Showing 1213 items matching "moulded"

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageLeisure object - Tobacco Pipe, Early 20th century

People in ancient civilisations smoked pipes during various healing and religious ceremonies. By the end of the 15th century, after tobacco was discovered in America, smoking had become a common pastime for everyday people. From that time, tobacco pipes were fashioned from many materials ranging from gold and silver to corn cobs and clay. A popular material was meerschaum, an expensive, soft, white stone from Turkey. In the 1820s, French craftsmen carved pipes out of the wood from the growth on the root of a Mediterranean White Heath. This material became increasingly popular due to its durable, heat-resistant qualities. The growth was called ‘bruyere’, now anglicised to ‘briar’ wood. Bakelite was the first plastic made from synthetic components. It was developed by Leo Baekeland of New York in 1907. The material was heat-resistant and could be moulded into any shape and hardened to keep its shape. This invention greatly impacted the industrial world and the products available to the domestic market, making more objects available at reduced cost.This smoker's tobacco pipe symbolises one of the leisure activities of the early 20th century that has continued into modern times. The shape and materials of the pipe represent a point in time in the evolution of tobacco pipes, including the revolutionary impact that the 1900s invention of Bakelite had on objects available in the domestic and industrial markets.Smoker's tobacco pipe; a round brown wooden pipe bowl joined to a dark brown mouthpiece. The French pipe's bowl is made from briar wood, and its mouthpiece is Bakelite. There is an inscription on the pipe."French Briar Pipe"warrnambool, shipwreck coast, flagstaff hill, flagstaff hill maritime museum, flagstaff hill maritime village, smoker's pipe, tobacco pipe, briar wood pipe, wooden pipe, smoking, french pipe, bakelite, smoker's equipment -

Ambulance Victoria Museum

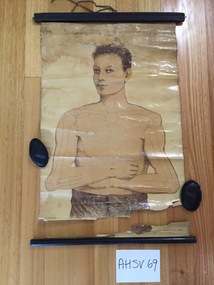

Ambulance Victoria MuseumChart, medical, human body, Ruddiman, Johnston & CO., Ltd

Rectangular chart made from printed and coated paper on a fabric base. The chart shows the upper torso of a human male. The chart is mounted at either end on timber batons using small metal tacks. Masking tape has been placed over the metal tacks in an attempt to repair the chart. The upper baton is moulded, while the lower baton is circular in cross-section. Both batons are stained black.Two screwed metal eyelets have been attached at either end of the upper baton for use in hanging the chart. A short length of brown/white cotton tape is attached to the mid-point of the upper baton with a metal tack. the tape is used to secure the chart after it has been rolled up.Printed on the RHS front face of the chart at bottom edge are the words 'All rights reserved'. Printed on the LHS front face of the chart at bottom edge are the words 'RUDDIMAN, JOHNSTON & CO., Ltd., LONDON'ruddiman johnston & co, medical chart -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, lady’s Pince-nez ½ with fine gold chain, c1900

Glasses, also known as eyeglasses or spectacles, are frames bearing lenses worn in front of the eyes. They are normally used for vision correction or eye protection. Pince-nez is a French style of spectacles, popular in the 19th century, that are supported without earpieces, by pinching the bridge of the nose. The name comes from French pincer, "to pinch", and nez, "nose". Although pince-nez were used in Europe in the 15th, 16th, and 17th centuries, modern ones appeared in the 1840s and reached their peak popularity around 1880 to 1900 A solid bridge piece is moulded to fit the curvature of the bridge of the nose. They are anchored onto the bridge of the nose via two small spring-loaded clips terminating in special nose-pads made from bone or tortoise shell on metal called plaquettes, which are tweezered apart for placement on the face through applying pressure to two small lever-like finger-pieces located on the front of the bridge. Plaquettes could be either hinged and flexible, permitting a better fit, or static as in the older examples of this type.. They were popular from the 1890s through to the 1950s, One half of a pair of lady’s Pince-nez eyeglasses with 1 gold rimmed glass lens , a gold style bridge and a fine gold chain that is attached to the side of the lens frame and to a shaped over- ear metal piece. eyes, spectacles, eye glasses, optometry, moorabbin, bentleigh, cheltenham, market gardeners, pioneers, early settlers, pince-nez -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950s

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter Pat/Profiler has on its base two patterns. On each end it has horizontal grooves cut into the wood which produce distinct lines onto the surface of the butter. between these grooves there is a section of two double lines crossing in the middle and separated by eleven horizontal lines The base has an elongated rectangular shape. The upper body has been sanded into a smooth convex shaped form where a wooden circular hand grip has been fashioned.On the top of the hand grip is stamped in black print"T. & W. Davies" and under this"TAWONGA 3697"domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter, Circa 1950

This butter pat profiler may have been manufactured post 1967 (year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter pat is one of two,see KVHS 0071 (B). It has been crafted from wood. One side has grooves running from the handle to the square shaped bottom. These grooves would stop the wet butter from clinging to the pat. The top side of the pat has been bevelled on both sides and the bottom edge. The hand grip is flat and curved to allow for a comfortable hold.domestic food preparation, wooden butter pat, butter mould circular, dairy industry, butter -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyPat Butter Profiler, Circa 1950

This butter pat profiler may have been manufactured post 1967(year post codes appeared in Australia) however the post code was only stamped on after it was machined. This type of butter mould was used by rural families to fashion home/farm made butter. This period was in most rural regions a time of self sufficiency where any domestic type implement which could be fashioned by the family would be crafted with skill. Shopping for goods required catalogues from stores located in major rural towns and cities and involved lengthy waiting times. Travelling to and from these specialised stores was not pleasant due to the relatively poor quality of the roads and the lengthy times taken. The small general stores in the Kiewa Valley could not cater for all the needs of the valley. The 1960's was a time when facilities especially goods and services started to improve drastically. The S.E.C. of Victoria with its Kiewa Hydro Electricity Scheme provided not only an improvement of facilities in the valley but also a increase in the population. This increase resulted in a greater demand for local produce.This item is one of many domestic food processing implements used by Kiewa Valley households in the mid 1900s, whether on the farm or in the small towns and hamlets. Self sufficiency was the key to survival during these early times. Where ever possible supplies from within the valley were preferred to that brought in by travelling salesmen or traders. This butter mould and butter pat was commonly used to fashion "home" made butter throughout the valley and in some cases supplied to "outside" regional towns. Although this method of production was phased out by better access to goods from nearby cities the revival of the good organic home grown produce in the 1980s saw a greater demand of this type of farm based produce.This butter pat is one of two,see KVHS 0071 (A). It has been crafted from wood. One side has grooves running from the handle to the square shaped bottom. These grooves would stop the wet butter from clinging to the pat. The top side of the pat has been bevelled on both sides and the bottom edge. The hand grip is flat and curved to allow for a comfortable hold.domestic food preparation, wooden butter pat, butter mould circular, dairy industry -

Federation University Historical Collection

Federation University Historical CollectionEquipment - Object, Otto Waschatz, Cast of Hand, Plaster Cast Drawing Prop

