Showing 168 items

matching steam iron

-

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Magazine - HORWOOD COLLECTION: STEAM SUPREME MAGAZINE, June 2013

... Engines at Mudgee Joel Horwood Bendigo Iron Works National Steam ...Magazine 'Steam Supreme', National Steam Centre, Melbourne. Article on Joel Horwood 'Horwood's Foundry' written by John Horwood, descendant. Joel Horwood JP 1832 - 1900, the pioneer foundry man of the Sandhurst Goldfields. National Steam Centre Melbournemagazine, organization, steam engines, horwood foundry, steam engines at mudgee, joel horwood, bendigo iron works -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDecorative object - Brass Finial, Russell & Co, circa 1886

In the 19th century, the Industrial Revolution meant that shipbuilders could build ships using iron. These iron ships could be much larger, with more space for cargo and they didn't need as much work to keep them in good condition. Isambard Kingdom Brunel's "Great Britain" built in 1843, was the first ship to be built entirely of wrought iron. In the 1880's steel began to be used instead of iron. Ships also began to be fitted with steam engines although a great deal of coal was needed to travel even short distances. For this reason, ships continued to be fitted out with sails even though many came with engines. The iron-hulled, four-masted barque, the Falls of Halladale, was a bulk carrier of general cargo. She left New York in August 1908 on her way to Melbourne and Sydney. In her hold, along with 56,763 tiles of unusual beautiful green American slates (roofing tiles), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6500 gallons of oil, 14400 gallons of benzene, and many other manufactured items, were 117 cases of crockery and glassware. Three months later and close to her destination, a navigational error caused the Falls of Halladale to be wrecked on a reef off the Peterborough headland at 3 am on the morning of the 15th of November, 1908. The captain and 29 crew members all survived, but her valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. ABOUT THE ‘FALLS OF HALLADALE’ (1886 - 1908) Built: in1886 by Russell & Co., Greenock shipyards, River Clyde, Scotland, UK. The company was founded in 1870 (or 1873) as a partnership between Joseph Russell (1834-1917), Anderson Rodger and William Todd Lithgow. During the period 1882-92 Russell & Co., standardised designs, which sped up their building process so much that they were able to build 271 ships over that time. In 1886 they introduced a 3000 ton class of sailing vessel with auxiliary engines and brace halyard winches. In 1890 they broke the world output record. Owner: Falls Line, Wright, Breakenridge & Co, 111 Union Street, Glasgow, Scotland. Configuration: Four masted sailing ship; iron-hulled barque; iron masts, wire rigging, fore & aft lifting bridges. Size: Length 83.87m x Breadth 12.6m x Depth 7.23m, Gross tonnage 2085 ton Wrecked: the night of 14th November 1908, Curdies Inlet, Peterborough south west Victoria Crew: 29 The Falls of Halladale was a four-masted sailing ship built-in 1886 in Glasgow, Scotland, for the long-distance cargo trade and was mostly used for Pacific grain trade. She was owned by Wright, Breakenridge & Co of Glasgow and was one of several Falls Line ships, all of which were named after waterfalls in Scotland. The lines flag was of red, blue and white vertical stripes. The Falls of Halladale had a sturdy construction built to carry maximum cargo and able to maintain full sail in heavy gales, one of the last of the ‘windjammers’ that sailed the Trade Route. She and her sister ship, the Falls of Garry, were the first ships in the world to include fore and aft lifting bridges. Previous to this, heavily loaded vessels could have heavy seas break along the full length of the deck, causing serious injury or even death to those on deck. The new, raised catwalk-type decking allowed the crew to move above the deck stormy conditions. This idea is still used today on the most modern tankers and cargo vessels and has proved to be an important step forward in the safety of men at sea. On 4th August 1908, with new sails, 29 crew, and 2800 tons of cargo, the Falls of Halladale left New York, bound for Melbourne and Sydney via the Cape of Good Hope. The cargo on board was valued at £35,000 and included 56,763 tiles of American slate roofing tiles (roof slates), 5,673 coils of barbed wire, 600 stoves, 500 sewing machines, 6,500 gallons of oil, 14,400 gallons of benzene, plumbing iron, 117 cases of crockery and glassware and many other manufactured items. The Falls of Halladale had been at sail for 102 days when, at 3 am on the night of 14th November 1908, under full sail in calm seas with a six knots breeze behind and misleading fog along the coast, the great vessel rose upon an ocean swell and settled on top of a submerged reef near Peterborough on the south-west Victoria’s coast. The ship was jammed on the rocks and began filling with water. The crew launched the two lifeboats and all 29 crew landed safely on the beach over 4 miles away at the Bay of Islands. The postmistress at Peterborough, who kept a watch for vessels in distress, saw the stranding and sent out an alert to the local people. A rescue party went to the aid of the sailors and the Port Campbell rocket crew was dispatched, but the crew had all managed to reach shore safely by the time help arrived. The ship stayed in full sail on the rocky shelf for nearly two months, attracting hundreds of sightseers who watched her slowly disintegrate until the pounding seas and dynamiting by salvagers finally broke her back, and her remains disappeared back into deeper water. The valuable cargo was largely lost, despite two salvage attempts in 1908-09 and 1910. Further salvage operations were made from 1974-1986, during which time 22,000 slate tiles were recovered with the help of 14 oil drums to float them, plus personal artefacts, ship fittings, reams of paper and other items. The Court of Marine Inquiry in Melbourne ruled that the foundering of the ship was entirely due to Captain David Wood Thomson’s navigational error, not too technical failure of the Clyde-built ship. The shipwreck is a popular site for divers, about 300m offshore and in 3 – 15m of water. Some of the original cargo can be seen at the site, including pieces of roof slate and coils of barbed wire. This particular artefact was one of many found by John Laidlaw (a local Warrnambool diver) when diving on the Falls of Halladale in the 1960's. In August 1973, John Laidlaw and Stan McPhee went on to discover the underwater location of the Schomberg - a passenger ship that ran aground on December 26th 1855 near Peterborough and which now lies in 825 metres of water. When John Laidlaw died, his family donated a number of artefacts to Flagstaff Hill. The brass finial may have been part of a larger decorative item such as a lamp or clock bracket.This item is significant as it was taken from the Falls of Halladale shipwreck which is listed on the Victorian Heritage Register (No. S255). She was one of the last ships to sail the Trade Routes. She is one of the first vessels to have fore and aft lifting bridges. She is an example of the remains of an International Cargo Ship and also represents aspects of Victoria’s shipping industry. The wreck is protected as a Historic Shipwreck under the Commonwealth Historic Shipwrecks Act (1976)A brass, bell shaped object with a body approximately 3 cm high. It has an outer lip, straight sides that taper in and a flat "cap". The inside of the object is plain with evidence of vertigris. It has a decorative topping almost 2 cm high which has a double concave hollow neck.flagstaff hill, flagstaff hill divers, flagstaff hill maritime museum and village, great ocean road, warrnambool, falls of halladale, falls of halladale wreck, shipwreck artefact, artefact, brass artefact, brass finial, brass fitting, shipwreck coast, diver, john laidlaw, finial, brass decoration, handmade -

Victorian Railway History Library

Victorian Railway History LibraryBook, Burke, David, Kings of the Iron Horse, 1985

A history of the Victorian Railways Chief Mechanical Engineers Alfred.E. Smith and Fred.J.Shea.index, ill, p.248.non-fiction A history of the Victorian Railways Chief Mechanical Engineers Alfred.E. Smith and Fred.J.Shea.locomotives - australia - drawings - biography, steam engines - australia - design - biography -

Victorian Railway History Library

Victorian Railway History LibraryBook, Burke, David, Man of Steam E.E. Lucy - A Gentleman Engineer in the Great Days of the Iron Horse, 1986

