Showing 138 items matching "ship engines"

-

Bendigo Historical Society Inc.

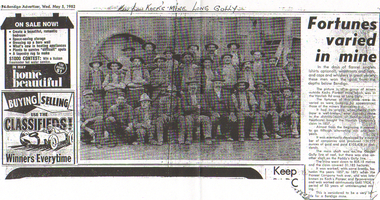

Bendigo Historical Society Inc.Newspaper - LONG GULLY HISTORY GROUP COLLECTION: KOCK'S MINE WORKERS

The initial partnership in a quartz crushing plant between Henry Koch, Simon Albert and Charles Wallin was dissolved in 1860 with Koch becoming the sole owner. In 1866 the crushing plant consisted of a 50 hp engine and 48 stamping heads capable of crushing 600 tons of quartz per week. By 1902 there were 72 stamps and this was by far the largest crushing plant in the area, serving many quartz mines. Henry Koch (1800-1889) was a German sailor who signed off when his ship reached Melbourne in 1851. Having heard of the gold discovery he proceeded to Bendigo where he was initially employed in puddling in the Myers Flat area. He was soon employed and then made partner in a quartz crushing plant that he became sole owner of in 1860. He was also landlord at the British and American Hotel and the Silver Mines Hotel. HE also started the Perseverance United gold claim. He married Anna Maria Theresia Heinz in 1857. In 1872 he sold the crushing plant for 75,000 pounds and took his family back to Germany. He resumed his trade as a ship builder although he maintained many Bendigo mining interests.Photocopy of an article from the Bendigo Advertiser, dated 5/5/1982 titled Fortunes carried in mine. Written above the photo is: Men from Kock's Mine Long Gully. One man is wearing a suit and the rest are in work clothes. The mine was worked, with some breaks, between 1857 and 1871 when the Pioneer Company took over, and was later known as Koch's Pioneer and Perseverance and worked continuously until 1924, a period of 53 years of uninterrupted mining.bendigo, history, long gully history group, the long gully history group - kock's mine workers, bendigo advertiser 5/5/1982, kochs pioneer mine, henry koch, havilah company's claim, garden gully line of reef, paddy's gully line, koch's pioneer and perseverance -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Negative - ALBERT RICHARDSON COLLECTION: KOCH'S PIONEER CRUSHING BATTERY (EARLY PERIOD)

The initial partnership in a quartz crushing plant between Henry Koch, Simon Albert and Charles Wallin was dissolved in 1860 with Koch becoming the sole owner. In 1866 the crushing plant consisted of a 50 hp engine and 48 stamping heads capable of crushing 600 tons of quartz per week. By 1902 there were 72 stamps and this was by far the largest crushing plant in the area, serving many quartz mines. Henry Koch (1800-1889) was a German sailor who signed off when his ship reached Melbourne in 1851. Having heard of the gold discovery he proceeded to Bendigo where he was initially employed in puddling in the Myers Flat area. He was soon employed and then made partner in a quartz crushing plant that he became sole owner of in 1860. He was also landlord at the British and American Hotel and the Silver Mines Hotel. HE also started the Perseverance United gold claim. He married Anna Maria Theresia Heinz in 1857. In 1872 he sold the crushing plant for 75,000 pounds and took his family back to Germany. He resumed his trade as a ship builder although he maintained many Bendigo mining interests.Envelope containing a negative of Koch's Pioneer Crushing Battery. Image shows large building, chimney on left. Negative not scanned.bendigo, mining, koch's pioneer crushing battery -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - Norman Penrose collection: Views of Bendigo No.31

The initial partnership in a quartz crushing plant between Henry Koch, Simon Albert and Charles Wallin was dissolved in 1860 with Koch becoming the sole owner. In 1866 the crushing plant consisted of a 50 hp engine and 48 stamping heads capable of crushing 600 tons of quartz per week. By 1902 there were 72 stamps and this was by far the largest crushing plant in the area, serving many quartz mines. Henry Koch (1800-1889) was a German sailor who signed off when his ship reached Melbourne in 1851. Having heard of the gold discovery he proceeded to Bendigo where he was initially employed in puddling in the Myers Flat area. He was soon employed and then made partner in a quartz crushing plant that he became sole owner of in 1860. He was also landlord at the British and American Hotel and the Silver Mines Hotel. HE also started the Perseverance United gold claim. He married Anna Maria Theresia Heinz in 1857. In 1872 he sold the crushing plant for 75,000 pounds and took his family back to Germany. He resumed his trade as a ship builder although he maintained many Bendigo mining interests.Sepia coloured photograph of Koch's Pioneer quartz crushing plant, Long Gully. The phot shows Perseverance United claim, Wind-mill and hill in the distance. N.J. Caire phot Sandhurst.Casey & Wenborn's print. Forbes & Holmes agentsviews of bendigo, n.j. caire, sandhurstr, quartz crushing plant, kock -

Bendigo Historical Society Inc.

