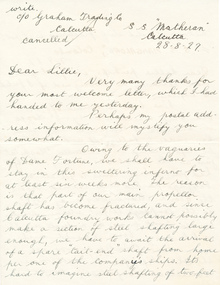

Mission to Seafarers VictoriaLetter - Correspondence, Letter to Lillie from Ted

The "letters to Lillie" show the international nature of the Mission to Seafarers. They are an important display of the handwriting style of the time, revealing courting attempts and give us an insight into life in 1925.Lillie Duncan was a member of the Harbour Lights Guild and this letter forms part of a collection of letters sent to her by different seafarers.Letter addressed to Miss L Duncan, 11 Paxton St, East Malvern, Melbourne, Australia from Ted in three parts: Envelope (0112.1) Letter page 1 (0112.2) Letter page 2 (0112.3). Both the envelope and the letter are creamy yellow in colour with black curly writing. Both sides of each page of the letter are written on. The first page of the letter begins with "Write. c/o Graham Trading Co. Calcutta. cancelled" placed at the top left of the page and "S.S. Matheran Calcutta 28-8-27" placed at the top right of the page. The first line begins with "Dear Lillie, Very many thanks for...". The reverse side of the first page starts "...thickness of solid steel fracturing is it not?". The second page begins with "...be home two months..." and the reverse side concludes with "Hope if you write to me you will use the address below, that will find me. 'Lyndale 117 Greenway Road, Taunton, Somerset, England".The envelope is torn across the top for access to its contents. The address has been typed in black ink. It has one red stamp to the top right hand corner of the envelope with the text "Ceylon 9c". There is also a black ink stamp in the form of several horizontal lines running from top left to top right of the envelope with "Colombo" written in the middle.ss matheran, calcutta, ss mangalore, colombo, ted, lillie duncan, lhlg -

Kew Historical Society Inc

Kew Historical Society IncPhotograph, J F C Farquhar, Bird's Eye View Looking North, 1891

At the beginning of the 1890s, the Kew businessman and Town Councillor, Henry Kellett, commissioned J.F.C. Farquhar to photograph scenes of Kew. These scenes included panoramas as well as pastoral scenes. The resulting set of twelve photographs was assembled in an album, Kew Where We Live, from which customers could select images for purchase.The preamble to the album describes that the photographs used the ‘argentic bromide’ process, now more commonly known as the gelatine silver process. This form of dry plate photography allowed for the negatives to be kept for weeks before processing, hence its value in landscape photography. The resulting images were considered to be finely grained and everlasting. Evidence of the success of Henry Kellett’s venture can be seen today, in that some of the photographs are held in national collections.It is believed that the Kew Historical Society’s copy of the Kellett album is unique and that the photographs in the book were the first copies taken from the original plates. It is the first and most important series of images produced about Kew. The individual images have proved essential in identifying buildings and places of heritage value in the district.This panoramic view was probably taken from the roof of Xavier College. It invites the viewer to look down on the buildings and streets of Kew, and across to the distant horizon. Mansions and solid bourgeois villas dominate the view of Charles and Wellington Streets. The imposing spires of the Presbyterian and Methodist Churches, built in one of the highest areas of Kew, can be seen in the distance. In the foreground, the photographer includes three significant mansions: Molina, Roxeth and Elsinore. Molina, in the foreground, and the group of weatherboard buildings in its yard was used at this stage for the privately operated ‘Kew High School’ (founded 1872). Roxeth, the home of Herbert Henty can be identified by its distinctive four-sided tower. All three buildings are now part of Trinity Grammar. Other built structures observable in the photograph include Wilton (now the Kew RSL), designed by Guyon Purchas for Dr William Walsh in 1886, and the only known image of the Prospect Hill Hotel prior to the renovation of 1935. Bird's Eye View Looking Northkew illustrated, kew where we live, photographic books, henry kellett -