A history of the New South Government Railways Chief Mechanical Engineer Ernest Edward Lucy.index, ill, p.280.non-fiction A history of the New South Government Railways Chief Mechanical Engineer Ernest Edward Lucy.locomotives - australia - drawings - biography, steam engines - australia - design - biography -

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Document - Instruction manual, Details of component parts for Broadbent suspended steam driven Hydro Extractors, C 1926

Thomas Broadbent $ sons Ltd was established in 1864 in Huddersfield England. They are an engineering firm , specialists in heavy duty engineering products. By 1893 Broadbent had progressed to steam powered engines for the textile industry. Some of these machines operated for upwards of 50 years Today Broadbent is a leading world designer in the manufacture and maintenance of advanced centrifuges. This document is a manual for a suspended direct steam driven hydro extractor. It shows the various parts , maintenance instructions and erection and working instructions. While it is stamped as Albion Woollen mills which were situated at Geelong, it is likely to have connections to the Warrnambool Woollen Mills.This document is a good example of machinery manual. It is possibly linked to the Warrnambool Woollen Mill. The fact that the company which manufactured these items is still in existence today after 150 years is testament to the quality of the items produced.Cream coloured document with mainly black text with some red text for headings contained in the document. It is printed front and back and is folded in three sections.Stamp at top "Albion Woollen mills Pty Ltd" .4H x 4 in red pencil in top RHC. Printed on front page. Thomas Broadbent & Sons Ltd Central Iron Works Huddersfield. warrnambool, warrnambool woollen mill, broadbent direct steam driven hydo extractors,, broadbent centrifuge -

Tatura Irrigation & Wartime Camps Museum

Tatura Irrigation & Wartime Camps MuseumIron, 1940's

Made by internee at Camp 3 Tatura and used there to iron garments.Metal laundry iron. Covered with silver paint. Hinged lid, wooden handle painted red. Vents in base and lid to allow steam from coals to escape. Handmade.iron, wied l, camp 3 -

Bendigo Historical Society Inc.

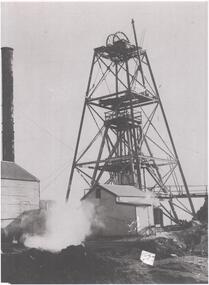

Bendigo Historical Society Inc.Photograph - DEBORAH GOLD MINE POPPET HEAD 1930'S

Black and white photograph, copy, of the metal poppet head of the 'Big' Deborah Gold Mine, Golden Square. Poppet head has been erected over the top of an earlier timber poppet head. In foreground, corrugated iron shed at base of poppet head legs, metal chimney on extreme LH side, adjoining a shed. Steam emanating from shed.bendigo, mining, deborah gold mine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Boiler, T & F Johnson, boilermakers, late 19th century

A steam boiler like this late 18th century boiler, is often called a colonial boiler. Steam boilers were used in factories throughout Australia, mounted over similar designs of brick furnaces. This heat from the fire travels through the tubes in this fire tube boiler and the water heats as it circulates around them. Another kind of boiler is a water tube boiler, in which the water is inside the tubes and the heat of the combustion surrounds the tubes. The boiler in our collection burned wood as fuel but others of this design could also burn coal, coke, gas and liquid fuels. The boiler was made by T & F Johnson, boilermakers. In 1922 their factory was located at Coventry Street, South Melbourne. They were still advertising their 'Colonial, multi, vertical boilers, all sizes' at the same address in 1934. The connected pressure gauge, made in London by Dewrance, measures 0 to 400 pounds per square inch. John Dewrance is renowned as a pioneer of the steam locomotive in the early 19th century. He founded John Dewrance & Co. in South London in 1844. His son Sir John Dewrance took over in 1879. In 1939 the company became a subsidiary of Babcock & Wilcox, and was eventually owned by Emerson. How the boiler works: - A boiler is about two-thirds filled with water and heat is applied, in this case in the form of burning wood. The heat is transferred through the metal of the boiler to the water. When the water boils the steam rises to the top, and as it escapes from the boiler the steam pressure builds up in the steam space to later be released to do work; drive machinery such as ship and train engines, turbines, presses, wheels, and driving belts to operate looms and saws. The heat associated with the boiler can be used for preserving food, sterilising, factory manufacturing processes, and steaming wood for shipbuilding. Every boiler has several components fitted for safe operation: - - Safety valves - Gauge glass - Pressure gauge - Main steam stop valve - Water check valve - Blowdown valve - Manhole doorThe boiler is a significant item that gives us a snapshot of early Melbourne's industrial history. It is an example of the technological advancement during the Industrial Revolution where steam-driven machinery and motors could perform tasks more efficiently than manual labour. The makers were one of many boilermaker businesses in Melbourne during the early late-19th andearly 20th centuries. The maritime trade and skills of boilermaking are still learned and applied today. The Dewrance steam pressure gauge connected to the boiler was made by the London firms foundered by John Dewrance. He was renowned for developing the steam locomotive in the early 19th century.Boiler; a horizontal cylindrical underfired steam boiler. It is a multi-tubular design and is timber plank-clad, with brass fittings and pressure gauges. The boiler has an iron door at one end with a metal chimney above it. It is installed over a brick-enclosed solid fuel furnace. Two large, wood-mounted pressure gauges are connected to the boiler and have inscriptions. An inscription is on a red, cast iron plaque above the boiler door. The boiler's maker is T & F Johnson, South Melbourne. One of the pressure gauges was made by Dewrance, London..Maker's plate: "T & F JOHNSON / BOILERMAKERS / SOUTH MELBOURNE" Pressure gauge: "POUNDS PRESSURE / PER [square] INCH / DEWRANCE LONDON"flagstaff hill, warrnambool, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, boiler, multi tube boiler, steam boiler, steam technology, underfired boiler, horizontal boiler, timber clad boiler, steam power, industrialisation, boilermakers, south melbourne, dewrance, john dewrance, pressure gauge, dewrance pressure gauge, t & f johnson, london, steam engine, steam locomotive, pounds per square inch, 19th century, steam machine, johnson tyne foundry, colonial boiler, fire tube boiler -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Document - MINING REPORTS - LIST OF GOLD MINES OR MINING COMPANIES