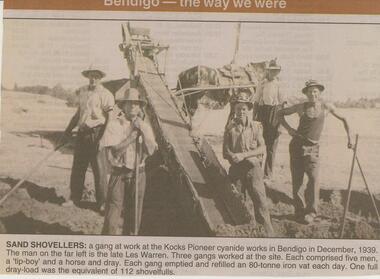

Bendigo Historical Society Inc.Newspaper - JENNY FOLEY COLLECTION: SAND SHOVELLERS

The initial partnership in a quartz crushing plant between Henry Koch, Simon Albert and Charles Wallin was dissolved in 1860 with Koch becoming the sole owner. In 1866 the crushing plant consisted of a 50 hp engine and 48 stamping heads capable of crushing 600 tons of quartz per week. By 1902 there were 72 stamps and this was by far the largest crushing plant in the area, serving many quartz mines. Henry Koch (1800-1889) was a German sailor who signed off when his ship reached Melbourne in 1851. Having heard of the gold discovery he proceeded to Bendigo where he was initially employed in puddling in the Myers Flat area. He was soon employed and then made partner in a quartz crushing plant that he became sole owner of in 1860. He was also landlord at the British and American Hotel and the Silver Mines Hotel. HE also started the Perseverance United gold claim. He married Anna Maria Theresia Heinz in 1857. In 1872 he sold the crushing plant for 75,000 pounds and took his family back to Germany. He resumed his trade as a ship builder although he maintained many Bendigo mining interests.Bendigo Advertiser ''The way we were'' from 2002. Sand shovelers: a gang at work at the Kocks Pioneer cyanide works in Bendigo in December, 1939. The man on the far left is the late Les Warren. Three gangs worked at the site. Each comprised five men, a 'tip-boy' and a horse and dray. Each gang emptied and refilled an 80-tonne iron vat each day. One full dray-load was the equivalent of 112 shovelfuls. The clip is in a folder.newspaper, bendigo advertiser, the way we were -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Foyle Photographic Studio, 1908

The photograph is of the sailing ship Falls of Halladale. The ship is in shallow water at Peterborough where it sank on November 14th 1908. The inscription on the photograph reads "Nov 4th 1908". The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. The photograph shows the ship Falls of Halladale in full sail, demonstrating the sails used for power at sea.A sepia landscape photograph; image of a sailing ship in shallow water in full sail. The vessel is the"Falls of Halladale" aground off Peterborough 1908. A figure is in the foreground. Photographed in 1908 by Foyle of Warrnambool. A pencil inscription on the back is underlined. A white sticker is attached.In pencil on reverse "The Falls of Halladale / Wrecked at Peterborough / Nov 4th 1908" [Note: the ship was wrecked on Nov 14th 1908] On white sticker "131"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, photograph, falls of halladale, sailing ship, vessel, shipwreck, foyle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Original image recorded between 14 Nov 1908 and early Jan 1909

The photograph represents the original complete landscape (southerly) view of the FALLS OF HALLADALE shipwreck which occurred at 3 am on the 14th of November 1908. This image includes three groups of well-dressed Edwardian sightseers on the clifftop and a rocky headland. Subsequent reproductions of this well-known image have been cropped to a striking portrait view, emphasising the vertical line of the masts and sails of the sailing ship, and excluding the groups of sightseers on the adjoining headland. The small girl in the foreground and the loose topsail on the foremast are common to both the landscape and the cropped portrait images of this memorable scene. The photograph was taken at an early stage of the ship’s final days, somewhere between the date of her grounding in mid-November 1908 and early January 1909, when salvagers began dynamiting her masts to get to the cargo in her holds. The heavily laden FALLS OF HALLADALE was 102 days out of New York when the swell of the Southern Ocean lifted her onto the rocks near Peterborough. At the time she was sailing at six knots in a light breeze, her sails fully set and on an ENE tack. Mist over the land created an optical illusion of a distant horizon and the crew believed they were at least ten miles off the coast. When high cliffs loomed up out of the darkness it was too late in the light conditions to change tack or let go the anchors. Within minutes of running aground, her decks were awash and the holds filling with water. Captain Thomson and his 29 crew took to the boats, leaving the vessel stranded on the reef, looking awkwardly graceful in her predicament, firmly wedged between two parts of the reef and with all her square-rigged sails still set, FALLS OF HALLADALE provided a landmark visible for miles. Over the following two months, she attracted hundreds of sightseers, including contemporary photographers. A Court of Marine Inquiry at Melbourne on 30 November 1908 found Captain Thomson guilty of a gross act of misconduct ― in that he carelessly navigated the ship, neglecting to take proper soundings and failing to place the ship on the port tack before it was too late to do so. His Master’s Certificate of Competency was suspended for six months and he was ordered to pay £15/15/- toward the costs of the inquiry. It was an expensive outcome for the captain but his error provided many weeks of inexpensive entertainment for coastal residents and visitors to Peterborough. To judge from the standard of formal dress in this photograph, visiting the wreck was considered a special occasion as well as a popular one. Falls of Halladale: - The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co. they standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29The shipwreck of the FALLS OF HALLADALE is of state significance: Victorian Heritage Register No. S255. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Black and white photograph on cream-coloured backing card and in good condition. Description of Image: Quadrant 01, vessel with full set of sails perched on reef with stern submerged; Quadrant 02, predominantly clear sky over flat calm sea; Quadrant 03, two groups of standing sightseers on rocky promontory with three individuals approaching from far left foreground; Quadrant 04, fifteen well dressed sightseers seated on grassed cliff top including one child and six women. There is a deliberately obscured inscription in white ink along lower border or foreground of photograph.Letters in upper case and white contrast stretching across the grassed foreground of photograph have been smudged over by development process and are largely indecipherable. However rear of backing board of identical but reduced image Reg. No. 3207 bears pencilled words “Mrs Francis” and “Wreck of ‘Falls of Halladale’ Peterborough 1908”, which accords with what remains of the initial inscription.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, falls of halladale, shipwreck spectacle, shipwreck photograph, peterborough reef, edwardian sightseers, russell & co. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Original image taken between 14 November 1908 and early January 1909