Kew Historical Society Inc

Kew Historical Society IncPhotograph - 'Clutha', Studley Park Road, 1860-1890

Clutha was the home of John Carson, the second mayor of Kew. Leonard Terry designed the house for him in 1856. Terry was the architect of the Melbourne Club (1858), the former London Chartered Bank (1861), Lothian Terrace in Carlton (1865), and the ES&A Bank in Hawthorn (1873). The commission for Clutha was won three years after Terry’s arrival in Victoria.An extremely rare photograph of a major residential architectural commission of Leonard Terry. The photograph of the house has statewide significance as the home of the Victorian pioneer and businessman, John Carson. A rare, nineteenth century photograph of ‘Clutha’ in Studley Park Road, Kew. The sepia-toned photograph is of the front of the house, with its bluestone foundations and its second storey balcony. A real estate advertisement in 1875 described the house as: 'First-class family mansion, and about 8½ acres of pleasure grounds and fruit garden. The house, erected under the plans and supervision of Mr. Leonard Terry, is most substantially built of brick, stuccoed, on solid bluestone pediment, forming a noble basement story, large entrance hall, and lobby, with conservatory on the left. *** A wide verandah and balcony, erected on cast-iron columns, runs round the house, the views from which are perhaps unequalled in extent and beauty in the neighbourhood of the city, commanding the bay, shipping, Mount Macedon, and Dandenong Ranges. Th e whole forming a most complete gentleman's residence, no expense having been spared in its erection and comfortable finish.'"Clutha West Side Studley Park Road Kew / Clutha West Side"clutha, john carson, leonard terry -

Mission to Seafarers Victoria

Mission to Seafarers VictoriaPainting - Painting, Acrylic, Ramon Honisett, Untitled, 1990-2000

Ramon (Ray) Francis Honisett (11.04.1931 - 30.08.2019), Fellow RMIT and medallist specialised in philatelic design, marine and military aircraft painting art and was active in the 1960s - 1990s. Ray Honisett used to live in Rye, in the Mornington Peninsula. According to Gavin Fry's book: The painting likely depicts the Lysaght Endeavour loading at Hastings. "The Lysaght Endeavour and its sister ship Lysaght Entreprise were built in Newcastle in 1973 specifically to serve the regional steel industry on the route Port Kembla - Westernport - Adelaide. Even after being lengthened by 17 metres, the two ships had remarkably short working lines, with both being broken up by 1988."Maritime artLarge framed unglazed landscape format painting predominantly green depicting in foreground a merchant vessel, a roll-on roll-off cargo ship moored at a single quayside on a river or river mouth. The middle ground shows a moderate solid jetty leading to large storage sheds at right. The background appears primarily rural with fields and hills in the distance. The location is probably Hastings Western Port in Victoria - notice the forklifts loading rolls of steel produced at the nearby steel rolling mill - the buildings in the distance. You can see the rolls of steel lined up on the hard stand to the right of the ship. The funnel colours suggest the Australian National Line. The frame incorporates a beige fabric slip with gilt edge the actual dark wood frame also with inset banded gilt edge. The back of the painting is covered with brown paper in places damaged. Hangs on a cotton cord threaded between two screw in eyelet hooks.at lower right corner single uc word in black paint : "HONISETT"tankers, marine painting, maritime art, ramon honisett, ray honisett, anl maritime art prize, acta maritime art prize, hastings, western port, victoria, steel, roll on roll off, forklift, mornington peninsula, artwork-paintings -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Video recordings: Instructional NMCOT and NMIT 1980s

U-Matic Video recordings (Master tapes) mostly dated in the 1980s. Alphabetically: A house of all trades [No date] (14 min). An Introduction to floor managing An introduction to floor managing. Architrave: running the mould. Solid plastering. [No date] (17 min). Boom spray calibration (turf management). [No date] (6 min). Drafting. Module C51 Step no 4.(footwear) (1987) [No time] (Edit master) Fibrous plastering (1988) (Duration 11.00) Firm foundations: presenting a case for finance (21 min) Flux cored arc welding. Roof plumbing: fitting outlet. Friction in engineering (20 min). Grafting and budding techniques. (1986) (Duration 10.00) Horticultural courses at Collingwood College of TAFE. [No date] (10 min). Making a hand made thread. [No date] [No time] Making a hand-made thread Manual metal arc welding [No date] (24 min). Master saddlery; stitching: 1 saddle, 2 back. Microphones and their use in location sound recording [No date] [No time] Microphones and their uses in location sound recording Mold cutting [No date] [No time] Plain sailing: a film about business planning (20 min). Potentiometers, Part 1. (1983)(16 min). Preparation of artwork for video tape production (1977)(162 min). Preparation of instructional video tapes (1977)(12 min). Roof plumbing: fixing eaves cutters: Part 1 – fixing methods. [no time] Saddlery: hand stitching Safe saddle making. (1985) [No time] Solid plastering/Setting in Plaster and lime (1987) (Duration 10.00) (Edit master) Special electronic effects in video production. [No date] [No time] Splitting a stone using plugs and feathers [No date, possibly 1987] (Duration 9.40) (Master edit) The necessary art; videotape lighting: practical tips. (1974)(15 min). Tiling a staircase (1987) (Duration 25.00) (master edit) Water resistant board (W.R. Board): What is a word processor (26 min). WR Board northern metropolitan college of tafe, handbooks, nmit -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyScales Weighing, early 1900's