Handwritten list, (typed copy) by Albert Richardson, of Gold Mines or Mining Companies. Listed are: Australian United Quartz Co Sandhurst, Advance Co, Big Hill Tribute Co, Birds Reef Railway Reserve Mine Co, British Banner Gold M Co, Brookfield Gold M Co, Carlisle North Garden Gully, Caroline Gold M Co, Central Garden Gully, Charles Gavin Duff Gold M Co, Charleston Quartz, Cinderella Co, Collman Tacchi & Nelson, Confidnece Gold M Co, Cornish United Gold M Co, Derby Gold Mine Co, Dixon's Tribute Co, Ellesmere black Lead Tribute Co 1871, Empire Amalgamated, Extended Gold M Co (Majorca), Extended Co Victoria Reef, First Chance Tribute, Fortuna, Golden Fleece & Heales United, Garden Gully United, Garden Gully, Golden Fleece, Golden Point, Golden Lion Tribute Garden Gully Reef, Great Golden Fleece Co, Great Wonder Co, Gilmons Golden Palm Trib Co, Golden Garden Gully Co 1873, Golden Sovereign Extended Trib Co 1872, Great Extended Garden Gully Co 1874, Great Extended South Hustlers Co 1872, Great Republic Corp, Ironbark Co, Kangaroo Flat Steam Puddling & Qaurtz M Co, Riverpool Gold M Co, Iron Duke Co 1871, Henry Van Der Hugen Pioneer G M Co, Kent M Co, Kentish Co, Mariners Reef Co, Mary Hill Trib Co, Morning Star Gold Mine Co, Mount Korong Lane's Reef M Co, New Chum & Victoria Trib Co, New Hopeful Gold M C, New Homeward Bound, New Lord Warden Trib Co, North Lord Warden Trib Co, North Nelson, North Golden Pyke Co, North Old Chum, North Shamrock, North Birds Reef Co, North Birds Tribute Co, New Chum Freehold, New Era, No 3 Wilson's G M C, Odin Reef Co, Oriental Perserverance G M C, Paddy's Reef Trib Co, Palm Gold M Co, Palm Tribute Co, Pearl Tribute Co, Pegleg Gully Quartz G M C, Pegleg Quartz M C, Princess Dagmar G M C, Prince of Wales Amalgamated (Tarnagulla), Pyrances Gold M C, Passby United G M C, Quartz Hill Quartz M C, Pevieres Victory Trib Co, Royal Oak Quartz, Royal Standard Trib Co, Royal George Quartz G M C, Royal Golden Fleece, Sable Chief G M C, Sainia Reef Quartz M Co, South Fraser Reef G M C, Southern New Chum Gold M C, Shanandoor Tribute, Sebastian Gold M Co, Sophia & Redan G M Co, Youth Bell Vue Co, Shannon Company, South Extended Wallaby Co, South Ramrod Co, South Royal Hustlers Co, South Wallaby Trib Co, United Hustlers, United Hustlers & Redan Co, United Bros Tribute Co (Myrtle Creek), United Gold Mine Co, Victoria Reef Gold M Co, Victorian Consolidated M Co, Victoria Reef Quartz, Virginia Gold M Co, Victory and Pandora, Young Chum, South Homeward Bound Co, South Shilling Co, South Nuggetty Co, South Devonshire Co,South Keep it Dark, Try Again Tribute Co Victoria Hill.document, gold, mining reports, mining reports, list of gold mines or mining companies, australian united quartz co sandhurst, advance co, big hill tribute co, birds reef railway reserve mine co, british banner gold m co, brookfield gold m co, carlisle north garden gully, caroline gold m co, central garden gully, charles gavin duff gold m co, charleston quartz, cinderella co, collman tacchi & nelson, confidnece gold m co, cornish united gold m co, derby gold mine co, dixon's tribute co, ellesmere black lead tribute co1871, empire amated, extended gold m co (majorca), extended co victoria reef, first chance tribute, fortuna, golden fleece & heales united, garden gully united, garden gully, golden fleece, golden point, golden lion tribute garden gully reef, great golden fleece co, great wonder co, gilmons golden palm trib co, golden garden gully co 1873, golden sovereign extended trib co 1872, great extended garden gully co 1874, great extended garden gully co 1874, great extended south hustlers co 1872, great republic corp, ironbark co, kangaroo flat steam puddling & qaurtz m co, riverpool gold m co, iron duke co 1871, henry van der hugen pioneer g m co, kent m co, kentish co, mariners reef co, mary hill trib co, morning star gold mine co, mount korong lane's reef m co, new chum & victoria trib co, new hopeful gold m c, new homeward bound, new lord warden trib co, north lord warden trib co, north nelson, north golden pyke co, north old chum, north shamrock, north birds reef co, north birds tribute co, new chum freehold, new era, no 3 wilson's g m c, odin reef co, oriental perserverance g m c, paddy's reef trib co, palm gold m co, palm tribute co, pearl tribute co, pegleg gully quartz g m c, pegleg quartz m c, princess dagmar g m c, prince of wales amalgamated (tarnagulla), pyrances gold m c, passby united g m c, quartz hill quartz m c, pevieres victory trib co, royal oak quartz, royal standard trib co, royal george quartz g m c, royal golden fleece, sable chief g m c, sainia reef quartz m co, south fraser reef g m c, southern new chum gold m c, shanandoor tribute, sebastian gold m co, sophia & redan g m co, youth bell vue co, shannon company, south extended wallaby co, south ramrod co, south royal hustlers co, south wallaby trib co, united hustlers, united hustlers & redan co, united bros tribute co (myrtle creek), united gold mine co, victoria reef gold m co, victorian consolidated m co, victoria reef quartz, virginia gold m co, victory and pandora, young chum, south homeward bound co, south shilling co, south nuggetty co, south devonshire co, south keep it dark, try again tribute co victoria hill. -

Vision Australia

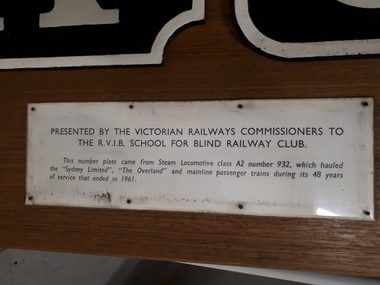

Vision AustraliaPlaque - Object, A2 932 train number plate

Cast iron numberplate (white on black background) mounted on wood, with a braille and a written nameplate which reads: "Presented by the Victorian Railways Commission to the R.V.I.B. School for Blind Railway Club. This number plate came from steam locomotive class A2 number 932, which hauled the 'Sydney Limited', the 'Overland' and mainline passenger trains during its 48 years of service that ended in 1961." Cast iron numberplate on wood royal victorian institute for the blind, rvib school -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePrint - Vessel, Sailing Ship, A.V. Gregory, ca. 1899-1922

This photograph is a print from an original painting by the Australian marine artist A V Gregory (1867-1957), also known as Arthur Victor Gregory. Gregory lived and worked in South Melbourne. He took over the Gregory Studio owned by his father, George Frederick Gregory, painting actively between 1899 and 1932. He usually signed his works as ‘A V Gregory’. Some of his original works have been sold for thousands of dollars. The four-masted iron barque 'Rowena' was built in 1883 by Barclay, Curle & Co. of Glasgow as the 'Cluny Castle', and renamed about 1890 as 'Rowena' by owners Rowena Ship Co.. After consequent owners, the ship was converted to a hulk in 1922 at Port Adelaide. The detailed image of the vessel depicted in this print shows one of the many sail and steam vessels painted by the renowned Victorian marine artist A V Gregory, whose original works are highly valued today by marine collectors.Photograph of a print, black and white, mounted onto card. It depicts the four-masted iron barque ship 'Rowena', originally named 'Cluny Castle'. The original painting was by marine artist A V Gregory.Painted on bow "ROWENA"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, photograph, photograph of rowena, gregory, cluny castle, a v gregory, rowena, iron baque, rowena ship co., barclay, curle & co, glasgow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessel, Sail and Steam Ship, S.S. Warrnambool