The photograph was taken towards the ESE from Peterborough headland. It reproduces an original landscape view of the FALLS OF HALLADALE shipwreck which occurred at 3 am on 14 November 1908 (and confirms that the vessel was on an ENE tack at the time of the collision). The image includes three groups of formally dressed Edwardian sightseers on the cliff top and an adjacent rock ledge. Subsequent versions of this well-known image are usually cropped to present a striking portrait view, emphasising the vertical lines of the ship’s masts and sails, and excluding the groups of sightseers on the right hand of the original image. The small girl in the foreground and the loose sail on the foremast are common to both the landscape and edited portrait versions of this memorable scene. The photograph was taken at an early stage of the ship’s final days, somewhere between the date of her grounding in mid-November 1908 and early January 1909 (when salvagers began dynamiting her iron masts so they could get to the valuable cargo still in her holds). Firmly wedged between two parts of the reef and with all of her square-rigged sails fully set, the FALLS OF HALLADALE provided a spectacle for many miles along the coast. Over these weeks she attracted hundreds of sightseers, and photographers, before the pounding seas finally broke her weakened hull and she disappeared back into deeper waters. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., they standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29The shipwreck of the FALLS OF HALLADALE is of state significance: Victorian Heritage Register No. S255. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976). The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Photograph; sepia-toned black and white, mounted on grey card. Image of a fully rigged sship, the Falls of Halladale, stranded near the shore with a group of people in the foreground seated on the ground. The photograph is well-worn. Description of Image: Quadrant 01, vessel with full set of sails perched on reef with stern submerged; Quadrant 02, predominantly clear sky over flat calm sea; Quadrant 03, two groups of standing sightseers on rocky promontory with three individuals approaching from left foreground; Quadrant 04, fifteen well-dressed sightseers seated on grassed cliff top including one child and six women. There is a deliberately obscured inscription in white ink along the lower border or foreground of the photograph.Lettering of white uppercase in grassed foreground of initial image is smudged out by subsequent development process and largely indecipherable. However pencilled writing on rear of card ― “Mrs Francis” and “Wreck of ‘Falls of Halladale’ Peterborough 1908”.flagstaff hill maritime village, shipwreck coast, peterborough reef, shipwreck photograph, falls of halladale, warrnambool, flagstaff hill, shipwrecked image, flagstaff hill maritime museum, shipwrecked coast, maritime museum, edwardian sightseers, shipwreck spectacle, photograph, mrs francis, wreck of falls of halladale, peterborough 1908, 1908, peterorough, shipwreck -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sailing Ship, Falls of Halladale 1886 - 1908, 1908

