Showing 168 items

matching grinding

-

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

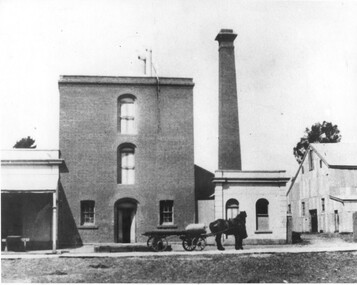

Tarnagulla History ArchivePhotograph of Flour Mill, Tarnagulla, Flour Mill, Tarnagulla, circa 1920 (original image)

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. Thomas Comrie was the proprietor and was responsible for the Mill being built. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. This is a poor copy of an older original. Copy probably made by Murray Comrie in the late 1960s. Monochrome photograph of the Flour Mill in Tarnagulla, around 1920. Cropped version of 2019.0047.tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Federation University Art Collection

Federation University Art CollectionWork on paper - Printmaking - Multiplate Etching, Dean Bowen, 'The Car Park' by Dean Bowen, 1994

Dean BOWEN (1957 -) Born Maryborough, Victoria Dean Bowen's work combines humour and gentle irony with technical proficiency to explore the world around him. 'The car park epitomises qualities found in the best of his post 1990 work. Born out of the daily grind of stop-start commuting by car along Melbourne's Punt Road to and from his former workplace, the feeling of this large work (just over two metres long) is of duality. On the one hand there is the crowded chaos of a relentless number of cars choking the roads; on the other, order is imposed in his aerial view of cars 'parked' around intersecting roads as well as the actual charting of roads and interstitial spaces. Zooming in as though from above, cars are alternately cross-sectioned and flattened in outline. Despite his denial that there is nothing reminiscent of Aboriginal art in this work, to the onlooker there are quite a number of similarities. Not that he presumes anything of the Aboriginal experience or imagery (indeed, that it is unconscious is probably the only reason it works), such qualities are nevertheless present. The aerial perspective, for example, is so like the Aboriginal system of painting song lines and dreaming tracks from above. And as seen in the famous 'X ray' paintings of Arnhem Land, his cars and buildings are cross-sectioned to reveal the objects (usually humans) within. The impression of Aboriginally is further given by his use of earthy browns and by the outlining of shapes (cars, roads, trees).' (Susan McCulloch) This work was selected by the Art Acquisitions Committee (1995) to be placed in the 1870 Founders Hall at Mt Helen Campus. The Federation University Art Collection features over 2000 works and was listed as a 'Ballarat Treasure' in 2007.A multiprint etching depicting a carpark that won the 1994 Fremantle Print Award;Edition 12/20art, artwork, dean bowen, bowen, etching, multi-plate etching, printmaking, printmaking etching, carpark -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRazor Strop

This razor strop is made like a leather strap. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Double Swing Razor Strop. Use for honing razors.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, swing razor strop, barber's equipment, shaving equipment, personal accessory -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden paddle strop, (or raxor strop or cushion strop). Strop has two leather sides, numbered 1 and 2, on a slotted paddle. Marked on handle “Hamon”. Sides are numbered 1 and 2. Has two slits in body of strop. "Hamon" stamped on handle. "Hamon" stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wooden strop, paddle strop, strop, razor strop, shaving accessory, barber's equipment, personal grooming -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Has two slits in body of strop. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, strop, paddle strop, personal effects, shaving equipment, razor strop, barber's equipment -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePaddle Strop

This razor strop is called a paddle strop. ABOUT STROPS Straight razors and cut throat razors were the major tools for shaving before the safety razor was invented in the 1880’s and even today specialty shaving shops still sell the straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap using a shaving brush with boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade’s edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are hand held. To use the strop draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish. Wooden strop, paddle strop design (sometimes called razor strop). Has leather attached to one side. Sides are numbered 1 and 2. Has two slits in body of strop. Stamped Hamon Paris France. "Hamon Paris France. "flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, paddle strop, strop, shaving equipment, personal effects, barber's equipment, personal grooming accessory -

Tarnagulla History Archive

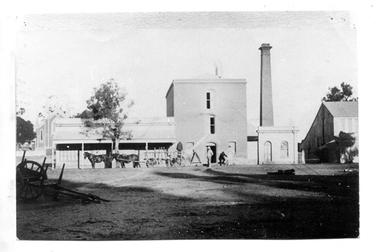

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a poor copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0211Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