This photograph and a matching earlier photograph are the images of a painting of the British steamship SS Warrnambool at Dover Strait in the English Channel. The photographs were donated by the painting’s owner, who acquired the 30” x 56” (76 x 142.5 cm) oil on canvas painting in 1998. Both photographs were accompanied by a letter, one written in 2001, and the other in 2003. The letters confirm that the artist of the painting was Charles Keith Miller, signed with the initials “CKM” and dated “1893”. The painting shown in the photographs was a gift to the Town Council of Warrnambool, presented to Warrnambool folks in Melbourne on December 1, 1892, by the Captain of William Lund’s ship SS Warrnambool. The painting was given by Lund in appreciation of the Ladies of Warrnambool who had presented the ship with a ‘house’ flag bearing the Blue Anchor Line’s symbol of a diagonal blue anchor on a white background; the ladies had made the decision to present the flag only a month earlier. A few days later, December 6th, the SS Warrnambool was on its homeward journey to Britain, sailing via Adelaide. It anchored for a short time off the Port of Warrnambool. A boat was launched from Lady Bay to take a group of friends to the ship with a delivery of gifts. After cheers were roused for both the ship and the Captain, the ship continued on its way. The photograph shows the gifted white flag with a diagonal blue anchor flying from the masthead. The same symbol is painted on the ship’s black funnel. The signal flags on the foremast display ‘M’ ‘R’ ‘V’ ‘B’. These letters are most likely the ship’s call number ‘MRVB’. Although the painting was given as a gift in December 1892, it is post-dated “1893”. Perhaps the painting was given earlier than anticipated; or the date added later, but whatever the reason, the provenance of the painting was confirmed at auctions of this painting and other works by the same artist. CHARLES KEITH MILLER 1836-1907:- Captain Charles Miller left his home in Scotland at the age of 15 years for a life at sea. He earned his Master’s Certificate ten years later. After being the captain of sailing ships he moved over to the steamships because they were faster. In 1866 he married and settled in Glasgow. Over the following eleven years he and his wife had five children, then sadly his wife passed away. Captain Miller returned to the sea for a while but in 1888 he gave up his sea life to spend his time as a marine artist. His understanding of seafaring life and vessels, combined with his artistic skills, gave him the ability to produce fine art and several galleries and museums have collections of his sought-after works. S.S. WARRNAMBOOL 1892-1925:- The steamship SS Warrnambool was built in 1892 by the Sunderland Ship Building Company for the Lund Line of London, founded by William Lund in 1869. It efficiently carried both passengers and cargo across the world to Australia, under the command of her master Captain Joshua Edward Iibery, who had many years of experience with the Blue Anchor Line. The company, referred to as the Blue Anchor Line or BAL, owned a fleet of both sail and steamships. The funnels of all of the steamships were painted black, with a white band around the top bearing a diagonal blue anchor and chain. The company’s house flag was also white with a diagonal blue anchor. The SS Warrnambool carried passengers and cargo in a ‘no frills’ service to and from Europe around the Cape of Good Hope, stopping at some ports in between. The ship was involved in bringing home returned solders in 1895. At one time it carried a doctor from Victoria, Australia, to assist at the war front in South Africa. The ship had a very good reputation for its cargo arriving ‘almost always in excellent condition.’ Exported goods from Australia included iron safes, flour, wool, apples, frozen rabbits, butter, cheese, pork, cattle, poultry and sheep. One remarkable delivery contained Ostriches for Queen Victoria and they survived the journey well. The SS Warrnambool was sold in 1900 to the British and South American Steam Navigation Co. Ltd of Liverpool and was renamed ‘Harmodius’. The company was managed by R.P. Houston & Company of London and its Houston Line funnels were red with a black top. The Harmodius was sold in 1919 to K.S.S. Co. Ltd, managed by Kaye Son & Co. Ltd. of Liverpool, and was renamed ‘Kut’. The line had black funnels with a white ‘K’ in a diamond or between white stripes. In 1926 it was purchased by T.W. Ward Ltd. and broken up. NOTE- other vessels named “Warrnambool” Two other vessels carried the name “Warrnambool” (1)- HMAS Warrnambool J202 (1941-1947), a Bathurst Class corvette vessel owned by the Royal Australian Navy, destroyed by a mine. The photograph is significant for its association with the painting "SS Warrnambool" by well-known early 20th century marine artist Charles Keith Miller, whose paintings are well valued. The painting and the photograph of it are namesakes of Warrnambool and are connected through the gifts exchanged between the ship company owner, the City of Warrnambool and the Ladies of Warrnambool; the House Flag and the painting by C K Miller. The image is a good likeness to original photographs of the late-19th to early-20th century steam and sale vessel. Coloured photograph of a painting, the steamship S.S. Warrnambool. The three-masted ship has lowered sails. It is in calm water, land on one side, and other vessels in the water. The ship has four raised signal flags, a house flag and a blue ensign. The funnel also bears the house flags symbol. Smoke emits from the funnel. Figures are visible onboard. There is a signature and a title on the lower edge of the photograph. (Artist of the painting in the photograph was Charles Keith Miller)House flag symbol, [diagonal blue anchor on white background] Text "CKM" and "1893" Text "S. S. WARRNAMBOOL."flagstaff hill, warrnambool, photograph, steam ship warrnambool, flagstaff hill maritime village, shipwreck coast, ss warrnambool, captain, charles keith miller, ckm, 1893, william lund, warrnambool town council, blue anchor line, lund line, ladies of warrnambool, house flag, diagonal blue anchor, captain miller, sunderland ship building company, migrant ship, 1892 ship, home flag, bal, australian export, s.s.warrnambool, dover strait, english chanel, port of warrnambool, lady bay, mrvb, captain charles miller, captain joshua edward iibery, ostriches, queen victoria, british and south american steam navigation co., harmodius, r.p. houston & company, houston line, k.s.s. co. ltd, kaye son & co. ltd, kut, t.w. ward ltd -

Flagstaff Hill Maritime Museum and Village

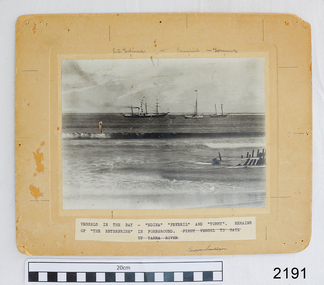

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessels, Sailing Ships, Vessels in the bay, 1890's