The Ballarat Technical Art School boasted a well-stocked Antique Room replete with plaster copies of classical, Renaissance and Gothic sculptural examples, which were used as drawing props by students. The school inherited some casts from its predecessor institutions, and further consignments were purchased during the 1920s, including full length, bust and relief figures, as well as dozens of ornamental and architectural casts. Unfortunately, much of the collection was lost or destroyed in the late 1950s. This is one of the few surviving pieces, with TAFE students reportedly drawing from it into the twenty-first century. This plaster hand is inscribed “Waschatz, Modeller, Melbourne.” Otto Waschatz was a German plasterer who opened a plaster business in the Melbourne suburb of Richmond, and was responsible for the invention of the first true fibrous plaster - using a layer of hemp laid between plaster to create light and strong panels. By 1912 Waschatz's Lottoid Pty Ltd was a thriving and creative business, and possessed over 5,000 moulds for all kinds of plasterwork. The business closed in 1915, as the result of anti-German sentiment during World War One. Plaster cast of a hand used as a teaching aid at the Ballarat Technical Art School. The Victorian Education Department courses required art students to create studies based on ancient sculptures so copies of famous works were purchased as teaching aids. Among these courses were 'Drawing the Human Figure from Cast' and ‘Drawing from the Antique’. Waschatz, Modeller, Melbourneballarat school of mines, art, arts academy, ballarat technical art school, vikki nash, plaster cast, otto waschatz, lattoid pty ltd, school of mines, plaster copy, drawing from the antique, drawing the human figure from cast -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationFire extinguisher

The Minimax conical fire extinguishers were manufactured until 1960 and then removed from the company’s product range. The earliest model had been produced with a simple handle made of folded pressed metal that is similar if not the same as that on the Point Hicks extinguisher. Later handles were moulded and had more substance to the way they were cut and then folded to form a solid grip. The Point Hicks Minimax extinguisher is an early model that probably dates from the years when these devices were demonstrated across parts of Australia. While numerous examples of the extinguishers survive in public and private collections in northern hemisphere countries, few appear to exist in Australian museum collections. However, the auction house records confirm that some do survive in private collections. The Point Hicks extinguisher was found by lighthouse keepers in 1974 buried in the sand in a flattened but surprisingly intact condition. It was beaten back into its original shape but the body still retains various dents. In 2010, AMSA located the extinguisher at the National Trust’s Polly Woodside historic ship museum and it is now at the Point Hicks Lightstation. The Minimax conical extinguisher has first level contributory significance as a historic item of early fire-fighting equipment from the lightstation that dates from the early twentieth century.Conical shaped brass fire extinguisher painted red with small nozzle at one end and a pump section at the other end. There is a handle on one side with closely spaced rivets down one side. Brass plaque with instructions attached to the body. There ia a square hook to hang the object form a wall or similar." ...ANKS ... / QUENCH.../ FOR FIRE / DRIVE IN PLUNGER / AT BIG END / ...ON GROUND /..../..../..." -

Kiewa Valley Historical Society

Kiewa Valley Historical SocietyBottle Milk, Circa mid to late 1900's

This glass milk bottle was manufactured and used mid to late 1900's (1834 Victorian dairy industry was founded) up to the time that a cheaper container was invented(plastic bottles and polyethylene plastic lined cardboard cartons) and produced. In 1909 the supply of pure bottled milk was required for babies to overcome infant mortality due to unhygienic milk sources (unclean containers and unpasteurized milk). Due to the volume of milk being processed and hand milking could not keep up with demand, dairy farms introduced milking machines in the late 1930's. The great increases in dairy herds from the average of 18 cows per heard in 1950's to 142 cows per herd in 1996 required milk tankers to pick up the regions milk supply. This bottle was so constructed to be easily moved within the milk processing plants from the delivery vats/holding tanks to the final corking/sealing of the bottles for eventual distribution. From 1958 the milk bottle slowly became phased out of production. At this point in time Melbourne was drawing 160,000 bottles per week from the two major glass bottle works companies, e.g. Melbourne Glass Bottle Works Co. Victoria was the major state supplier of cows milk in the history of Australian milk production from the early 1800's. The Kiewa Valley and its region was a major contributor to meet that demand. Each bottle was "branded" during manufacturing to show the contents (pasteurized milk) and where it originated from (region and supplier). This method of recycling the bottles back to specific dairy farms was a good control method but an uneconomical "on cost" which was replaced by the "throw away" less costly plastic and cardboard containers. Kiewa Valley dairy herds had marked bottles bearing "90/9", "6/18", "6/33", "6/35" and "6/36" This particular one has "7/14".This heavy gauged glass milk bottle has a rim and a distinctive head at the top. This head has been manufactured to facilitate the movement of the bottled along the milk production line. The method of pouring milk into the bottle has been part of the "production line". This bottle has a one Imperial pint capacity and is made from "clear" glass. There are other milk bottles that have a "green" tint in them. Around the bottom side of the bottle and blown into the glass "ONE IMPERIAL PINT". Below these markings and stenciled is "KIEWA" (in freehand style and underlined) underneath is "PASTEURISED FULL CREAM MILK" underneath this ,in freehand stiyle is "USE" next to this in block style "KIEWA BUTTER, CREAM, AND ICE CREAM MIX" to the left of this ,and barely readable is stenciled "THIS BOTTLE ALWAYS REMAINS/ THE PROPERTY OF/ NORTH EASTERN DAIRY Co. Ltd". On the base of the bottle is molded a big "2". with a smaller "m". An identification mark of "7" over "14" is within a circled boundary. Below this is moulded "RM - 15". glass bottles, commercial milk containers, domestic milk bottles, pasteurized milk bottles -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - EPIRB Transmitter

This distress EPIRB unit (Emergency Position Indication Radio Beacon) was found on the beach at Levy's Point, Warrnambool, in December 2000 by a Warrnambool resident. Local police were alerted at the time. This distress signal unit is a world-wide COSPAS/SARSAT, satellite assisted, SAR (Search and Rescue) system for location of distress transmissions emitted by an EPIRB. Offshore cruising vessels must have such a unit as part of its essential safety equipment. This model EPIRB relies on four satellites with orbit times of approximately 100 minutes. Earlier units relied solely on aircraft flying overhead to detect and forward on the EPIRB’s location to Search And Rescue authorities, whereas this new system utilises satellites. An employee from the Lokata firm provided additional information about the Lokata EPIRB units. They had a machined aluminium case with labels that were also made on site. The units could be activated manually or automatically released when a magnetic switch in the case casing was activated. This later model, circa 1983, would have been mounted externally on a vessel's bulkhead in a spring-loaded, stainless-steel protective 'skeleton' mounting, The unit released when the water pressure sensor detected a set time it was under the water, in a similar way that life crafts were released. Each unit was registered to a particular vessel - the vessel's details on this unit are indecipherable. The Lokata Company was established in 1970, designing and manufacturing marine products including communications. The company no longer makes products with the “Lokata” brand. In 2001 Sartech Engineering Ltd. took over the support for the Lokata EPIRB beacons. This emergency location device is a late 20th century invention to help save lives at sea. It adds to the history of maritime life, its risks, the lives lost as sea, and the many inventions aimed as rescuing and saving lives. The local area is notorious for the number of lives lost through shipwreck. It also carries stories of heroic efforts to save lives, and other inventions to help reduce the chance of accidents at sea.EPIRB unit; “Emergency Position Indication Radio Beacon”. A distress communication unit for sending a distress location transmission in an emergency at sea. The EPIRB is a yellow, rectangular box with dials, buttons, indicator lights and instruction. An antenna protrudes from the top of the unit. The EPIRB unit sends a 406P (X) EPIRB, with 406M-Hz frequency, 48-hour duration signal. The maker was LOKATA Ltd in England. Remnants of a white label remain on the side. Circa 1980s."NAME OF VESSEL 'SERVICE IF SELF TEST FAILS' " “LO-KATA” moulded into the body. "406P (X) EPIRB" “Model 406” "Lokata Type No 92408" "UK Type approved to MPT 1278" "Class 2" "Made by Lokata Ltd, Falmouth Cornwall England TR10 8AE"" "LOKATE LTD. New North Road Hainault, Ilford Essex IG6 2UR" "ARMED / SAFE / TRANSMIT / CODE / DISPLAY / SET / wait / pass / fail / TEST" "IDENTIFIER / 1349:24034234N" [some characters may be different] "COUNTRY / DENMARK" "VESSEL IDENTITY / 124 [the rest is indecipherable]flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, emergency position indicating radio beacon, epirb, lokata ltd, marine safety equipment, satellite transmitting beacon, safety equipment, distress signal, life saving, safety at sea, shipwreck location, lo-kata, falmouth, emergency, beacon, radio signal, communication, marine equipment -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryMachine - Shipway's Apparatus, Circa 1916