The photograph shows some of the hundreds of sightseers who visited the site of the wreced Falls of Halladale, watching the fully rigged ship slowly disintegrate over two months or more. The Falls of Halladale was a four-masted sailing ship built in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for the Pacific grain trade. The ship was sturdy. It could carry maximum cargo and maintain full sail in heavy gales. It was one of the last of the ‘windjammers’ that sailed the Trade Route, and one of the first vessels to include fore and aft lifting bridges, which kept the crew safe and dry as they moved around the decks in stormy conditions. It was one of several Falls Line ships named after the waterfalls of Glasgow by its owner, Wright, Breakenridge & Co of Glasgow. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000. It included 56,763 tiles of American slate roofing tiles, 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items (a list of items held at Flagstaff Hill Maritime Village is included below). The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m off-shore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four-masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). It was one of the last ships to sail the Trade Routes. The ship was one of the first vessels to have fore and aft lifting bridges. The wreck is an example of an International Cargo Ship and represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Photograph, behind glass in a timber frame. Image of a group of people seated on the ground with the stranded barque, the Falls of Halladale, in full sail nearby in the water. The photograph was taken at Peterborough, southwest Victoria, on November 13th 1908. A typed inscription is below the picture.Typed beneath photograph "Falls of Halladale 1886 - 1908"flagstaff hill, maritime museum, maritime village, flagstaff hill maritime museum and village, great ocean road, shipwreck, peterborough, falls of halladale, 1908, barque, scotish, 4-masted, sailing ship, 1886, glasgow, trade, grain trade, cargo, windjammer, fore and aft bridges, falls line, wright, breakenridge & co, american slate, roofing tiles, barbed wire, sewing machines, oil, benzene, port campbell rocket crew, sightseers, salvage, captain david wood thomson, captain thomson, navigational error, clyde-built, russell & co -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Steamers - Julia Percy, Dawn and Coorong, Chuck Photo Ballarat, Circa 1885

