Showing 1594 items

matching prior street

-

National Wool Museum

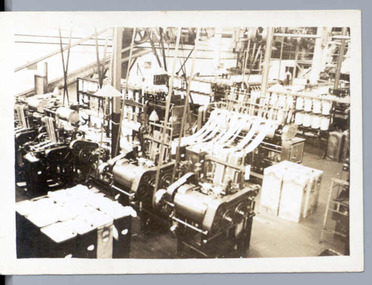

National Wool MuseumPhotograph

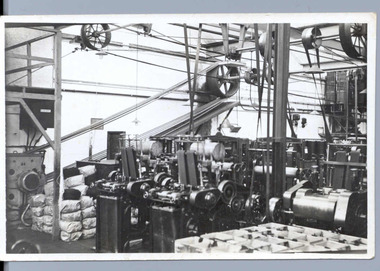

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the spinning machinery for producing worsted thread. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, spinning machinery, yarn - worsted -

National Wool Museum

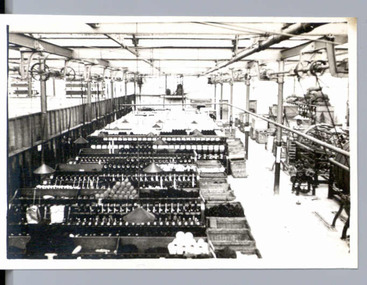

National Wool MuseumPhotograph

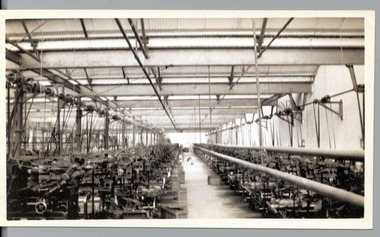

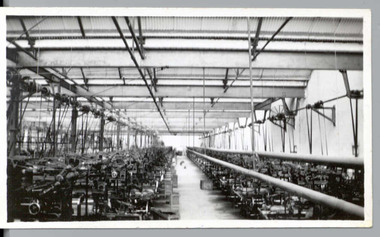

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

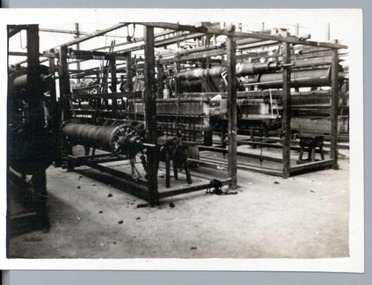

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows twisting and twisting machinery. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, twisting -

National Wool Museum

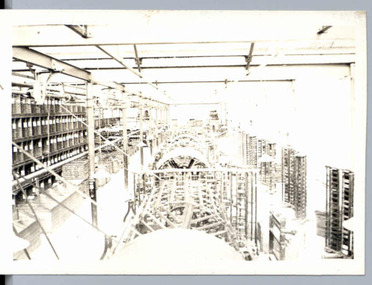

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the winding of the warp. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, winding, winding machinery -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows warping. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, warping, warping machinery -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows warping. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, warping, warping machinery -

National Wool Museum

National Wool MuseumPhotograph

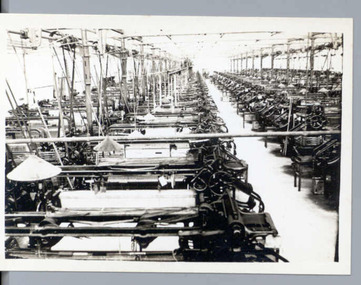

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows rows of weaving looms. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, weaving looms, weaving machinery -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the mending room, with the sloping tables which held the cloth to be mended. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, mending -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the dyeing room with the dyeing vats. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, dyeing -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows the dyeing room with the dyeing vats. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill, dyeing -

National Wool Museum

National Wool MuseumPhotograph

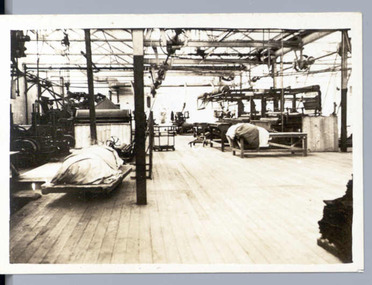

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the finishing area for worsted cloths. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile finishing, valley worsted mill, cloth - worsted -

National Wool Museum

National Wool MuseumPhotograph

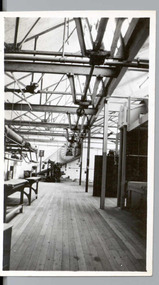

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and probably shows the mill maintenance shop, as a grinder, a diesel drum and a container for nuts and bolts can be seen. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

National Wool MuseumPhotograph

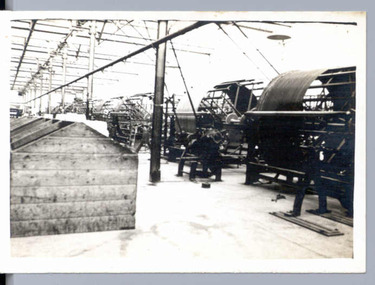

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

National Wool MuseumPhotograph

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows an unknown area of machinery within the mill. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.valley worsted mill -