Recognising that warmed ether was less irritating to the airway and patients receiving it were less likely to experience shock, Francis Shipway developed the Shipway's apparatus which was used during World War 1 and continued to be used through to World War 2. Reduction of shock for patients who had experienced trauma was crucial to their later recovery, particularly during war times. This example of the Shipway's apparatus also has the facility for administering chloroform.A triangular metal stand with two glass jars sitting in a metal tub and a green metal jar that looks like a thermos, also sitting in a metal tub. A metal pole has been screwed into the centre point of the stand, with a circular top to act as a handle. One of the jars has a rubber stopper in the neck with metal tubing attached to the stopper. The other glass jar has a metal screw top with a dropper spout. The two glass jars are connected via red rubber tubing. The apparatus has been sectioned in parts to show the inner mechanisms.Typed in black ink on white paper and adhered to metal bath: SHIPWAY'S APPARATUS •Typed in black ink on white paper and adhered to metal bath: ETHER VAPORISER •Typed in black ink on white paper and adhered to metal bath: THERMOS WITH HOT WATER •Typed in black ink on white paper and adhered to glass bottle: CHLOROFORM VAPORIZER •Typed in black ink on white paper and adhered to metal connector: TO AIR BELLOWS •Typed in black ink on white paper and adhered to tube in thermos: DELIVERY TUBE •Moulded into base of thermos: THERMOSshipway, world war i, warmed ether, endotracheal, chloroform -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Sample, Before 1878

On a piece of paper subsequently glued near one end of its curved upper face, this length of planed and polished hardwood timber bears the inscription: “A [p]iece of w[r]ec[k] of the Loch Ard wrecked near Sherbroke River”. The timber is carefully worked with rich dark colouring and a uniformly moulded design, suggesting that it was part of a fitting or furnishing that was publicly visible and prominent. If the artefact is what it is declared to be, then it is possible that it formed part of the ship’s railings or companionway stairs. The LOCH ARD was a 1,693 ton, 3 masted barque, built on the Clyde in 1873. In an age of increasing competition for the emigrant passenger trade from steam-driven vessels, special attention was paid to her wooden furnishings and fittings. The Loch Line owners prided themselves on their attractive, distinctively painted, sailing ships. Below decks, where cargo and third class passengers were stowed, was made of iron. But everything above deck, and on show to the saloon and second class passengers, was carved and varnished timber. Captain Daish’s 1878 report for the ship’s underwriters notes “a quantity of general Cargo washed up in a confused mass” in the cove and “a number of Cases, Casks and Bales; also deals and boards floating about in some of the gorges” further west of the shipwreck. Contemporary newspaper accounts also reported a large quantity of cargo and timber washed ashore in the days following the LOCH ARD shipwreck, adding “but those were speedily removed by persons who came down from Port Campbell, Scott’s Creek and other places with carts and pack horses”. The appearance and good condition of this wood artefact, and the aged patina and dated hand-writing style of its pasted on inscription, support the suggestion that it was ‘souvenired’ from the floating debris of the LOCH ARD at or near the 1878 date of its foundering off Mutton Bird Island. HISTORY OF THE LOCH ARD The LOCH ARD belonged to the famous Loch Line which sailed many ships from England to Australia. Built in Glasgow by Barclay, Curdle and Co. in 1873, the LOCH ARD was a three-masted square rigged iron sailing ship. The ship measured 262ft 7" (79.87m) in length, 38ft (11.58m) in width, 23ft (7m) in depth and had a gross tonnage of 1693 tons. The LOCH ARD's main mast measured a massive 150ft (45.7m) in height. LOCH ARD made three trips to Australia and one trip to Calcutta before its final voyage. LOCH ARD left England on March 2, 1878, under the command of Captain Gibbs, a newly married, 29 year old. She was bound for Melbourne with a crew of 37, plus 17 passengers and a load of cargo. The general cargo reflected the affluence of Melbourne at the time. On board were straw hats, umbrella, perfumes, clay pipes, pianos, clocks, confectionary, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were items included that intended for display in the Melbourne International Exhibition in 1880. The voyage to Port Phillip was long but uneventful. At 3am on June 1, 1878, Captain Gibbs was expecting to see land and the passengers were becoming excited as they prepared to view their new homeland in the early morning. But LOCH ARD was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4am the fog lifted. A man aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head on into the wind, the ship lost momentum, the sails fell limp and LOCH ARD's bow swung back. Gibbs then ordered the anchors to be released in an attempt to hold its position. The anchors sank some 50 fathoms - but did not hold. By this time LOCH ARD was among the breakers and the tall cliffs of Mutton Bird Island rose behind the ship. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves broke over the ship and the top deck was loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of LOCH ARD and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as LOCH ARD Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael had raced onto deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke open case of brandy which had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a state of exhaustion, he told the men of the tragedy. Tom returned to the gorge while the two men rode back to the station to get help. By the time they reached LOCH ARD Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland, this time by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost family in the LOCH ARD disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost all of her family in the tragedy. Ten days after the LOCH ARD tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of LOCH ARD still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some was washed up into what is now known as LOCH ARD Gorge. Cargo and artefacts have also been illegally salvaged over many years before protective legislation was introduced. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton porcelain peacock - one of only nine in the world. The peacock was destined for the Melbourne International Exhibition in 1880. It had been well packed, which gave it adequate protection during the violent storm. Today, the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck it has now become Australia's most valuable shipwreck artefact and is one of very few 'objects' on the Victorian State Heritage Register. The Loch Ard wreck is of state significance – Victorian Heritage Register S417. However there is a lack of documented provenance that limits the interpretive value of this piece of timber (for example, its potential to interpret nineteenth century souveniring and scavenging from shipwrecks along the south west coast of Victoria). Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best known shipwrecks in Victoria’s history. A length of hardwood timber, planed and varnished to smooth finish on three sides, with two unfinished tongues protruding from each end (one broken off), possibly from the wreck of the LOCH ARD. The front or upper face is moulded and routed to a regular, linear (skirting board type) design along its entire length, the two sides flat planed. One side contains two inserted dowel rods that have been broken off. The bottom face has not been finished to the same standard. The sample is good quality wood that has retained its density and weight and shows no evidence of having been submerged in seawater for any length of time. Glued on to the upper face of the length of timber near the right hand end is a deteriorated square of paper bearing an inscription. The paper, peeling back and with torn edges, is stuck over an original wood stain but under a subsequent layer of varnish. The faded ink words are indecipherable where paper is missing, but written carefully in an old fashioned cursive script.The inscription on the paper reads: “A [p]iece of w[r]ec[k] of the Loch Ard wrecked near Sherbroke River”. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, nineteenth-century souveniring, shipwreck scavenging, loch line sailing ships, wood sample -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, miniature oval hand mirror, c1900