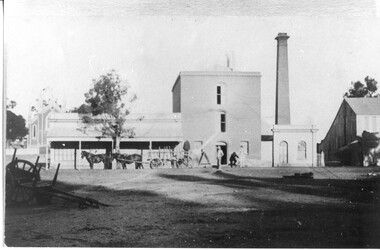

Tarnagulla History ArchivePhotograph of Flour Mill complex, Tarnagulla, Flour Mill complex, Tarnagulla, circa 1882-1920

Murray Comrie Collection. Information written by Murray Comrie: A meeting was called at the Golden Age Hotel on 11th June 1868 when it was resolved to build a flour mill. Thomas Comrie was the proprietor and was responsible for the Mill being built. Tenders were called by H.C. Bristol, in the Tarnagulla Courier of January 10, 1874, for the erection of the mill. Building of the Mill commenced in 1874. Pipes were laid to Company's Dam to obtain water for the Mill's boilers. Steam was got up for the first time on 30th March, 1882. A boiler burst about April 29th. Two men (J.H. Smith and W. Hargreaves) died as a result and two others were seriously injured. The mill commenced operations on 13th June 1882 with Mr. W. Fitzgerald as manager. The Mill operated with grinding stones until 1899 when new rollers and a considerable amount of new equipment was installed, including a new, more powerful engine to drive the Mill. In January 1901, 6,000 bags of wheat were received weekly and it was a common sight to see the streets lined with wagons. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914, wheat came in at the rate of 1500 bags a day with 20,000 bags in storage. Thomas Comrie died on 4th August 1910. The Mill was carried on by his executors, then closed for a short period prior to being sold in September 1918 to a Mr. O. Albert of Talbot. Albert operated the Mill for a few years but during the 1920s it was closed down and then pulled down. It was later re-erected at Mildura where it operated for many years. The far left section of the complex was originally John Pierce's Southern Cross General Store, a wholesale grocer and spirit merchant. It was put up for sale after Pierce's death in 1871, and later incorporated into the Mill complex. This is a reasonable copy of an older original. Copy probably made by Murray Comrie in the 1960s. Monochrome photograph of men, horses and a wagon outside the Flour Mill complex formerly situated on the south east corner of King Street and Commercial Road in Tarnagulla. At far left the Methodist church is partially visible in the background. At far right is part of the Mill's storage shed. Same image as THA-2019.0048Written on reverse: 'M. Comrie'tarnagulla, commerce, agriculture, food production, mill, milling, horses, transport, buildings, commercial road, main street -

Tarnagulla History Archive

Tarnagulla History ArchivePhotograph - Photograph: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Monochrome photograph depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'J. Caldwell and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Tarnagulla History Archive

Tarnagulla History ArchivePostcard - Photographic postcard: Company's Dam and Flour Mill, Tarnagulla, c. 1880 - 1920