The photograph, taken in the 1890s, shows sailing ships and a wreck in Lady Bay, Warrnambool. Lady Bay was once a very busy port of trade in Warrnambool and was also called the Port of Warrnambool or Warrnambool Harbour. ENTERPRISE (1847-1850) NOTE: The “Enterprise” wrecked in 1850 in Warrnambool should not be confused with John Pascoe Faulkner’s ‘Enterprise’, which was wrecked in NSW in 1847. The 58-ton schooner Enterprise was built by David Hay in Waiheke, New Zealand in 1847 and registered by owners John Watson and Edward Byam in Melbourne, Australia. She was a single-deck sailing ship with two masts, used for carrying cargo such as local agricultural produce and general commodities between Melbourne and other colonial ports. On September 14th, 1850 the Enterprise had sailed from Melbourne under the control of the ship’s Master, James Gardiner Caught, and was moored in at the Tramway Jetty in Lady Bay, laden with wheat and potatoes. The vessel rode out a south-easterly gale but eventually dragged anchor and was beached, bow first and then broadside. Buckwall, a local indigenous man, braved the heavy surf and reached the stricken vessel with a rescue line, saving all five crew on board. There were no passengers on board. The Enterprise wreck was in an area called Tramway Jetty in Lady Bay. Since then the area has become the location of Lady Bay Hotel and now, in 2019, it is in the grounds of the Deep Blue Apartments. In fact, with the constantly changing coastline through built-up sand, the wreck site is now apparently under the No 2 Caravan Park on Pertobe Road, perhaps 150 metres from the high tide. Its location was found by Ian McKiggan (leader of the various searches in the 1980s for the legendary Mahogany Ship). The Warrnambool Wreck Enterprise is listed on the Victorian Heritage Database VHR S238. DIFFERENTIATING the New Zealand Schooner “Enterprise” from John Fawkner’s “Enterprize“ Dr Murray Johns, Melbourne, says in his article The Mahogany Ship Story, “…the Enterprise, wrecked in Lady Bay, Warrnambool in 1850 ... was soon covered by sand but was exposed again after several storms in 1887. “Samples of timber were then cut from the wreck, which would then have been buried for 37 years. In November 1887 the Warrnambool Standard reported that “the timber looks sound and hard, a penknife scarcely making any impression.” “For many years there was confusion about the identity of that ship in Lady Bay. Most people believed it was the wreck of John Pascoe Fawkner’s Enterprize, which had sailed from Tasmania to Victoria bringing the pioneer settlers to Melbourne in 1835. “In fact, as I documented in 1985, the Warrnambool wreck was of an entirely different ship, also called Enterprize [Enterprise], but built in New Zealand in 1847. Fawkner’s ship had already been sold to Captain Sullivan in 1845 and was wrecked on the Richmond Pier in northern New South Wales early in 1847. “In 1985 a piece of timber from the local Enterprise, which had been kept at the Warrnambool Museum since 1892, was identified histologically as a New Zealand timber, not Tasmanian timber such as blue gum, from which Fawkner’s Enterprize would have been built in 1830. This confirmed the identity of the Warrnambool Enterprize.”[Dr. M.W. Johns later wrote an article called “The Schooner Enterprise: A Final Word on a Historic Wreck.”] ABOUT THE S S EDINA The three-masted iron screw steamer SS Edina was built in Glasgow, Scotland, in 1854 by Barclay and Curle. She was adorned with the figurehead of the ‘fair maid of Judea’. The many years of service made SS Edina famous worldwide as the longest-serving screw steamer. (The term screw steamer comes from being driven by a single propeller, sometimes called a screw, driven by a steam engine.) SS Edina’s interesting history includes English Chanel runs, serving in the Crimean Ware carrying ammunition, horses and stores to the Black Sea, and further service in the American Civil War and later, serving in the western district of Victoria as well as in Queensland and carried gold, currency and gold prospectors Australia to New Zealand. SS Edina had the privilege of being an escort vessel to H.R.H. the Duke of Edinburgh during his visit to Australia in 1867. In March 1863 SS Edina arrived in Port Phillip Bay, Melbourne and was bought by Stephen Henty, of Portland fame, to work the cargo and passenger run from Melbourne – Warrnambool – Port Fairy - Portland. After a short time of working the run from Australia to New Zealand, with passengers and cargo that included gold and currency, she returned to her Melbourne - Warrnambool – Port Fairy run, with cargo including bales of wool produced in the western district of Victoria. The Warrnambool Steam Packet Company purchased SS Edina in 1867; she was now commanded by Captain John Thompson and Chief Engineer John Davies. She survived several mishaps at sea, had a complete service and overhaul and several changes of commanders. In 1870 SS Edina was in Lady Bay, Warrnambool, when a gale sprung up and caused a collision with the iron screw steamer SS Dandenong. SS Edina’s figurehead was broken into pieces and it was not ever replaced. SS Edina was re-fitted in 1870 and was then used as a coastal trader in Queensland for a period. She was then brought to Melbourne to carry cargo and passengers between Melbourne and Geelong and performed this service from 1880-1938. During this time (1917) she was again refitted with a new mast, funnel, bridge and promenade deck, altering her appearance. In 1938, after more collisions, SS Edina was taken out of service. However, she was later renamed Dinah and used as a ‘lighter’ (a vessel without an engine or superstructure) to be towed and carry wool and general cargo between Melbourne and Geelong. In 1957, after 104 years, the SS Edina was broken up at Footscray, Melbourne. Remains of SS Edina’s hull can be found in the Maribyrnong River, Port Phillip Bay. This photograph is significant for its association with the screw steamer SS Edina, heritage listed on the Victorian Heritage Database VHR S199. She had endeared herself to the people of Port Phillip Bay as a passenger ferry, part of their history and culture. She played a significant role in the Crimean War, the American Civil War and the gold rush in New Zealand. She also served western Victoria for many years in her cargo and passenger runs. The SS Edina is famous for being the longest-serving screw steamer in the world. After spending her first nine years overseas she arrived in Melbourne and her work included running the essential service of transporting cargo and passengers between Melbourne and the western Victoria ports of Warrnambool, Port Fairy and Portland. The SS Edina was purchased in the late 1860s by the local Warrnambool business, the Warrnambool Steam Packet Co. and continued trading from there as part of the local business community. Her original ‘fair maid of Judea’ figurehead was broken to pieces in a collision with another vessel (the SS Dandenong) in a gale off Warrnambool, Victoria, in 1870. The photograph is significant for its association wreck of the Victorian Heritage Listed schooner Enterprise, VHR S238, being a New Zealand-built but Australian-owned coastal trader. The wreck was also significant for its association with the local indigenous hero, Buckawall, who saved the lives of the five crew on board. Photograph "Vessels in the Bay". Black and white photograph of several vessels in Lady Bay, Warrnambool, including some small vessels and "S.S. Edina", the "Peveril" and "Tommy", plus the remains of the wrecked vessel "Enterprise" in the foreground. Photograph is mounted on beige card with label describing the vessels, plus pencilled vessel names. There are several pin holes in each corner of the photograph. Typed label under the photograph “VESSELS IN THE BAY – “EDINA” “PEREVIL” AND “TOMMY”. / REMAINS OF “THE ENTERPRISE” IN FOREGROUND. (Also crossed out on the label “FIRST VESSEL TO SAIL UP YARRA RIVER). In pencil script above the vessels on the photograph “S.S. Edina”, “Peveril” “Tommy”. On the reverse is a printed sticker with “F-Ph 59/2 74”, red felt-tip pen “88”, green pen script repeating the text that is under the photograph on the front.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enterprize, port of warrnambool, warrnambool harbour, peveril, tommy, ss edina, lighter dinah, warrnambool steam packet company, lady bay, pleasure steamer, edina, trade, travel, screw ship, coastal trader, cargo, victoria, buckawall, indigenous rescue, indigenous hero -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessels Speculant and S. S. Flinders, Between 1902 and 1907

