Showing 324 items

matching weaving mills

-

National Wool Museum

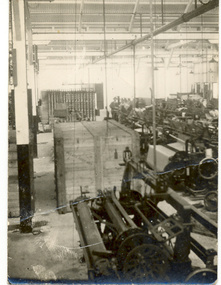

National Wool MuseumPhotograph, Views of the Collins Bros Mills

... OF THE WEAVING AND FINISHING MILLS/ MAKERS OF THE FAMOUS PHYSICIAN BRAND... MANUFACTURERS GEELONG/ VIEWS OF THE WEAVING AND FINISHING MILLS/ MAKERS ...Views of the Collins Bros Mills.COLLINS BROS PTY LTD / WOOLLEN MANUFACTURERS GEELONG/ VIEWS OF THE WEAVING AND FINISHING MILLS/ MAKERS OF THE FAMOUS PHYSICIAN BRAND/ BLANKETS, FLANNELS, LADIES' DRESS MATERIALStextile mills - history, collins bros mill pty ltd -

Stawell Historical Society Inc

Stawell Historical Society IncNorwellan Woolen Mills, Wooden Spool

... for weaving at Norwellan Woolen Mills North Western Woolen Mills... for weaving at Norwellan Woolen Mills North Western Woolen Mills ...Wooden Spool held yarn to be wound onto loom bobbins for weaving at Norwellan Woolen Mills North Western Woolen Mills became Norwellan Textiles then AUNDEWooden Spool from weaving Loom, metal rims over wooden ring ends centre hole runs though to hold in placeindustry, norwellan -

Bendigo Historical Society Inc.

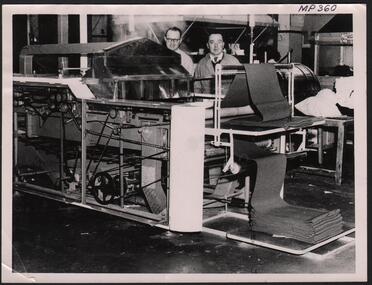

Bendigo Historical Society Inc.Photograph - HANRO COLLECTION: PHOTOGRAPH OF HANRO WEAVING MACHINE

... in black ink is *MP 360 Weaving Machine Hanro Mills Bendigo... Weaving Machine Hanro Mills Bendigo*. Bottom left is hand written ...BHS CollectionPhotograph of Hanro Weaving Machine: Black and white photo with white border. The photo has two men standing behind the weaving machine showing pulleys and wheels as finished fabric is rolled out at the end. Top left hand side hand printed in blue ink is *MP 360*. On the back is a circular stamp in blue ink of the Royal Bendigo Historical Society of Victoria. Hand printed in black ink is *MP 360 Weaving Machine Hanro Mills Bendigo*. Bottom left is hand written in pencil is the word *Hanro* with a line under it. Box 116Aphotograph, building, hanro, hanro -

National Wool Museum

National Wool MuseumPhotograph Album, The Valley Worsted Mills, Geelong

... . Warping at the Valley Mill, Geelong, c.1920s. Weaving... which was established in 1923. Textile Mills warehouses Weaving ...Photograph album containing 15 photographs of the textile processes which took place at the Valley Worsted Mill which was established in 1923.Photograph album contains 15 photographic postcards of textile processes from the Valley Mill, c.1920s. Valley Mill, Geelong, c.1920s. Wool sorting at the Valley Mill, Geelong, c.1920s. Wool scouring at the Valley Mill, Geelong, c.1920s. Woollen carding at the Valley Mill, Geelong, c.1920s. Worsted carding at the Valley Mill, Geelong, c.1920s. Combing and drawing at the Valley Mill, Geelong, c.1920s. Woollen spinning at the Valley Mill, Geelong, c.1920s. Worsted spinning at the Valley Mill, Geelong, c.1920s. Winding at the Valley Mill, Geelong, c.1920s. Warping at the Valley Mill, Geelong, c.1920s. Weaving at the Valley Mill, Geelong, c.1920s. Mending at the Valley Mill, Geelong, c.1920s. Wet finishing at the Valley Mill, Geelong, c.1920s. Dry finishing at the Valley Mill, Geelong, c.1920s. Warehouse at the Valley Mill, Geelong, c.1920s.PHOTOGRAPHS THE / VALLEY WORSTED MILLS / GEELONG WOOL SORTING / WOOL SCOURING / WOOLLEN CARDING / WORSTED CARDING / COMBING & DRAWING / WOOLLEN SPINNING / WORSTED SPINNING / WINDING / WARPING / WEAVING / MENDING / WET FINISHING / DRY FINISHING / WAREHOUSE C.J. Frazer Photographer / Melbournetextile mills warehouses, weaving, textile production, textile mills, valley worsted mill, scouring, carding, combing, drawing, spinning, winding, warping, wet finishing, mending, milling, dry finishing, textile mills - warehouses -