Williams Family Collection. On the 20th December 1873 it was reported in the Tarnagulla Courier that arrangements were being made for the erection of a steam flour mill at Tarnagulla. Mr Bristol had purchased the necessary plant which would be erected with as little delay as possible. The site chosen was the premises occupied previously by Mr John Pierce, grocer and wine and spirit merchant, at the corner of King and Commercial Road. These premises were incorporated in the mill building. Suitable buildings for receiving and storing grain and flour had been erected already. On 10th January, 1874 an advertisement in the Courier called for tenders from masons, bricklayers and carpenters for the erection of a flour mill at Tarnagulla for H. C. Bristol, Esq. with all enquiries to be made from G. Minto, Engineer. In December 1881 the proprietors made a request to the Tarnagulla Borough Council for permission to lay pipes to the Municipal Dam, which was generally known as the Company's Dam, and to obtain water from the dam for milling purposes. This was granted. Steam was got up for the first time on 30th of March, 1882. A large quantity of wheat was stored ready for milling. Just prior to 29th of April 1882 the boiler at the mill burst, as the result of which two men, J. H. Smith and W. Hargreaves died and H. Joyce Bousfield, senior and junior, were seriously injured. The mill commenced operations on 13th June, 1882 with Mr W Fitzgerald as manager. The price offered for wheat was thirty-seven pence per bushell. It operated with grinding stones until considerable renovations were done in the early part of 1899 when new rollers and more up to date equipment installed. The mill was then known as the Tarnagulla Flour Mill Co., with Thos. Comrie as proprietor, Mr Fitzgerald was still manager, and Mr T. Leonard was the traveller. Much new equipment was put in and each of the three floors had different processes. The rollers were on the ground floor, the purifiers and elevators reel were on the second floor, plus the clean wheat bin directly over the Ganz rollers. On the top floor was the chop reel, bran reel, inter-elevator reels, brush machine cyclone sack hoist, dirty wheat shaker, clean wheat bin, dust rooms and also double damping rooms. A plant was also erected for the making of an improved quality of wheaten meal, for which purpose special machinery was procured and a pair of stones was left for grinding the meal. A complete plant for the crushing of oats etc was also erected. The driving power of the mill was supplied by a new engine complete with 16 inch cylinder, manufactured and erected by Bousfield & Co. of Eaglehawk. It was fitted with Pickering governors, connected with the cylinder was a super heater. The boiler was tested and all connections etc. overhauled, with much of it being completely renewed. There was a complete network of belts, spouts, elevators etc. all over the building, all conveniently placed. The plans etc for the new plant were drawn up by Mr J. Kilborn, manager of the firm of Bodington & Co., engineers and millwrights of Carlton, which supplied the whole of the machinery, excepting the engine. The work of erection was carried out by Mr Kilborn and his assistants to the entire satisfaction of Mr Comrie, who had gone to considerable expense to bring the mill to a completely up-todate machine, fitted with all of the most modern appliances available. An advertisement on May 6th, 1899 read: "Tarnagulla Flour Mill Co., Patent Roller Flour. Also their Digestive Wheaten Meal specially prepared for Porridge or Bread." In January 1901, 6000 bags of wheat were received weekly at the mill and it was a common sight to see the streets lined with wagons. In May 1902 the mill was lighted by gas and in July 1906 an application was made to the Tarnagulla Borough Council for permission to lay a tram track from the mill to the Railways Station. Council was agreeable to this provided suitable plans were submitted. In 1913, 15,000 bags of wheat were bought at three shillings and four pence per bushell. In January 1914 the mill was renovated. At this time 1500 bags of wheat were coming in daily, with 20,000 bags in storage. On 15th December, 1917 the mill was advertised for sale, to be sold on Friday, 21st December,.1917, on behalf of the Estate of the Late Thomas Comrie, who had died on 4th August, 1910. The Courier at that time recorded him as being responsible for the building of the mill and with being the sole proprietor. The mill was closed, apparently, for a short period. The Courier reported on 13th of September, 1918 that the mill had been sold to Mr O. Albert of Talbot and that it would re-open. An advertisement read: ALBERT. O. & SON, MILLERS. During 1920 the mill was closed and pulled down. It was later re-erected at Mildura where it operated for many years. (by Donald Clark)Photographic postcard, front image depicting view of Company's Dam and the flour mill in Tarnagulla. Handwritten on reverse: 'A Merry Christmas and a Happy New Year, E. Bool' and photographer's stamp 'C. Bock Photo Tarnagulla'.tarnagulla -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Razor Strop, circa 1922

A razor strop such as this one was used to sharpen and polish straight-edged razors. This particular design has a swivel hook with a locking clip that allows for movement as the strop is being used. This strop is branded "Sherlite". On May 5th, 1922 the Commonwealth officially accepted and advertised the Trade Mark Application of Thomas Sherry of Victoria, for the Trade Mark of "Sherlite" to be used under the heading of "Leather, Skins unwrought and Wrought”. Thomas Sherry’s application was to use the word “Sherlite” for detachable soles made of rubberised leather. Straight razors and cut-throat razors were the major tools for shaving before the safety razor was invented in the 1880s and even today specialist shaving shops still sell straight razors. Along with the razor, the process of shaving would commonly involve lathering up shaving soap with a shaving brush that had boar bristles. Men could own several razors and rotate them through the week and some shops sold the razors in a set, a razor for each day of the week. Straight razors could require stropping more than once during the shaving of a heavy beard, and stropping would also be performed at the end of each shave. Honing would only be performed two or three times a year, preserving the blade's edge. A lot of skill was needed to hone and strop the blades of these early razors and the methods to do so were a large part of the curriculum in Barber colleges. The razor would be sharpened on a grinding wheel then honed on sharpening stone and finally finished using a strop. Straight edge razors would usually be sold unfinished and that process would be completed by the customer. A razor strop, usually made from leather, thick canvas, or light timber, would be used to straighten and polish the straight razor for shaving. Strops could also be used to polish other blades such as knives, small metal tools, and chisels. Sometimes an abrasive polishing compound is also used to give a mirror finish. Some strops, such as this one in our Collection, are designed to be used while hanging from a nail or peg, while others are handheld. The person using the strop would draw the spine of the blade down along the strop with the blade following, without putting any pressure on the blade. At the end of the stroke, rotate the blade over its spine then draw the spine along the strop again so that the edge moves away from the top. The finer grade of leather strap is used to give the final finish.Razor strop, leather, and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has a padded, bulbous-shaped leather grip handle, the other end has a metal, swivel hook hanger. Inscriptions painted in gold on leather at the hook end.Razor strop, leather and metal. Sherlite brand, double straps: two straps of different grade leather joined at ends with metal fittings. Stropping faces; sharpening surface is stained red and finishing surface is stained black. One end has padded, bulbous shaped leather grip handle, the other end has metal, swivel hook hanger. Inscriptions printed in gold on leather at hook end.Printed gold lettering stamped “Sherlite”flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shaving leather, shaving accessory, barber’s equipment, barber shop razor strop, razor strop, straight razor, razor and knife sharpener, sherlite razor strop, personal effects, toiletries, thomas sherry -

