Showing 1243 items

matching collector

-

Bendigo Military Museum

Bendigo Military MuseumBook - MEMORABILIA CATALOGUE, USA, GREGG Dennis M, "A Collector's Identification and price guide for/Grand Army of the Republic/, 2005

Grand Army of the Republic (GAR) was in existence for 83 years.Soft cover book Soft cover - cardboard with glossy cover, white and yellow print on front, spine and back. Illustrations,. Front - in colour medal and ribbons superimposed over black and white montage of portrait photographs. Book - in colour collections of army memorabilia with portrait photograph centre. 97 pages, cut, plain, glossy white paper, illustrated black and white photographs.books, memorabilia, history usa -

Bendigo Military Museum

Bendigo Military MuseumBook - BOOK, WW2, Douglas Botting, The D-Day Invasion. World War II Collectors Edition, 1978

The Second Front earlier edition of this book.Hard cardboard cover, glossy finish, silver & white print on front & spine. Front background has black & white photo, out of focus back view of soldiers. Dust cover has silver & white print on front, spine & back. Front background has black & silver photo as cover. 208 pages, cut, plain, white. Illustrated in black & white / colour, photographs & drawings. Printed in black ink - front fly leaf - name plate: “From Bishop Noel Daly's collection 2004” Handwritten in blue ink on title page: “Sister M Seagrave”. “RSL stamps”book, d day, invasion 1944 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlane Compass, 1941-1943

This compass is the type used by an artillery unit of the Australian Military Forces during World War 2 and made by J W Handley. Although having owned the factory site since 1935 at 657 Victoria St J W Handley began to produce various items for the Australian Military forces after purchasing and expanding the factory to 655 Victoria St. It appears that he, or some one else may already have been occupying the site for industrial purposes, such as (Manufacturing, Foundry and Electroplating) since at least 1929. J W Handley Pty Ltd was actively producing items for the Military during the war years, a newspaper article from 1939 shows the factory in production and employing 420 people during 1939. J W Handley after the war moved into producing other non military items including a range of fishing reels. The company ceased trading in 1987 and was deregistered as J W Handley Pty Ltd in 1990.The item demonstrates the industrial capability of Australia at the start of World War 2. This item is actively sort by collectors of Australian Military memorabilia and represents a time in Australian history when the country was at war and the general population was concerned about an invasion from Japanese forces. It also therefor is of social significance as many Australians served in the Military forces at that time and the item is complete and in very good condition.A plane table compass, sometimes referred to as a trough compass, used by surveyors and artillery crew to accurately establish magnetic north. The compass is precision machined of brass material with a long needle to ensure accuracy. The compass scale is marked with a centre zero (for magnetic north) and graduations indicating plus and minus five degrees. The compass is housed in a protective wooden case with a sliding lid. The lid has a brass slide which locks the compass needle during periods when the compass is not in use.J.W.H./V Mark 11 D↑D. Made by J W Handley Richmond Melbourne, Victoria. Serial No 353flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, trough compass, navigation instrument, surveyor's instrument, j w handley, artillery, australian army, trough, plane compass, world war 2 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlane Compass, 1941-1943

This compass is the type used by an artillery unit of the Australian Military Forces during World War 2 and made by J W Handley. Although having owned the factory site since 1935 at 657 Victoria St J W Handley began to produce various items for the Australian Military forces after purchasing and expanding the factory to 655 Victoria St. It appears that he, or some one else may already have been occupying the site for industrial purposes, such as (Manufacturing, Foundry and Electroplating) since at least 1929. J W Handley Pty Ltd was actively producing items for the Military during the war years, a newspaper article from 1939 shows the factory in production and employing 420 people during 1939. J W Handley after the war moved into producing other non military items including a range of fishing reels. The company ceased trading in 1987 and was deregistered as J W Handley Pty Ltd in 1990.The item demonstrates the industrial capability of Australia at the start of World War 2. This item is actively sort by collectors of Australian Military memorabilia and represents a time in Australian history when the country was at war and the general population was concerned about an invasion from Japanese forces. It also therefor is of social significance as many Australians served in the Military forces at that time and the item is complete and in very good condition.A plane table compass, sometimes referred to as a trough compass, used by surveyors and artillery crew to accurately establish magnetic north. The compass is precision machined of brass material with a long needle to ensure accuracy. The compass scale is marked with a centre zero (for magnetic north) and graduations indicating plus and minus five degrees. The compass is housed in a protective wooden case with a sliding lid. The lid has a brass slide which locks the compass needle during periods when the compass is not in use.J.W.H./V Mark 11 D↑D. Made by J W Handley Richmond Melbourne, Victoria. Serial number 92 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, trough compass, navigation instrument, surveyor's instrument, j w handley, artillery, australian army, trough, plane compass, world war 2 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePlane Compass, 1941-1943