National Wool Museum

National Wool MuseumClothing - 1984 Los Angeles Olympics Men's Opening Ceremony Shirt, c. 1984

... to select a pure wool faille fabric from Foster Valley weaving mill... to select a pure wool faille fabric from Foster Valley weaving mill ...On the 1984 Los Angeles Olympic Uniforms donator Doug wrote- During the 1980s the Australian wool industry was at its most prosperous times with record numbers of sheep producing wool receiving ever increasing values due to the success of the Reserve Price Scheme, and the overall guidance of the Australian Wool Corporation (AWC). As a humble technician, my role was a low profile newly created position of “Controller, Technical Marketing” where wool was to be marketed on its technical properties, as distinct from the “Product Marketing Group” which exploited trhe traditional high profile approach of marketing wool;s superior fashion attributes. The Woolmark was the tool central to this approach. When the forthcoming Los Angeles Olympic Games was announced, the Product Marketing Group seized upon the chance to show the world that we could make top fashion garments and display them on our elite athletes on the world stage. A concept was launched using a contemporary top designer, Adel Weiss, with the most exclusive fabrics and knits available, and all with a lot of hype. This launch failed dismally for the following reasons- - The designer did a wonderful job presenting an excellent fashion range on perfect skinny models. The AOC however wanted a uniform which had an obvious Australian appearance when fitted to elite, and frequently muscular, athletes. - The fabrics chosen did not reflect the performance required by travelling athletes, there was no recognition of the need for ‘easy care.’ - There was no recognition given to the problem of measuring, manufacturing and distribution of a range of articles when the selected athlete could be domiciled anywhere in Australia. - There was no appreciation of such historical facts as Fletcher Jones, who had been unofficial suppliers dating back to the 1954 Olympics in Melbourne, and the Fletcher Jones board member, who was also an AWC board member, and was not in favour of the change. The project passed from Product Marketing to Public Relations, a big spending off-shoot of the AWC Chairman David Asimus, and due to the day to day operations of the project was passed to me and PR took care of the financial matters. The first task was to meet with the AOC and find out exactly their requirements. This lead to the production of a design and manufacturing brief, cointaining exact time lines for each event required to ensure an appropriate uniform on every athlete chosen to represent his/her country on the date given for the Opening Ceremony in Los Angeles. Working backwards the timeline becomes- 1. Noted the exact date of the Opening Ceremony. 2. Estimated the date for distributing completed garments to each athlete. 3. Estimated the time span available for measuring each athlete and commence making each component of the ensemble to the individual measurements of each athlete. 4. Decided the date for making the final choice of uniform design concept. 5. Decided the date for distribution of the design brief to selected designers. These five steps were spread out over a two year period. The Commonwealth Games occur midway between each Olympic Games, work on the Olympic uniform commences the week after the Commonwealth Games closing ceremony and MUST be ready by the prescribed day two years hence. The project also had to remain cognisant of trade politics existing within the span of the task, as well as the temperament of designers in general. It is no overstatement to say that in the past every designer in Australia believed they could, and should, be chosen to design the Australian Uniform. The final choice of designer almost always faced criticism from the fashion press and any designer who had been overlooked. However, with the contenders receiving an exacting brief the numbers of serious contenders greatly reduced. The Los Angeles Olympic Uniforms. A further reason for the AWC bid failure to design the LA uniform was that the AOC had already chosen Prue Acton to design it. This was based on her proven performance during previous games as she had a talent for creating good taste Australiana. Her design concepts also considered the effect when they