Showing 149 items

matching oil industry

-

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyDocument - Advertising circular, Australasian Oil and Paint Company, Jan 1893

A circular from the Australasian Oil and Paint Company advertising its wares. Received by the Town Clerk in 1893Paint prices 6/- to 12/- Carbo Oil prices 3/-business and traders - paints/chemicals, industry, edward c crockford, town clerks -

Port Melbourne Historical & Preservation Society

Port Melbourne Historical & Preservation SocietyPhotograph - COR tanker, Douglas Smallpage, 1920s

From the SMALLPAGE family collection, donated by Ann SMALLPAGE. Doug SMALLPAGE was the COR photographer.Photograph of COR tanker circa 1928industry, transport - motor vehicles, doug smallpage, commonwealth oil refineries, cor -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - Seal Embossing Press

The Corona Paint Company Pty. Ltd. Bendigo was formed in November 1920 with £10,000 capital, in £1 shares. By July 1921, the Company had completed its factory and plant at Bendigo East, ready to begin the manufacture of paints. The Corona Paint works were opened on Saturday 28 January by the Prime Minister (Mr. Hughes) during a visit to Bendigo. Many new manufacturing industries were opened during this time after calls to address the decline of mining in the region. The factory of the CORONA PAINT COMPANY, BENDIGO, was advertised for sale in The Argus on 5 October 1923. It consisted of a “building on a railway siding, plant and machinery, including dry grinding plant, kalsomine mixer, paint mill, furnace, electric motor, etc., large stores of raw and finished material, kalsomine with range of 21 colours, oil paints, &c.”A cast iron embossing press. It's painted black with gold coulered floral decorations. The base is 18 centimetres long, nine centimetres wide and one and a half centimetres thick. A curved protrusion rises from the base that is eight centimetres by four centimetres which narrows to four centimetres by two and a half centimetres with a three-quarter centimetre wide slot. Inside the slot is a lever action with a ten centimetre by two and a half centimetre wooden handle. There is a removeable die on the end of the lever and an opposite removeable die the base. A small oval metal disc with paten no 3965 on is attached. The seal is The Corona Paint Company proprietary Limited seal embossing press, corona paint company -

Bendigo Historical Society Inc.

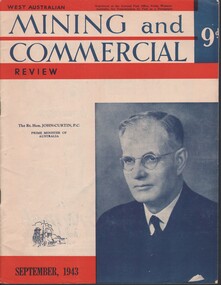

Bendigo Historical Society Inc.Document - MCCOLL, RANKIN AND STANISTREET COLLECTION: WEST AUSTRALIAN MINING AND COMMERCIAL REVIEW, 1943

Documents: September 1943 issue of the West Australian Mining and Commercial Review Magazine - 32 Pages plus cover. It has a photo of the Australian Prime Minister, Hon John Curtin P.C. and the cost is 9d dated September, 1943. The back cover is advertising for Goodyear V-Belt Drivers. Articles on Municipal Finance, Port War Radio, W.A. Mining Industry, Ore Deposits, Rand Gold Producers. Advertising for Mobil Oil, Fibrolite, Bromet Alloy Tungsten Carbide, Steel Machinery Covers, Dept.., of Industrial Development, Hume Steel Ltd, State Saw Mills etc.MCCOLL RANKIN AND STANSISTREETorganization, business, gold mining magazine, mccoll rankin and stansistreet -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Driptorch - Firebug (hand held), c 1985