Celluloids are a class of compounds created from nitrocellulose and camphor, with added dyes and other agents. Generally considered the first thermoplastic, it was first created as Parkesine in 1856 and as Xylonite in 1869, before being registered as Celluloid in 1870. Celluloid is easily moulded and shaped, and it was first widely used as an ivory replacement. The main use was in movie and photography film industries, which used only celluloid films prior to acetate films that were introduced in the 1950s. Celluloid is highly flammable, difficult and expensive to produce and no longer widely used, although its most common uses today are in table tennis balls, musical instruments and guitar picks. Celluloid was useful for creating cheaper jewellery, jewellery boxes, hair accessories and many items that would earlier have been manufactured from ivory, horn or other expensive animal products. It was often referred to as "Ivorine" or "French Ivory". It was also used for dressing table sets, dolls, picture frames, charms, hat pins, buttons, buckles, stringed instrument parts, accordions, fountain pens, cutlery handles and kitchen items. The main disadvantage the material had was that it was flammable.. It was soon overtaken by Bakelite.A miniature, oval, Ivorine hand mirror with floral engraving on back. An accoutrement for use in a lady's Evening bag c19thCFloral design engraving on back of mirrormoorabbin, brighton, early settlers, pioneers, cheltenham, craft work, mirors, ivorine, evening bags, celluloids, bakelite, plastics, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle & Case, 1934 – Mid 1950’s