were viewed on a single athlete as well as the impact when viewed on a 400 strong team coming on to the arena. A blazer trouser/skirt uniform in bright gold was chosen for the formal uniform. It was my task to select a pure wool faille fabric from Foster Valley weaving mill and have sufficient woven and ready within the prescribed timeline. The trouser/skirt fabric selected was a 60/40 wool polyester plain weave fabric from Macquarie Worsted. This fabric had a small effect thread of linen that was most attractive when dyed to match some eucalyptus bark Prue had brought back from central Australia. For the Opening Ceremony uniform, Prue designed a series of native fauna, a kookaburra for the men’s shirt and a pleated skirt with a rural scene of kangaroos, hills and plants. This presented an insurmountable printing challenge to the local printing industry as it had an unacceptably large repeat size and the number required (50) was also commercially unacceptable. The solution was a DIY mock up at RMIT and the employment of four student designers. The fabric selected for this garment was a light weight 19 micron, pure wool with a very high twist yarn in alternating S and Z twist, warp and weft. This fabric proved to be the solution to a very difficult problem, finding a wool product which is universally acceptable when worn next to the sin by young athletes competing in the heat of a Los Angeles summer. Modifications to this fabric were developed to exploit its success when facing the same problem in future games. Garment Making- The most exacting garment in the ensemble is the tailored blazer, plus the related trouser/skirt. Unfortunately tailoring athletes that come in various shapes and sizes such as; - Weight lifters develop an enormous chest, arms and neck size. A shirt made to a neck size of 52 would produce a shirt with cuffs extending well beyond the wearer’s hands. - Basketball players are up to 7 feet tall and garments relying ona chest measurement grading would produce a shirt with cuffs extending only to elbow length. - Swimmers develop enormous shoulders and slim hips, cyclists by contrast develop thighs I liken to tree trunks and a uniform featuring tight trousers must be avoided at all cost. Suffice to say many ensembles require specialist ‘one off’ treatment for many athletes. Meanwhile there is a comfortable in between group who can accept regular sizes so you can cater for these by having back up stock with plenty of built in contingencies. Athletes may be domiciled anywhere in Australia, this creates a fundamental problem of taking their measurements. The Fletcher Jones organisation was key to answering this problem due to their presence in every capital city, as well as many provincial towns around Australia. Each athlete on being selected for the Olympic Team was simultaneously requested to visit their nearest Fletcher Jones shop. The standardised measurement data collected was shared with the other manufacturers, e.g. Pelaco Shirts, Holeproof Socks and Knitwear, Maddison Belts, and even Hush Puppy Shoes. As the time for the Games approached the AOC made arrangements for combining meeting of all. Selected available athletes at the Australian Institute of Sport, Canberra, where, among other things, they were fitted and supplied with their uniform. The method evolved as follows.Men’s cream coloured button up, collared shirt. Images of a kookaburra have been printed onto the shirt, a single kookaburra on the left breast and a pair of kookaburras on the reverse of the shirt. The kookaburras are printed in a brown tone to complement the cream colour of the fabric.On tag - FMaustralian wool corporation, 1984 los angeles olympics, olympic uniforms, men's uniforms, sport, athletes -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Book, J. W. Hutchinson, Bradford, England, The Art of Loom Tuning, 1946

... The Warrnambool Woollen Mill Company Limited (stamp.... In the 1940s the mill employed 700 workers. It was the first factory ...Technical Information on loom tuningThis is a book of 603 pages. It has a maroon-coloured cover with gold printing on the front and the spine. The pages contain printed text, black and white illustrations and advertisements.non-fictionTechnical Information on loom tuningloom tuning, warrnambool woollen mill -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's embossed nylon organza collar, c1950

