Showing 12824 items

matching brown

-

National Vietnam Veterans Museum (NVVM)

National Vietnam Veterans Museum (NVVM)Painting - Vietnamese painting in 4 panels

A set of four panels that make up one painting 11,999 gold and brown background one stork with leaves 11,999.1 gold and brown background three storks with nest 1 egg 11,999.2 gold and brown background onestork in flight with leaves 11,999.3 gold and brown background one small stork flying with leavespainting -

Creswick Campus Historical Collection - University of Melbourne

Creswick Campus Historical Collection - University of MelbourneStill Image, 1962

Subject: Ballarat-Creswick Plantations Block A . 4 brown envelopes marked Run 4 No. 135 - 138 of c.30 prints total. Marked up with red pen. Stored in a brown cardboard file box marked Errinundra Project..Combien Project...Ballarat Plantation. commissioned by Forests Commission Victoria 1962.Aerial Photographs -

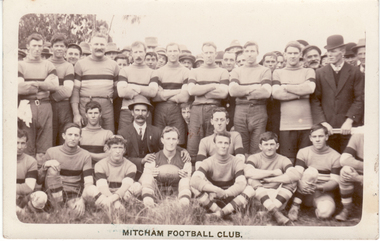

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Photograph, Mitcham Football Club

Black and white photo of Mitcham Football Club. Identification is uncertain but they may be|Standing: 1. J.Kiker; 3. Proudfoot; 7. W.Wilson|Centre: 1. G Dempster|Front Row: 2. E Sewart; 3. T Brown; 4. Mick George; 5. Lew Barrelli|Man with beard at rear is H. Alderton.mitcham football club, ringwood historical research group, kiker, j, proudfoot, neilson, w, dempster, george, sewart, e, brown, t, mick, barelli, lew, alderton, harry -

Bendigo Military Museum

Bendigo Military MuseumPainting - PORTRAIT, FRAMED, post WW1

Lt Col John McCRAE BA MD Born Guelph, Ontario, Canada 1872. Died France OAS 1918.Head & shoulders colour portrait of Lt Col John McCRAE in jacket with Sam Brown strap & colour bar over LH pocket. No head gear. In brown wooden frame with glass front. Brown paper & cardboard backing.passchendaele barracks trust, framed, painting -

Cheese World Museum

Cheese World MuseumBottle, Stone hot water bottle

The Percy Uebergang family lived at Tooram Park, Allansford from 1912 until 1992. Percy and Myrtle Uebergang's children were twins, Ray and Joyce born in 1926 who lived at Tooram Park until their deaths, Ray in 1986 and Joyce in 1992. Neither Ray nor Joyce married and following the death of her brother Joyce set up the Ray and Joyce Uebergang Foundation which supports the local community. This hot water bottle is part of the collection of items given into the care of the Cheese World Museum. Uebergang catalogue No.F61 Brown stoneware cylindrical hot water bottle with dark brown knob at one end used as a handle; a round hole in dark brown on top used to fill the bottle, stopper missing; slightly flattened base to prevent rolling.Uebergang No. F61 (on base) -

Geoffrey Kaye Museum of Anaesthetic History

Geoffrey Kaye Museum of Anaesthetic HistoryPhotograph

The Lidwill machine was designed by Mark Lidwill in 1913, for the purpose of mechanical or insufflation anaesthesia. It was manufactured by Elliott Bros. of Sydney.Colour photograph of a Lidwill anaesthetic machine sitting on carpet. A circular metal ether vaporiser sits on a brown wooden base, with brown tubes connecting to a trap bottle and metal valves, and a brown tube connected to the valve is coiled on the floor.anaesthetic equipment, lidwill anaesthetic machine, mark lidwill, ether vaporiser, elliott bros sydney -

Kilmore Historical Society

Kilmore Historical SocietyClothing - Pair Child's Leather Button up Shoes, Child's Leather Shoes

Grained brown leather with decorative stitching around edges of shoes. Small matching brown leather bow on instep. Nailed on leather sole and built up heel. Eyelet punch on instep flap to take small brown button.On sole circle stamp "All Leather IHM" 11 on sole towards toe -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Jug

