Showing 217 items

matching farm tool

-

National Wool Museum

National Wool MuseumTool - Numnuts, Numnuts, 2020

Worldwide, more than 100 million lambs are castrated, and their tails are docked each year. Numnuts is a technological innovation to improve animal welfare. It combines traditions with innovation. In the mid-1990s it was scientifically shown that the immense pain felt during castration and tail docking could be significantly reduced with the use of anaesthetic. For the next 15 years, the industry said the cost the welfare devices and development were too high. But todays ethical consumer has demanded that sheep have no more pain. Initiated in Glasgow in 2009, Numnuts took nearly a decade to develop. Here you can see five stages of development, from an early prototype to the Numnuts device farmers use today. Each phase of development took years of on-farm trails to achieve the final product. Today there is even NumOcaine, an approved local anaesthetic used by Numnuts. Using the simple elastrator ring and adding an anaesthetic injector, Numnuts delivers pain relief during tail docking and castration. In the world’s first rubber ring applicator with a pain relief delivery mechanism. Through innovation and consumer pressure the wool industry is going through a moment of rapid change.8098.1 - Numnuts tool made with stainless steel and black, orange and grey plastic. 8098.2 - Glass bottle with orange and grey plastic nozzle containing water for injection. 8098.3 - Yellow plastic case containing 12 stainless steel needles 8098.4 - 10 green plastic elastrator rings 8098.5 - Product cardboard box with the product image on the front8097.2 - on label - For animal treatment only WATER FOR INJECTION 100mL 8097.3 - On case - numnuts 12x Veterinary Hypodermic Needles On needdles - 18G 8097.5 - Numnuts targeted pain relief for tail docking and castrationnumnuts, tools, sheep, castration, docking -

National Wool Museum

National Wool MuseumTool - Water Pump, c.1960

A windmill may be considered one of the most iconic sights of Australian Farming life. A pump like this rest at the heart of all such windmills, turning wind energy into water for farmers both here in Australia and worldwide alike. The water windmills access is referred to as an aquifer, an underground layer of water trapped in rocks but accessible with use of water wells and windmills. Australia is home to an underground aquifer known as the Great Artesian Basin. It is the largest and deepest aquifer in the world. Stretching over 1,700,000 square kilometres, the Basin underlies nearly a quarter of the continent including most of Queensland, the south- east corner of the Northern Territory, the north-east part of South Australia and the northern part of New South Wales. The basin is 3,000 metres deep in places and is estimated to contain 64,900 cubic kilometres of groundwater. To try and give this number context, a megalitre is a million litres. The Great Artesian Basin contains 65,000 million megalitres of water. This would be enough to cover all the land on the planet in almost half a metre of water.Lift style piston pump typical of an Australian farm connected to a multi-bladed windmill. Bronze cylindrical construction coming up from removable wood base. Rotating lever is above outlet pipe which would send water to the storage tank.windmill, australian farming, great artesian basin, aquifer -

National Wool Museum

National Wool MuseumTool - Grinder, 1960-69

Cooper S.E. Ball Bearing Grinder made and guaranteed by Sunbeam Corporation Limited. Grinders like this example have been made the same since the early 1900s, with this grinder thought to have been produced in the 1960s. It is belt driven, with the other end of the belt being attached to an engine; the same engine that would have powered the overhead shearing equipment in shearing sheds. It was common for shearing teams to bring their own equipment, especially pre-1960 as most shearing sheds were not connected to power, and shearers preferred to work with their own equipment. The engines that powered the shears and grinder were typically fuelled with kerosene or petrol. The large circular disks are attached to the bolt that protrudes from the grinder and fastened tightly with a nut. An example of seeing a similar grinder in action can be found on the following link - https://www.youtube.com/watch?v=O7eimI_Gm9o. Inventor Frederick Wolseley made the world's first commercially successful power-shearing system in Australia in 1888. US company Cooper, which had been founded in 1843 as a maker of sheep dip, began selling Wolseley equipment in the USA in 1895. The Chicago Flexible Shaft Company successfully entered the power-shearing market a few years later and entered a joint venture with Cooper. It set up a branch in Sydney and sold shearing sets, and engines to power them, into the Australian market. In 1921 the US parent company, realising it needed to make products whose sales were not as seasonal as those of shearing equipment, made its first household appliances and branded them Sunbeam. In 1933, changes in exchange rates and taxes led the company to manufacture engines and shearing equipment in Australia via subsidiary Cooper Engineering, which changed its name to Sunbeam in 1946. Although most Australians know of this company as a major manufacturer of household appliances, its rural division flourished and retained the Sunbeam name for shearing equipment even after it was taken over by New Zealand company Tru-Test in 2001. The grinder is formed from a central arch shaped block of green painted metal. Much of this paint has been lost to age, leaving the grinder in a ‘farm used’ condition with much surface oxidation present. On the front of the arch is a specification plate, reading “Cooper S.E. ball bearing grinder. Made and guaranteed by Sunbeam”. At the foot of the arch, three bolt holes are found for securing the grinder to the base of a solid wooden surface. Two of the bolt holes are found on the front of the grinder, with another found on the rear. From the central arch, a bolt protrudes to the right of the grinder. This large bolt is for securing a grinding plate to the grinder. Above the central arch is a pendulum which holds the comb / cutter that is being sharpened. From the pendulum, a large arm extends down (not pictured) to meet and strike the plate spinning at a rapid speed. On the left-hand side of the central arch of the grinder, a wheel is found which a belt is attached to for power. This belt is then attached to a separate engine, spinning the wheel and hence powering the grinder. The wheel is partially covered with a section of protective bent tube, designed to provide protection from the rapidly spinning wheel. Below this wheel is the belt shifter. It is designed to move the protective bent tube from one side of the grinder to the other, to accommodate the grinder in the setup of different shearing sheds. The two separate grinding plates are identical. They have a slight slope for sharpening the comb and cutters in the correct method, with a slight bias towards the base, or “tooth”, of the equipment. The disks have a large central bolt for attaching to the grinder. They have tags on the horizontal axis of the grinding plates, for securing the plates in transportation, and to help with initial alignment when setting up the grinder. The reverse of these grinding plates has the same green painted metal finish found on the grinder. This paint is also in a ‘farm used’ condition, with surface oxidation present. The grinder would be provided from the factory with a comb holder, shifter for securing the grinding plates, emery cloth and emery glue. The emery cloth is what does the actual grinding and is applied to the grinding disks, replacing once well worn. These items can be seen in the final images in the multimedia section, showcasing advertising for this grinder. Plate. Inscribed. “Cooper / S.E. BALL BEARING GRINDER / MADE AND GUARANTEED BY / Sunbeam / CORPORATION LIMITED / SYDNEY MELBOURNE / ADELAIDE BRISBANE ”sheep shearing, shearing equipment, sunbeam, grinder -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel, used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheelwright's Spanner, c1920