Organza is a thin, plain weave, sheer fabric traditionally made from silk. Many modern organzas are woven with synthetic filament fibres such as polyester or nylon. Silk organza is woven by a number of mills along the Yangtze River and in the province of Zhejiang in China. A coarser silk organza is woven in the Bangalore area of India. Deluxe silk organzas are woven in France and Italy. Organza is used for bridal wear and eveningwear. In the interiors market it is used for effects in bedrooms and between rooms. Double-width organzas in viscose and acetate are used as sheer curtains. Nylon organza was very popular as the new fashion material in the 1950’sA lady's collar white embossed nylon organza with machine lace edge. C1950clothing, nylon, organza, dressmaking, moorabbin, bentleigh, cheltenham, fashion -

Clunes Museum

Clunes MuseumTool - WEAVER'S KNOTTER, Mellor Bromley & Co. Ltd

Weaving Knotter used in Clunes Knitting Mill early 1900'sBoyce Weaver's Knotter Serial No. A22944 .1 Green rectangular tin to contain the apparatus .2 Knotter, metal implement attached to tan leather strapping with a metal circle with lever to position the knotter .3 Printed pamphlet for care and maintenance of the knotter .4 Instruction sheet .5 Printed pamphlet with operating instructionsboyce weaver's knotter, textile tool -

National Wool Museum

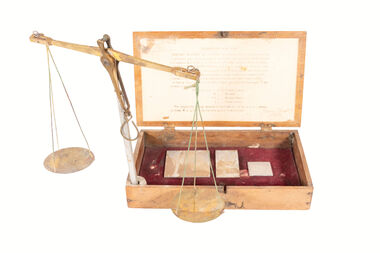

National Wool MuseumInstrument - Scales, 1880-1898

At the time of sale, the last of the Hirst family to work in the mill located in Geelong gave Donald (donor Bruce's father) Doherty a set of scales that had been used by several generations of Hirsts and adapted by them over time for specific use in their mill. These Scales were saved from waste and being thrown away at the time of sale to remain in use in the industry in the hands of someone who knew how to use them. The scales were used in calculating the weight of cloth and simultaneously calculating the amount of yarn required to weave it following the instructions printed within the box. The box bears the signatures of two Hirst family members, one being Lewis Hirst dated at 1898. The original brass pole has been replaced with a replica metal somewhere throughout the years after the brass pole broke through use. Hirst was brought by McKendrick in the 1960s and these scales sat for 12 months as part of the 12 month "cooling off" period. The scales were then handed to Donald rather than being disposed of.Scales used for weighing and calculating weight and thread count of textile samples. Originated from Godfrey Hirst Mills in Geelong. Writing describes how to utilise scales. Scales are made from brass, pole for holding scales once brass now replaced with metal pole. Scales held inside wooden box with black text in ink depicting use of scales on paper located inside and outside of box.Outside of box. Wording: APPARTUS for TESTING the WEIGHT per YARD of CLOTHS & COUNT of YARN from a small SAMPLE. -------------------------------------------------------------------------------------------------------------------------------------------------- Indispensable to Manufactures, Merchants & handling Woollen, Worsted, Cotton, Linen, Jute, Hemp, Flannel, Felt, Army, Navy, Police, Railway, Sail & other Cloths -------------------------------------------------------------------------------------------------------------------------------------------------- USED IN GOVERNMENT DEPARTMENTS -------------------------------------------------------------------------------------------------------------------------------------------------- The apparatus consists of Scales, Weights, 1, 2 & 4 sq. inch Cutting Templates & Book of Tables --------------------------------------------------------------------------------------------------------------------------------------------------By weighing a small Sample the accurate Weight in Ounces of a yard of Cloth any width from 18 to 64 inches, the Weight per Square Metre in Grams, the Counts* of Warp and Weft, and the approximate length of full & short ends of pieces of fabrics, [without unrolling and measuring for stocktaking & other purposes] can be ascertained without any Calculation --------------------------------------------------------------------------------------------------------------------------------------------------Price in United Kingdom, 25s., Carriage Paid. Price to Canada & U.S.A. $6.75 do. H. Lord. 10, And Place, Bradford, England. --------------------------------------------------------------------------------------------------------------------------------------------------*When ordering, state on what system you base your YARN COUNTS. Inside of box. Wording: DIRECTIONS FOR USE --------------------------------------------------------------------------------------------------------------------------------------------------TESTING WEIGHT OF CLOTHS. Place sample to be tested on a piece of cardboard, put a Cutting Template on it, cut card and cloth round template with scissors and weigh it according to instructions given in Book of Tables. TESTING FOR YARN COUNTS. Cut out 1 square inch of cloth, draw out wrap or weft threads, according to which is being tested, and the number of inches so drawn, that balance respective weight is the approximate Count. The same rule holds good when number of inches are drawn from a bobbin. In testing from the cloth, allowance has to be made for loss or gain in the process of manufacture. Weight marked C is for Cotton Counts " " W " " Worsted " " " WS " " Woollen Skeins " " L " " Linen Counts. The weights for testing samples of cloth are 20, 10, 10, 5, 3, 2, 1, grains in brass & '5, '3, '2, '1 [tenths of a grain] in aluminium. Inside of box. Signtures, handwritten: Bottom right: Lewis Hirst !898 Top Left (Smudge ?) W Hirst !935godfrey hirst, hirst family, textile design, textile creation -