This compass is the type used by an artillery unit of the Australian Military Forces during World War 2 and made by J W Handley. Although having owned the factory site since 1935 at 657 Victoria St J W Handley began to produce various items for the Australian Military forces after purchasing and expanding the factory to 655 Victoria St. It appears that he, or some one else may already have been occupying the site for industrial purposes, such as (Manufacturing, Foundry and Electroplating) since at least 1929. J W Handley Pty Ltd was actively producing items for the Military during the war years, a newspaper article from 1939 shows the factory in production and employing 420 people during 1939. J W Handley after the war moved into producing other non military items including a range of fishing reels. The company ceased trading in 1987 and was deregistered as J W Handley Pty Ltd in 1990.The item demonstrates the industrial capability of Australia at the start of World War 2. This item is actively sort by collectors of Australian Military memorabilia and represents a time in Australian history when the country was at war and the general population was concerned about an invasion from Japanese forces. It also therefor is of social significance as many Australians served in the Military forces at that time and the item is complete and in very good condition.A plane table compass, sometimes referred to as a trough compass, used by surveyors and artillery crew to accurately establish magnetic north. The compass is precision machined of brass material with a long needle to ensure accuracy. The compass scale is marked with a centre zero (for magnetic north) and graduations indicating plus and minus five degrees. The compass is housed in a protective wooden case with a sliding lid. The lid has a brass slide which locks the compass needle during periods when the compass is not in use.J.W.H./V Mark 11 D↑D. Made by J W Handley Richmond Melbourne, Victoria. Serial number 1279flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, trough compass, navigation instrument, surveyor's instrument, j w handley, artillery, australian army, trough, plane compass, world war 2 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClocks, 1950

In 1865 James Jones Elliott of 156 Cheapside in the City of London, was apprenticed to a clockmaker"Bateman" of 82 St John Street, Smithfield, London., to learn the art of clock making. Initially, J J Elliott specialized in producing pinions and balance shafts for clocks. He eventually progressed to making, and patenting, a weight-driven movement which had chimes on tubes. This clock was very successful and resulted in considerable trade with America. James Elliott's son, Frank Westcombe Elliott, when he was 17 years old, went into business with his father after his father had bought a partnership with a jeweler called “Walden” of Brompton Road, London. In 1904, JJ Elliott died and Frank succeeded his father in clock making business. In 1909 company of JJ Elliott amalgamated with Grimshaw Baxter, and the factory moved to Grays Inn Lane, London, in 1911, followed by a further move, in 1917, to larger premises in St Ann’s Road, Tottenham, London. In 1921 the partnership with Grimshaw Baxter was dissolved and Frank Elliott joined a well-known firm of Bell Founders and Clockmakers, Gillett and Johnson Ltd, in Croydon. In 1923, two years later, he took over their clock factory and formed the famous company of F.W. Elliott Ltd. He was joined by his two sons, Leonard and Horace Elliott, who had served their apprenticeships in the trade. The third son, Ronald, joined the company in 1929. Elliott's started to produce clocks for the armed forces when war was declared in 1939, together with test gear and apparatus for the Rolls Royce engines used in the RAF planes. In 1944, Frank Elliott died at the age of 69 and Horace Elliott assumed the role of Managing Director. Whilst Horace controlled sales from a showroom in Hatton Garden. In 1952, Horace Elliott was elected Chairman of the British Horological Institute in the same year as Tony, one of Horace's sons, joined the company after he had completed training as a cabinet maker. Ronald Elliott died suddenly in 1966, at the age of 54, his son Peter continued to manage the company until 1998 when it ceased trading. An item that is now regarded as vintage, sought by horology collector’s worldwide and is in excellent condition. The item is unique in that it was made specifically for ships by a well-known British clock manufacture. Its provenance is well established as the serial numbers on the clock indicate it was made in 1950. Production by F.W Elliott for this design of ships clock ceased in 1959. Clock has a gold color case with a 150 mm white painted dial and Roman numerals. The movement has a balance wheel escapement and a slow-fast timekeeping adjuster to the top of the dial. The back of the clock is stamped “made by F W Elliott Ltd of Croydon” and a serial number 21B/829, an additional number 994 is also stamped on the back casing. Thsi model clock finished production in 1959. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock, f w elliott, maritime clock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageInstrument - Marine Telescope, 1870-1880