The origins of the humble handheld driptorch have been lost in time. They are widely used for ignition in controlled burning operations in forest and grasslands. The “Pacific Forester“ with its short central wand and somewhat leaky ball-valve was made by the American Wajax company in the 1940s. The Pacific Forester is slightly different in design from the more robust and common “Panama” driptorch first manufactured in 1933 and used extensively by Queensland cane farmers. The Panama is closely related to the current “Firebug” used in Victoria which is manufactured by Rodney Industries in Brisbane and has an offset wand design which gives it good balance. The fuel is a mixture of petrol and diesel and every FCV District had their own closely-guarded secret formula ... 2:1, 3:1, 1:1, 4:1 or 3:2 ratio. There was also the choice of 91, 95 or 98 octane petrol mixed with summer or winter diesel. Occasionally some of the old Avgas or Jet-A1 lying around the depot was added with a splash of engine oil to make the mixture stick to the fuel to be ignited. The fuel mixed also varied between autumn or spring, heathland, mixed forest, or high-intensity slash burnsCommon driptorch used throughout AustraliaDrip torch with handle Wand has loop and valve. The loop is designed to assist with even flow of fuel which flows out onto the burning head of the wand. Pressure equalising value in top of aluminum fuel container which holds 4 litres of burner mix. Gravitational feed of the driptorch allows the unit to drip fire, making it simple and quick to operate. Instructions for use. CF+L written with texta pen.bushfire -

Latrobe Regional Gallery

Latrobe Regional GalleryPainting, MARTIN, Mandy b. 1952, Adelaide, South Australia, Briquette Factory Site, 1989

Oil on canvasSigned, titled and dated versofactory, industry, power, landscape, industrial -

Ballarat Heritage Services

Ballarat Heritage Servicesdigital photographs, Lisa Gervasoni, Glenthompson Brickworks, c2010-2017

The Thompson brothers, George and Joseph, formerly of Ballarat and the new owners of Yallum Park, established the Glenthompson Brickworks in 1900. The entire process of creating a solid, pressed Glenthompson Brick happens on site, where red and cream clay is excavated. Brick presses dating back to 1940 are still in operation today, the kilns are stacked by hand to ensure specific needs are met and colour varieties are achieved. Refined oil is used to fire down draught kilns, which allows temperatures to be adjusted to ensure unique colour ranges are achieved.Colour photographs of kilns at Glenthompson Brickworks. building, heritage, glenthompson, industry, industrial heritage, brickworks, oven, glenthompson brickworks, george thompson, joseph thompson -