National Wool Museum

National Wool MuseumBook, Modern Developments in the Australian Wool Industry

"Modern Developments in the Australian Wool Industry", c.1923. Examines the operations of the Yarra Falls Spinning Co. Pty Ltd and the Australian Knitting Mills Limited (makers of Golden Fleece and Kookaburra knitted underwear). Includes photos of processes and of the buildings.F H Murgatroyd/20 Kensington Rd/ Leopold 3224weaving textile industry - history textile production machine knitting textile mills, yarra falls spinning co. pty ltd australian knitting mills limited, yarn - woollen, cloth - worsted, yarn - worsted, wool tops, yarn - cashmere, weaving, textile industry - history, textile production, machine knitting, textile mills -

National Wool Museum

National Wool MuseumRug

... of the Weaving Room until his death in 1952. Woollen Mills - history ...Mr Mears father Horace Mear bought the rug c1933. He was ex British Navy and had migrated to Australia in 1920. Horace worked as a loom tuner at Valley Woollen Mill Geelong in the early 1920's then worked at Federal Woollen Mills as the Manager of the Weaving Room until his death in 1952.RETSOL RUG D E MEARwoollen mills - history, returned soldiers and sailors mill valley worsted mill federal woollen mills ltd, retsol rugs, weaving -

National Wool Museum

National Wool MuseumCatalogue, Hartmann Webstuhle

... Machinery Textile Mills Yarn production Hartmann Weaving Looms ...Hartmann catalogue of textile machinery.AUSTRALOVER MACHINERY COY PTY LTD/ 486 BOURKE ST. MELB LOOMStextile machinery textile mills yarn production, hartmann, weaving looms, weaving machinery, spinning machinery, carding, textile machinery, textile mills, yarn production -

National Wool Museum

National Wool MuseumPrice list, Price lists for Loom Accessories

"Price lists for Loom Accessories"-R Gruenhut & Son Pty Ltd"Price lists for Loom Accessories"-R Gruenhut & Son Pty LtdPrice lists for Loom Accessoriestextile machinery textile mills textile mills, r. gruenhut and son pty ltd, weaving machinery, weaving looms, textile machinery, textile mills -

National Wool Museum

National Wool MuseumEnvelope

... Yarra Falls Mill. Textile Machinery Weaving Yarra Falls Mill ...Envelope, "David Sowden & Sons, Engineers, Iron, Brass and Copper Founders, Shipley, York". Contained photographs of "David Sowden & Sons looms and was in a package of material from Yarra Falls Mill.textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

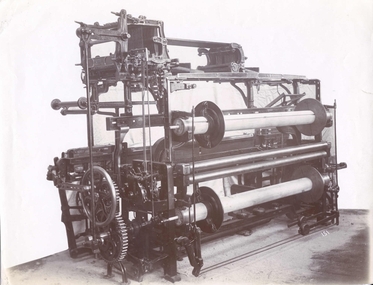

National Wool MuseumPhotograph

... Mill Textile Machinery Weaving Yarra Falls Mill David Sowden ...Photograph probably for promotional purposes, of a "David Sowden & Sons" loom, with the number 151 on the floor in front of it. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls MillPhotograph of a "David Sowden & Sons" loom, with the number 151 on the floor in front of it.textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumBook, Pattern, The University of Leeds Textile Industries Department Designing & Weaving