Although these scales cannot be identified against a historical period of Australian development they are therefore placed in a time frame when commercial markings from manufacurers were not important enough to have domestic kitchen items labeled. These cast iron scales were made for domestic and possibly rural areas and not for cities where demand for known branded utensils was more an issue. These scales are very "basic" and not to the level of weighing detail that commercial scales had to be at. These scales do not show any visible markers for accurate measurement. The "near enough is good enough" principle can be related to these scales.These scales are significant as they identify one of the basic preparation items for the weighing of foodstuff before the televising of "cooking" shows (1960s onward). The meals for which quantity measurements are required for domestic cooking is not exact however the use of cup measurements for large dishes is tedious and these scales offer the capacity for a larger mixture and an easier method for the "cook". As the need for accurate measurements of ingrediants for rural domestic meals has in the past been not been critical the requirement of accuracy that these scales do not provide is of no consequence. Domestic kitchens in the Kiewa Valley and the type of meals produced would not have required the accuracy of ingrediants that "modern " international cuisines of the later 1900's require. These kitchen scale were used whenrecipes had the terms "pinch, dollop, squidge and smidgen" were about as accurate as most recipes needed to be.Black cast iron, medium weighing scales, with a two arm cradle. On one side of the cradle is a two half circle holding frame for the retention of the metal container scoop. This light weight steel scoop/dish allows for the weighing of loose grain or similar type material to be contained and held in place for establish its saleable contents. On the other side of the weighing cradle is a flat circular platform to hold various metal disc. All the disks used on this platform have their weight stamped on them. When the produced filled in the scoop balances with the metal weight on the opposite end of the balance match (visual horizontal appraisal) the appropriate quantity required is obtained. This scale does not have any visual markings on the arms to identify a true balance. It is therefore reasonable to assume that these scales were for domestic use only and not for commercial transactions. There are two weights that are useable with these scales, one is stamped "1 lB"(pound) and one stamped "1" and both are made as a solid round piece of cast metal.The smaller disc has a "1 lb" moulded and pressed form within a marked inner circle and a mouled ridge outer circle enclosure. The other weight is slightly larger and has a moulded "1" located on the top within a raised circular edge.domestic kitchen scales, weighing scales, metal scales -

Ballarat Tramway Museum

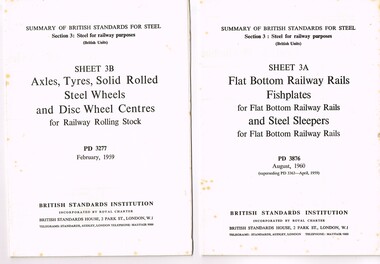

Ballarat Tramway MuseumPamphlet, British Engineering Standards Association, British Standards Institution, 1959 - 1960

Set of 6 technical data sheets, published by the British Standards Institution in 1959 / 1960 providing information about the standards for various railway products in a summary sheet form. Each sheet has been folded into 8 with the title and other sheets on the outside when folded. .1 - Sheet 3A - Flat Bottom Railway Rails, fishplates and Steel sleepers - PD 3876 - August 1960. .2 - Sheet 3B - Axles, Tyres, Solid Rolled Steel Wheels and disc wheel centres - PD3277 - December 1959 .3 - Sheet 3C - Steel billets, blooms, bars and forgings for railway rolling stock - PD 3361 - April 1959 .4 - Sheet 3D - Steel slabs, plates, sections, bars and rivets for loco boilers, locomotives, carriages and wagons - PD 3387, May 1959. .5 - Sheet 3E - Laminated springs and spring steels - PD 3365 April 1959 .6 - Sheet 3F - Helical and Volute Springs and Spring Steelstrams, tramways, steel, wheels, springs, specification, materials -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAward - Medal, Nelson Johnson, November 1880