This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool. Shipping was the cheapest and most practical means of carrying produce and goods during the period 1840-1890. Regular domestic steamer services commenced in the Warrnambool district in the late 1850’s and by 1870 the passenger trade was booming. Four coastal traders made regular stops at Warrnambool in the 1880's - S. S. Julia Percy, S. S. Dawn, S. S. Nelson and S. S. Casino. The S.S. Julia Percy (later named Leeuwin) was an iron passenger-cargo steam ship built in 1876. At one point in time the Julia Percy would sail from Warrnambool to Melbourne every Friday and return from Melbourne to Warrnambool every Tuesday. The cost of a return ticket for a Saloon Fare was £1.0.0. The Julia Percy was built in Glasgow by Thomas Wingate & Company, Whiteinch, in 1876 for the Warrnambool Steam Packet Company, which commissioned it for trade in Victoria’s western district. It was first registered in Warrnambool, Victoria in 1876. Two steamships, the Julia Percy and the Nelson, collided on 25th December 1881. The Julia Percy was at that time owned by its first owners, the Warrnambool Steam Packet Company, and she sailed under the command of Captain Chapman. It had left Melbourne the evening of 24th December, with about 150 passengers, sailing in fine weather through Port Phillip Heads around 9pm. It was headed for Warrnambool, Belfast (now named Port Fairy) and Portland. The Julia Percy was off Apollo Bay when Captain Chapman was woken by the ship’s whistle after midnight, the steamer Nelson being on a collision course with the Julia Percy. The Nelson struck Julia Percy midship. Boats were lowered from the ship (apart from a damaged lifeboat) and about 30-40 of the passengers boarded the Nelson. The engine room and the forehold were checked and found clear of water. The company manager, Mr. Evans, had been on the Nelson, so he boarded and inspected the Julia Percy and the decision was made to continue on to Warrnambool with the passengers as there appeared to be no immediate danger. However, Captain Thomas Smith said the Nelson was taking on water, so Julia Percy followed it for about an hour towards Melbourne on standby in case of need. Then Julia Percy turned around towards Warrnambool again. Shortly afterwards the Nelson turned to follow her, the ships stopped and passengers were returned to Julia Percy, and three from Julia Percy boarded the Nelson. Both ships proceeded on their way. Julia Percy passed Cape Otway light afterwards, signaling that there had been a collision. It was discovered later that one of the passengers was missing, then thought to have boarded the Nelson but later thought to have fallen into the sea and drowned while trying to jump from Julia Percy to Nelson. There had been 3 tickets purchased under the same name of that passenger “Cutler”; a father, son and friend named Wordsworth, which had caused quite some confusion. No further mishap occurred to either ship and both the Julia Percy and the Nelson reached their destinations safely. An enquiry was instigated by the Victoria Steam Navigation Board regarding the cause of the accident between the two steamships, in connection with the death of Cutler who was supposed to have lost his life by the collision. The enquiry resulted in Captain Thomas Smith having his master's certificate suspended for six months. The Julia Percy changed hands several times. Its next owner was the Western Steam Navigation Co (1887), managed by Mr. T.H. Osborne (the company’s office was on the corner of Timor and Liebig Streets - its north-western wall is now part of the current Warrnambool Regional Art Gallery.) The Melbourne Steamship Co became the next owners (1890), followed by William Howard Smith and Sons (1901) for use in Queensland coastal trades and then it was bought by George Turnbull in 1903 and used for local mail contract in Western Australia. The Julia Percy was sold to the Melbourne Steamship Company Ltd. (1906) and re-named the “Leeuwin” but continued in her Western Australian coastal run. It was converted into a coal hulk in Melbourne in 1910 as a result of damaged caused when it was driven against the jetty at Dongara during a gale. The ship was eventually dismantled and scuttled off Port Phillip Heads on 28 December 1934. The steamship "Dawn" was a 522-ton coastal trader built in 1876 and the vessel operated around the Victorian west coast from 1877 until 1898 for the Portland & Belfast Steam Navigation Co. sailing between Melbourne and Portland, via Warrnambool. The vessel was then owned in October 1885 by the renamed company, Belfast & Koroit Steam Navigation Co., until March 1896 when its ownership moved to W Howard Smith & Sons Ltd. This Melbourne company used the ship to service most ports around Australia. Captain F. Chapman took over from Captain Jones and served on the SS Dawn from 1898 until 1900 when he took command of the SS Casino. On September 4th 1880, the three masted clipper ship, "Eric the Red" struck Otway Reef, near Cape Otway. The S. S. Dawn, under the command of Captain Jones, was returning to Warrnambool from Melbourne, its sailing time different to its usual schedule. The provedore of the Dawn, Benjamin Lear, heard cries of distress coming through the portholes of the saloon. He gave the alarm and the engines were stopped. Cries could be heard clearly, coming from the land. Captain Jones sent out crew in two boats, and fired off rockets and blue lights to illuminate the area. They picked up the three survivors who were in the long boat from "Eric the Red". Two men were picked up out of the water, one being the owner’s son who was clinging to floating kerosene boxes. At daylight the Dawn then rescued the 18 men from the floating portion of the deckhouse, which had drifted about 4 miles from where they’d struck the reef. Shortly after the rescue the deckhouse drifted onto breakers and was thrown onto rocks at Point Franklin, about 2 miles east of Cape Otway. Captain Jones had signalled to Cape Otway lighthouse the number of the Eric the Red and later signalled that there was a wreck at Otway Reef but there was no response from the lighthouse. The captain and crew of the Dawn spent several more hours searching unsuccessfully for more survivors, even going back as far as Apollo Bay. On board the Dawn the exhausted men received care and attention to their needs and wants, including much needed clothing. Four men (three crew and one passenger) died. A week after the shipwreck, the Australian Government had also conveyed its thanks to the Captain and crew of the S.S. Dawn - “Captain Griffith Jones, S.S. Dawn, The Hon. Mr Clark desires that the thanks of the Government should be conveyed to you for the prompt, persevering and seamanlike qualities displayed by you, your officers and crew in saving the number of lives you did on the occasion referred to. The Hon. The Commissioner has also been pleased to award you a souvenir in commemoration of the occasion, and a sum of 65 pounds to be awarded to your officers and crew according to annexed scale. I am, &c, W Collins Rees, for and in the absence of the Chief Harbour Master.” The Awards are as follows: - Crew of DAWN'S lifeboat-Chief Officer, Mr G. Peat, 15 pounds; boat's crew-G. Sterge, A.B., 5 pounds; T. Hammond, A.B., 5 pounds; J. Black, A.B., 5 pounds; H. Edwards, A.B., 5 pounds. Dinghy's Crew-Second Officer, Mr Christie, 10 pounds; boat's crew -F. Lafer, A.B., 5 pounds; W. Johnstone, A.B., 5 pounds; Mr Lear, provedore, 5 pounds; Mr Dove, purser, 5 pounds. Captain Jones receives a piece of plate. (from “Wreck of the ship Eric the Red” by Jack Loney). Medals of Bravery were awarded to the Captain and crew of the S.S. Dawn by the President of the United States, through the Consul-general (Mr Oliver M. Spencer), in July 1881 “ … in recognition of their humane efforts in rescuing the 23 survivors of the American built wooden sailing ship, the Eric the Red, on 4th September 1880.” The men were also presented with substantial monetary rewards and gifts. The city of Warrnambool’s care of the survivors was also mentioned by the President at the presentation, saying that “the city hosted and supported the crew ‘most graciously’. The Medal of Bravery awarded to Nelson Johnson is in the collection at Flagstaff Hill Maritime Museum and Village in Warrnambool. Prior to 1882, and the arrival of the S. S. Casino, the "Dawn" was the only steamer to be able to navigate up the Moyne River at Port Fairy and unload at the wharf. The other regular steamers had to anchor in the bay instead. In February 1891 (as reported in The Age newspaper) the "Dawn" became the first vessel to berth alongside the newly completed Warrnambool Breakwater. The occasion was celebrated with a number of prominent townspeople assembling on board to "participate of a glass of wine". In 1895 the owners of the S.S. Dawn, the Portland and Belfast Steam Navigation Co., wound up and sold out to the Belfast Company who took over the Dawn for one year before selling it to Howard Smith. It took over the Melbourne to Warrnambool run in 1906 when the S. S. Flinders was sold. The S. S. Dawn was condemned and sunk in Suva in 1928. The State Library of Victoria has a lithograph in its collection depicting the steamer Dawn and the shipwrecked men, titled. "Wreck of the ship Eric the Red, Cape Otway: rescue of the crew by the Dawn". The third ship depicted in the photograph was thought to be the S. S. Coorong but there was a question mark next to its name. The photograph was thought to have been taken in 1885 and it's possible the S.S. Coorong was working in Clarence River, N. S. W. by this time. The steamer "Coorong" was built in 1862 by J. G. Lawrie of Glasgow. It was an "iron screw" steamer of 304 tons. It had many owners including Joseph Darwent of Adelaide (1863 - 1871), McMeckan Blackwood and Company, Melbourne (1871 - 1877), Mount Gambier Steamship Company Ltd. (1877 - 1881). William Whineham, Port Adelaide (1882), John See and Company, Sydney (1884 - 1892) and the North Coast Steam Navigation Company Ltd, Sydney (1892 - 1910). In 1911 it was hulked in Sydney Harbour and in 1921 it was being used as a coal hulk at Sydney. It had been originally imported into South Australia for the Port Augusta trade (primarily transporting goods needed by the early settlers) however the owners recognized that it had too much space for that purpose, so it was moved to work on the Adelaide to Melbourne line. Its passenger accommodation was enlarged and it enjoyed a "first class reputation" and by 1874 had made 313 voyages between Melbourne and Adelaide. Its captains included Captain McLean, Captain Ashton and Captain Dowell. In 1867, when 25 miles west of Cape Otway, while travelling from Adelaide to Melbourne, it came across the crew of the schooner "Black Watch" who had abandoned ship after it began quickly taking on water. The crew (six men) were able to get away in a small boat with a compass, chart and few candles. They were "excessively cold from exposure to the weather" when the S. S. Coorong picked them up. In 1877 the Coorong ran aground when entering the Outer Harbour at Adelaide (but was not damaged) and in 1882 it was stranded (for a short time) near Curdies Inlet (Victoria) with some slight damage to its bottom plates. Note - A ship with the same name "Coorong" (a coal carrying barque) was often on the Newcastle / Wollongong to Adelaide route also stopped several times in Warrnambool in the mid 1880's. The photograph has the label "Chuck Photos" printed on the front. Thomas Foster Chuck (born 1826 in London) was a photographer and entrepreneur who arrived in Victoria in 1861. The following year he produced and toured a "Grand Moving Diarama" of dramatic painted scenes from the Burke and Wills expedition. By 1866 he had established a photography studio in Daylesford and later he returned to Melbourne where he opened a studio in the Royal Arcade. In 1874 a collection of Chuck's photographs won a gold medal at the Annual International Exhibition in London. Throughout the 1870's he took over 700 individual photographs of prominent citizens for his historical photographic montage titled "Historical Pictures of the Explorers and Early Colonists of Victoria" which is now in the collection of the National Library of Australia. By 1888 he had sold his Melbourne studio and had established a studio in Ballarat (with his son Thomas Henry Chuck). In 1886 they produced an album titled "Warrnambool and District 1886, Western Hotel - J. Fox proprietor" containing over sixty large photographs of local coastal scenes and seascapes, for the use of patrons of the Western Hotel. This photo (of the three steamers in Lady Bay) was taken at this time and is in the album. Thomas Chuck died on December 7th, 1898, in Albert Park, Melbourne and his son Thomas Henry continued to operate the photography studio in Ballarat into the 1920's.This photograph is a significant record of several of the well-known coastal traders (S. S. Julia Percy, S. S. Dawn and possibly S. S. Coorong) that sailed along the southwest coast of Victoria for many years - transporting goods and passengers between Melbourne and Warrnambool in the 1880's. They are also significant in the role they played in the history of Warrnambool and the other coastal ports they visited as well as being examples of the dangers and hazards associated with navigating the waters along the southern coast of Australia. It is also a good example of a photograph taken by a well-known and significant photographer of that era.Black and white photograph of three steam ships anchored in Lady Bay, Warrnambool. They each have a funnel and two masts and are side on to the beach. A small rowboat with a crew can be seen on the far right. The words "CHUCK-PHOTO" are on the bottom left of the photograph. On the back of the photograph is the name and telephone number of the donor (handwritten in black ball point pen) and the names of the three steamships and date written in uppercase letters in dark blue ink. There is a four-figure number stamped in the centre of the back.Front - "CHUCK-PHOTO" Back - Name of donor and telephone number "6944" "JULIA PERCY, DAWN & KOORONG(?) IN LADY BAY 1885"flagstaff hill maritime museum and village, warrnambool, great ocean road, fred trewartha, s. s. julia percy, s. s. dawn, s. s. nelson, s. s. casino, leeuwin, steamer, steamship, coastal trader, warrnambool steam packet company, captain chapman, victorian steam navigation board, western steam navigation company, melbourne steamship company, william howard smith and sons, portland and belfast steam navigation company, w howard smith and sons ltd, eric the red, captain jones, medal of bravery, rescue, moyne river, warrnambool breakwater, lady bay, s. s. coorong, mount gambier steamship company, black watch, thomas foster chuck, chuck photos, chuck photography -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Photograph of S. S. Eumeralla launch, 1908