Design book of Fred Murgatroyd whilst he was a weaving/textiles student at the University of Leeds.Design book of a weaving/textiles student at the University of Leeds. Design book of a weaving/textiles student at the University of Leeds.The University of Leeds Textile Industries Department Designing & Weaving C Scott F. Murgatroyd Stenhouse 1928textile industry - education textile design textile mills, university of leeds, beaumont, professor - university of leeds murgatroyd, mr fred, textile industry - education, textile design, textile mills -

National Wool Museum

National Wool MuseumAdvertising Sign, Is there a Physician in the house?

... Industry Weaving Collins Bros Mill Pty Ltd Wool Marketing Textile ...Advertising material from the "Physician Mix n' Match" advertising campaign 1970.Advertising material from the "Physician Mix n' Match" advertising campaign 1970. Advertising material from the "Physician Mix n' Match" advertising campaign 1970. Advertising material from the "Physician Mix n' Match" advertising campaign 1970.wool marketing textile industry weaving, collins bros mill pty ltd, wool marketing, textile industry, weaving -

National Wool Museum

National Wool MuseumAdvertising Sign, Is there a Physician in the house?

... Industry Weaving Collins Bros Mill Pty Ltd Wool Marketing Textile ...Advertising material from the "Physician Mix n' Match" advertising campaign 1970.Advertising material from the "Physician Mix n' Match" advertising campaign 1970. Advertising material from the "Physician Mix n' Match" advertising campaign 1970. Advertising material from the "Physician Mix n' Match" advertising campaign 1970. Advertising material from the "Physician Mix n' Match" advertising campaign 1970.wool marketing textile industry weaving, collins bros mill pty ltd, wool marketing, textile industry, weaving -

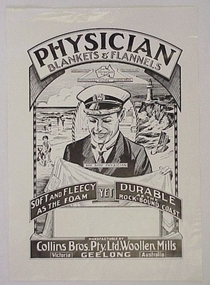

National Wool Museum

National Wool MuseumPoster, Physician blankets and flannels

... Bros Mill Pty Ltd Wool Marketing Textile Industry Weaving ...A Collins Bros Pty Ltd ,"Physician" blankets advertising poster.A Collins Bros Pty Ltd ,"Physician" blankets advertising poster.wool marketing textile industry weaving, collins bros mill pty ltd, wool marketing, textile industry, weaving -

National Wool Museum

National Wool MuseumLetter

... of Technology The Myer Woollen Mills Pty Ltd Dyeing Weaving Looms Hand ...Letter, on "The Myer Woollen Mills Pty Ltd" letterhead, printed black, dated 19th June, 1941 from H Lewis, Designer, to W R Lang offering to gift shade cards of yarn.wool - research textile design textile research, gordon institute of technology the myer woollen mills pty ltd, dyeing, weaving looms, hand spinning, lang, dr w. roy lewis, h - the myer woollen mills pty ltd, wool - research, textile design, textile research -

National Wool Museum

National Wool MuseumBook, Textile design and colour

... Calculations Classweave Industries Pty Ltd Federal Woollen Mills Ltd ..."Textile design and colour" - William Watson (1921)THE FEDERAL WOOLLEN MILLS PROPRIETRY/ T22 ROBERTSON'S BOOKSELLERStextile industry - education textile design textile calculations, classweave industries pty ltd federal woollen mills ltd, dyeing, jacquard, weaving, watson, mr william, textile industry - education, textile design, textile calculations -

![Book, [Weaving Dept employee list]](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065ff29821f50e3cc9fa25/item-media/54065ff29821f50e3cc9fa26/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumBook, [Weaving Dept employee list]

Acquired when "Classewave Industries" closed down.textile mills - staff woollen mills - history world war ii, federal woollen mills ltd classweave industries pty ltd, textile mills - staff, woollen mills - history, world war ii -

National Wool Museum

National Wool MuseumAdvertising Sheet, success story twice

... down. Textile Industry Textile Design Weaving Knitting Federal ...Acquired when "Classweave Industries" closed down.textile industry textile design weaving knitting, federal woollen mills ltd classweave industries pty ltd textile council of australia, textile industry, textile design, weaving, knitting -