Ballarat Tramway Museum

Ballarat Tramway MuseumBook, "Ballarat Illustrated", 1972

Original c 1914 (see below), facsimile copy - re-published 1972. Original features photos of Ballarat City and Town, its buildings, parks and the various industries and organisations that were in Ballarat at the time of publication, including ESCo. Many photos features ESCo trams. Photos sepia toned. Has some red colour block printing on the front cover and rear, for Star Oil Engines. On inside back cover is a map with the places of interest and tram route map, marked in red. Pages are un-numbered. Original published by Ballarat East Town Council and Ballaarat City Council. On cover has number stamped in black in, "No. 87" (assume facsimile copy No.). Photos with publication show tram No. 21, built 1913 and ESCo photo page shows Mr. Pringle as Manager. Mr Pringle became manager in January 1911, As there is no photos of the "Avenue of Honour", or other mention of the first world war, assume original published about 1913 or 1914. Original shows Engravings and printing by "Campbell Wilson Prop Ltd, Ballarat". See Other Information as well for more listing details. High Resolution image added 31/8/2012 of i2 of ESCo page and i3 for Ballarat identies and sheet i4 extracted for Mr Pringle. PDF scan of full document added 21/5/2019 - see images btm633-1i.pdf and btm633-2i.pdf Notes on "Ballarat Illustrated" Reg. Item No. 733 From notes made by Neville Gower 12/1/1997 Cover: Inside front cover: Last paragraph, "Facilities for Travelling" - Electric trams serve all parts of Ballarat. Page 3: Street Scene, Municipal Town Hall, showing tram wiring Page 7: Street Scene, Lydiard St. North, intersection and tramway centre, with ESCo tram No. 21 in the bottom photo. Other photos features trams as well in Sturt St and Lydiard St. North. Page 9: Street Scene, Top photo of Sturt St. from Lydiard St. looking east, shows piles on right-hand side of road. Car parked by Post Office has a car registration number "9007". Bottom photo, an tram climbing hill, shows double trolley in the street, with early English type of pull offs. Page 13: Street Scenes and Historic Buildings: One of five photos, shows Victoria St. looking East, with tram track prominent in photo and how stone work was set up about the rails and overhead poles. Page 23: Street scene, Gardens North Entrance gates, shows details of gates near St. Aidans Drive. Note double trolley wire on poles, and style of insulators. No trams in photo, three ladies walking down the track. Page 37: Street Scene; Lydiard St views, top left hand photo, shows Railway station and railway gates with signal gantry and horse drawn vehicles. Tram tracks apparent. Bottom left hand photo shows Lydiard St. North, near Post Office, double track with centre poles - Single wire per track. Top right hand photo, showing Cemetery gates in background. Bottom right hand photo - from north end of Lydiard St. South, looking north, with an ESCo tram in background. Also has a parked car on left hand side. Page 45: Street Scenes - Bridge St; top photo at west end of Bridge St. with ESCo No. 11 with possibly double trolley wire in photo. Bottom photo at east end of Bridge St. with tram in background, shows junction. Double trolley heading out to Mt. Pleasant, single trolley for Victoria St. Page 45: Street Scenes - Bridge St; top photo at west end of Bridge St. with ESCo No. 11 with possibly double trolley wire in photo. Bottom photo at east end of Bridge St. with tram in background, shows junction. Double trolley heading out to Mt. Pleasant, single trolley for Victoria St. Page 61: Street Scenes and Historic Buildings - Public Institutions Ballarat - top left hand photo of the Hospital shows some tram track in foreground, with double trolley wire. Top right photo is of the Orphanage, the name of the tram terminus for many years. Page 68: Electric Supply Co. of Victoria's pages - top photo showing powerhouse in background, across the lake, can hardly see anything for the trees, except for the chimney. Bottom photos of the steam Turbo Generators and the switchboard. Gives Mr. P.J. Pringle as Chief Engineer and General Manager. He took over in Jan. 1911. Page 69: Ballarat East Views - features photo of Black Hill open cut, Ballarat East Railway Station, Ballarat Fire Station and "Victoria St. looking East", repeat of photo printed on page 12, but slightly darker. Image on system includes fire station and railway station, - Ballarat East. Page 78: Series of photos of various Ballarat VIP's of the era, fourth one in on top line features "P.J.Pringle, Electric Supply Co." Inside Back cover - map of Ballarat including tram lines and places of interest marked in red. Gives a detailed photographic presentation of Ballarat in 1914.80 page book with, in addition, light green card covers, titled "Ballarat Illustrated". Loose copy of page 9 and 10 held.trams, tramways, ballarat, local history, heritage buildings, esco -

Stawell Historical Society Inc

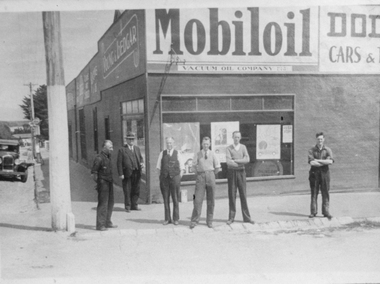

Stawell Historical Society IncPhotograph, Young and Ledgar’s Garage at corner of Scallan and Wimmera Streets c1920's

Men standing in front of Young and Ledgar’s Garage at corner of Scallan and Wimmera Streets. Oil advertising above display window. Mid 1920'sstawell transport industry -

Federation University Art Collection

Federation University Art CollectionOil on Masonite, 'Buckboard Over the Plains' by Neville Bunning, 1977

This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.art, artwork, oil, oil painting, neville bunning, bunning, alumni, school of mines and industry -

Federation University Art Collection

Federation University Art CollectionOil on masonite, Storm over Merimbula - Pambula Beach by Neville Bunning