National Wool Museum

National Wool MuseumRug

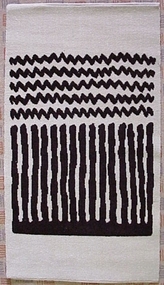

Rug was made on National Wool Museum Brinton Axminster Gripper Loom by Brintons Carpets Geelong Staff prior to the visit of Queen Elizabeth. On the afternoon of 28/4/1988 Queen Elizabeth was presented with a similiar rug but latex backed and labelled.weaving, axminster -

National Wool Museum

National Wool MuseumRug

Rug was made on National Wool Museum Brinton Axminster Gripper Loom by Brintons Carpets Geelong staff prior to the visit of Queen Elizabeth. On the afternoon of 28/4/1988 Queen Elizabeth was presented with a similiar rug but latex backed and labelled.Rug was made on National Wool Museum Brunton Axminster Gripper Loom by Brintons Carpets Geelong staff prior to the visit of Queen Elizabeth. Detail of rug made on National Wool Museum Brunton Axminster Gripper Loom by Brintons Carpets Geelong staff prior to the visit of Queen Elizabeth II. Label on rug made on National Wool Museum Brunton Axminster Gripper Loom by Brintons Carpets Geelong staff prior to the visit of Queen Elizabeth II. Label for rug made on National Wool Museum Brunton Axminster Gripper Loom by Brintons Carpets Geelong staff prior to the visit of Queen Elizabeth II.weaving, national wool museum, axminster -

National Wool Museum

National Wool MuseumTool - Finishing machine

Variable speed cloth puller, used for tightening and smoothing blanket edges, prior to them being sewn or bound. Used at Collins Bros Mill.Textile finishing machine. Horizontal, made from grey steel with a small encased gear box and two attached rollers. Separate belt drive and nine other rollers. Enclosed in original brown cardboard box, used for shipping.SUISIE / VARIABLE SPEED / VERSATILE CLOTH PULLERtextile machinery, collins bros mill pty ltd, blankets -

National Wool Museum

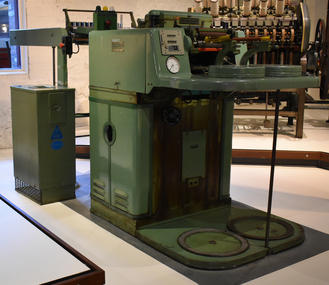

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

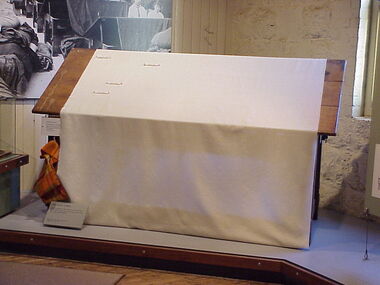

National Wool MuseumFunctional object - Mending Table, c1930

Any faults in the final product can be repaired by mending. Prior to more advanced machinery, fabric was draped over a mending table and carefully inspected for faults. Quick eyes and nimble fingers were needed. Repairing faults was a highly skilled manual operation. Any knot or thickness had to be removed without affecting the quality of the fabric and mending had to be invisible. In the 1930s to make the day pass faster, popular records were played to the factory workers in the mending room. The top of the table is propped up to make it a well-lit surface over which bolts of fabric were unrolled to check for faults. Menders repaired them with invisible hand stitching. Each weaver stitched a coloured thread in the selvage to show the start of their shift, therefore if mistakes were found the company could easily find who was responsible. This table was used by Gail Morris in teh 1960s. Large wooden table with tilted top. mending table, wool processing, fabric, textile industry -

National Wool Museum

National Wool MuseumPhotograph

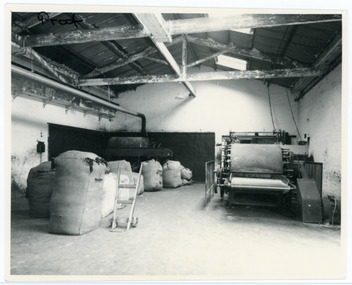

Depicts the blending room (where fibres were blended prior to carding) from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, blending, carding -

National Wool Museum

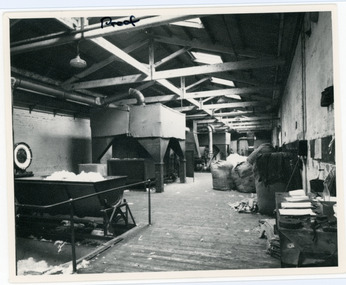

National Wool MuseumPhotograph

Depicts the blending room (where fibres were blended prior to carding) from one of the Godfrey Hirst mills in 1966. In 1966 McKendrick Consolidated Industries Ltd purchased Godfrey Hirst Ltd to operate a carpet manufacturing concern and this photo was taken at the time of the takeover.Proof IAN HAWTHORNE / PHOTOGRAPHER / Commercial, Portrait, Wedding, Colour Processor / Upstairs, 140 Moorabool St., Geelong Ph. 98096godfrey hirst and co. pty ltd, blending, carding -