Pens, nib pens and later fountain pens, with suitable inks, were commonly used for writing communications from the 18th century to the mod 20th century. Fountain pens continue to be used and enjoyed. Dip pens with a wide variety of nibs are used for calligraphy writing, a hobby enjoyed by many people. The quality of the pen handle, the nib and the ink all work together to produce fine handwriting that expresses the character and mood of the writer. This Bakelite ink case has been specifically moulded to snugly contain an ink bottle, with just enough room to wrap the bottle with a padding or card or blotting paper. The screw top lid fits the case well and this container would be a good way to travel with ink because any spillage would be kept within the waterproof case. The Bakelite material is lightweight and strong. Ink bottle cases, or travelling cases, have been made as an accessory for nib pen writers. The first patent for a “pocket-case for bottles”, a wooden case, was applied for in the US in 1891. Other materials such as steel, pewter and aluminum as well as Bakelite have also been used. The British Museum has an elaborately decorated bronze ink pot holder that is inlaid with turquoise. Today ink bottle cases are even available in fabric with loops to attach to a belt. Bakelite, the material used for this ink bottle case, is made from synthetic materials and is an early form of plastic, developed in 1907 and used extensively until the 1940’s. It is still in used today for specific applications but has been largely replaced by more modern forms of plastics. This ink bottle case carries the imprint of Mabie, Todd & Co. (Aust.) Pty. Ltd. This form of company name was used from 1938 to the mid 1950’s. The Swan ink bottle’s information says it was made by Mabie, Todd & Co. Ltd., London and Sydney, so dates the ink bottle from about 1908 until 1934. (Australian newspapers display advertisements dated 1908 until 1934 for Sydney wholesalers and agents for Mabie, Todd & Co. Ltd.) ABOUT PERSONAL FOUNTAIN PENS (FOUNT PENS) A 1917 newspaper advertisement recommends that the owner of a “Swan” doesn’t lend it to anyone else to use due to its qualities of it personalised to the owner. It reads “Don’t lend your “Swan” fountpen, recommend it, but don’t let other people use it. You see, a good pen doesn’t wear, but its “tamper” (or spring) works into the writer’s pressure and manner of holding. Another person with a dashing style of writing may strain it do that it will no longer feel just like your own.” This personalisation of nib pens may be the reason that legal documents in the past being acceptable only if they were signed using a ‘wet ink’ pen. Forgeries of signatures could be easily detected as the nib takes on the character of the pen’s owner. A ballpoint pen was not acceptable. This is a strong contrast to modern times when a digital signature is widely accepted. ABOUT MABIE TODD Pty Ltd. The American company Mabie Todd began by making pencil cases in New York in the 1860’s. The Bard Brothers, makers of Gold nibs, joined Mabie Todd and the company was established in the 1870’s as Mabie Todd and Bard. In 1878 the company filed a patent for the design of a fountain pen and in 1884 the first Swan fountain pen was released. In 1884 a Mabie Todd and Bard office and showroom was established in London. In 1906 the company’s name changed to Mabie Todd & Co, New York. The UK offices also used this new name and in 1907 the UK began producing their own Swan pens. Manufacturing was going so well in England that New York sold their rights to European and Colonial business to the new Mabie Todd & Company Ltd of England. By the end of the 1930’s all components for the pens were being made in the UK; the pens in the London factory, the gold nibs in Birmingham and the ink in Liverpool. Newspaper articles from 1934 stated that Mabie Todd were large buyers of Tasmanian iridium, which had been welded with gold and used since 1834 for the tips of nib and fountain pens. Fountain pen points were the largest market buyers for Tasmanian iridium, which was classed as “the best in the world”. Production growth continued up until WWII times, when the headquarters and main factory were destroyed. Mabie Todd & Company Ltd of England rebuilt out of the inner city and by 1946 pen production began again. The market for nib and fountain pens was diminishing by this time, with people beginning to use the new ballpoint ‘Biro’ pens. The Mabie Todd bought shares in Biro Pens and in 1952 became Biro Swan. They went on to make more ballpoint pens than any other manufacturer in Britain. The ink refills that Biro-Swan produced came in five different viscosity or thickness xhoices, depending on the season and location of where the pen would be used . Along with the ballpoint pens, Biro-Swan also introduced a range of Calligraph pens to attract those following the new trend for italic writing. In 1948 Mr. T. Burke, a director for Mabie Todd & Co. (Aust.) Pty Ltd., announced that there would be a £40,000 factory built in Sydney in 1949 for the manufacture of ink. The plant for the factory would be imported from overseas. Sadly the company struggled against competition and in 1956 Mabie Todd closed business and no more Swan pens were produced. The ink bottle and container was donated to Flagstaff Hill Maritime Village by the family of Doctor William Roy Angus, Surgeon and Oculist. It is part of the “W.R. Angus Collection” includes historical medical equipment, surgical instruments and material once belonging to Dr Edward Ryan and Dr Thomas Francis Ryan, (both of Nhill, Victoria) as well as Dr Angus’ own belongings. The Collection’s history spans the medical practices of the two Doctors Ryan, from 1885-1926 plus that of Dr Angus, up until 1969. ABOUT THE “W.R.ANGUS COLLECTION” Doctor William Roy Angus M.B., B.S., Adel., 1923, F.R.C.S. Edin.,1928 (also known as Dr Roy Angus) was born in Murrumbeena, Victoria in 1901 and lived until 1970. He qualified as a doctor in 1923 at University of Adelaide, was Resident Medical Officer at the Royal Adelaide Hospital in 1924 and for a period was house surgeon to Sir (then Mr.) Henry Simpson Newland. Dr Angus was briefly an Assistant to Dr Riddell of Kapunda, then commenced private practice at Curramulka, Yorke Peninsula, SA, where he was physician, surgeon and chemist. In 1926, he was appointed as new Medical Assistant to Dr Thomas Francis Ryan (T.F. Ryan, or Tom), in Nhill, Victoria, where his experiences included radiology and pharmacy. In 1927 he was Acting House Surgeon in Dr Tom Ryan’s absence. Dr Angus had become engaged to Gladys Forsyth and they decided he further his studies overseas in the UK in 1927. He studied at London University College Hospital and at Edinburgh Royal Infirmary and in 1928, was awarded FRCS (Fellow from the Royal College of Surgeons), Edinburgh. He worked his passage back to Australia as a Ship’s Surgeon on the on the Australian Commonwealth Line’s T.S.S. Largs Bay. Dr Angus married Gladys in 1929, in Ballarat. (They went on to have one son (Graham 1932, born in SA) and two daughters (Helen (died 12/07/1996) and Berenice (Berry), both born at Mira, Nhill ) According to Berry, her mother Gladys made a lot of their clothes. She was very talented and did some lovely embroidery including lingerie for her trousseau and beautifully handmade baby clothes. Dr Angus was a ‘flying doctor’ for the A.I.M. (Australian Inland Ministry) Aerial Medical Service in 1928 . Its first station was in the remote town of Oodnadatta, where Dr Angus was stationed. He was locum tenens there on North-South Railway at 21 Mile Camp. He took up this ‘flying doctor’ position in response to a call from Dr John Flynn; the organisation was later known as the Flying Doctor Service, then the Royal Flying Doctor Service. A lot of his work during this time involved dental surgery also. Between 1928-1932 he was surgeon at the Curramulka Hospital, Yorke Peninsula, South Australia. In 1933 Dr Angus returned to Nhill and purchased a share of the Nelson Street practice and Mira hospital (a 2 bed ward at the Nelson Street Practice) from Dr Les Middleton one of the Middleton Brothers, the current owners of what previously once Dr Tom Ryan’s practice. Dr Tom and his brother had worked as surgeons included eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. He had been House Surgeon at the Nhill Hospital 1902-1926. Dr Tom Ryan had one of the only two pieces of radiology equipment in Victoria during his practicing years – The Royal Melbourne Hospital had the other one. Over the years Dr Tom Ryan had gradually set up what was effectively a training school for country general-practitioner-surgeons. Each patient was carefully examined, including using the X-ray machine, and any surgery was discussed and planned with Dr Ryan’s assistants several days in advance. Dr Angus gained experience in using the X-ray machine there during his time as assistant to Dr Ryan. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. His practitioner’s plate from his Nhill surgery is now mounted on the doorway to the Port Medical Office at Flagstaff Hill Maritime Village, Warrnambool. When Dr Angus took up practice in the Dr Edward and Dr Tom Ryan’s old premises he obtained their extensive collection of historical medical equipment and materials spanning 1884-1926. A large part of this collection is now on display at the Port Medical Office at Flagstaff Hill Maritime Village in Warrnambool. In 1939 Dr Angus and his family moved to Warrnambool where he purchased “Birchwood,” the 1852 home and medical practice of Dr John Hunter Henderson, at 214 Koroit Street. (This property was sold in1965 to the State Government and is now the site of the Warrnambool Police Station. and an ALDI sore is on the land that was once their tennis court). The Angus family was able to afford gardeners, cooks and maids; their home was a popular place for visiting dignitaries to stay whilst visiting Warrnambool. Dr Angus had his own silk worm farm at home in a Mulberry tree. His young daughter used his centrifuge for spinning the silk. Dr Angus was appointed on a part-time basis as Port Medical Officer (Health Officer) in Warrnambool and held this position until the 1940’s when the government no longer required the service of a Port Medical Officer in Warrnambool; he was thus Warrnambool’s last serving Port Medical Officer. (Masters of immigrant ships arriving in port reported incidents of diseases, illness and death and the Port Medical Officer made a decision on whether the ship required Quarantine and for how long, in this way preventing contagious illness from spreading from new immigrants to the residents already in the colony.) Dr Angus was a member of the Australian Medical Association, for 35 years and surgeon at the Warrnambool Base Hospital 1939-1942, He served with the Australian Department of Defence as a Surgeon Captain during WWII 1942-45, in Ballarat, Victoria, and in Bonegilla, N.S.W., completing his service just before the end of the war due to suffering from a heart attack. During his convalescence he carved an intricate and ‘most artistic’ chess set from the material that dentures were made from. He then studied ophthalmology at the Royal Melbourne Eye and Ear Hospital and created cosmetically superior artificial eyes by pioneering using the intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering in artificial eye improvements. He was Honorary Consultant Ophthalmologist to Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. He represented the Victorian South-West subdivision of the Australian Medical Association as its secretary between 1949 and 1956 and as chairman from 1956 to 1958. In 1968 Dr Angus was elected member of Spain’s Barraquer Institute of Barcelona after his research work in Intrasclearal cartilage grafting, becoming one of the few Australian ophthalmologists to receive this honour, and in the following year presented his final paper on Living Intrasclearal Cartilage Implants at the Inaugural Meeting of the Australian College of Ophthalmologists in Melbourne In his personal life Dr Angus was a Presbyterian and treated Sunday as a Sabbath, a day of rest. He would visit 3 or 4 country patients on a Sunday, taking his children along ‘for the ride’ and to visit with him. Sunday evenings he would play the pianola and sing Scottish songs to his family. One of Dr Angus’ patients was Margaret MacKenzie, author of a book on local shipwrecks that she’d seen as an eye witness from the late 1880’s in Peterborough, Victoria. In the early 1950’s Dr Angus, painted a picture of a shipwreck for the cover jacket of Margaret’s book, Shipwrecks and More Shipwrecks. She was blind in later life and her daughter wrote the actual book for her. Dr Angus and his wife Gladys were very involved in Warrnambool’s society with a strong interest in civic affairs. He had an interest in people and the community They were both involved in the creation of Flagstaff Hill, including the layout of the gardens. After his death (28th March 1970) his family requested his practitioner’s plate, medical instruments and some personal belongings be displayed in the Port Medical Office surgery at Flagstaff Hill Maritime Village, and be called the “W. R. Angus Collection”. The ink bottle case is significant for its association with writing methods commonly used during the colonisation of Australia until the mid-20th century. The protective Bakelite case demonstrates the value placed on caring for the user’s supply of ink and protecting other belongings of the user, enabling writers to easily carry and safely transport their ink without the concern of spilling it. The case’s design is a good example of the use of new technology. The properties of Bakelite have enabled its moulded design and make it waterproof and lightweight, easily cleaned, closely fitted to the shape of the ink bottle within and lid and base join together using a smooth screwing action. The maker’s marks have also been moulded into the Bakelite, therefore not distracting from the simple but elegant design. This ink bottle case also represents the period of early to mid-20th century when handwriting materials for writers using ink and nib pens were imported into Australia and developed for the Australian market and sold by wholesalers on behalf of overseas companies. Vintage brown Bakelite travelling ink bottle case (or holder, pot, well) containing glass ink bottle and original textured cardboard liner, made by Swan Ink, Mabie, Todd & Co. (Aust) Pty.. Ltd. The Bakelite container is shaped to fit snugly around the ink bottle. It still retains its original shiny finish, the lid screws on and off perfectly. The maker’s name is embossed on lid and base of the Bakelite container. The inkwell contains a glass Ink bottle with a tiny amount of dried up ink Swan triple filtered ink inside. The bottle is cylindrical with curved shoulders tapering to a neck of around 2cm. The white metal screw-on lid and the white and red paper label on the side of the bottle both have a printed description of the ink and maker. Circa 1934-1950’sBAKELITE INK CASE - embossed on either side of the lid “ “SWAN” INK / ”SWAN” INK “ - embossed into base, written in a circle “MABIE TODD & Co (Aust.) PTY. LTD.” GLASS BOTTLE – printed on lid “SWAN”/ [corporate logo combining letters ‘M, T, co’]/TRIPLE FILTERED/ INK.” - printed on label “SWAN” INK /FOR FOUNTAIN & / STEEL PENS / A BLUE BLACK INK OF/ THE FINEST QUALITY/ MADE IN ENGLAND/ MABIE. TODD & CO LTD …….. LONDON. SYDNEY/ Makers of “SWAN” Pens, Gold Pens & Ink“ - moulded into the base of the ink bottle and written around the bottom outside edge of the bottle are the words “THIS BOTTLE ALWAYS REMAINS THE PROPERTY OF/ MABIE TODD/AUST”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ink bottle holder, ink bottle case, ink bottle pot, travelling inkwell, portable inkwell, travelling ink pot, travelling ink bottle case, ink bottle, inkwell, ink well, swan ink, bakelite, dip pen ink, nib pen ink, fountain pen, fontpen, writing methods, stationery, mabie todd & co, swan fountain pens, biro-swan -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hat Box, John Brush, Son & Co, 1920s