Neville Bunning taught Sculpture and Ceramics at the School of Mines and Industry, Ballarat between 1945 and 1964. During that time, he formed the Ballarat Artist’s Society, a group that sponsored art and invited modernist artists to visit Ballarat to speak to students and the public. Bunning wrote a weekly art column in The Courier, where his insightful comments made readers aware of significant trends in Art. This item is part of the Federation University Art Collection. The Art Collection features over 1000 works and was listed as a 'Ballarat Treasure' in 2007.art, artwork -

Offshore & Specialist Ships Australia

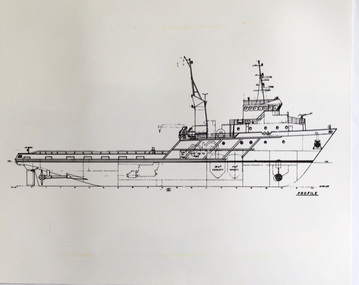

Offshore & Specialist Ships AustraliaPhotograph - Photos AHTS Vessel Lady Elizabeth building

B&W Photos of Building AHTS vessel Lady Elizabeth at ASI shipbuilders WA.Photo Captions. Australian Offshore Services, part of the Energy Services Division of P&O Australia Ltd. recently placed an order for a new anchor—handling supply vessel to be built by Australian Shipbuilding Industries (WA) Pty. Ltd. at Cockbum Sound, W.A. The 2,650 tonnes displacement ship will be the largest 111' the A.O.S. fleet and the first built for the Company in W.A. Delivery is scheduled for September 1982, after which the ship will join other units of the A.O.S. fleet serving 011 and gas projects in Bass Strait and off the W.A. coast. PRINCIPAL DIMENSIONS: Length, overall 66.30 metres 14.15 " 5.65 H Beam Depth A new oil rig supply vessel for Australian Offshore Services, part of the Energy Services Division of P&O Australia Ltd. is due to be launched on September 9 at the Australian Shipbuilding Industries shipyard at South Coogee (W.A.). The ship will be named Lady Elizabeth by Ms Anne Elizabeth Blanckensee, wife of Mr Alan Blanckensee, a Director of P&O Australia Ltd. A.O.S. operates a large fleet of supply Vessels which support oil and gas exploration projects off the W.A. and Victorian coasts and LADY ELIZABETH will be the 14th ship built in Australia for the Company in the last 14 years. LADY ELIZABETH (2,650 tonnes displacement) is 66.30 metres in length, 14.15 metres beam and 5.65 metres moulded depth. She Will be powered by four Daihatsu engines developlng a combined total of 7,200 b.h.p. After the ceremony, the vessel's fitting out will continue and she is expected to enter service in October, under the Command of Captain G.D. Mellor of Thornlie, W.A. -

Harcourt Valley Heritage & Tourist Centre

Harcourt Valley Heritage & Tourist CentreFrost Smoke Pot

Frost pots were used by orchardists to protect ripening fruit from the effects of frost. The drum base was filled with sump oil and set out in the orchard and set alight on frosty nights. These frost pots were used by Norris' orchards. It was not unusual for the Police to have to close the Midland Highway due to the dense clouds of billowing smoke emanating from this orchard when frost was expected.A local solution to a basic problem of the Harcourt Horticultural industry.Frost Pot rounded base with sliding opening on lid and galvanised iron chimney with perforations. -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionPacific firelighter