This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool. The two identifiable ships in this picture are the "Speculant" and the "S. S. Flinders" - both coastal trading vessels that regularly came and went from Warrnambool. The third steamer on the left hasn't been identified The barquentine SPECULANT was a steel, three-masted sailing ship built in 1895 in Inverkeithing, Scotland, registered in Warrnambool, Victoria and wrecked at Cape Paton, Victoria, 10th February 1911. The SPECULANT had been involved in the timber trade between the United Kingdom and Russia, until sold to its Warrnambool owners and timber merchants Messrs. P.J. McGennan & Co. (Peter John McGennan) in 1902 for 3000 pounds and had her sailed to Warrnambool as her new port. Peter John McGennan was born in 1844 and worked as a builder and cooper in Holyhead, Anglesea, Wales. He immigrated to Australia in 1869 as a free settler and arrived in Warrnambool in 1871 and undertook management of a property in Grassmere for Mr. Palmer. Peter met his wife Emily in South Melbourne and they married in 1873. They had ten children including Harry who lived to 1965, and Andrew who lived until 1958. (The other children were their four brothers - John who was killed in the Dardenalles aged 35, Frederick who died aged 8, Peter who died aged 28, Frank who died aged 5 weeks - and four sisters - Beatrice who died age 89, Edith who died aged 49, Blanche who died aged 89 and Eveline who died aged 48.) In 1874 Peter starting a boating establishment on the Hopkins River. In 1875 he opened up a Coopers business in Kepler Street next to what was Bateman, Smith and Co., moving to Liebig Street, next to the Victoria Hotel, in 1877. In 1882 he then moved to Lava Street (which in later years was the site of Chandlers Hardware Store). He was associated with the establishment of the Butter Factory at Allansford. He started making Butter Boxes to his own design and cheese batts for the Butter Factory. In 1896 established a Box Factory in Davis Street Merrivale, employing 24 people at its peak, (it was burnt down in 1923); and in Pertobe Road from 1912 (now the Army Barracks building). Peter was a Borough Councillor for Albert Ward from 1885 to 1891, he commenced the Foreshore Trust (including the camping grounds along Pertobe Road), and he was an inaugural Director of the Woollen Mill in Harris Street, buying an extensive share-holding in 1908 from the share trader Edward Vidler. They lobbied the Town Hall to have a formal ‘Cutting’ for the waters of the Merri River to be redirected from its natural opening south of Dennington, to its existing opening near Viaduct Road, in order to have the scourings from the wool at the Woollen Mill discharged into the sea. He sold Butter Boxes around the state, and had to ship them to Melbourne by rail. Peter’s purchase of the SPECULANT in 1902 enabled him to back-load white pine from Kaipara, New Zealand to Warrnambool to make his butter boxes then, to gain profitability, buy and ship potatoes and other primary produce bound to Melbourne. (McGennan & Co. had also owned the LA BELLA, which had traded in timber as well, until she was tragically wrecked with the loss of seven lives, after missing the entrance channel to Warrnambool harbour in 1905. It appears that the SPECULANT was bought to replace the LA BELLA.) In 1911 the SPECULANT had been attempting to depart Warrnambool for almost the entire month of January to undergo docking and overhaul in Melbourne. A month of east and south-easterly winds had forced her to remain sheltered in Lady Bay, Warrnambool apart from one morning of northerlies, when an attempt was made to round Cape Otway; she had to return to shelter in Portland after failing to make any headway. With only 140 tons of sand ballast aboard, the ship would not have been easy to handle. Captain Jacobsen and his crew of nine, mainly Swedes, decided to make for Melbourne, leaving Portland Harbour on 5th February 1911. By the 9th they had reached Cape Otway, where they encountered a moonless night, constant heavy rain, and a heavy sea with a south-easterly wind blowing. After safely rounding Cape Otway the course was changed to east, then north-east to take the vessel to a point six miles off Cape Patton, following the orders of Captain Jacobsen, who told the crew to be very careful with the steering, as the wind and sea was running to leeward. The patent log (used to measure speed) had been out of order for the last four months as no-one in Warrnambool was able to fix it: it was intended to have it repaired in Melbourne. In the meantime the crew measured the vessel's speed by looking over the side and estimating wind strength. This compounded the difficulties of imprecise positioning, as the strong cross wind and sea were acting on the lightly laden vessel to steadily drive it towards the shore. At 3.30am on Friday 10 February 1911 Captain Jacobsen and the first mate were looking over the side of the vessel when they heard the sound of breakers and suddenly struck the rocks. The crew immediately knew they had no chance of getting the SPECULANT off, and attempted to rescue themselves by launching the lifeboat, which was instantly smashed to pieces. One of the crew then volunteered to take a line ashore, and the rest of the crew were all able to drag themselves to shore, some suffering hand lacerations from the rocks. Once ashore they began to walk along the coast towards Lorne, believing it was the nearest settlement. Realising their mistake as dawn broke they returned westwards to Cape Patton, and found a farm belonging to Mr C. Ramsden, who took them in and gave them a change of clothes and food. After resting for a day and returning to the wreck to salvage some of their personal possessions, at 10am on Saturday they set out for Apollo Bay, a voyage that took six hours, sometimes wading through flooded creeks up to their necks. The Age described the wreck as "listed to starboard. All the cabin is gutted and the ballast gone. There is a big rock right through the bottom of her, and there is not the slightest hope of getting her off". A Board of Marine inquiry found that Captain Jacobson was guilty of careless navigation by not taking steps to accurately verify the position of the vessel with respect to Cape Otway when the light was visible and by not setting a safe and proper course with respect to the wind and sea. It suspended his certificate for 6 months and ordered him to pay costs. The location of the wreck site was marked for a long time by two anchors on the shoreline, until in 1970 the larger of the two anchors was recovered by the Underwater Explorers' Club and mounted on the foreshore at Apollo Bay. The bell from the wreck was also donated to the Apollo Bay Surf Lifesaving Club but is recorded to have been stolen. Rusting remains of the wreck can still be found on the shoreline on the southern side of, and directly below Cape Patton. Parts of the SPECULANT site have been buried by rubble from construction and maintenance works to the Great Ocean Road, as well as by naturally occurring landslides. Peter J McGennan passed away in 1920. The Gates in the western wall of the Anglican Church in Henna Street/Koroit St are dedicated to him for his time of community work, which is matched with other prominent Warrnambool citizens; Fletcher Jones, John Younger, J.D.E (Tag) Walter, and Edward Vidler. After Peter J McGennan's death Harry, Andrew and Edith continued to operate the family business until July 11th 1923 when the company was wound up. (Andrew lived in Ryot Street Warrnambool, near Lava Street.) Harry McGennan (Peter and Emily’s son) owned the Criterion Hotel in Kepler Street Warrnambool (now demolished). His son Sid and wife Dot lived in 28 Howard Street (corner of Nelson Street) and Sid managed the Criterion until it was decided by the family to sell, and for he remained Manager for the new owners until he retired. Harry commenced the Foreshore Trust in Warrnambool around 1950. The McGennan Carpark in Pertobe Road is named after Harry and there are Memorial-Stone Gates in his memory. (The Gates were once the original entrance to the carpark but are now the exit.). The Patent Log (also called a Taffrail log) from the SPECULANT, mentioned above, and a number of photographs, are now part of the Collection at Flagstaff Hill Maritime Village.. The S. S. Flinders was built by A. J. Inglis, Ltd, Pointhouse, Glasgow in 1878 for the "Tasmanian Steam Navigation Company', Hobart which merged with the "Union Steamship Company" of New Zealand and it was later sold to the firm "McIlwraith, McEacham and Company". It was built of iron and was 1000 tons and 227 feet, 1 inch long. It was described as "splendidly fitted up for the carriage of passengers and her cargo space was also very large". In the saloon about 130 passengers could be accommodated while the second class had sufficient room for one hundred passengers. In 1890, the S. S. Flinders would leave Melbourne on Mondays and Thursdays at 5 pm and reach Warrnambool the following morning at 8 am. On the return it would leave Warrnambool on Wednesdays and Saturdays at 5 pm and reach Melbourne the following morning. In 1896, the Weekly Times described the "steamer Flinders (otherwise known as "the Warrnambool mailboat") as "as good a sample of a seagoing steamer as there is trading on the Victorian Coast at the present time". In April 1896 newspaper reports noted the S. S. Flinders took 2915 bags of potatoes from Warrnambool to Melbourne (the largest shipment of that season) as well as 50 tons of tinned rabbits from the Hamilton Preserving Factory. It was also noted that particularly during the Christmas period, there were excessive demands for berths from holiday makers wanting to enjoy a holiday in Warrnambool. In May 1903, the S. S. Flinders narrowly escaped destruction when an explosion and subsequent fire occurred during the passage from Melbourne to Warrnambool. A drum (which apparently contained carbide of calcium) exploded and blew off a hatch cover. As the steamer got to within a mile or two of Warrnambool, smoke was seen coming out of the hold and (unknown to the passengers) flames had taken hold. The crew quickly got to work - closing down all the hatches and pumping water into the hold through a hole in the saloon floor. There were 30 or 40 cases of kerosene on board. The Flinders continued on to Warrnambool and berthed at the Breakwater. The passengers all went ashore - many unaware of the danger they had been in. A telephone message was sent to the local Fire Brigade Station however the fire was extinguished before the firemen and their equipment arrived. After the hold was checked, the Flinders was certified as seaworthy and left for Portland. The Flinders continued to transport Western District produce as well as passengers from Warrnambool to Melbourne until 1906 when (due to a decrease in shipping trade during the Winter and the availability of train services) the Flinders was replaced by the smaller steamer "Dawn" and in 1907 when it was sold to the "Adelaide Steamship Company" for use in the Western Australia coastal trade, it was replaced by the "S. S. Barrabool".This photograph is a significant record of two of the well known coastal traders (the "Speculant" and the "Flinders") that sailed along the south west coast of Victoria for many years - transporting goods and passengers between Melbourne and Warrnambool.Black and white photograph of the Breakwater in Warrnambool with two ships docked and another in the bay. On the front boat (the Speculant), men can be seen at the wheel, on the deck and on the bottom two booms where they appear to be furling the sails. The sails of the top booms are already furled. A small boy can be seen on the deck and a young girl, two women and a dog are on the Breakwater. There is a steam ship (the S. S. Flinders) tied up behind the "Speculant" and an unidentified steam ship (with smoke coming from its smokestack) in the bay. There is a blue and black handwritten label on the back of the photo - naming the ships and the owner of the photo.Speculant and Flinders / Passenger ship in / Lady Bay / name of donor and phone numberflagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, speculant, barque speculant, flinders, s. s. finders, steamship flinders, coastal trader, passenger ship, goods, steamer, breakwater, lady bay, warrnambool mailboat, p. j. mcgennan, peter john mcgennan, butter boxes, captain jacobsen, cape patton, tasmanian steam navigation company -