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/The form of the jug has been in use for many centuries.Stoneware jug. Two tone brown glaze with pierced lip behind spout. Spout chipped.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jug, ceramic jug -

Hume City Civic Collection

Hume City Civic CollectionContainer - Flagon - wine, END OF AN ERA - WORKS DEPOT, pre 1994

The flagon with port was issued to recognise the end of the Shire of Bulla Works Depot. The port was from the Mt Aitken Estates in Gisborne. Public Works previously administered by the Shire of Bulla went out to private tendering.A cream and brown glazed flagon with sloping sides. The lower half of the flagon is cream with brown printing. The upper half and neck is brown. There is a black unbroken seal over the cork and the port is still in the flagon. On the front there is the Shire of Bulla insignia and on the back: the Shire of Bulla logo with the list of all employees of the Works Depot.on front: END OF AN ERA / (Shire of Bulla Insignia) / WORKS DEPOT / REMEMBER / "Safety is no Accident" shire of bulla, works depot, mt aitken vineyards, vineyards, ackland, b, adams, s, aksalih, b, aquilina, r, bartley, p, beavis, a, bell, f, bentley, k, bernard, c, birrell, s, bishop, o, brabander, p, brown, n, clements, p, coundon, j, coundon, k, culhane, n, davis, d, farquahar, s, forster, m, gardner, t, gibbings-johns, r, green, k, hamilton, m, healy, p, houston, k, kostantinidis, m, lumsden, b, mazza, s, mazza, e, moxham, s, higgs, j, laws, g, bailey, n, acton, b, fitzmaurice, n, lee, m, hewson, t, lumsden, d, bryant, p, jankovic, d, riley, p, mott, b, naughton, p, olson, a, peavey, r, pittaway, b, morgan, s, morton, j, markman, o, lagana, f, ivakovic, m, jamieson, d, podolczak, n, prestage, d, pullen, p, pyke, b, richards, k, russell, r, sartore, a, schaffer, s, schembri, l, service, t, smith, b, taylor, n, thom, m, thomas, c, travers, k, travers, p, turner, r, tyquin, e, tyquin, k, tyquin, t, watts, j, wilson, h, whitworth, l, withers, d, george evans collection -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFootwear - Boots, Rossiters Ltd, 1908-1920

Rossi Boots started in 1910 when Arthur Edward Rossiter resigned from his position as a supervisor at the Adelaide Boot Company and started Rossiters Ltd in a small tin shed in his backyard. A larger factory was needed so the first of three stages of a factory was built. During the Second World War Rossi Boots was a major supplier to the military making hundreds of thousands of boots that saw service in various theatres including New Guinea. The war years saw the number of employees peak at around five hundred. As methods of manufacturing footwear changed as petroleum-based products such as glues, rubbers and plastics have replaced the traditional ones of leather, nails, and threads. More modern machinery was introduced to directly mould soles to the bottom of the boot. At the end of 1987, the company moved from Unley to Hilton this move allowed production to be carried out in a more modern, fit-for-purpose factory. Since then the company has continued to change; introducing computer-controlled machines for cutting, sewing, and attaching soles. These changes occurred whilst many of Rossi's competitors moved offshore. Whilst the introduction of these machines reduced the number of local staff, it has enabled Rossi Boots to continue to manufacture in Australia. In March 2019 Rossi Boots relocated the factory, warehouse, and headquarters from Hilton to Kilburn, South Australia. This move to a new, expansive location allows Rossi Boots to continue manufacturing in South Australia housing all operations under one roof. The items are significant as they show the beginnings of an important manufacturer and innovator that is still in the original founding family's ownership and is producing boots today with exports to many countries. Boots leather lace up brownNonewarrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Lara RSL Sub Branch

Lara RSL Sub BranchPersonal Records, Soldier Pay Book, First World War

Pay Book Of World War One Soldier of Samuel Warren Ellis 1918 Contains Pay details ( Earnings and Other Credits )period 1917 to 1918 Next of Kin, Medical and Training Courses Completed Brown Booklet Length 154mm W106mmPay Book 278607 Surname Ellis Christian Names Samuel Warren Reg No 640 Unit Australian Imperial Force Rising Sun Badge -

