Showing 334 items

matching textile machines

-

National Wool Museum

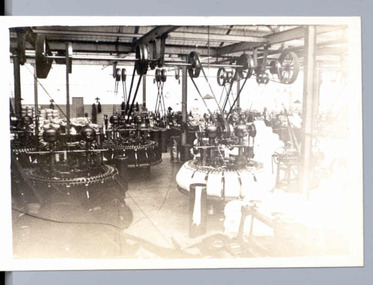

National Wool MuseumPhotograph - Noble Combs, Valley Worsted Mill, 1923

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs. "These 12 machines ended their working life in 1981 when the mill switched from the Bradford system of wool combing to the Continental system, the reason being was that the cost of maintaining them became too high, also the replacement rectilinear combs production rate was far greater and achieved higher yields although it could be argued that the Noble combs quality was superior". - Greg AldridgeBlack and white image showing the interior of a textile mill with machinery. Slightly overexposed on the right side.valley worsted mill, combing, noble comb, geelong -

National Wool Museum

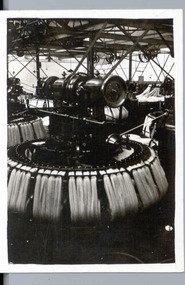

National Wool MuseumPhotograph, Noble Combing Machine, Valley Worsted Mill

This photograph shows the interior of the Valley Worsted Mill in 1923. The mill was first established at this time, and the photo shows the interior after tooling up but prior to the mill actually commencing operation. This photo is one of 31 in total and shows several Noble combs. The donor worked at the Valley Mill for many years. This mill still exists in Swanston Street, Geelong and is now being used by Melba Industries (an Austrim-Nylex company) to produce Jumbuck Nylon wool packs.Interior of Valley Worsted Mill, c.1923.textile mills, valley worsted mill foster valley mill pty ltd, combing, noble comb -

National Wool Museum

National Wool MuseumQuilt, Commercially made quilt

Commercially made quilt, c.1930s. Maker unknown, found in Ballarat. The Country Women's Association of Victoria had been active during the Depression in promoting the use of wool in domestic items and handcrafts in its "Handcrafts and Home Industries Committee". In 1933 during "Wool Week", a train jointly sponsored by the Wool Board, toured the state demonstrating amongst other crafts, the making of wool quilts and mattresses. Commercially made quilts much like this one marketed as 'Kosy Quilts', were used in these demonstrations.Quilt, plain light blue cotton cover with lambs wool filler. Machine sewn. Evidence of a label can be seen at one corner, however it has been removed.quilting history, textile mills, running stitch group, running stitch collection, ballarat, quilting - history -

National Wool Museum

National Wool MuseumTextile - Suitings Quilt

Origins are unknown, however it may be possible that since the creator of this quilt has used larger than usual pieces of suiting material, they may have worked as or knew of a tailor for their fabrics.Quilt made of large strips of men's suiting fabric. Machine stitched. Red flannel backing.quilting history, patchwork history, running stitch group, running stitch collection, quilting - history, patchwork - history -

National Wool Museum

National Wool MuseumTextile - Quilt, 1910 - 1940

Part of the "Wagga collection". Made from squares of patchwork suiting, machine stitched with red diamond and rectangle motifs at strategic positions. The diamonds look like they have been inserted in the fabric pieces where a dart has been cut and opened out.Quilt made of squares of patchwork suiting and fabric offcuts, machine stitched with red diamond and rectangle motifs at strategic positions.quilting history, patchwork history, running stitch group, running stitch collection, quilting - history, patchwork - history -

National Wool Museum

National Wool MuseumFunctional object - Time Card Rack

A time clock, sometimes known as a clock card machine, punch clock, or time recorder, is a device that recorded the time an employee entered and left the factory. In mechanical time clocks, this was accomplished by inserting a heavy paper card, called a time card, into a slot on the time clock. When the time card hit a contact at the rear of the slot, the machine would print day and time information (a timestamp) on the card. One or more time cards could serve as a time sheet or provide the data to fill one. This allowed a timekeeper to have an official record of the hours an employee worked to calculate the pay owed an employee.Metal time card rack.time sheet, time card, factory, employee, work life, punch clock, textile industry -