Flagstaff Hill Maritime Museum and Village

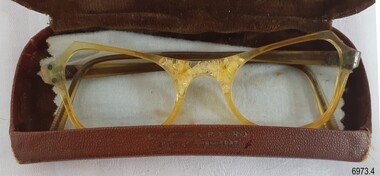

Flagstaff Hill Maritime Museum and VillageFunctional object - Spectacles and Case, Carter & Foord, 1902-1930s

The spectacles and case are an example of eyewear from the early 20th century. The case was made by Carter & Foord of Ballarat. According to the tag inside, the spectacles frame cost three pounds, three shillings and sixpence (£3.3.6). Carter & Foord was established in 1902. The firm advertised as opticians, oculists, watchmakers and jewellers. The staff repaired scientific instruments and were sole agents for the gramophone, demonstrating its advantages whenever there was an opportunity. In 1902 the business was located at 46 Lydiard Street, Ballarat. The staff in the ophthalmic department, under the care of Harold Foord, specialised in sight testing using up-to-date equipment and this service was free of charge. Customers were promised that they would be fitted with glasses guaranteed to correct the most complex sight. Mr F M Clacius performed the grinding of specific lenses. Julia Carter, Harold Foord and Clacius were all formerly from the business Carter & Warner, which had been sold to Frederick Clark around 1903 after Mr Carder passed away. Carter & Foord operated a few doors away from the former business. In 1912 advertisements in the Geelong Advertiser invited the community to visit Harold Foord, of Carter & Foord, to have their eyes examined at no charge. These spectacles are similar to others in the W.R. Angus collection, donated by the family of Dr W R Angus, surgeon and oculist. The W.R. Angus Collection spans the years 1885 to the mid-1900s and includes historical medical and surgical equipment and instruments from the doctors Edward and Thomas Ryan of Nhill, Victoria, with whom Dr Angus worked for several years. Dr Tom and his brother had worked as surgeons including in eye surgery. Dr Tom Ryan performed many of his operations in the Mira private hospital on his premises. When Dr Angus bought into the Nelson Street premises in Nhill he was also appointed as the Nhill Hospital’s Honorary House Surgeon 1933-1938. Dr Angus married Gladys in 1927 at Ballarat, the nearest big city to Nhill where he began as a Medical Assistant and had been Acting House surgeon at the Nhill hospital where their two daughters were born. Dr Angus and his family moved to Warrnambool in 1939, where Dr Angus operated his own medical practice. He later took on the part-time role of Port Medical Officer and was the last person appointed to that position. After convalescing from injury resulting from his service during WWII, Dr Angus studied ophthalmology at the Royal Melbourne Eye and Ear Hospital. He created cosmetically superior artificial eyes by pioneering the use of intrascleral cartilage. Angus received accolades from the Ophthalmological Society of Australasia for this work. He returned to Warrnambool to commence practice as an ophthalmologist, pioneering artificial eye improvements. He had been an Honorary Consultant Ophthalmologist at Warrnambool Base Hospital for 31 years. He made monthly visits to Portland as a visiting surgeon, to perform eye surgery. Both Dr Angus and his wife were very involved in the local community, including the planning stages of the new Flagstaff Hill and the layout of the gardens there. Dr Angus passed away in March 1970.The Carter &O Foord spectacles are significant as an example of early 20th-century eyewear and fashion. They are connected to the history of regional Victoria, being made in Ballarat and purchased for local use. The spectacles are significant for being connected to the W.R. Angus Collection, which is important for still being located at the site connected to Doctor Angus, Warrnambool’s last Port Medical Officer. Dr Angus and his wife brought their young family to Warrnambool in 1938 and he remained a resident until his death in 1970. Early in his profession in the town of Nhill, Dr Angus assisted Dr Tom Ryan in his pioneering use of X-rays and in ocular surgery, and Dr Angus later inherited these items. The W.R. Angus Collection includes these medical instruments and other related equipment and is culturally and historically significant as an example of the medical practice of the late 19th to the mid-20th century. Other items in the collection relate to Dr Angus’ service in the Flying Doctor Service and the Army.Spectacles in a hard brown textured case with rounded corners and a hinged lid. The case is lined with brown velvet. The opaque yellow oval frames, raised at the outer top corners, are decorated with sparkling jewell decorations on the bridge. The arms are reinforced with metal inside. Also in the case is a pale blue cleaning cloth and a cardboard price tag with handwritten text. An inscription in gold lettering is stamped inside the case. The case was made by Carter & Foord of Ballarat. The design of the frames is called ‘ewell These spectacles are part of the W.R. Angus Collection.Stamped: “CARTER & FOORD / STURT ST BALLARAT” Handwritten label: “JEWELL / £3.3.6”flagstaff hill, warrnambool, maritime village, maritime museum, shipwreck coast, great ocean road, dr w r angus, dr roy angus, dr ryan, warrnambool oculist, port medical officer, nhill base hospital, mira hospital nhill, oculist, spectacles, eyewear, glasses, carter & foord, ballarat oculist, w.r. angus collection, ophthalmology, royal melbourne eye and ear hospital., artificial eyes, intrascleral cartilage, eye surgery -