This sturdy, deep hat box has been carefully constructed to give the contents utmost protection in the roughest of travel conditions. At the same time, attention to detail and quality of materials makes the box an attractive, desirable and useful piece of luggage. The supports inside the hat box show that the hat’s brim dipped at the front and back in the popular 1920s Homburg or Derby style. The hat box was likely to have been purchased, complete with its fashionable hat and personalised with the initials ‘G.M.’. The five shipping labels on the hat box tell that the owner traveller overseas with it on more than one occasion. The owner had first travelled with the shipping line Peninsular & Orient Steam Navigation Company, and may have been one the first Australian passengers in 1932, as the remnant of label on the base reads Sydney. The owner later voyaged under the company’s new name of P & O. and travelled from at least one of the voyages from Melbourne to London The square label, with “P & O” and red printed “M” in centre of circle, refers to alphabetical organisation of baggage by surname, connecting the owner ‘G.M.’ to the owner’s voyage with P & O. The P & O shipping line’s early beginnings started with the partnership of London ship broker Brodie McGhie Willcox and Scottish sailor Arthur Anderson in 1822. The partnership was joined by Irish shipowner Captain Richard Bourne in 1835 and they began operation as the Peninsular & Orient Steam Navigation Company with a service between London- Spain - Portugal. In 1932 the company expanded to include Australia with its passenger services departing from Sydney; in 1840 the company was incorporated. After various take-overs of other shipping lines and businesses, it operated under the name P & O. JOHN BRUSH The hat box was made by Australian saddle designer and maker, John Brush, Sons & Co. Brush began his saddlery trade in Roma, Queensland, His designing process included consulting with the men who rode and worked the horses. He was described in the Sydney Morning Herald of December 15, 1897, as a leading Sydney saddler, well known and reliable, with every kind of English and Australian saddle on view. John Brush established his business in 1840, operating from 371 George Street Sydney. A catalogue from that era jointly advertises John Brush (371 George Sty Sydney) and Butlers & Brush (432-4 Queen Street Sydney), both under the name of Edward Butler & Co. Pty. Ltd. The catalogue included saddlery, harness equipment, riding wear and travel goods, and strongly promoted the Wienkek made saddles, which he distributed Australia wide. John Brush, So & co. advertised its ‘new’ address in 1887, as 403 George Street Sydney. In 1898 Brush made a side-saddle for a customer, a design popular with gentlewomen of the era. The business was still operating over 100 years later, producing a catalogue in the 1950s.This early 20th century hat box is significant for being one of a kind in our Collection. Its fitted design shows the shape of the hat, dating it from the 1920s men’s fashions. The hat box is significant for being a high quality hat box made in Sydney, Australia by prominent and successful early colonial saddler and leather goods business, John Brush, Son & Co. The labels on the outside of the hat box are also significant, representing the prosperous lifestyle of an Australian traveller who purchased quality goods and cared for them. The traveller was able to depart from firstly the Port of Sydney and later the Port of Melbourne. Hatbox, oval shape, brown leather, strong, sturdy construction, six pieces, and metal lock on base. Wide lid, then tapers to a narrower base that has a red leather trim. Brown velvet fabric lining inside and covers some accessories. Other internal accessories are trimmed with plain red paper and blue and white striped paper. The lid has two attached leather tabs and a leather handle and underneath it has a drawstring liner and oval, gold-lettered maker’s label. The internal oval box has a leather retention strap and brim support. Separate moulded brim support is included. A detached leather strap with catch is inside the base. Inscriptions are stamped on the lid, printed on the maker’s label, attached as printed paper labels to the lid, sides, and under the base. Maker is John Brush, Son & Co. of Sydney. The owner’s initials “G.M” are embossed on the lid.Stamped on lid “G. M.” Label, oval, inside lid “JOHN BRUSH, SON & CO. / MANUFACTURERS & IMPORTERS / of / SADDLERY AND HARNESS / 403, GEORGE ST. / SYDNEY” Label, paper: “BAGGAGE, MELBOURNE TO LONDON’, part of word ‘CABIN’ and “P & O” Label, square, white background, black print, circular emblem: ‘PE - - - - - & ORIEN-’, ‘STEAM NAVIATION COMPY.’ BAGGAGE’ and a red printed “M” in centre of circle. Label, rectangular, white background, black print; narrow line border, text in rows and an ‘X’ overprinted, from corner to corner of the border: “BAGGAGE / P. & O. S. N. Co. / MELBOURNE / To / LONDON” Label, paper, rectangular, white background, black print, an “X” across the label: “CABIN / P & O / “ Label, paper, on base, “– aid” [Paid], “SYDNEY” flagstaff hil, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, hat box, leather hat box, vintage hat box, top hat, homburg hat, derby hat, travel ware, luggage, leather goods, travel goods, clothing accessory, men’s clothing, john brush, son & co, saddler, sydney firm, peninsular & orient steam navigation company, p & o, g.m., melbourne to london, sydney port, melbourne port, hat case -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

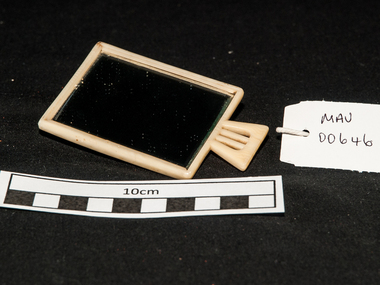

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Personal Effects, miniature square hand mirror, c1900

Celluloids are a class of compounds created from nitrocellulose and camphor, with added dyes and other agents. Generally considered the first thermoplastic, it was first created as Parkesine in 1856 and as Xylonite in 1869, before being registered as Celluloid in 1870. Celluloid is easily moulded and shaped, and it was first widely used as an ivory replacement. The main use was in movie and photography film industries, which used only celluloid films prior to acetate films that were introduced in the 1950s. Celluloid is highly flammable, difficult and expensive to produce and no longer widely used, although its most common uses today are in table tennis balls, musical instruments and guitar picks. Celluloid was useful for creating cheaper jewellery, jewellery boxes, hair accessories and many items that would earlier have been manufactured from ivory, horn or other expensive animal products. It was often referred to as "Ivorine" or "French Ivory". It was also used for dressing table sets, dolls, picture frames, charms, hat pins, buttons, buckles, stringed instrument parts, accordions, fountain pens, cutlery handles and kitchen items. The main disadvantage the material had was that it was flammable. Items made in celluloid are collectible today and increasingly rare in good condition. It was soon overtaken by Bakelite and Catalin.. A miniature, square, Ivorine hand mirror with bird engraved on back. An accoutrement for use in a lady's Evening bag c 19thCbird engraved on back of mirrormoorabbin, cheltenham, brighton, market gardeners, pioneers early settlers, mirrors, ivorine, celluloids, bakelite, plastics, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Ink Bottle, Caldwell’s Ink Factory, Late 19th to early 20th centuries