The origins of the humble handheld driptorch have been lost in time. They are widely used for ignition in controlled burning operations in forest and grasslands. The “Pacific Forester“ with its short central wand and somewhat leaky ball-valve was made by the American Wajax company in the 1940s. The Pacific Forester is slightly different in design from the more robust and common “Panama” driptorch first manufactured in 1933 and used extensively by Queensland cane farmers. The Panama is closely related to the current “Firebug” used in Victoria which is manufactured by Rodney Industries in Brisbane and has an offset wand design which gives it good balance. The fuel is a mixture of petrol and diesel and every FCV District had their own closely-guarded secret formula ... 2:1, 3:1, 1:1, 4:1 or 3:2 ratio. There was also the choice of 91, 95 or 98 octane petrol mixed with summer or winter diesel. Occasionally some of the old Avgas or Jet-A1 lying around the depot was added with a splash of engine oil to make the mixture stick to the fuel to be ignited. The fuel mixed also varied between autumn or spring, heathland, mixed forest, or high-intensity slash burnsKerosene drip torch Short wand no valveBCR Holdingsforests commission victoria (fcv), planned burning, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionBell Backburner Lighting Torch

The origins of the humble handheld driptorch have been lost in time. They are widely used for ignition in controlled burning operations in forest and grasslands. The “Pacific Forester“ with its short central wand and somewhat leaky ball-valve was made by the American Wajax company in the 1940s. The Pacific Forester is slightly different in design from the more robust and common “Panama” driptorch first manufactured in 1933 and used extensively by Queensland cane farmers. The Panama is closely related to the current “Firebug” used in Victoria which is manufactured by Rodney Industries in Brisbane and has an offset wand design which gives it good balance. The fuel is a mixture of petrol and diesel and every FCV District had their own closely-guarded secret formula ... 2:1, 3:1, 1:1, 4:1 or 3:2 ratio. There was also the choice of 91, 95 or 98 octane petrol mixed with summer or winter diesel. Occasionally some of the old Avgas or Jet-A1 lying around the depot was added with a splash of engine oil to make the mixture stick to the fuel to be ignited. The fuel mixed also varied between autumn or spring, heathland, mixed forest, or high-intensity slash burnsKerosene drip torch Long straight wand with control valveBell Backburnerforests commission victoria (fcv), planned burning, bushfire -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionFirebug

The origins of the humble handheld driptorch have been lost in time. They are widely used for ignition in controlled burning operations in forest and grasslands. The “Pacific Forester“ with its short central wand and somewhat leaky ball-valve was made by the American Wajax company in the 1940s. The Pacific Forester is slightly different in design from the more robust and common “Panama” driptorch first manufactured in 1933 and used extensively by Queensland cane farmers. The Panama is closely related to the current “Firebug” used in Victoria which is manufactured by Rodney Industries in Brisbane and has an offset wand design which gives it good balance. The fuel is a mixture of petrol and diesel and every FCV District had their own closely-guarded secret formula ... 2:1, 3:1, 1:1, 4:1 or 3:2 ratio. There was also the choice of 91, 95 or 98 octane petrol mixed with summer or winter diesel. Occasionally some of the old Avgas or Jet-A1 lying around the depot was added with a splash of engine oil to make the mixture stick to the fuel to be ignited. The fuel mixed also varied between autumn or spring, heathland, mixed forest, or high-intensity slash burnsKerosene drip torch Long straight wand with control valveBell Backburnerforests commission victoria (fcv), planned burning, bushfire -

Lakes Entrance Historical Society

Lakes Entrance Historical SocietyPhotograph - Richard Allen, 1970c

Owner, Owen Allan of EdenColour photograph of the fishing boat Richard Allan on slips, having sustained serious damage to the bow section after collision with oil rig supply boat. Lakes Entrance Victoriafishing industry, ships and shipping, shipwrecks, slipway -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Rib Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale rib bone with advanced stage of calcification as indicated by brittleness. None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

National Vietnam Veterans Museum (NVVM)

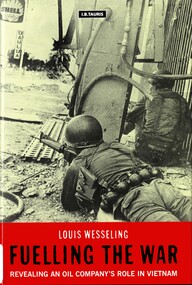

National Vietnam Veterans Museum (NVVM)Book, Wesseling, Louis, Fuelling the War: Revealing an Oil Company's Role in Vietnam, 2000