National Wool Museum

National Wool MuseumSketch

Artist's charcoal sketch with water colour panelfrom which carpet manufacturing pattern is graphed out, prior to preparation on Jacquard Card. Genoese (Axminster) 4/4225.Artist's charcoal sketch with water colour panelfrom which carpet manufacturing pattern is graphed out, prior to preparation on Jacquard Card. Genoese (Axminster) 4/4225. Artist's charcoal sketch with water colour panelfrom which carpet manufacturing pattern is graphed out, prior to preparation on Jacquard Card. Genoese (Axminster) 4/4225.4/418 Genoese MS. M6 RE MG. in Burgundy P2 S7 1st stockweaving, carpet -

National Wool Museum

National Wool MuseumSketch

Sketch from which carpet manufacturing pattern is graphed out, prior to preparation at Jacquard card. Genoese (Axminster) 4/4187.Genoese 4/4187. Consists of large gouache paint sketch and charcoal sketch.Sketch from which carpet manufacturing pattern is graphed out, prior to preparation at Jacquard card. Genoese (Axminster) 4/4187.Genoese 4/4187. Consists of large gouache paint sketch and charcoal sketch. Sketch from which carpet manufacturing pattern is graphed out, prior to preparation at Jacquard card. Genoese (Axminster) 4/4187.Genoese 4/4187. Sketch from which carpet manufacturing pattern is graphed out, prior to preparation at Jacquard card. Genoese (Axminster) 4/4187.Genoese 4/4187. Sketch from which carpet manufacturing pattern is graphed out, prior to preparation at Jacquard card. Genoese (Axminster) 4/4187.Genoese 4/4187. Consists of large gouache paint sketch and charcoal sketch.Genoese 4225weaving, carpet -

National Wool Museum

National Wool MuseumArtwork, other - Sketch

Sketch from which carpet manufacturing pattern is graphed out, prior to preparation of Jacquard card. Genoese (Axminster) 4/4226. Three sketches, gouache, two long and one short designs. The two long sketches are pasted at one end onto backing paper, which contain inscriptions. Floral design in blues, pink, mauves, white, grey and greens.Genoese 4/4226 AL Ingramweaving, carpet, ingram, a l -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Camera & Accessories, c1920

History prior to 1946 unknown. Camera etc was purchased by the donor in 1946 from Herbert Small Camera Supply then in Elizabeth Street Melbourne. Donor used camera regularly until recent years.'Etue' folding camera with accessories (camera, case, 3 negative containers in a imitation leather & cardboard container) and an additional slide tray. Camera can be used with glass plates, cut negative film and film packs. When camera is opened the lens, bellows etc slide into position. The whole lot slides on a rail system and can be locked in the position required. Item to be photographed can be viewed in a viewfinder which can be turned to a horizontal or vertical plane. In the viewfinder has a small bubble level. It includes an oblong chrome wire which is used to set the minimum distance from lens to object.|Camera is of steel covered and is covered with leather with a carrying handle. provision is made in the back to carry a film slide in a small envelope style pocket|Camera is made by Kamera Werkstatten of Dresden c1920.|It has a 'Zeiss Tessar' 1:4.5 lens of 10.5 cm focal length. Shutter is a 'Compur' with speeds of 1 to 1/250th of a second with Bulb and Time. It also has a delayed action feature. It also has a double extension for close up studies.|When folder it is a mere 4.5 cm from front to back, which cause it to be advertised as the slimmest camera made.|Camera case is made of brown tooled leather with a chrome clip and adjustable carrying handle - lid open upwards for the camera .Case is lined with a purple type of velvet material. 10 Items in total.photography, cameras, camera accessories -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, 24 McDowall Street, Mitcham, 13/06/2001 12:00:00 AM

Taken to mark change of ownership and change of use of building.Home of Arch & Eileen Kennedy and 6 children. Frank, second eldest son in photo, just prior to sale of house (Price $210,000) and conversion to dental clinic in 2000 (refer to eulogy for Arch) (ND1462).kennedy, arch, eileen, mcdowall street mitcham, no. 24 -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Prior to Widening Mitcham Road, 1/02/2000 12:00:00 AM

Coloured photograph of Mitcham Road looking back towards Mitcham. Nursery on left and Mulsanne Street on left. Photo taken before construction to widen Mitcham Road.mitcham road, donvale, mulsanne street -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Mitcham Road Prior to Widening, 1/02/2000 12:00:00 AM

... Mitcham. Ruby Street on left, William Street on right. Taken.... Ruby Street on left, William Street on right. Taken prior ...Coloured photograph of Mitcham Road looking South towards Mitcham. Ruby Street on left, William Street on right. Taken prior to construction to widen Mitcham Road.mitcham road, donvale, ruby street, william street