This medal for bravery, for rescue of the crew from the shipwreck “Eric the Red” on 4th September 1880, was awarded to one of the crew of the steamer S.S. Dawn by the President of the United States in July 1881. The medal is engraved with the name “Nelson Johnson” (the anglicised version of his Swedish name Neils Frederick Yohnson). It was donated to Flagstaff Hill Maritime Village in 2013 by Nelson’s granddaughter. Nelson had migrated from Sweden to Sydney in 1879. The next year in 1880, aged 24, he was a seaman on the steamship Dawn and involved in the rescue of the survivors of the Eric the Red. Nelson Johnson was a crew member of the S.S. Dawn and was one of the rescue team in the dinghy in the early morning of September 4th 1880. Medals were awarded to the Captain and crew of the S.S. Dawn by the President of the United States, through the Consul-general (Mr Oliver M. Spencer), in July 1881 “ … in recognition of their humane efforts in rescuing the 23 survivors of the American built wooden sailing ship, the Eric the Red, on 4th September 1880.” The men were also presented with substantial monetary rewards and gifts. The city of Warrnambool’s care of the survivors was also mentioned by the President at the presentation, saying that “the city hosted and supported the crew ‘most graciously’. Previously, a week after the shipwreck, the Australian Government had also conveyed its thanks to the Captain and crew of the S.S. Dawn “Captain Griffith Jones, S.S. Dawn, The Hon. Mr Clark desires that the thanks of the Government should be conveyed to you for the prompt, persevering and seamanlike qualities displayed by you, your officers and crew in saving the number of lives you did on the occasion referred to. The hon. The Commissioner has also been pleased to award you a souvenir in commemoration of the occasion, and a sum of 65 pounds to be awarded to your officers and crew according to annexed scale. I am, &c, W Collins Rees, for and in the absence of the Chief Harbour Master.” The Awards are as follows: - Crew of DAWN'S lifeboat-Chief Officer, Mr G. Peat, 15 pounds; boat's crew-G. Sterge, A.B., 5 pounds; T. Hammond, A.B., 5 pounds; J. Black, A.B., 5 pounds; H. Edwards, A.B., 5 pounds. Dinghy's Crew-Second Officer, Mr Christie, 10 pounds; boat's crew -F. Lafer, A.B., 5 pounds; W. Johnstone, A.B., 5 pounds; Mr Lear, provedore, 5 pounds; Mr Dove, purser, 5 pounds. Captain Jones receives a piece of plate. (from “Wreck of the ship Eric the Red” by Jack Loney) The medal’s history, according to the Editor of ‘E-Sylum’ (the newsletter of The Numismatic Bibliomania Society “… appears to be an example of an 1880 State Department medal, catalogued as LS-3 (page 322 of R. W. Julian's book, Medals of the United States Mint: The First Century 1792-1892). The reverse is mostly blank for engraving, surrounded by a thin wreath. It was designed by George Morgan, chief engraver for the Philadelphia Mint, and struck in gold, silver and bronze. The one pictured here (in The Standard newspaper, 2nd July 2013) appears to be silver.” The following is an account of the events which led to the awarding of this medal. The American ship Eric the Red was a wooden, three-masted clipper ship. She had 1,580 tons register and was the largest full-rigged ship built at Bath, Maine, USA in 1871. She was built and registered by Arthur Sewall, later to become the partnership E. & A. Sewall, the 51st ship built by this company. The annually-published List of Merchant Vessels of the U.S. shows Bath was still the home port of Eric the Red in 1880. The vessel was named after the Viking discoverer, Eric ‘the Red-haired’ Thorvaldsson, who was the first European to reach the shores of North America (in 980AD). The ship Eric the Red at first traded in coal between America and Britain, and later traded in guano nitrates from South America. In 1879 she was re-metalled and was in first-class condition. On 10th June 1880 (some records say 12th June) Eric the Red departed New York for Melbourne and then Sydney. She had been commissioned by American trade representatives to carry a special cargo of 500 exhibits (1400 tons) – about a quarter to a third of America’s total exhibits - for the U.S.A. pavilion at Melbourne’s first International Exhibition. The exhibits included furniture, ironmongery, wines, chemicals, dental and surgical instruments, paper, cages, bronze lamp trimmings, axles, stamped ware, astronomical and time globes, samples of corn and the choicest of leaf tobacco. Other general cargo included merchandise such as cases of kerosene and turpentine, brooms, Bristol's Sarsaparilla, Wheeler and Wilson sewing machines, Wheeler’s thresher machine, axe handles and tools, cases of silver plate, toys, pianos and organs, carriages and