This telescope was amongst various items collected from a sea dive in Port Phillip Bay. The diver was the caretaker of the Port Lonsdale Lighthouse, who dived on various wrecks in the bay during the 1960's. After the caretaker's death, his son sold off many of the shipwreck artefacts. The telescope was purchased from the caretaker's son in the 1990's by a previous owner of the Marine Shop, Queenscliff, Victoria. John Browning was particularly well known for his scientific advances in the fields of spectroscopy, astronomy, and optometry. Between 1856 and 1872, Browning acquired provisional patents for designs of numerous scientific instruments. He was also the recipient of an award at the 1862 International Exhibition held in London. Also recognised for his temperature-compensated aneroid barometer. Browning's scientific instruments were used in physics, chemistry, and biology. The products he designed and manufactured included spectroscopes, telescopes, microscopes, barometers, photometers, cameras, ophthalmologist, and electrical equipment such as electric lamps. John Browning was born around 1831 in Kent, England. His father, William Spencer Browning, was a maker of nautical instruments. John Browning's great-grandfather was also an instrument maker as well as John’s brother Samuel Browning of the firms Spencer & Browning and Spencer, Browning & Rust, who also manufactured navigational instruments. The latter firm was in operation in London from 1784 to 1840 and was succeeded by the firm of Spencer, Browning & Co. John Browning initially intended to follow the medical profession and entered Guy's Hospital, a teaching hospital and a school of medicine. Despite having passed the required examinations, however, he abandoned his plans. Instead, he apprenticed with his father, William Spencer Browning. At the same time, in the late 1840s, he was a student attending the Royal College of Chemistry several days per week. By the early 1870s, practical optics had become John Browning's primary interest, and he listed his occupation as an optician on the census records from 1871 to 1901. He was well known among London's ophthalmic surgeons for his various ophthalmic instruments. He had a large part in reforming the art of crafting spectacles. Other achievements were as an author of the book, How to Use Our Eyes and How to Preserve them by the Aid of Spectacles. Published in 1883, the book included thirty-seven illustrations, including a diagram demonstrating the anatomy of the eye. In 1895, he was one of the founders of the "British Ophthalmology" the first professional organisation for optometry. He was not only its first president but also registered as its first member so many considered him to be the first professional optometrist. Other professional organisations he belonged too was as a member of “The Aeronautical Society of Great Britain”. In 1871 constructing the first wind tunnel located at Greenwich Marine Engineering Works. He was also a member of other scientific organisations, such as the “Microscopical Society of London”, the “Meteorological Society”, and the “Royal”. Then in 1908 the company of W. Watson & Son, opticians and camera makers, took over John Browning's company since 1901 John Browning had been semi-retired but in 1908 he fully retired and moved to Bournemouth in Hampshire. He died in Cheltenham, Gloucestershire in 1925.The telescope is significant for its association with one of the world’s leading scientific instrument makers and inventor of the 19th and early 20th century. It is believed the donation came off a wreck either in Port Philip Bay or between Point Lonsdale and the Nepean Heads making it a significant maritime historical artefact. Its provenance is good given it was taken off a wreck in this area by the Point Lonsdale lighthouse caretaker. Examples of John Browning's telescopes because of their scientific and historical importance are highly valued by collectors.Marine style single draw brass telescope with a sunshade. The single draw has no split and the second cartridge is held in a long brass tube within the single draw, mounted from the objective end. The eyepiece is flat and at the end of the first draw in a very faded engraving that is believed to read "John Browning, 63 Strand, and should read London under the word strand but this is hard to establish given the engravings condition. This interpretation of the engraving has been arrived at by examination of other John Browning telescope engraving examples."John Browning, engraved to the first tube in copper plate style "63 STRAND" Engraved under in capital textflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, shipwreck artefact, port phillip bay, port lonsdale lighthouse, wreck, 1960’s diver, queenscliff marine shop, john browning, telescope, spectroscopy, optometry, scientific instruments, william spencer browning, optician, navigational instrument, microscopical society of london, aeronautical society, marine technology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Bentwood Chair, Mundas Furniture Manufactures, 1907 to 1920