Federation University Historical Collection

Federation University Historical CollectionPhotograph, Melba & Co, 7th Australian Infantry Training Battalion WW1

George Alfred Yung, known as Alf, pictured in the second row, 10th from the left, enlisted on 25/02/1916; embarked on 19/02/1917; was killed during the battle of Menin Gate at Yrpres, Belgium on 20/09/1917. https://www.awm.gov.au/collection/U51447 The 7th Battalion was among the first infantry units raised for the AIF during the First World War. Like the 5th, 6th and 8th Battalions, it was recruited from Victoria and, together with these battalions, formed the 2nd Brigade. The battalion was raised by Lieutenant Colonel H. E. "Pompey" Elliott within a fortnight of the declaration of war in August 1914 and embarked just two months later. After a brief stop in Albany, Western Australia, the battalion proceeded to Egypt, arriving on 2 December. It later took part in the ANZAC landing on 25 April 1915, as part of the second wave. Ten days after the landing, the 2nd Brigade was transferred from ANZAC to Cape Helles to help in the attack on the village of Krithia. The attack captured little ground but cost the brigade almost a third of its strength. The Victorian battalions returned to ANZAC to help defend the beachhead, and in August the 2nd Brigade fought at the battle of Lone Pine. While holding positions captured by the 1st Brigade, four members of the 7th Battalion, Corporal A. S. Burton, Acting Corporal W. Dunstan, Lieutenant W. Symons and Captain F. H. Tubb, earned the Victoria Cross - Burton posthumously. The battalion served at ANZAC until the evacuation in December. After the withdrawal from Gallipoli in December 1915, the battalion returned to Egypt. In March 1916, it sailed for France and the Western Front and entered the front line trenches for the first time on 3 May. The battalion's first major action in France was at Pozieres in the Somme valley where it fought between 23-27 July and 15-21 August. After Pozieres the battalion manned trenches in the Ypres salient in Belgium, before returning to the Somme valley. It saw out the horrendous winter of 1916-1917 rotating between training, working parties and duty in the trenches. In early 1917, the Germans withdrew to the Hindenburg Line and the 7th Battalion participated in the brief advance that followed and then came to a grinding halt before Bullecourt. The battalion was withdrawn from the front line for training on 9 May 1917 and did not return to action until the Ypres offensive of September and October. It fought major battles at Menin Road on 20 September and Broodseinde on 4 October, and then spent much of ensuing winter in the Ypres mud. In March and April 1918 the 7th helped stop the German spring offensive in northern France and later participated in the Allies' own great offensive of 1918, that began with the battle of Amiens on 8 August. The advance by British and empire troops on 8 August was the greatest success in a single day on the Western Front, one that German General Erich Ludendorff described as, "the black day of the German Army in this war". The battalion continued operations until late September 1918. At 11 am on 11 November 1918, the guns fell silent. The November armistice was followed by the peace treaty of Versailles signed on 28 June 1919. In November 1918 members of the AIF began to return to Australia for demobilisation and discharge. In March, the battalion was so reduced that it and the 6th Battalion were amalgamated to form a composite battalion. In turn, this battalion was merged with another, formed from the 5th and 8th Battalions, to form the 2nd Brigade Battalion. https://www.awm.gov.au/collection/U51447army, soldier, alf yung, 7th australian infantry battalion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageRangefinder, E R Watts & Sons, 1930-1945