Yankee notions. The Eric the Red left New York under the command of Captain Zaccheus Allen (or some records say Captain Jacques Allen) and 24 other crew including the owner’s son third mate Ned Sewall. There were also 2 saloon passengers on board. The ship had been sailing for an uneventful 85 days and the voyage was almost at its end. As Eric the Red approached Cape Otway there was a moderate north-west wind and a hazy and overcast atmosphere. On 4th September 1880 at about 1:30 am Captain Allen sighted the Cape Otway light and was keeping the ship 5-6 miles offshore to stay clear of the hazardous Otway Reef. However, he had badly misjudged his position. The ship hit the Otway Reef about 2 miles out to sea, southwest of the Cape Otway light station. Captain Allen ordered the wheel to be put ‘hard up’ thinking that she might float off the reef. The sea knocked the helmsman away from the wheel, broke the wheel ropes and carried away the rudder. The lifeboats were swamped, the mizzenmast fell, with all of its riggings, then the mainmast also fell and the ship broke in two. Some said that the passenger Vaughan, who was travelling for his health and not very strong, was washed overboard and never seen again. The ship started breaking up. The forward house came adrift with three of the crew on it as well as a longboat, which the men succeeded in launching and keeping afloat by continually bailing with their sea boots. The captain, the third mate (the owner’s son) and others clung to the mizzenmast in the sea. Then the owner’s son was washed away off the mast. Within 10 minutes the rest of the ship was in pieces, completely wrecked, with cargo and wreckage floating in the sea. The captain encouraged the second mate to swim with him to the deckhouse where there were other crew but the second mate wouldn’t go with him. Eventually, the Captain made it to the deckhouse and the men pulled him up. At about 4:30 am the group of men on the deckhouse saw the lights of a steamer and called for help. At the same time, they noticed the second mate and the other man had drifted nearby, still on the spur, and pulled them both onto the wreck. The coastal steamer SS Dawn was returning to Warrnambool from Melbourne, and its sailing time was different to its usual schedule. She was built in 1876 and bought by the Portland and Belfast Steam Navigation Co. in 1877. At the time of this journey, she was commanded by Captain Jones and was sailing between Melbourne and Portland via Warrnambool. The provedore the Dawn, Benjamin Lear, heard cries of distress coming through the portholes of the saloon. He gave the alarm and the engines were stopped. Cries could be heard clearly, coming from the land. Captain Jones sent out crew in two boats and fired off rockets and blue lights to illuminate the area. They picked up the three survivors who were in the long boat from Eric the Red. Two men were picked up out of the water, one being the owner’s son who was clinging to floating kerosene boxes. At daylight, the Dawn then rescued the 18 men from the floating portion of the deckhouse, which had drifted about 4 miles from where they’d struck the reef. Shortly after the rescue the deckhouse drifted onto breakers and was thrown onto rocks at Point Franklin, about 2 miles east of Cape Otway. Captain Jones had signalled to Cape Otway lighthouse the number of the Eric the Red and later signalled that there was a wreck at Otway Reef but there was no response from the lighthouse. The captain and crew of the Dawn spent several more hours searching unsuccessfully for more survivors, even going back as far as Apollo Bay. On board the Dawn the exhausted men received care and attention to their needs and wants, including much-needed clothing. Captain Allen was amongst the 23 battered and injured men who were rescued and later taken to Warrnambool for care. Warrnambool’s mayor and town clerk offered them all hospitality, the three badly injured men going to the hospital for care and others to the Olive Branch Hotel, then on to Melbourne. Captain Allen’s leg injury prevented him from going ashore so he and three other men travelled on the Dawn to Portland. They were met by the mayor who also treated them all with great kindness. Captain Allen took the train back to Melbourne then returned to America. Those saved were Captain Zaccheus Allen (or Jacques Allen), J. Darcy chief mate, James F. Lawrence second mate, Ned Sewall third mate and owner’s son, John French the cook, C. Nelson sail maker, Clarence W. New passenger, and able seamen Dickenson, J. Black, Denis White, C. Herbert, C. Thompson, A. Brooks, D. Wilson, J. Ellis, Q. Thompson, C. Newman, W. Paul, J. Davis, M. Horenleng, J. Ogduff, T. W. Drew, R. Richardson. Four men had lost their