This design of the bottle is sometimes called a ‘cottage’ or ‘boat’ shape. The Caldwell’s handmade glass ink bottle was mouth-blown into a three-piece mould, a method often used in the late 19th and early 20th centuries, with the maker's name engraved into the mould section for the base. The glass blower would cut the bottle off the end of his blowpipe with a tool and join a mouth onto the top, rolling the lip. The bottle was then filled with ink and sealed with a cork. This method of manufacture was more time-consuming and costly to produce than those made in a simple two-piece mould and 'cracked' off the blowpipe. The capacity for a bottle such as this was about 3 ½ oz (ounces) equal to about 100 ml. This particular bottle is unusual as it has four sloping indents at the corners of the shoulder, most likely for resting a pen with its nib upwards and the handle resting on a flat surface. Most of the bottles made during this era had horizontal pen rests that were indented into both of the long sides of the shoulder. Pen and ink have been in use for handwriting since about the seventh century. A quill pen made from a bird’s feather was used up until around the mid-19th century. In the 1850s a steel point nib for the dip pen was invented and could be manufactured on machines in large quantities. This only held a small amount of ink so users had to frequently dip the nib into an ink well for more ink. Handwriting left wet ink on the paper, so the blotting paper was carefully used to absorb the excess ink and prevent smudging. Ink could be purchased as a ready-to-use liquid or in powdered form, which needed to be mixed with water. In the 1880s a successful, portable fountain pen gave smooth-flowing ink and was easy to use. In the mid-20th century, the modern ballpoint pen was readily available and inexpensive, so the fountain pen lost its popularity. However, artisans continue to use nib pens to create beautiful calligraphy. Caldwell’s Ink Co. – F.R. Caldwell established Caldwell’s Ink Company in Australia around 1902. In Victoria, he operated from a factory at Victoria Avenue, Albert Park, until about 1911, then from Yarra Bank Road in South Melbourne. Newspaper offices were appointed as agencies to sell his inks, for example, in 1904 the New Zealand Evening Star sold Caldwell’s Flo-Eesi blue black ink in various bottle sizes, and Murchison Advocate (Victoria) stocked Caldwell’s ink in crimson, green, blue black, violet, and blue. Caldwell’s ink was stated to be “non-corrosive and unaffected by steel pens”. A motto used in advertising in 1904-1908 reads ‘Makes Writing a Pleasure’. Stationers stocked Caldwell’s products and hawkers sold Caldwell’s ink stands from door to door in Sydney in the 1910s and 1920s. In 1911 Caldwell promised cash for returned ink bottles and warned of prosecution for anyone found refilling his bottles. Caldwell’s Ink Stands were given as gifts. The company encouraged all forms of writing with their Australian-made Flo-Eesi writing inks and bottles at their impressive booth in the ‘All Australian Exhibition’ in 1913. It advertised its other products, which included Caldwell’s Gum, Caldwell’s Stencil Ink (copy ink) and Caldwell’s Quicksticker as well as Caldwell’s ‘Zac’ Cough Mixture. Caldwell stated in a 1920 article that his inks were made from a formula that was over a century old, and were scientifically tested and quality controlled. The formula included gallic and tannic acids and high-quality dyes to ensure that they did not fade. They were “free from all injurious chemicals”. The permanent quality of the ink was important for legal reasons, particularly to banks, accountants, commerce, municipal councils and lawyers. The Caldwell’s Ink Company also exported crates of its ink bottles and ink stands overseas. Newspaper advertisements can be found for Caldwell’s Ink Company up until 1934 when the company said they were the Best in the business for 40 years.This hand-blown bottle is significant for being the only bottle in our collection with the unusual sloping pen rests on its shoulder. It is also significant for being made in a less common three-piece mould. The method of manufacture is representative of a 19th-century handcraft industry that is now been largely replaced by mass production. The bottle is of state significance for being produced by an early Melbourne industry and exported overseas. This ink bottle is historically significant as it represents methods of handwritten communication that were still common up until the mid-20th century when fountain pens and modern ballpoint pens became popular and convenient and typewriters were becoming part of standard office equipment.Ink bottle; rectangular base, hand-blown clear glass bottle with its own cork. The bottle has side seams from the base to the mouth, an indented base and an applied lip. The corners of the shoulder sides have unusual diagonal grooves that slope down and outwards that may have been used as pen rests. Inside the bottle are remnants of dried blue-black ink. The glass has imperfections and some ripples on the surface. The bottle has an attached oval black label label with gold-brown printed text and border. The base has an embossed inscription. The bottles once contained Caldwell’s blend of blue black ink.Printed on label; “CALDWELL's BLUE BLACK INK” Embossed on the base "CALDWELLS"flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, ink, nib pen, writing ink, writing, copying, banks, lawyers, commerce, student, permanent ink, blue black ink, stationery, record keeping, handwriting, writing equipment, writing accessory, office supply, cottage bottle, boat bottle, mouth-blown bottle, cork seal, f r caldwell, caldwell’s ink company, albert park, south melbourne, inkstands, stencil ink, copy ink, quicksticker, zac cough mixture, three part mould, cauldwells, cauldwell's -

Bendigo Historical Society Inc.

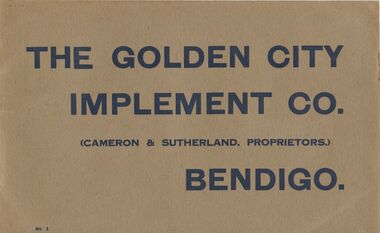

Bendigo Historical Society Inc.Document - THE GOLDEN CITY IMPLEMENT CO, BENDIGO, CATALOGUE

[a] Ten page Golden City Implement Co catalogue with company name and Cameron & Sutherland, proprietors Bendigo printed on cover. Catalogue predates 1925 as a Mr Osborne bought business that year. Horse drawn agricultural machinery indicates an early 20th Century date. Illustrations of Beam Scarifiers with patent points & tynes, Disc Cultivators, Spike Roller, Drag Harrows, Harrow Cart, Mould Board Plows, Circular Coulter, Earth Scoop, Pulley Chain Jokes, Fluted Spring Steel Swings & Pipe Bars, Leveller and Smoother, Delver and Crowder, Buck Scraper, Louvre Grader, Stock Troughs, Windmill Parts are listed. [b] Newspaper clipping dated 21/2/90 contains photograph of Charlie and Walter Osborne amid the clutter of their foundry. A brief history of the foundry is included. A complete print out of the catalogue book, (8201a), has been listed in the book collection at Nolan Street Bendigo .bendigo, industry, agriculture. -