E. R. Watts and Son, makers of theodolites and other surveying instruments, of 123 Camberwell Road, London. The company was established in 1856 by Edwin Watts at twenty-three he had saved £100 from his earnings to start the business with his staff consisting of one boy and later Alexander Clarkson as an apprentice with the workshop a small room over a Bemondsey stable. Watts' first order was from Negretti and Zambra for a mining dial Alexander Clarkson In the early days the firm worked mainly on marine compasses. Edwin Watts would go down to the Docks to adjust the compasses once they had been installed on the ships. In May 1873 the business moved to larger premises a house with a garden. The workshop was also the home of Mr and Mrs Watts and their five sons and three daughters. By now there were fifteen to twenty men employed by the firm. The company were commissioned to supply the Theodolites and Levels for the construction to the Canadian Pacific Railway in 1881. Towards the end of the century, the firm began to make heliographs continuing to produce them for the government until just before the Second World War when by agreement assigned their manufacture to another firm. 1904 The first dividing engine was completed by George William Watts. It was so remarkable an instrument at the time and for years afterwards, In 1907 Arthur Ames went to Canada and started an organisation in Winnipeg in 1909 this became a separate company called E. R. Watts and Son Ltd. of Ottawa. This firm developed considerably and was eventually with the co-operation of three other instrument companies (Cambridge Instrument Co, Ross, and Negretti and Zambra), were reconstituted as ”Instruments Ltd” of Ottawa and Toronto. During the next ten years, the firm expanded greatly to include glass grinding, leather work, dividing and engraving, testing, adjusting and packing. This expansion was continued during the First World War when workshops were completed and the machinery installed and running within eleven weeks from the start of construction. During the war, a Sergeant Coles, among the rats, lice and mud of the trenches, fitted various bits of scrap into his cocoa tin and made the first Flash Spotter for plotting the positions of enemy guns. Coles was rushed home to the firm's factory where he and George William Watts designed a spotter not made out of a cocoa tin and as a result, the Watts Vertical Force Variometer was developed during WWI. Other Watts instruments made in the First World War included the Light Mountain Theodolites which were taken on Mt Everest expeditions. In 1919 ER Watts and Sons was incorporated as a limited company and in 1939 G. A. Whipple joined the Board of Directors. Shortly afterwards, Frank Charles Watts died having been Chairman of the firm for over 37 years and seen it through the First World War with all its expansions and difficulties. He was succeeded by his brother George William Watts with the vacant post of Managing Director being filled by G. A. Whipple. During the Second World War, the company expanded further and the number of employees rose to well over 1,300. In 1946 Watts acquired 78% of Adam Hilger and the microscope maker James Swift and Son Who were Manufacturers of Theodolites, Levels, Alidades, Meteorological Instruments, Variometers, and many other types of scientific instruments Then in 1948 the company amalgamated with Adam Hilger as Hilger and Watts which was then incorporated as a public company.Naval Rangefinder with a vertical wooden handle, and an arrangement of optical lenses. Three reversible brass inserts calibrated on both sides in yards, correspond to various base heights, (20 and 25 feet, 30 and 35 feet and 40 and 50 feet). They are fitted along the axis of the instrument. When the scale for the appropriate base height is selected and inserted, the carriage can be slid for coincidence and the distance read at the index mark on the sliding carriage.inscribed "Rangefinder Cotton Type Mk II" Calibrated scale up to 5000 yds (50 ft), 5000 yds (35 ft), 4000 yds (25 ft) made by E. R. Watts & Son.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, rangefinder, cotton type, e r watts & sons, naval range finder, marine equipment -

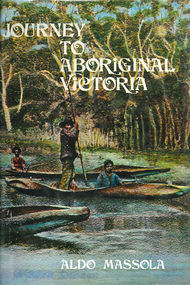

Victorian Aboriginal Corporation for Languages

Victorian Aboriginal Corporation for LanguagesBook, Aldo Massola, Journey to Aboriginal Victoria, 1969