lives; three of them were crew (Gus Dahlgreen ship’s carpenter, H. Ackman steward, who drowned in his cabin, and George Silver seaman) and one a passenger (J. B. Vaughan). The body of one of them had been found washed up at Cape Otway and was later buried in the lighthouse cemetery; another body was seen on an inaccessible ledge. Twelve months later the second mate James F. Lawrence, from Nova Scotia passed away in the Warrnambool district; an obituary was displayed in the local paper. Neither the ship nor its cargo was insured. The ship was worth about £15,000 and the cargo was reportedly worth £40,000; only about £2,000 worth had been recovered. Cargo and wreckage washed up at Apollo Bay, Peterborough, Port Campbell, Western Port and according to some reports, even as far away as the beaches of New Zealand. The day after the wreck the government steamship Pharos was sent from Queenscliff to clear the shipping lanes of debris that could be a danger to ships. The large midship deckhouse of the ship was found floating in a calm sea near Henty Reef. Items such as an American chair, a ladder and a nest of boxes were all on top of the deckhouse. As it was so large and could cause danger to passing ships, Captain Payne had the deckhouse towed towards the shore just beyond Apollo Bay. Between Apollo Bay and Blanket Bay, the captain and crew of Pharos collected Wheeler and Wilson sewing machines, nests of boxes, bottles of Bristol’s sarsaparilla, pieces of common American chairs, axe handles, a Wheelers’ Patent thresher and a sailor’s trunk with the words “A. James” on the front. A ship’s flag-board bearing the words “Eric the Red” was found on the deckhouse; finally, those on board the Pharos had the name of the wrecked vessel. During this operation, Pharos came across the government steamer Victoria and also a steamer S.S. Otway, both of which were picking up flotsam and wreckage. A whole side of the hull and three large pieces of the other side of the hull, with some of the copper sheathing stripped off, had floated onto Point Franklin. Some of the vessels' yards and portions of her masts were on shore. The pieces of canvas attached to the yards and masts confirmed that the vessel had been under sail. The beach there was piled with debris several feet high. There were many cases of Diamond Oil kerosene, labelled R. W. Cameron and Company, New York. There were also many large planks of red pine, portions of a small white boat and a large, well-used oar. Other items found ashore included sewing machines (some consigned to ‘Long and Co.”) and notions, axe and scythe handles, hay forks, wooden pegs, rolls of wire (some branded “T.S” and Co, Melbourne”), kegs of nails branded “A.T. and Co.” from the factory of A. Field and Son, Taunton, Massachusetts, croquet balls and mallets, buggy fittings, rat traps, perfumery, cutlery and Douay Bibles, clocks, bicycles, chairs, a fly wheel, a cooking stove, timber, boxes, pianos, organs and a ladder. (Wooden clothes pegs drifted in for many years). There seemed to be no personal luggage or clothing. The Pharos encountered a long line, about one and a half miles, of f locating wreckage about 10 miles off land, southeast of Cape Otway, and in some places about 40 feet wide. It seemed that more than half of it was from Eric the Red. The ship’s crew rescued 3 cases that were for the Melbourne Exhibition and other items from amongst the debris. There were also chairs, doors, musical instruments, washing boards, nests of trunks and flycatchers floating in the sea. Most of the goods were saturated and smelt of kerosene. A section of the hull lies buried in the sand at Parker River Beach. An anchor with a chain is embedded in the rocks east of Point Franklin and a second anchor, thought to be from Eric the Red, is on display at the Cape Otway light station. (There is a photograph of a life belt on the verandah of Rivernook Guest House in Princetown with the words “ERIC THE RED / BOSTON”. This is rather a mystery as the ship was registered in Bath, Maine, USA.) Parts of the ship are on display at Bimbi Park Caravan Park and at Apollo Bay Museum. Flagstaff Hill Maritime Village also has part of the helm (steering wheel), a carved wooden sword (said to be the only remaining portion of the ship’s figurehead; further research is currently being carried out), a door, a metal rod, samples of wood and this medal awarded for the rescue of the crew. Much of the wreckage was recovered by the local residents before police and other authorities arrived at the scene. Looters went to great effort to salvage goods, being lowered down the high cliff faces to areas with little or no beach to collect items from the wreckage, their mates above watching out for dangerous waves. A Tasmanian