Flagstaff Hill Maritime Museum and Village

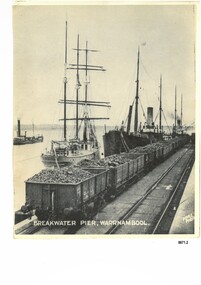

Flagstaff Hill Maritime Museum and VillagePhotograph - Vessels at Breakwater Pier, Warrnambool, Foyle Photographic Studio, circa 1906

This photograph was one of ten photographs donated to Flagstaff Hill Maritime Museum and Village by Fred Trewartha. Frederick John Fox Trewartha (Fred) was a well-known Warrnambool businessman. He was born in Beeac near Geelong in 1920 and came to Warrnambool with his family as a very young child. He was apprenticed to his father John, as a saddler and later opened his own shop on Raglan Parade. He then moved into working with tarpaulins and canvases for the trucking industry. Fred was keenly interested in photography (and was a member of the Warrnambool Cine Club), yachting and boat building. He kept his yacht moored at Port Fairy for many years and participated in sailing events locally and interstate. He also built boats with his sons. He had the opportunity to meet many older sailors and it's thought this photo (and others in the set) may have been given to him by one of these men. Fred Trewartha died in 2016 in Warrnambool. The three identifiable ships in this picture are the "Speculant", the "S. S. Barrabool" and the "S. S. Flinders" - coastal trading vessels that regularly came and went from Warrnambool. The steamer on the left hasn't been identified. The barquentine SPECULANT was a steel, three-masted sailing ship built in 1895 in Inverkeithing, Scotland, registered in Warrnambool, Victoria and wrecked at Cape Paton, Victoria, 10th February 1911. The SPECULANT had been involved in the timber trade between the United Kingdom and Russia, until sold to its Warrnambool owners and timber merchants Messrs. P.J. McGennan & Co. (Peter John McGennan) in 1902 for 3000 pounds and had her sailed to Warrnambool as her new port. Peter John McGennan was born in 1844 and worked as a builder and cooper in Holyhead, Anglesea, Wales. He immigrated to Australia in 1869 as a free settler and arrived in Warrnambool in 1871 and undertook management of a property in Grassmere for Mr. Palmer. Peter met his wife Emily in South Melbourne and they married in 1873. They had ten children including Harry who lived to 1965, and Andrew who lived until 1958. (The other children were their four brothers - John who was killed in the Dardenalles aged 35, Frederick who died aged 8, Peter who died aged 28, Frank who died aged 5 weeks - and four sisters - Beatrice who died age 89, Edith who died aged 49, Blanche who died aged 89 and Eveline who died aged 48.) In 1874 Peter starting a boating establishment on the Hopkins River. In 1875 he opened up a Coopers business in Kepler Street next to what was Bateman, Smith and Co., moving to Liebig Street, next to the Victoria Hotel, in 1877. In 1882 he then moved to Lava Street (which in later years was the site of Chandlers Hardware Store). He was associated with the establishment of the Butter Factory at Allansford. He started making Butter Boxes to his own design and cheese batts for the Butter Factory. In 1896 established a Box Factory in Davis Street Merrivale, employing 24 people at its peak, (it was burnt down in 1923); and in Pertobe Road from 1912 (now the Army Barracks building). Peter was a Borough Councillor for Albert Ward from 1885 to 1891, he commenced the Foreshore Trust (including the camping grounds along Pertobe Road), and he was an inaugural Director of the Woollen Mill in Harris Street, buying an extensive share-holding in 1908 from the share trader Edward Vidler. They lobbied the Town Hall to have a formal ‘Cutting’ for the waters of the Merri River to be redirected from its natural opening south of Dennington, to its existing opening near Viaduct Road, in order to have the scourings from the wool at the Woollen Mill discharged into the sea. He sold Butter Boxes around the state, and had to ship them to Melbourne by rail. Peter’s purchase of the SPECULANT in 1902 enabled him to back-load white pine from Kaipara, New Zealand to Warrnambool to make his butter boxes then, to gain profitability, buy and ship potatoes and other primary produce bound to Melbourne. (McGennan & Co. had also owned the LA BELLA, which had traded in timber as well, until she was tragically wrecked with the loss of seven lives, after missing the entrance channel to Warrnambool harbour in 1905. It appears that the SPECULANT was bought to replace the LA BELLA.) In 1911 the SPECULANT had been attempting to depart Warrnambool for almost the entire month of January to undergo docking and overhaul in Melbourne. A month of east and south-easterly winds had forced her to remain sheltered in Lady Bay, Warrnambool apart from one morning of northerlies, when an attempt was made to round Cape Otway; she had to return to shelter in Portland after failing to make any headway. With only 140 tons of sand ballast aboard, the ship would not have been easy to handle. Captain Jacobsen and his crew of nine, mainly Swedes, decided to make for Melbourne, leaving Portland Harbour on 5th February 1911. By the 9th they had reached Cape Otway, where they encountered a moonless night, constant heavy rain, and a heavy sea with a south-easterly wind blowing. After safely rounding Cape Otway the course was changed to east, then north-east to take the vessel to a point six miles off Cape Patton, following the orders of Captain Jacobsen, who told the crew to be very careful with the steering, as the wind and sea was running to leeward. The patent log (used to measure speed) had been out of order for the last four months as no-one in Warrnambool was able to fix it: it was intended to have it repaired in Melbourne. In the meantime the crew measured the vessel's speed by looking over the side and estimating wind strength. This compounded the difficulties of imprecise positioning, as the strong cross wind and sea were acting on the lightly laden vessel to steadily drive it towards the shore. At 3.30am on Friday 10 February 1911 Captain Jacobsen and the first mate were looking over the side of the vessel when they heard the sound of breakers and suddenly struck the rocks. The crew immediately knew they had no chance of getting the SPECULANT off, and attempted to rescue themselves by launching the lifeboat, which was instantly smashed to pieces. One of the crew then volunteered to take a line ashore, and the rest of the crew were all able to drag themselves to shore, some suffering hand lacerations from the rocks. Once ashore they began to walk along the coast towards Lorne, believing it was the nearest settlement. Realising their mistake as dawn broke they returned westwards to Cape Patton, and found a farm belonging to Mr C. Ramsden, who took them in and gave them a change of clothes and food. After resting for a day and returning to the wreck to salvage some of their personal possessions, at 10am on Saturday they set out for Apollo Bay, a voyage that took six hours, sometimes wading through flooded creeks up to their necks. The Age described the wreck as "listed to starboard. All the cabin is gutted and the ballast gone. There is a big rock right through the bottom of her, and there is not the slightest hope of getting her off". A Board of Marine inquiry found that Captain Jacobson was guilty of careless navigation by not taking steps to accurately verify the position of the vessel with respect to Cape Otway when the light was visible and by not setting a safe and proper course with respect to the wind and sea. It suspended his certificate for 6 months and ordered him to pay costs. The location of the wreck site was marked for a long time by two anchors on the shoreline, until in 1970 the larger of the two anchors was recovered by the Underwater Explorers' Club and mounted on the foreshore at Apollo Bay. The bell from the wreck was also donated to the Apollo Bay Surf Lifesaving Club but is recorded to have been stolen. Rusting remains of the wreck can still be found on the shoreline on the southern side of, and directly below Cape Patton. Parts of the SPECULANT site have been buried by rubble from construction and maintenance works to the Great Ocean Road, as well as by naturally occurring landslides. Peter J McGennan passed away in 1920. The Gates in the western wall of the Anglican Church in Henna Street/Koroit St are dedicated to him for his time of community work, which is matched with other prominent Warrnambool