This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool. The Eumeralla (sometimes spelt Eumerella) was built in 1908 in Scotland by Messrs. Scott of Kinghorn on the Firth of Forth. It was a steel screw steamer and had been designed to meet the growing demand for a thoroughly up to date passenger and cargo steamer for the Melbourne to Portland service for John McIlwraith and Company in partnership with the Belfast, Koroit Steam Navigation Company and Howard Smith Company Ltd. This photograph appeared in the Leader (Melbourne) on Saturday 28th November 1908 with the headline "Launching the Eumeralla" and shows the ship being launched on October 10th, 1908, in Scotland. It was described as "Length, 190 feet; breadth, 30 feet; depth 15 feet". It went on to say it had a speed guaranteed at 11 knots and was expected in Melbourne by the following January. It could accommodate sixty saloon passengers and thirty in steerage and had electric light fitted throughout. While on the Melbourne to Portland service the Eumeralla had several mishaps. In 1909 it crashed into the breakwater at Portarlington, splintering the woodwork and leaving a gap of about 12 feet. On Saturday 9th August 1913, as it was leaving Warrnambool, it encountered heavy seas and a passenger (Frederick Mahoney) sustained fatal injuries after hitting his head on the bulwark - and the second mate was found dead after the water poured off the deck. Several other passengers were also injured. Between 1912 and 1913 it was used to carry passengers between Brisbane, Maryborough and Rockhampton before being sent back to Melbourne for an overhaul. In 1915 it was selected for the Winter service to run daily trips between Melbourne and Geelong. In 1925 it nearly sank in the Yarra (at Queens Wharf) when it developed a list and water entered the engine room. Firemen from the Eastern Hill Station, crew and wharf workers were able to stop it from sinking. Between 1928 and 1935 the Eumeralla was laid up in Hobson's Bay before being sold to a Chinese firm to be used on the short coastal run between Shanghai and Wen Chow. It was renamed "Mel Lee (Mow Lee) Number 2". It arrived on July 12th, 1935, at Tanghai (a small Chinese port to the south of Shanghai) with 400 local passengers. The population of the town turned out to welcome the new ship with a fireworks display which caused the passengers to rush across to the side of the ship nearest the scene. The steamer immediately listed to one side and sank.This photograph is significant because of its association with the coastal trader S.S. Eumeralla and its important contribution to trade along Victoria's West Coast in the early 20th century.Black and white photograph showing a crowd of people standing on a shore watching a steamer (the Eumeralla) being launched. The crew of the steamer are standing in the bow, waving at the crowd. A single oarsman is in a small rowboat nearby. On the back of the photograph, the name, address and telephone number of the donor is written in black, ballpoint pen. More writing, in cursive script (in blue ink) gives a brief description of the ship and the events depicted in the photograph.Name of donor, address and telephone number "S. S. Eumeralla / Built in Scotland / being launched/ in Scotland/ 1904"warrnambool, flagstaff hill maritime museum and village, great ocean road, portland, port fairy, eumeralla, s. s. eumeralla, eumerella, steamer eumeralla, john mcilwraith and company, belfast and koroit steam navigation company, howard smith ltd, portarlington, geelong, melbourne, mel lee no. 2, mow lee no. 2, tanghai, steamship, steamer, fred trewartha, frederick john fox trewartha -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Brass rod, Russell & Co, Circa 1886