Bentwood furniture is a type of furniture made by bending wooden rods into the required shape after they have been heated with steam. Mundus bentwood chairs are among the most successful examples of early mass-produced furniture. Mundus furniture was a manufacturing company, active in several places in the Austro Hungarian Empire, at the end of the 19th century and early 20th century. Factories seem to have existed in multiple locations, as the products carry diverse labels, such as "Budapest", "Borlova", "Czechoslovakia", etc. Some of the furniture was co-signed with "Jacob and Josef Kohn". In 1914 Mundus merged with J. & J. Kohn, and in 1922 with Gebrüder Thonet the inventor of the bentwood chair.The item is significant as it is an early example of mass-produced manufactured furniture from a company in Austria that pioneered this type of furniture around the turn of the 19th century. The item is now a collector's piece giving it additional significance.Bentwood ChairMundus Vienna Austriashipwreck coast, flagstaff maritime museum, flagstaff hill village, bentwood chairs, mundus furniture company, furniture, manufactured furniture, vienna austria -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Two plates, Broadhurst Staffordshire Ironstone Pottery, 1950-1960

Broadhurst China was established in 1862 the firm was based at the Crown Pottery, Longton, Staffordshire until 1870 where James Broadhurst made a range of gold and silver lusterwares. In 1870 the firm moved to the Portland Pottery at Fenton, Staffordshire and continued to produce good quality earthenware. In 1897 "& Sons" was added to the company name and "Ltd" from C.1922. The full name, James Broadhurst & Sons Ltd. appears from 1957. In 1984 James Broadhurst & Sons Ltd became Churchill Tableware Ltd.Items made around 1950s or slightly later that are now collectors items made by one of the founders of ironstone pottery in England.Two Staffordshire ironstone dinner plates willow patternThe back is stamped "WILLOW BROADHURST STAFFORDSHIRE IRONSTONE Made in England Detergent and Dishwasher Proof"flagstaff hill museum, ceramics, pottery, plates, domestic items, kitchen ware, dinner sets, staffordshire ironstone pottery, staffordshire england -

Flagstaff Hill Maritime Museum and Village

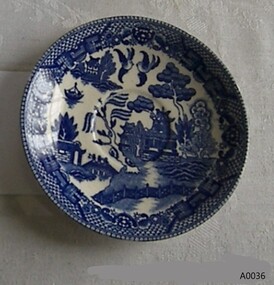

Flagstaff Hill Maritime Museum and VillageCeramic - Bowl, Broadhurst Staffordshire Ironstone Pottery, 1950s - 1960s

Broadhurst China was established in 1862 the firm was based at the Crown Pottery, Longton, Staffordshire until 1870 where James Broadhurst made a range of gold and silver lusterwares. In 1870 the firm moved to the Portland Pottery at Fenton, Staffordshire and continued to produce good quality earthenware. In 1897 "& Sons" was added to the company name and "Ltd" from C.1922. The full name, James Broadhurst & Sons Ltd. appears from 1957. In 1984 James Broadhurst & Sons Ltd became Churchill Tableware Ltd.Items made around 1950s or slightly later that are now collectors items made by one of the founders of ironstone pottery in England.Small ironstone willow pattern bowlThe back is stamped "WILLOW BROADHURST STAFFORDSHIRE IRONSTONE Made in England Detergent and Dishwasher Proof" Mass produce, Ceramic, Potteryironstone pottery, staffordshire pottery, flagstaff hill museum, crockery, dinner set, willow pattern -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Moulding Plane, Joseph Gleave & Sons, Late 19th to Early 20th Century