National Wool Museum

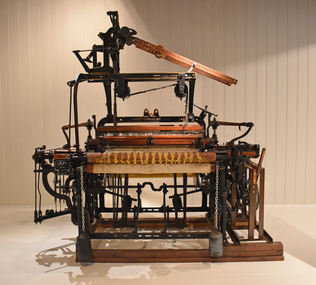

National Wool MuseumMachine - Loom, George Hattersley and Sons Ltd, 1920 - 1935

Weaving is the interlacing of two yarns, one at right angles to the other. Yarns that run the length of the fabric are called the warp. Yarns that run across the fabric are called the weft. Most woven fabrics are produced on a loom. The warp yarns are raised to form an opening - the shed. The weft carrier, usually the shuttle, shoots through the shed. Then the warp yarns change position up and down. Finally, the weft is pushed tight against the previous yarns, gradually building up the fabric. Hattersley dobby loom. In working order, black painted cast iron.weaving, george hattersley and sons ltd, weaving machinery, loom, wool processing, textile industry -

National Wool Museum

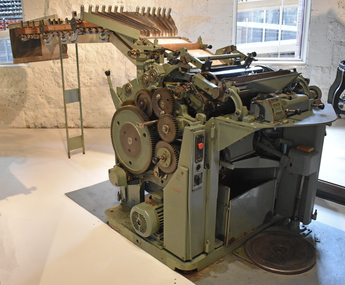

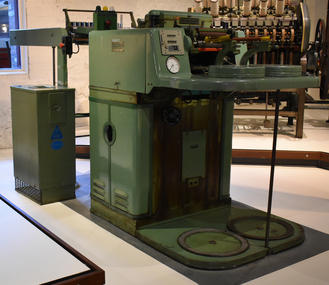

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

... processing Textile Industry Factory Machine comb restoration fibres ...Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

National Wool MuseumMachine - Cap Spinner, 1925

... and knitting. weaving knitting cap spinning cap spinner machine textile ...This cap spinner squeezes the thread under the stationary cap and winds them onto the bobbin. Spinning transforms tops into yarns. The tops are pulled out into fine strands known as rovings. They are then twisted to bind the thread together to give the yarn greater strength. The yarns are wound into differently shaped tools. They are then sent off for weaving and knitting.Cap spinning machine.weaving, knitting, cap spinning, cap spinner, machine, textile industry, factory -

National Wool Museum

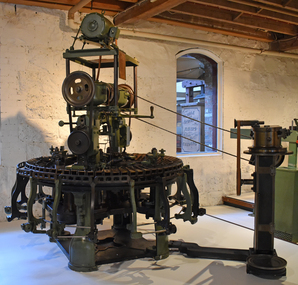

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

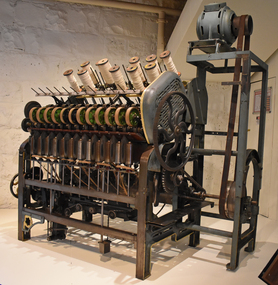

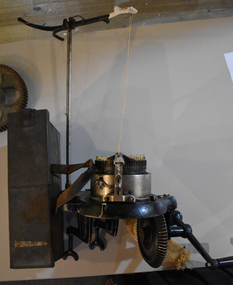

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

National Wool Museum

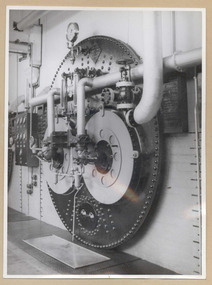

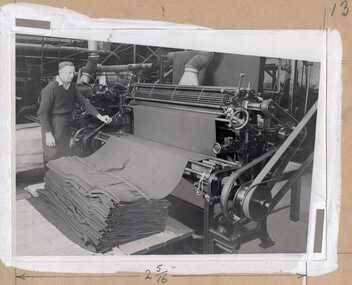

National Wool MuseumPhotograph, Foster Valley Mill

Depicts part of the textile mach inery used at Foster Valley Mill. This particular machine has something to do with steam - possibly an autoclave?Textile machinery from Valley Mill.textile machinery, valley worsted mill -