Looks at the Aboriginal community from the time of white contact, across many parts of Victoria. Chap.1; Melbourne - early missions, camp of Native Police, corroboree trees, canoe trees, grave &? headstone of Derrimut; quarries at Keilor, excavation sites at Green Gully &? Keilor; quarry at Mt. William, notes on inheritance of quarries Coranderrk settlement - Barraks grave, notes on his life; Chap.2; Geelong - Yawangi group of the Wothowurong tribe, camping grounds in area quarries; Notes on William Buckley, Gellibrand (a notable Aboriginal), graves in the Western Cemetery; Chap.3; Colac - war between Colac &? Geelong tribes; Mission at Birregurra, reason for failure of Buntingdale Mission; brass plate to Coc-coc-coine; reserve at Elliminyt, native ovens, camp sites, initiation site &? ritual; quarry sites, axegrinding factory, rock pecking &? engraving; dried hand &? 3 Aboriginal skulls found; Chap.4; The south-west coast - middens, camp sites notes on Framlingham Stn., fish traps at Tyrendarra; Chap.5; The far west - massacres of Aborigines near Casterton; camp sites, oven mounds; the first cricket team formed; Aboriginal cemetery; Chap.6; Hamilton - camps; Mount Rouse Station, axegrinding grooves at Nareeb Nareeb, shelters described, fish traps, massacre at Lake Condah; mission; canoes; Chap.7; Camperdown - legend about Lake Bullen Merri; obelisk erected in memory of Aborigines of district especially chief Wombeetch Puyuun; Jarcoort tribe; fish weirs, camps, intertribal fights between Booluc-burrers, Jarcoorts &? Ellengermote groups; bartering place at Mount Noorat; articles traded, legend of Flat-Top Hill; Chap.8; Ballarat - camp at Lake Wendouree; White Stone Lagoon; legends concerning Mt. Buninyong &? waterfalls at Lal-lal; camp sites; pygmy-type implements near Meredith, quarry at Glue Pot Rocks near Durdidwarrah; brass plate of King Billy; Chap.9; Ararat - Tjapwurong territory; camp sites, quarries, shield &? canoe trees; Bunyip belief at Lake Buninjon of Muk-jarawaint &? Pirtkopen-noot tribes, gives legend; stone implements; mill stones; fish weirs; stone arrangement near Lake Wongan; ground drawing of a bunyip, paintings in rock shelter near Mt. Langi Ghiran; Chap.10; Maryborough - camps, oven mounds, rock wells, stone arrangement at Carisbrook; camp sites at Mt. Franklin; Chap.11; Charlton - belief in Mindye (snake); canoe trees, ovens, camp sites, water holes, rock wells, stone implements; method of rainmaking; Chap.12; Horsham-Stawell, The Wimmera - Wotjobaluk land; camps, fish traps at Toolondo; Black Range cave paintings, Flat Rock shelters (detailed account of these paintings); Bunjils Cave; Chap.13; Horsham-Stawell, The Mallee - camp sites, implements; Ebenezer Mission, Willie Wimmera taken to England by Rev. Chase to become a missionary, died in England; Chap.14; The Murray River, Mildura Swan Hill - Battle of the Rufus; ceremonial ground, Lake Gol Gol, canoe &? shield trees; stone implements; camp sites, fire place arrangements; fish traps; oven mounds; Chap.15; The Murray River, Swan Hill-Echuca - legend about Lake Boga; camps, oven mounds, the Cohuna skull, Kow Swamp, method of burial; Chap.16; Shepparton ovens; brass plates of King Paddy of Kotupna &? King Tattambo of Mulka Stn., native well, camps; Chap.17; Wangaratta -camps, quarry, rock holes, the Faithful massacre; grinding rocks at Earlston; Chap.18; The High Plains - Ya-itma-thang; camps, Bogong moth feasts, native paths for trade &? intertribal fights, articles traded; painted shelters; Koetong Ck. Valley, near Mt. Pilot &? near Barwidgee Ck.; Chap.19; Dandenong - water holes, list of 8 holes in Beaumaris - Black Rock area; camps, middens, stone implements (microliths), legend of Angels Cave, stone axes, Native Police Force, Narre Narre Warren Station, legend about rocks on Bald Hill, kangaroo totemic site; Chap.20; Wonthaggi- Yarram - natives visit Phillip Is., murder of William Cook and Yankee by five Tasmanians (listed as Bon Small Boy, Jack Napoleon Timninaparewa, Fanny Waterpoordeyer, Matilda Nattopolenimma and Truganini) near Cape Patterson, men; camp sites, middens, legend of White Rock; Chap.21; Sale - Bairnsdale, The Lakes Country middens, camps; legend at Wulrunjeri; story of a white woman supposedly living with with the Tutangolung tribe, efforts made to prove story; canoe trees; Chap.22; Sale-Bairnsdale, The Inland Braiakolung tribe, camps, implements, canoe &? shield trees; Ramahyuck Mission, grinding rocks, fights with Omeo tribe; native tracks, death through enemy magic - procedure, belief in ghosts; Chap.23; Lakes Entrance and the Country to the east - Kroatungolung people, legend of Kalimna