Bendigo Military Museum

Bendigo Military MuseumAccessory - SOAP STICK, c.WWII

Item re Frederick Gardner DAVEY DFC No 410533 RAAF. Refer Reg No 3536P for his service details.Brown, cylindrical, shaving soap stick.soap, stick -

Federation University Historical Collection

Federation University Historical CollectionBook, Edward Hart, A Handbook of Volumetric Analysis, 1878

Brown/black book of 326 booksnon-fictionvolume, analysis -

Federation University Historical Collection

Federation University Historical CollectionBook, Holy Bible of Common Prayer, 1851

Dark brown leather covered bible.o.e. wilson -

Greensborough Historical Society

Greensborough Historical SocietyBook, Rules of golf 1988

Rules of Golf 1988.Thomastown Golf Club was a social club formed in 1976. This is part of the Robert (Bob) Jones collection of Club memorabilia.Small book with brown and white cover..thomastown golf club, bob jones, golf - rules -

![Memorabilia - Patch, Thomastown Golf Club, Thomastown Golf Club [fabric patch]](/media/collectors/4f729f5697f83e03086015b8/items/64c0c581d07af9549e8c60c2/item-media/65ac6b2ffc29fd7dc16a018e/item-fit-380x285.jpg) Greensborough Historical Society

Greensborough Historical SocietyMemorabilia - Patch, Thomastown Golf Club, Thomastown Golf Club [fabric patch]

Golf 'patch' available to Thomastown Golf Club members. Patches such as this would be sewn onto an outer garment to identify team members.Thomastown Golf Club was a social golf club formed in 1976. This is part of the Robert (Bob) Jones collection of Club memorabilia.Fabric golf patch in yellow and brown.thomastown golf club, robert jones, identity patch -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Grinding Stone, Unknown

Donated by Alan West found in Northern TerritoryFlat light brown Grinding StoneKulpitjata, Northern Territoryaustralian aboriginal history, aboriginal artifact, stone implement, grinding stone -

Phillip Island and District Historical Society Inc.

Phillip Island and District Historical Society Inc.Photograph, Anderson Family, 1890

Horses of Robert Anderson Snr. on farmland - grazingThree brown horses grazing on farmlocal history, photography, photographs, slides, film, horses, sepia photograph, mrs emma anderson jacobs -

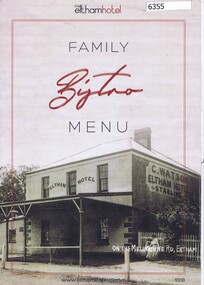

Greensborough Historical Society

Greensborough Historical SocietyMenu, The Eltham Hotel: Family bistro menu; and news clipping, 2018_10

Menu from The Eltham Hotel with photograph of the original hotel on menu cover; with photocopy of newspaper clipping 24/02/1955 describing Hotel's target of 1000 pounds for the Children's Hospital Appeal.Black and brown print on white cardeltham hotel, eltham -

Greensborough Historical Society

Greensborough Historical SocietyLeaflet, Boys from 7 to 13 years: join a great club! Rosanna Soccer Club Juniors, 1989_

1989 advertisement for the Rosanna Soccer Club Juniors.Leaflet printed in brown, single-sided.rosanna soccer club -

Greensborough Historical Society

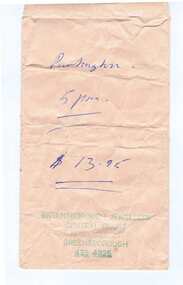

Greensborough Historical SocietyEnvelope, Greensborough Jewellers, 1960c

Greensborough Jewellers operated in Main Street in the 1960s-1970s. It was possibly a branch of Busby Jewellers in Preston.Jewelery repair envelope, brown paperCustomer: Partington; Price: $13.95; rubber stamped business name, address and telephone numbergreensborough jewellers, main street shops, central court main street greesborough -