In the 19th century, the Industrial Revolution meant that shipbuilders could build ships using iron. These iron ships could be much larger, with more space for cargo and they didn't need as much work to keep them in good condition. Isambard Kingdom Brunel's "Great Britain" built in 1843, was the first ship to be built entirely of wrought iron. In the 1880's steel began to be used instead of iron. Ships also began to be fitted with steam engines although a great deal of coal was needed to travel even short distances. For this reason, ships continued to be fitted out with sails even though some came with engines. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. This particular artefact was one of many found by John Laidlaw (a local Warrnambool diver) when diving on the Falls of Halladale in the 1960's. In August 1973, John Laidlaw and Stan McPhee went on to discover the underwater location of the Schomberg - a passenger ship that ran aground on December 26th 1855 near Peterborough which now lies in almost 9 metres of water. When John Laidlaw died, his family donated a number of artefacts to Flagstaff Hill.This item is significant as it was recovered by a local diver from the Falls of Halladale. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).Long, slender, smooth brass rod tapering from 1.5 cm diameter at one end to .8 cm and widening back out to 1.5 cm at opposite end. One end has a smooth, rounded edge and the other end curves in and out with the end showing evidence of a piece having been broken off.flagstaff hill, flagstaff hill maritime museum and village, flagstaff hill divers, great ocean road, shipwreck coast, warrnambool, falls of halladale, falls of halladale wreck, shipwreck artefact, artefact, brass artefact, brass rod, brass fitting, diver, john laidlaw -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Brass Finial, Russell & Co, circa 1886