National Wool Museum

National Wool MuseumAdvertising Sheet, success story twice

... down. Textile Industry Textile Design Weaving Knitting Federal ...Acquired when "Classweave Industries" closed down.textile industry textile design weaving knitting, federal woollen mills ltd classweave industries pty ltd textile council of australia, textile industry, textile design, weaving, knitting -

National Wool Museum

National Wool MuseumPhotograph

... Mills, Federal Mill, Tweedside, Collins Mills and set up looms ...James Murgatroyd worked at Warrnambool Woollen Mills, Federal Mill, Tweedside, Collins Mills and set up looms for Alexander Spinning Mills Sydney, his son Fred Murgatroyd worked as a loom tuner at Yarra Falls, Tweedside and Collins mills in Victoria as well as in Sydney, and studied at Leeds University.Murgatroyd Photograph CollectionFred Murgatroydtextile machinery textile mills - history textile mills, collins bros mill pty ltd tweedside woollen mills yarra falls mill, weaving machinery, murgatroyd, mr fred murgatroyd, mr james, textile machinery, textile mills - history, textile mills -

National Wool Museum

National Wool MuseumPhotograph

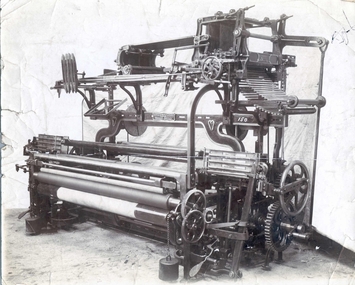

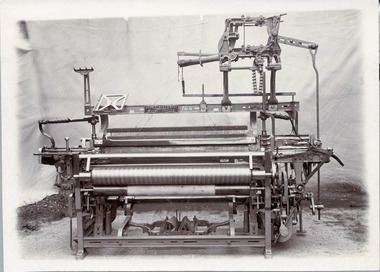

... Mill Textile Machinery Weaving Yarra Falls Mill David Sowden ...Photograph probably for promotional purposes, of a "David Sowden & Sons" loom. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls MillPhotograph. black and white, of a "David Sowden & Sons" loom.textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

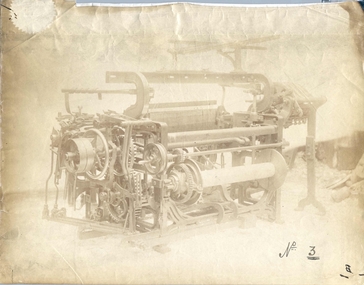

National Wool MuseumPhotograph

... from Yarra Falls Mill Textile Machinery Weaving Yarra Falls ...Photograph of a loom. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls MillSepia coloured photograph of a loom. Photograph is faded at edges.No.3textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

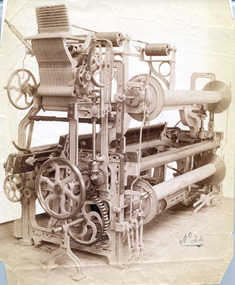

National Wool Museum

National Wool MuseumPhotograph

... from Yarra Falls Mill Textile Machinery Weaving Yarra Falls ...Photograph of a loom. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls MillSepia coloured photograph of a weaving loom.No 24textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumPhotograph

... Mill. Textile Machinery Weaving Yarra Falls Mill David Sowden ...Photograph probably for promotional purposes, of a "David Sowden & Sons" loom. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls Mill.Photograph. black and white, of a "David Sowden & Sons" loom.textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving -

National Wool Museum

National Wool MuseumPhotograph

... Mill. Textile Machinery Weaving Yarra Falls Mill David Sowden ...Photograph probably for promotional purposes, of a "David Sowden & Sons" loom. Photograph was with other photographs in an envelope printed "David Sowden & Sons" among items from Yarra Falls Mill.Photograph, sepia, of a "David Sowden & Sons" loom.41textile machinery weaving, yarra falls mill david sowden & sons, weaving looms, weaving machinery, textile machinery, weaving