Joseph Gleave & Sons was working as a plane maker in Manchester from 1832 and was at Oldham Street from 1854 to 1868 and (as Joseph Gleave & Son) from 1868 to 1913. The company made complex wood planes of which the subject item is an early example. The company sold tools from other makers as well and was based in Oldham Street Manchester. Since that time the company has adapted and mutated and is still buying and selling tools and industrial supplies to this day. However the company stopped making complex wood planes in 1926. A vintage tool made by a known maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before routers and spindle moulders came into general use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims, etc. or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish.A significant tool from the late 19th to early 20th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any decorative timber item.Complex Moulding Plane, Torus Bead. Stamped J. Gleave (Maker), No 7 & T. Moody (owner)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, josphe, joseph gleave & sons, complex plane makers, carpenders tools, woodworking tool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1819-1901

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools. Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, Anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset and they began trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter died in 1826, trading under the name Holtzapffel & Deyerlein. Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel's lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required "for building purposes". The firm then moved to 13 and 14 New Bond Street and was in premises in the Haymarket from 1907 to 1930. John's son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co. Charles continued to run the business after his father's death. He wrote a 2,750-page treatise entitled Turning and Mechanical Manipulation, published in 1843 which came to be regarded as the bible of ornamental turning. The final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928. A vintage tool made by a well-known firm made for firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Holtzaffel 64 Charing & Owner J Heath 9/16" marked opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Plane, Mid to Late 19th Century

A smoothing plane is typically used after the work piece has been flattened and trued by the other bench planes, such as the jack, fore, and joiner planes. Smoothing planes can also be used to remove marks left by woodworking machinery. When used effectively alongside other bench planes, the smoothing plane should only need a handful of passes removing shavings as fine as 0.002 inches (0.051 mm) or less. The work piece is then ready to be finished, or can be further refined with a card scraper or sandpaper. The smoothing plane is usually held with both hands, and used in a similar manner to the other bench planes. Though designed for smoothing, a smoothing plane can be used as an 'all-round' bench tool and for rougher work depending on how it is set up. Being smaller than other bench planes, the smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more maneuverable. It has also been claimed that the coffin design exposes more end grain, enabling the plane to better adjust to changes in humidity. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a smooth finish to timber. The tool was used when timber items needed to have a smooth finish these types of planes were used in conjunction with profiled planes that provided a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Smoothing Plane coffin design Maker J Moseley & Son London & 2 1/4"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . Stamped HB on one end and 8 on otherflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Moulding Plane, 1770-1809

The story of Christopher Gabriel born on April 2, 1746, in Falmouth England is a tale of a poor boy who made good. Shortly before he turned thirteen years of age in 1759 he was apprenticed to a local master carpenter, recorded as a Mr Barnicot the master trained his apprentice well as we can assume by Christopher's later successes. The apprenticeship ended in 1766 after seven years when Christopher reached twenty. Then in 1768, he relocated to London walking the two hundred miles from Falmouth carrying his possessions in a sack. He no sooner arrived in London when he met Alice Trowell who became his wife in March 1769. They set up house on Albermarie Street Clerkenwell and by the first of 1770, Gabriel had begun his business of plane making. It has been speculated that Gabriel took over the shop of John Cogdell aided with an investment from his in-laws of 131 pounds. He went on to prosper as a plane-maker and lumber merchant over the next forty years. His business did well and in 1774 Gabriel moved to a house in Golden Lane, London and 1779 moved again to a home in Ould Street London. By now Gabriel was making a name for himself and his business at this time was located at 32 Banner Street Golden Lane, the following year he purchased another home in Banner Street and 1793 purchased the house next door. At the time of his death in 1808, he owned twenty-seven houses and commercial building. Christopher Gabriel s descendants became quite prominent in England and his grandson, Sir Thomas Gabriel became the Sheriff of London and Middlesex in 1859 and the Lord Mayor of London 1866 and 1867. Gabriel was an extremely prolific plane-maker with a lot of examples made in the 18th century can still be found today. He made good quality tools and was an innovator of several new plane designs. A vintage tool made by a well-known plane-maker, this item was made commercially for firms and individuals that worked in wood and needed a tool that could give a decorative finish to timber. These planes came in various shapes and sizes to achieve a finish to timber surfaces and came in many sizes. A significant Christopher Gabriel plane from the mid to late 18th century that after 200 years can still be used today. Planes made by Gabriel are eagerly sought after by collectors. The tool gives us a snapshot of how furniture and other finishes were created on timber by the use of cutting edged hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative or even finish that was needed for the finishing of timber items. Moulding multi patterned plane has a "5" long bladeStamped Maker C Gabriel (owner JB).flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, side rabbet plane, gabriel m hobling -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Side bead Moulding Plane Alex Mathieson & Son. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding Plane J Moseley & Son maker also stamped (Previous Owners) HIT & E Dunstan, RA Dixon with an N inside a W flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Late 19th to Early 20th century