newspaper reports on a court case in Stawell, Victoria, noting a man who was caught 2 months later selling tobacco from the wreckage of Eric the Red. Some of the silverware is still treasured by descendants of Mr Mackenzie who was given these items by officials for his help in securing the cargo. The gifts included silver coffee and teapots, half a dozen silver serviette rings and two sewing machines. A Mr G.W. Black has in his possession a medal and a purse that was awarded to his father, another Dawn crew member who was part of the rescue team. The medal is similarly inscribed and named “To John Black ….” (from “Shipwrecks” by Margaret E. Mackenzie, 3rd edition, published 1964). The wreck and cargo were sold to a Melbourne man who salvaged a quantity of high-quality tobacco and dental and surgical instruments. Timbers from the ship were salvaged and used in the construction of houses and shed around Apollo Bay, including a guest house, Milford House (since burnt down in bushfires), which had furniture, fittings and timber on the dining room floor from the ship. A 39.7-foot-long trading ketch, the Apollo, was also built from its timbers by Mr Burgess in 1883 and subsequently used in Tasmanian waters. It was the first attempt at shipbuilding in Apollo Bay. In 1881 a red light was installed about 300 feet above sea level at the base of the Cape Otway lighthouse to warn ships when they were too close to shore; It would not be visible unless a ship came within 3 miles from it. This has proved to be an effective warning. Nelson Johnson married Elizabeth Howard in 1881 and they had 10 children, the father of the medal’s donor being the youngest. They lived in 13 Tichbourne Place, South Melbourne, Victoria. Nelson died in 1922 in Fitzroy Victoria, age 66. In 1895 the owners of the S.S. Dawn, the Portland and Belfast Steam Navigation Co., wound up and sold out to the Belfast Company who took over the Dawn for one year before selling her to Howard Smith. She was condemned and sunk in Suva in 1928. The State Library of Victoria has a lithograph in its collection depicting the steamer Dawn and the shipwrecked men, titled. "Wreck of the ship Eric the Red, Cape Otway: rescue of the crew by the Dawn". The medal for bravery is associated with the ship the “The Eric the Red which is historically significant as one of Victoria's major 19th century shipwrecks. (Heritage Victoria Eric the Red; HV ID 239) The wreck led to the provision of an additional warning light placed below the Cape Otway lighthouse to alert mariners to the location of Otway Reef. The site is archaeologically significant for its remains of a large and varied cargo and ship's fittings being scattered over a wide area. The site is recreationally and aesthetically significant as it is one of the few sites along this coast where tourists can visit identifiable remains of a large wooden shipwreck, and for its location set against the background of Cape Otway, Bass Strait, and the Cape Otway lighthouse.“ (Victorian Heritage Database Registration Number S239, Official Number 8745 USA) This medal was awarded to Nelson Johnson by the U.S. President for bravery in the rescue of the Eric the Red crew. The obverse of the round, solid silver medal has an inscription around the rim. In the centre of the medal is the head of Liberty to the left, hair in a bun, with a sprig of leaves in the top left of a band around her head. There is a 6-pointed star below the portrait, between the start and end of the inscription. There are two raised areas on the rim, horizontally opposite each other, from the edge to just below the lettering and coinciding with the holes drilled in the edge. Slightly right of the top is a round indentation in the rim. The reverse has a wreath of leaves as a border, joined at the bottom by a ribbon bow. In the centre of the medal is an inscription, decorated with 3-pronged design and dots. The edge is plain with 2 small, rough and uneven holes horizontally opposite to each other, as though they had been used for mounting the medal at some stage. The medal has a matte finish on both sides and is slightly pitted and scratched.“PRESENTED BY THE PRESIDENT OF THE UNITED STATES” around the perimeter of the obverse of the medal. “TO / Nelson Johnson, / seaman of the British, / str “Dawn”, for bravery, / at risk of life, / in / rescuing the crew of / the American Ship / “Eric the Red.” “M” on obverse, truncation of the portraitwarrnambool, flagstaff hill, flagstaff hill maritime village, maritime museum, shipwreck coast, great ocean road, shipwreck artefact, eric the red, zaccheus allen, sewall, 1880, melbourne exhibition, cape otway, otway reef, victorian shipwreck, medal, nelson johnson, neils frederick yohnson, s.s. dawn, george morgan, hero