April 1975, Saigon, US helicopters cumbersomely lift off from the roof of the American Embassy, heavily laden with fleeing diplomats, military officers and senior officials.April 1975, Saigon, US helicopters cumbersomely lift off from the roof of the American Embassy, heavily laden with fleeing diplomats, military officers and senior officials.shell oil company, vietnam war, 1961-1975, petroleum industry and trade -- vietnam, us helicopters, saigon, south vietnamese, vietcong, american embassy, military officers, senior officials -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkBook, Yarra Ranges Regional Museum, Oil Paint and Ochre, The incredible story of William Barak and the de Purys, 2015

This book tells the story of William Barak and the de Pury family, where descendants of both sides still live today. It also has national significance as a story that explores the complex, first generation negotiations between Aboriginal and European people. Also the establishment of Coranderrk Aborignal Station at Healesville and the growth of the wine industry in the Yarra Valley. William Barak was a Wurundjeri leader and the de Purys' were a wine making family. The book complemented and exhibition called Oil Paint and Ochre 29 Aug - 22 Nov 2015.Soft cover paperbackwilliam barak, de purys, corranderk -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Driptorch - hand held - unknown date, design or manufacturer

The origins of the humble handheld driptorch have been lost in time. They are widely used for ignition in controlled burning operations in forest and grasslands. The date, origins and manufacturer of this particular model are unknown. The “Pacific Forester“ with its short central wand and somewhat leaky ball-valve was made by the American Wajax company in the 1940s. The Pacific Forester is slightly different in design from the more robust and common “Panama” driptorch first manufactured in 1933 and used extensively by Queensland cane farmers. The Panama is closely related to the current “Firebug” used in Victoria which is manufactured by Rodney Industries in Brisbane. The fuel is a mixture of petrol and diesel and every FCV District had their own closely-guarded secret formula ... 2:1, 3:1, 1:1, 4:1 or 3:2 ratio. There was also the choice of 91, 95 or 98 octane petrol mixed with summer or winter diesel. Occasionally some of the old Avgas or Jet-A1 lying around the depot was added with a splash of engine oil to make the mixture stick to the fuel to be ignited. The fuel mixed also varied between autumn or spring, heathland, mixed forest, or high-intensity slash burnsEarly driptorch designDrip torch with handle Wand has loop and valve. The loop is designed to assist with even flow of fuel which flows out onto the burning head of the wand. Soldered tin fuel container which holds burner mix. Gravitational feed of the driptorch allows the unit to drip fire, making it simple and quick to operate. bushfire, forests commission victoria (fcv) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Baleen

A baleen whale has hard bristly baleen that hangs from its upper jaw inside its mouth instead of teeth. Baleen is made from a protein called keratin, just like human hair and fingernails, and its colour can vary between species, from black to yellow or white. The whale uses the tough, flexible baleen like a sieve to catch its food, filtering the small sea creatures out of the sea water it releases from its mouth. In the19th Century, whales were hunted for the products that could be made from their bodies, such as oil for lubricating machinery, soap making, lamps, heaters and fuel for the lighthouse lights. The flexible baleen was used for whip handles, carriage springs and umbrella ribs. It was also used for the skirt hoops, hat ribs, and rigid ‘stays’ in tightly fitting bodices to enhance their figures. The Southern Right Whales, as well as Blue Whales and Humpback Whales, are baleen whales. The Southern Rights annually visit the ocean off the southwest coast during the breeding season. In the early 1800s whalers hunted along this coastline in their dangerous pursuit of money for the precious cargoes of whale oil and bones. The population of these large animals dwindled quickly and by the late 1840s the whaling industry dwindled. Whaling recommenced from the 1940s to the 1980s when the whale products were used to make margarine and dog food. The baleen sample has been used to educate people about whaling and about the properties of baleen. The baleen sample is significant for its association with 19th century women's fashion. It helps to understand how garments were supported to shape a woman's figure. The baleen sample represents a period when whales were hunted and killed to provide income and products for for the local settlers and for the export industry.Baleen sample from a whale's jaw. Its black shiny hard yet flexible surface is slightly rippled and textured. One end is fringed and the other and a smooth cut edge. The colour varies in places, with stripy brown colouring. flagstaff hill maritime museum and village, great ocean road, shipwreck coast, baleen, whalebone, baleen whale, keratin, 19th century, whaling industry, women's fashion, stays, bodice, women's figures, fashion, clothing, whale oil, baleen colour, whale hunting, whale products, southern right whale, blue whale, humpback whale, southwest victoria, whalers, whale bones -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Functional object - car lantern, Joseph Lucas Ltd. Birmingham, England, Lucas King of the Road Lantern, c.1930