A Jack plane is used for smoothing timber that is used in the manufacture of furniture or other wooden objects. Traditionally, smoothing planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to smooth or even out timber. The blade or iron was likewise secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used for the smoothing of a piece of timber that was then used in some form of cabinet manufacture or wood working. A significant item from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made. Jack Plane; a wooden smoothing plane, made by Alex Mathieson & Son, Glasgow. Plane has inscriptions."Alex Mathieson & Son Glasgow" Stamped "GN" inside with a "W" on endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jack plane, smoothing plane, woodworking tool, woodwork, cabinet making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower with a symbol "M"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower Size 9/16"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Charles Nurse, 1860-1900

The original Nurse family business began in 1841 in Maidstone Kent until 1861 where they were plane makers, moving to London in 1887 the company became C Nurse & Co. And continued until 1937 under that name at the (Invicta works). The majority of their plane making was done in London but there are Sheffield and Brighton marks on their tools as well. The company was not only wood plane makers but tool makers in general with the Charles Nurse & Co catalogue having 350 pages of tools for sale of varying types for different building trades and over 138 pages dedicated to woodworking tools. Records show that the company was at 182 Walworth Road London from 1887-1949. However, they had several retail outlets before this time and records indicate before 1887 Charles Nurse was at 32 Mill St Maidstone Kent, from 1844 -1860 but were in business before then. Also in Brighton at 135 Queens Road from 1865 -1871 and at 3 Mill Street Maidstone, again from 1872 - 1889 listed on records of the time as “plane and tool makers.”A vintage item made by a significant tool maker and retailer from the middle of the nineteenth century and into the first half of the twentieth century. These items were made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before electric or mechanical routers or spindle moulders came into use. They were used by craftsmen to produce decorative mouldings by hand. These profiled planes came in various shapes and sizes. A significant tool that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Moulding Plane a Casing Moulding Plane with two Scotia profiles Maker C Nurse and Co London. Owner A. E. NunnMaker C Nurse & Co & A E Nunn (previous owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Charles Nurse, 1860-1900

The original Nurse family business began in 1841 in Maidstone Kent until 1861 where they were plane makers, moving to London in 1887 the company became C Nurse & Co. And continued until 1937 under that name at the (Invicta works). The majority of their plane making was done in London but there are Sheffield and Brighton marks on their tools as well. The company was not only wood plane makers but tool makers in general with the Charles Nurse & Co catalogue having 350 pages of tools for sale of varying types for different building trades and over 138 pages dedicated to woodworking tools. Records show that the company was at 182 Walworth Road London from 1887-1949. However, they had several retail outlets before this time and records indicate before 1887 Charles Nurse was at 32 Mill St Maidstone Kent, from 1844 -1860 but were in business before then. Also in Brighton at 135 Queens Road from 1865 -1871 and at 3 Mill Street Maidstone, again from 1872 - 1889 listed on records of the time as “plane and tool makers.”A vintage item made by a significant tool maker and retailer from the middle of the nineteenth century and into the first half of the twentieth century. These items were made commercially for firms and individuals that worked in wood and needed a tool that could produce an ornamental finish to timber. The tool was used before electric or mechanical routers or spindle moulders came into use. They were used by craftsmen to produce decorative mouldings by hand. These profiled planes came in various shapes and sizes. A significant tool that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools only. Cornice Moulding plane type Maker C Nurse and Co. Has A E Nunn stamped on end (Owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane side beadStamped Mathieson and Son also ( size "W" & ¾" )also GN (previous owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing wood Plane, Mid to Late 19th Century