In the 19th century, the Industrial Revolution meant that shipbuilders could build ships using iron. These iron ships could be much larger, with more space for cargo, and they didn't need as much work to keep them in good condition. Isambard Kingdom Brunel's "Great Britain" built in 1843, was the first ship to be built entirely of wrought iron. In the 1880's steel began to be used instead of iron. Ships also began to be fitted with steam engines, although a great deal of coal was needed to travel even short distances. For this reason, ships continued to be fitted out with sails even though many came with engines. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual, beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908): - Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92, Russell & Co. standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886, they introduced a 3000-ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890, they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four-masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough, south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and was able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck in stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors, and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. This particular artefact was one of many found by John Laidlaw (a local Warrnambool diver) when diving on the Falls of Halladale in the 1960's. In August 1973, John Laidlaw and Stan McPhee went on to discover the underwater location of the Schomberg - a passenger ship that ran aground on December 26th 1855 near Peterborough and which now lies in almost 9 metres of water. When John Laidlaw died, his family donated a number of artefacts to Flagstaff Hill. The brass finial may have been part of a larger decorative item such as a lamp or clock bracket.This item is significant as it was taken from the Falls of Halladale shipwreck which is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976)A brass, bell-shaped object with a body approximately 3 cm high. It has an outer lip, straight sides that taper in and a flat "cap". The inside of the object is plain with evidence of vertigris. It has a decorative topping almost 2 cm high, which has a double concave hollow neck.flagstaff hill, flagstaff hill divers, flagstaff hill maritime museum and village, great ocean road, warrnambool, falls of halladale, falls of halladale wreck, shipwreck artefact, artefact, brass artefact, brass finial, brass fitting, shipwreck coast, diver, john laidlaw, finial, brass decoration, handmade -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Metal ship's bolt, Russell & Co, Circa 1886

In the 19th century, the Industrial Revolution meant that shipbuilders could build ships using iron. These iron ships could be much larger, with more space for cargo and they didn't need as much work to keep them in good condition. Isambard Kingdom Brunel's "Great Britain" built in 1843, was the first ship to be built entirely of wrought iron. In the 1880's steel began to be used instead of iron. Ships also began to be fitted with steam engines although a great deal of coal was needed to travel even short distances. For this reason, ships continued to be fitted out with sails even though some came with engines. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. This particular artefact was one of many found by John Laidlaw (a local Warrnambool diver) when diving on the Falls of Halladale in the 1960's. In August 1973, John Laidlaw and Stan McPhee went on to discover the underwater location of the Schomberg - a passenger ship sailing from Liverpool that ran aground on December 26th 1855 near Peterborough which now lies in almost 9 metres of water. When John Laidlaw died, his family donated a number of artefacts to Flagstaff Hill.This item is significant as it was recovered from the Falls of Halladale by a local diver. The Falls of Halladale shipwreck is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976).A thick metal bolt with a flattened head at one end, a smooth shaft approximately 4 cm long followed by a 6 cm long screw section - some of which is damaged and flattened. The end appears to have had a part broken off and is showing rust damage. flagstaff hill, flagstaff hill divers, flagstaff hill maritime museum & village, great ocean road, warrnambool, shipwreck coast, falls of halladale, falls of halladale wreck, shipwreck artefact, artefact, diver, john laidlaw, bolt, metal bolt, metal artefact, ship's bolt -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrint - Lithograph, sea rescue, R.N. Duffield, Australian cruiser “MELBOURNE” (Tons 5600) rescuing crew of sinking four-masted schooner “HELEN B. STERLING” of Halifax NS Canada, Tons 1343 in a gale in the Pacific Ocean, 19-11-1924