citizens; Fletcher Jones, John Younger, J.D.E (Tag) Walter, and Edward Vidler. After Peter J McGennan's death Harry, Andrew and Edith continued to operate the family business until July 11th 1923 when the company was wound up. (Andrew lived in Ryot Street Warrnambool, near Lava Street.) Harry McGennan (Peter and Emily’s son) owned the Criterion Hotel in Kepler Street Warrnambool (now demolished). His son Sid and wife Dot lived in 28 Howard Street (corner of Nelson Street) and Sid managed the Criterion until it was decided by the family to sell, and for he remained Manager for the new owners until he retired. Harry commenced the Foreshore Trust in Warrnambool around 1950. The McGennan Carpark in Pertobe Road is named after Harry and there are Memorial-Stone Gates in his memory. (The Gates were once the original entrance to the carpark but are now the exit.). The Patent Log (also called a Taffrail log) from the SPECULANT, mentioned above, and a number of photographs, are now part of the Collection at Flagstaff Hill Maritime Village.. The S. S. Flinders was built by A. J. Inglis, Ltd, Pointhouse, Glasgow in 1878 for the "Tasmanian Steam Navigation Company', Hobart which merged with the "Union Steamship Company" of New Zealand and it was later sold to the firm "McIlwraith, McEacham and Company". It was built of iron and was 1000 tons and 227 feet, 1 inch long. It was described as "splendidly fitted up for the carriage of passengers and her cargo space was also very large". In the saloon about 130 passengers could be accommodated while the second class had sufficient room for one hundred passengers. In 1890, the S. S. Flinders would leave Melbourne on Mondays and Thursdays at 5 pm and reach Warrnambool the following morning at 8 am. On the return it would leave Warrnambool on Wednesdays and Saturdays at 5 pm and reach Melbourne the following morning. In 1896, the Weekly Times described the "steamer Flinders (otherwise known as "the Warrnambool mailboat") as "as good a sample of a seagoing steamer as there is trading on the Victorian Coast at the present time". In April 1896 newspaper reports noted the S. S. Flinders took 2915 bags of potatoes from Warrnambool to Melbourne (the largest shipment of that season) as well as 50 tons of tinned rabbits from the Hamilton Preserving Factory. It was also noted that particularly during the Christmas period, there were excessive demands for berths from holiday makers wanting to enjoy a holiday in Warrnambool. In May 1903, the S. S. Flinders narrowly escaped destruction when an explosion and subsequent fire occurred during the passage from Melbourne to Warrnambool. A drum (which apparently contained carbide of calcium) exploded and blew off a hatch cover. As the steamer got to within a mile or two of Warrnambool, smoke was seen coming out of the hold and (unknown to the passengers) flames had taken hold. The crew quickly got to work - closing down all the hatches and pumping water into the hold through a hole in the saloon floor. There were 30 or 40 cases of kerosene on board. The Flinders continued on to Warrnambool and berthed at the Breakwater. The passengers all went ashore - many unaware of the danger they had been in. A telephone message was sent to the local Fire Brigade Station however the fire was extinguished before the firemen and their equipment arrived. After the hold was checked, the Flinders was certified as seaworthy and left for Portland. The Flinders continued to transport Western District produce as well as passengers from Warrnambool to Melbourne until 1906 when (due to a decrease in shipping trade during the Winter and the availability of train services) the Flinders was replaced by the smaller steamer "Dawn" and in 1907 when it was sold to the "Adelaide Steamship Company" for use in the Western Australia coastal trade, it was replaced by the "S. S. Barrabool". The S. S. Barrabool was a coastal steamer built by "Palmer Shipbuilding and Iron Company Limited" in Jarrow, Durham in 1874. It was bought by "Howard Smith Ltd" who was a pioneer in the coal trade between Melbourne and Newcastle. Howards Smith's early fleet contained ships named after local hills and mountains -"You Yangs", "Macedon", "Dandenongs" and "Barrabool". Later they extended their fleet to include ships that were well known in Warrnambool including the "Dawn" and the "Edina". The S. S. Barrabool had a chequered start and was nicknamed the "Great Australian Ram" because of the numerous accidents it was involved in. Between 1875 and 1883 it collided with three other vessels - sinking the "Queensland" on August 3rd, 1876, near Wilson's Promontory and sinking the "Bonnie Dundee" on 10th March 1879 off Lake Macquarie, New South Wales (with the loss of five lives). In August 1884 the Barrabool collided with the steamer "Birksgate" in Port Jackson causing considerable damage to "Birksgate". However in a newspaper article published in the "Truth" in March 1899 the S. S. Barrabool was described as "one of the fine old type of vessels" and "still a stout a craft as ever". The article was describing the practice of a "two-mate" system on board many ships (the Barrabool being one) whereby the company only employs two men (a first and second mate who must alternate watches of four hours each) rather than three mates who work four hours on and eight hours off. It was suggested that ships employing the "two-mate" system may find their insurance policies "null and void" should an accident occur. However the writer did note that the Barrabool was "officered by a captain and first and second mates .. whom it would be impossible to find more capable officers amongst the maritime fleet of the colonies". Between 1900 and 1909 the Barrabool was making regular trips along the east coast of Australia, carrying coal to Hobsons Bay (Melbourne) from Newcastle, Bellambi and Sydney. In 1907 it was brought in as a temporary replacement on the Melbourne to Warrnambool route for the S.S. Flinders. In 1912 the S. S. Barrabool ran aground off the Fitzroy River in Queensland and was found to be uneconomic to repair. It was brought back to Sydney and converted into a hulk. In August 1952 it was towed 17 miles off Sydney and scuttled. “Foyle” written on the photograph is the name of Foyle’s Photographic studio - originally owned by James Charles Foyle. He owned “Foyle’s Photo Card Studios” in Liebig St, Warrnambool, which operated between 1889 – 1919 At the time of the photograph the studio was owned by both Charles and Lilian Foyle (sometimes known as Lillian or Lily), either of whom could have taken this photograph. They also worked together at a later date on the photographs, sketches and paintings of the famous and historical Pioneers’ Honour Board.This photograph is a significant record of three of the well-known coastal traders (the "Speculant", the "S. S. Barrabool" and the "S. S. Flinders") that sailed along the southwest coast of Victoria for many years - transporting goods and passengers between Melbourne and Warrnambool.A black and white photograph titled "Breakwater Pier, Warrnambool". A line of coal trucks on rails are on the Breakwater. There are three ships (one sailing ship and two steamers) moored at the pier. In the left side of the picture is another ship. The name of the photographer is printed in the lower right corner. On the back of the photograph are the handwritten names of the moored ships written in blue pen. It also has the handwritten name, town and telephone number of the donor. In the bottom right hand corner is an upside down stamped number in black ink.Front of photograph - "BREAKWATER PIER, WARRNAMBOOL." "FOYLE PHOTO" Back of photograph - "Sailing Ship" "Speculant sail ship" "Barrabool coal ship" "Flinders Passenger ship" Name of donor W'Bool (and telephone number) "K-7148 M" (stamped upside down)flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, speculant, barque speculant, p. j. mcgennan, peter john mcgennan, speculant wreck, captain jacobsen, s. s. flinders, steamer flinders, a. j. inglis ltd, tasmanian steam navigation company, mcilwraith mceacham and company, warrnambool mailboat, coastal steamer, s. s. barrabool, howard smith ltd, two-mate system, coal ship, dawn, edina, lady bay, breakwater, warrnambool breakwater, foyle, foyle photographic studio warrnambool -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Steamers - Julia Percy, Dawn and Coorong, Chuck Photo Ballarat, Circa 1885