This lantern or lamp was used for lighting an automobile or motor cycle in the 1920s or 1930s. It could also have been used in a household or carried by a person. It was made by the English firm of Joseph Lucas Ltd., a business founded in 1860 which originally made scoops, buckets and plant holders. In 1875 it began the production of lamps and in the early 20th century made automotive components. Today after having merged with a North American company it makes components for the automotive and aerospace industries. The term 'King of the Road' was reserved for products that were regarded as the most prestigious and the ones commanding the highest price. This lamp was advertised as one that 'will not blow out in the toughest gale'.This item is retained as an interesting example of the lighting used for cars and bicycles early in the 20th century.This is a metal lantern which is much rusted but which may have been chrome or nickel plated. It has a lighting mechanism enclosed in glass, a handle on the top, a winding screw on the side, an oil container and a metal plaque on the base. LUCAS No. 636 KING of the ROAD JOS.LUCAS LTD. B'HAMcar components, automobile lighting, lucas industries, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone vertebrae. Advanced stage of calcification as indicated by deep pitting. Off white to grey.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Vertebrae, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Whalebone The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The bone of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as whalebone. Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale bone Vertebrae with advanced stage of calcification as indicated by deep pitting. Off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale Jaw Bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone during the 17th, 18th, 19th and early 20th centuries was an important industry providing an important commodity. Whales from these times provided everything from lighting & machine oils to using the animal's bones for use in corsets, collar stays, buggy whips, and many other everyday items then in use.Whale jaw bone one side, long & curved with advanced stage of calcification off white to grey.None.warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whale bones, whale skeleton, whales, whale bone, corsets, toys, whips, whaleling industry, maritime fishing, whalebone -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Vessel, Whaleboat, Flagstaff Hill Boat Builders, 1989

The Huon Pine whaleboat was made on site by the boat builders at Flagstaff Hill in1989, of the clinker-planked construction method. Whaling was carried out in the 1790s up until the 1970s in the Southern Ocean off the coast of Australia, including southwest Victoria. The whales were hunted for their oil, baleen, meat and other products. It was a lucrative but very dangerous occupation. The small whaleboats with their five crew members were easy to maneuver but also easily overturned by a writhing whale. The Southern Right whales had desirable attributes; they came close to shore, they were slow swimmers and they floated when dead - hence the name 'Right' describing the right whale to hunt. The whale population was greatly reduced until 1979 when the Australian government prohibited whaling. These whales still visit the area annually to breed in the shallow bays along what is now called the Shipwreck Coast of Victoria. The whaleboat represents a significant time in Australia between the 1790s and 1979, when the whaling trade was carried in this area, and around Australia, providing employment and meeting the demand for whale oil, meat and other products. A time during which the population of whales was greatly depleted. Australian whaleboat; a long narrow vessel constructed of clinker-planked Huon Pine timber. It has provision for a crew of 5five oarsmen and a sweep or helmsman. Made in 1989.flagstaff hill maritime museum and village, maritime museum, maritime village, great ocean road, shipwreck coast, whaleboat, vessel, clinker built, huon pine whaleboat, whaling, whaleling industry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Falls of Halladale 1886 - 1908, 1908