Greensborough Historical Society

Greensborough Historical SocietyCup (pair), Earthenware mugs, 1980s

Gift to Eric and Dot Wittingham from Rosie BrayPair of earthenware cups, light brownInscribed "Dot" and "Eric"; maker's initials impressed on bottom "EJ" whittingham family, rosie bray -

Greensborough Historical Society

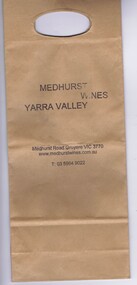

Greensborough Historical SocietyPaper bag, Medhurst Wines, Yarra Valley, 2016_

This bag was obtained from Medhurst Wines, Yarra Valley, as a gift for Faye Fort, who is a descendant of the Medhurst family. The Medhurst family moved to Gruyere in the Yarra Valley in 1855. They farmed the land that is now the vineyard that bears their name. In 1898 they moved to Greensborough.Brown paper bag with company logo."Medhurst Wines Yarra Valley"medhurst family, medhurst wines yarra valley -

Geelong RSL Sub Branch

Geelong RSL Sub BranchLeather Helmet & Goggles, Early 20th Century

This helmet and goggles are originals from WW2.This helmet and goggles are the originals as issued during WW2.A brown leather Helmet with goggles attached.Lasica's Australia helmet goggles ww2 -

Glenelg Shire Council Cultural Collection

Glenelg Shire Council Cultural CollectionSouvenir - Pen - History House Portland, n.d

Pen, biro, brown with gold trimsFront: 'HISTORY HOUSE (OLD TOWN HALL) PORTLAND VIC 3305 -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomTraining Manual, His Majesty's Stationery Office, Field Service Pocket Book 1913, 1913

Pocket book in brown fabric coverRubber stamp: " 17th Light Horse" Signature: Lt A Chantertraining manual, 1913 -

Emerald Museum & Nobelius Heritage Park

Emerald Museum & Nobelius Heritage ParkSepia photograph, Nightingale/Thompson Collection, c 1870 to 1915

Photograph of farmhouse with family members on front veranda. Inscription on the back reads: 'To dear Emma with love from Lizzy'. Emma is possibly Emma Augusta Nightingale (nee Thompson) b 1859; d 1949. Lizzie is possibly Elizabeth Anna Thompson (nee Fleming) b 1874; d 1954 information sourced from Nightingale Family History folder Clear photograph depicting country farmhouse with large family on front veranda, very good example of charming country cottage garden with plants easily recognisable Sepia photograph mounted on brown card'To dear Emma with love from Lizzy'thompson collection, nightingale -

Orbost & District Historical Society

Orbost & District Historical Societybook, Burn's Justice, 1814

This book was used for ceremonies by a parish officer or justice of the peace. It is the second volume in a series of five. Richard Burn was born in Westmorland. He matriculated at The Queen's College, Oxford in 1729. He was not awarded his B.A. until 1735, three years after he left the university to accept a position as schoolmaster at Kirkby Stephen in Westmorland. Burn then entered the Church of England, and in 1736 became vicar of Orton in Westmorland. He was a justice of the peace for the counties of Westmorland and Cumberland, and devoted himself to the study of law. In 1762, after Burn had attained notoriety as a legal scholar, the University of Oxford awarded him an honorary LL.D. He was appointed chancellor of the diocese of Carlisle in 1765, an office which he held until his death aged 86. Burn's Justice of the Peace and Parish Officer, first published in 1755, was for many years the standard authority on the law relating to justices of the peace. It has passed through some 30 editions, half of which appeared after Burn's death. (info. Wikipedia)This book was was for many years the standard authority on the law relating to justices of the peace and is a useful research tool.A book with a rough brown leather cover,burn-richard law -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, 1890-1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s.Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Brown salt glaze stoneware bottle None (possibly made by Royal Doulton UK)flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, flagstaff hill maritime village, great ocean road, bottle, stoneware bottle, storage, kitchen ware, salt glazed, stoneware, shipwreck coast -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1920-1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthenwares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s. Item's significance is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past.Brown Stoneware jug with short neckThe number "1" under neck flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, salt glaze