Orbost & District Historical Society

Orbost & District Historical Societyglass containers, first half 20th century

These items were used at the pharmacies in Orbost. Chemists who worked in Orbost included Henry Cottman; James Alfred Dubois Williams; Harry Arthur Murray; Miss P.E .Mason (Phyllis Estelle?); Miss Sybil Monica Buzza; Thomas James Frazer; Australia Shaw; James David Torley; John William Zimmer; Dalkeith William Steele; William Thomas Hollingsworth; E.E. Cohen; R.S. Anderson; Frances John Perry Faith Everard Pardew and Charles Anthony Wurf. Castor oil and Eichorn's Remedy were home based remedies for non life threatening injuries. The practices of early pharmacists are revealed through these glass containers. The items have a clear association with Orbost and indicate that many rural households had first-aid sources. .Six glass containers. 3210.7 is a deep blue coloured glass bottle. It has a narrow neck and a screw on lid. It has an embossed manufacturer's name, logo and contents (Castor Oil) on one side and identification marks embossed on the underside. 3210.8 is a small clear glass flat bottle with a metal top.It is labelled "SIGMA JUNIPER BACC'. It contains pale brown liquid 3210.9 is a a small moulded clear glass flat bottle with a white bakelite cap.It is labelled "EICHORNS REMEDY 100 ml HELP IN EVERY DROP". 3210.10 is a clear glass bottle with no lid.It has embossed manufacturer's stamp on base. 3210.11 isa clear glass beaker with a label on the front of two concentric green circles inside of which is "PYREX Made in England" with 200 ml below this. 3210.12 is a lear glass jar / bottle with a black lid. The front and sides are ridged with part of a label - "CAL". This bottle contains some pink powder.3210.7 - "Rolfes Medicinal Tasteles Castor Oil - Rolfe & Co King St Melbourne. Contents 5oz" 3210.8 - "SIGMA JUNIPER BACC SIGMA COMPANY LIMITED, Melbourne" 3210.9 - "EICHORNS REMEDY 100 mm Help in Every Drop" 3210.10 - on base -"J983 / M 2 " 3210.11 - "PYREX Made in England 200 ml" 3210.12 - "CAL"glass-containers pharmacies-orbost medicines chemists-orboet -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Dundas Pottery, Late 1800s to early 1900s

This bottle was made in Scotland and recovered decades later from a shipwreck along the coast of Victoria. It may have been amongst the ship's cargo, its provisions or amongst a passenger's personal luggage. It is now part of the John Chance collection. Stoneware bottles similar to this one were in common use during the mid-to-late 19th century. They were used to store and transport. The bottles were handmade using either a potter's wheel or in moulds such as a plaster mould, which gave the bottles uniformity in size and shape. The bottle would then be fired and glazed in a hot kiln. Makers often identified their bottles with the impression of a small symbol or adding a colour to the mouth. The manufacturer usually stamped their bottles with their name and logo, and sometimes a message that the bottle remained their property and should be returned to them. The bottles could then be cleaned and refilled. DUNDAS POTTERY WORKS - The Dundas Pottery works were established in 1828 by William Johnstone in partnership with John Forsyth and John Mc Coll. Located where the Forth and Clyde Canal joined the Monkland Canal, North of Glasgow. Johnstone sold the pottery in 1835 to Robert Cochran and James Couper. Mc Coll was retained as manager until 1837when in 1839 Cochran & Couper sold the pottery and purchased the St Rollex Glass Works. George Duncan took over briefly but died in 1841, with the pottery possibly being run by his widow Helen and a potter named Alexander Paul. James Miller was the manager at the time and he bought the pottery in 1856, in partnership with John Moody. Miller's long and careful stewardship of the pottery saw success from the export market which allowed him to purchase the North British pottery in 1867 until 1874 when it was sold. In 1875, Miller, in partnership with John Young, leased part of Caledonian Pottery, naming it Crown Pottery, however, it burned down in 1879. In the early 1880s, Young extended the pottery and named it Milton Pottery. Miller’s son, James W., became a partner in Milton pottery in 1905. James Miller Snr died in 1905 and the company continued as a limited liability company, being sold to the Borax Consolidation Ltd in 1929, but it was unsuccessful and Possil pottery purchased some of the company's equipment before it finally closed in 1932. From 1828 until the James Miller period of circa 1856, the pottery produced salt-glazed stoneware for the local industrial trade; mainly bottles and drain pipes. James Miller produced various bottles, whisky and acid jars, casks, butter crocks, jam jars and domestic wares in Bristol glaze. He streamlined the water filter manufacturing, which had become a specialty of the pottery, and a dedicated section of the pottery was created solely for their production, which was exported worldwide. This stoneware bottle is historically significant for its manufacture and use in the late 19th to the early 20th century. This bottle is historically significant for its connection with the well-known stoneware manufacturers, Dundas Pottery of Glasgow, Scotland. The bottle is also significant as it was recovered by John Chance, a diver, from a wreck on the coast of Victoria in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Bottle, salt glazed stoneware, beige, sealed with wax, discolouration above base. Inscriptions stamped near base. Stamp: [symbol of concentric ovals], text within the symbol "PORT DUNDAS POTTERY COY." and "GLASGOW". Stamp:[Symbol - square with short vertical line in centre of base line] flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, stoneware, ironstone, pottery, bottle, port dundas pottery, glasgow, john chance, antique bottle, william johnstone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Dundas Pottery, Late 1800s to early 1900s

This bottle was made in Scotland and recovered decades later from a shipwreck along the coast of Victoria. It may have been amongst the ship's cargo, its provisions or amongst a passenger's personal luggage. It is now part of the John Chance collection. Stoneware bottles similar to this one were in common use during the mid-to-late 19th century. They were used to store and transport. The bottles were handmade using either a potter's wheel or in moulds such as a plaster mould, which gave the bottles uniformity in size and shape. The bottle would then be fired and glazed in a hot kiln. Makers often identified their bottles with the impression of a small symbol or adding a colour to the mouth. The manufacturer usually stamped their bottles with their name and logo, and sometimes a message that the bottle remained their property and should be returned to them. The bottles could then be cleaned and refilled. DUNDAS POTTERY WORKS - The Dundas Pottery works were established in 1828 by William Johnstone in partnership with John Forsyth and John Mc Coll. Located where the Forth and Clyde Canal joined the Monkland Canal, North of Glasgow. Johnstone sold the pottery in 1835 to Robert Cochran and James Couper. Mc Coll was retained as manager until 1837when in 1839 Cochran & Couper sold the pottery and purchased the St Rollex Glass Works. George Duncan took over briefly but died in 1841, with the pottery possibly being run by his widow Helen and a potter named Alexander Paul. James Miller was the manager at the time and he bought the pottery in 1856, in partnership with John Moody. Miller's long and careful stewardship of the pottery saw success from the export market which allowed him to purchase the North British pottery in 1867 until 1874 when it was sold. In 1875, Miller, in partnership with John Young, leased part of Caledonian Pottery, naming it Crown Pottery, however, it burned down in 1879. In the early 1880s, Young extended the pottery and named it Milton Pottery. Miller’s son, James W., became a partner in Milton pottery in 1905. James Miller Snr died in 1905 and the company continued as a limited liability company, being sold to the Borax Consolidation Ltd in 1929, but it was unsuccessful and Possil pottery purchased some of the company's equipment before it finally closed in 1932. From 1828 until the James Miller period of circa 1856, the pottery produced salt-glazed stoneware for the local industrial trade; mainly bottles and drain pipes. James Miller produced various bottles, whisky and acid jars, casks, butter crocks, jam jars and domestic wares in Bristol glaze. He streamlined the water filter manufacturing, which had become a speciality of the pottery, and a dedicated section of the pottery was created solely for their production, which was exported worldwide. This stoneware bottle is historically significant for its manufacture and use in the late 19th to the early 20th century. This bottle is historically significant for its connection with the well-known stoneware manufacturers, Dundas Pottery of Glasgow, Scotland. The bottle is also significant as it was recovered by John Chance, a diver, from a wreck on the coast of Victoria in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value.Bottle, salt glazed stoneware, beige, sealed with wax, some discolouration above base. Inscription stamped near base..Stamp: [symbol of concentric ovals], text within the symbol "PORT DUNDAS POTTERY COY." and "GLASGOW". Stamp:[Symbol - square with short vertical line in centre of base line]flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, shipwreck artefact, stoneware, ironstone, pottery, bottle, port dundas pottery, glasgow, antique bottle, william johnstone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Dundas Pottery, Late 1800s to early 1900s