The photograph shows some of the hundreds of sightseers who visited the site of the wreced Falls of Halladale, watching the fully rigged ship slowly disintegrate over two months or more. The Falls of Halladale was a four-masted sailing ship built in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for the Pacific grain trade. The ship was sturdy. It could carry maximum cargo and maintain full sail in heavy gales. It was one of the last of the ‘windjammers’ that sailed the Trade Route, and one of the first vessels to include fore and aft lifting bridges, which kept the crew safe and dry as they moved around the decks in stormy conditions. It was one of several Falls Line ships named after the waterfalls of Glasgow by its owner, Wright, Breakenridge & Co of Glasgow. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000. It included 56,763 tiles of American slate roofing tiles, 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items (a list of items held at Flagstaff Hill Maritime Village is included below). The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m off-shore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four-masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). It was one of the last ships to sail the Trade Routes. The ship was one of the first vessels to have fore and aft lifting bridges. The wreck is an example of an International Cargo Ship and represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Photograph, behind glass in a timber frame. Image of a group of people seated on the ground with the stranded barque, the Falls of Halladale, in full sail nearby in the water. The photograph was taken at Peterborough, southwest Victoria, on November 13th 1908. A typed inscription is below the picture.Typed beneath photograph "Falls of Halladale 1886 - 1908"flagstaff hill, maritime museum, maritime village, flagstaff hill maritime museum and village, great ocean road, shipwreck, peterborough, falls of halladale, 1908, barque, scotish, 4-masted, sailing ship, 1886, glasgow, trade, grain trade, cargo, windjammer, fore and aft bridges, falls line, wright, breakenridge & co, american slate, roofing tiles, barbed wire, sewing machines, oil, benzene, port campbell rocket crew, sightseers, salvage, captain david wood thomson, captain thomson, navigational error, clyde-built, russell & co -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncPhotograph - Bradford Kendall, Wodonga

Bradford Kendall was established in 1922 by Lesley Bradford and Jim Kendall, investing their winnings on a race horse. They both previously worked at the BHP Steel Works. They gained contracts with the railways and mining industry. During World War II they also manufactured armaments. During the boom of the 1950s they established several foundries in South Australia, Western Australia, Queensland and Victoria. Bradford Kendall Ltd Wodonga foundry was established in 1954. It melted down old railway wheels, rails and redundant machinery to produce a range of low-alloy steel products, especially for earth-moving vehicles, railways, oil rigs and sugar factories. Wodonga was ideally placed as a change point between the different rail gauges of Victoria and New South Wales, close to the Hume Highway and the Snowy Mountain Scheme. The first sod for the site was turned on 2nd June 1954 and the first melt and pour of molten metal at Wodonga took place on 7th July 1954. Bradford Kendall Plant No.5 in Wodonga became one of the most profitable foundries in the Bradford Kendall group. Bill Black became the first plant Manager, a position he held for 30 years. Another long term employee was Pat Gooding who began work at a 15 year old and retired for the position of Bradken foundry Manufacturing Manager 51 years later. In the early 1980s, Australian National Industries Ltd bought Bradford Kendall and other heavy engineering companies. The Wodonga foundry with its (then) 170 or so staff became part of Bradken Consolidated along with nine other foundries in Australia and New Zealand. In 1989, Kerry Packer’s Consolidated Press Holdings Ltd took control of ANI. In January 1999, Smorgon Steel Group acquired ANI, which included the Bradken business. The company changed hands again in 2001 when Smorgon Steel Group sold Bradken to Castle Harlan Australian Mezzanine Partners (CHAMP). In 2016 negotiations began for Bradken to be taken over by Hitachi Construction for A$689 million. In April 2017 Bradken became a wholly owned subsidiary of Hitachi Construction Machinery Co. Limited.A collection of black and white images and advertising for Bradford Kendall (Bradken) Wodonga.bradford kendall, wodonga industries, wodonga businesses