Hand forged steel spanner used for tightening grease cap to end of axle.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Vice, c1920

Blacksmith's vice called a leg vice. It rests on a solid block on the floor and secured on the bench with bolts. The vice was made of wrought iron with hardened steel jaws.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Hand forged steel used for holding hot steel whilst it was being forged.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

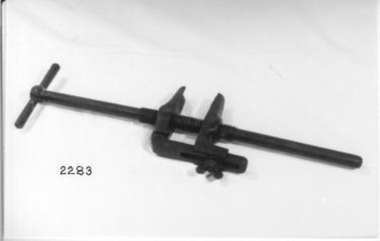

Whitehorse Historical Society Inc.Tool - Clamp, c1920

Clamp - consisting of two tightened by 'T' screw having a left and right threads. Possibly used by a wheelwright.rural industry, farm machinery, trades, wheelwrighting -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Farrier's Hammer, c1920

Hand forged steel used by farrier for shaping horse shoes.rural industry, farm machinery, trades, farriery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Sledge Hammer, c1940

Made by a power hammer. Solid Steel.1791 12 lbs Brales Corural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Hand forged steel used for holding hot steel whilst it was being forged.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

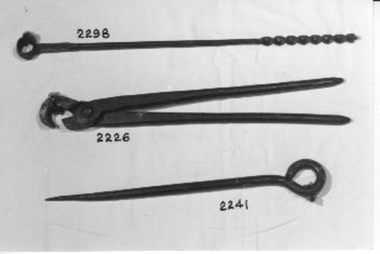

Whitehorse Historical Society Inc.Tool - Wood Auger, c1920

Hand forged steel, used for boring holes through timber.rural industry, farm machinery, trades, carpentry -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Coke Sieve, c1920

Sheet metal frame with metal mesh sieve. Used for sieving 'breeze' or dust from coke to help in maintaining a clean fire.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Anvil, c1920

See NA2323 for history of donor and photo.Anvil - made from forged steel and used by the blacksmith as a table to hand forge hot steel etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel; whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Tongs, c1920

Made from hand forged steel, used for holding hot steel whilst being forged.trades, blacksmithing, rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Gouge

Straight metal handle with knob on top and scoop at end.rural industry, farm machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Post Drill Set

Used by donor's father, John Palmer, on his parents dairy farm at Mupunga East and later on his own dairy farm at Allansford. From 1966 until 1992 used in Mitcham and Blackburn.A post mounted drill stand with a gearing arrangement driven by a handle. The depth of drill is adjusted by a large red wheel which raises or lowers the drill. There are other adjusting devices on the drill.Buffalo Forge Co, Buffalo N.Y. No 151 (on both sides of main casting)trades, tools, metalworking -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Wheel

Iron wheel with long shaft - part of a plough.rural industry, farm machinery -

Whitehorse Historical Society Inc.

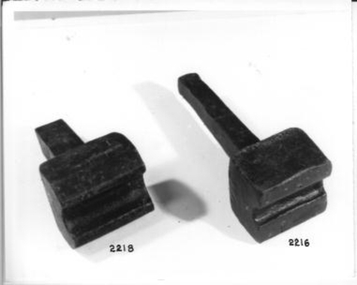

Whitehorse Historical Society Inc.Tool - Bottom Swage, c1920

Bottom swage used with top swage to round of rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom Swage, c1920

Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Tool - Bottom swage, c1920

Bottom swage used with top swage to round up rods etc.rural industry, farm machinery, trades, blacksmithing