Valley; camps, stones of Nargun, bunyip, devils at Lake Tyers, excavation at Buchan, carbon dates; middens, ochre at Cape Conrad, stone fish-hook file at Thurra River; note on Bidwel tribe; Each chapter gives historical details, early contacts, relationships with settlers; Aboriginal place names and detailed description of sites and geographical features.b&w photographs, b&w illustrations, colour illustrationsgeelong, colac, hamilton, camperdown, ballarat, ararat, maryborough, charlton, horsham, stawell, murray river, shepparton, wangaratta, dandenong, wonthaggi, yarram, sale, bairnsdale, lakes entrance -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . J Moseley. maker and R Knight & J Heath also stamped stamped (Owners)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Moulding Plane . Stamped HB on one end and 8 on otherflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Moulding Plane J Moseley & Son maker also stamped (Previous Owners) HIT & E Dunstan, RA Dixon with an N inside a W flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. John Moseley & Son: Records indicate that before 1834, the firm is listed at number 16 New Street, London and according to an 1862 advertisement the shop had been established in New Street since 1730, The Sun insurance records from the time show that John Moseley was the possessor of a horse mill in the yard of his premises, which means that some kind of manufacturing was taking place, as the mill would have provided power to run a saw or perhaps a grinding wheel so the probability is that he did not just sell tools, he made them as well. John Moseley died in 1828 and his will he names his four sons: John, Thomas, William and Richard. To complicate matters he also had brothers with the same first names; brothers Richard (of Piccadilly) and William (of Peckham Rye) are named as two of the executors. Brother Thomas is not mentioned in this will, but became a minister and was one of the executors of brother Richard’s estate when he died in 1856. From John’s will, we also learn that, although the shop was in New Street, he resided in Lympstone, Devon. The family must have had a house in that county for quite some time as both sons Richard and William are baptised in Devon, although John and Thomas were baptised in London. In the 1841 and 1851 census records, we just find William in New Street, but in 1861 both William and Richard are listed there as toolmakers. That Richard was staying overnight at New Street was probably just accidental as in 1851 and 1871, we find him with his wife Jane and children in Clapham and Lambeth respectively. In 1851 Richard is listed as “assistant clerk cutlery warehouse” and in 1871 as “retired plane maker and cutler”. Although the actual place of work is not stated, one may assume he worked in the family business. 1862 is a year full of changes for the firm. In that year, William had a new property built at 27 Bedford Street. In the catalogue for the 1862 International Exhibition, 54 Broad Street (later 54-55 Broad Street) is listed for the first time, which may very well coincide with the split of the business into a retail and a wholesale branch. Around the same time, they must have moved from New Street to 17 & 18 King Street because their manufacturing premises had been pulled down to form the New Street from Cranbourne Street to King Street. In January 1865, William died and Richard continued the business. In 1867, the partnership he had with his son Walker and Thomas Elis Hooker, is dissolved. Richard continued tool making at King Street and Bedford Street. Richard retired somewhere between 1867 and 1871, but the business continued. The business is taken over by W M Marples & Sons and tools continued to be made in London until 1904 when manufacturing relocated to Sheffield. A vintage tool made by a well documented company, this item was made commercially for firms and individuals that worked in wood and needed a tool that could produce a ornamental finish to timber. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture, door trims etc or other items had to be accomplished using hand tools and in particular one of these types of planes. These profiled planes came in various shapes and sizes to achieve a decorative finish. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Side Bead Single Box moulding plane J Moseley & Sons maker also stamped Healy 188 High Street Poplar Surrey (retailers) marked (owners A Bowen & J W Gower with a symbol "M"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, moulding plane, plane, j heath, moseley -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Mid to Late 19th Century