National Wool Museum

National Wool MuseumMachine - Teasel Gig, c1890

When the fabric is removed from the loom it is often stiff, rough and uneven. There are a number of finishing processes, both mechanical and chemical that give wool fabrics their special look and feel. The fabric is often scoured again to remove oils and dirt picked up during manufacture. It is then pressed. For a soft and fluffy surface, the fabric is brushed. For a smooth surface, it is shorn. For centuries, machines similar to this teasle gig were used to finish fabrics. It uses the prickly flower head off the teasle plant (Dispsacus Fullonum) to do the delicate work to raise the surface, or nap, the woollen cloth. At least 1,500 teasle heads are needed for one gig. The teasel is a thistle like plant whose dried heads are used on the teasel gig. They are fixed to frames around the drum, or gig. The gig turns in the opposite direction to the flow of the cloth until the nap is raised. Also spelled as Teazel Gig.Large metal machine with wooden rollers and teasel covered drum.textile finishing, raising, raising machinery, teasel gig, fabric, wool processing, plants, thistle, drum -

National Wool Museum

National Wool MuseumPhotograph

Depicts the a cloth shearing machine within a mill, c.1950s. Part of a series of photos depicting the various operations within a textile mill, all of which have been edited for publication.textile mills - operation, dry finishing, cloth shearing -

National Wool Museum

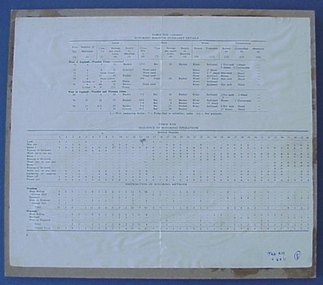

National Wool MuseumSheet, Instruction

... Processes. Scouring Machine Auxiliary Details over. Textile Mills ...Instruction sheet for mill floor operator, Appendix IV Materials Used in Scour, Lathes, Mill & Wash-Off Processes. Scouring Machine Auxiliary Details over.Other side of sheet.textile mills, collins bros mill pty ltd -

National Wool Museum

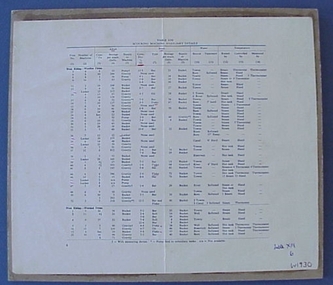

National Wool MuseumSheet, Instruction

... XIII Scouring Machine Auxiliary Details. Textile Mills Collins ...Instruction sheet for mill floor operator, Table XIII Scouring Machine Auxiliary Details.textile mills, collins bros mill pty ltd -

National Wool Museum

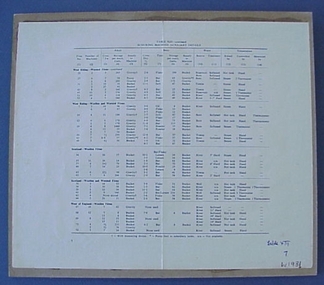

National Wool MuseumSheet, Instruction

... XIII Scouring Machine Auxiliary Details - continued. Textile ...Instruction sheet for mill floor operator, Table XIII Scouring Machine Auxiliary Details - continued.Other side of sheet.textile mills, collins bros mill pty ltd -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine, G Stibbe and Co, c.1928

... until 1978. Sock Knitting Machine Manufacturing Textiles Socks ...Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Dellruss Pty Ltd original owner Llyold Henry Coburg. Mock ribber fitted post World War 2. In use from c.1928 until 1978.Stibbe Maxim circular sock knitting machine.sock knitting machine, manufacturing, textiles, socks, machines, circular, clothing, industry, wool -

National Wool Museum

National Wool MuseumMachine - Sock Knitting Machine

... into seamless clothing. Sock Knitting Machine Textile Industry Wool ...Knitted fabric is made with a single yarn or sets of yarns moving in only one direction. Whether done by hand or by machine, the process is the same. The knitting needle loops the yarn through itself to make a chain of stitches. These chains, or rows, are connected to produce the knitted cloth. There are two types of commercial knitting machine. A flat-bed has its needles, one for each loop, arranged in a straight line to produce a flat fabric. A circular machine has its needles arranged on a rotating circle. The cloth forms as a tube which can be made into seamless clothing. Griswold bench-type sock knitting machine hand operated by turning the handle.sock knitting machine, textile industry, wool, fashion, clothing -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Textile - Supper cloth, not known

not knownCream linen supper cloth with wide border of machine made lace. From collection of Bette Jones.domestic items, table setting, handcrafts, lacemaking -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Textile - Embroidered panel

Part of Bette Jones collectionHand embroidered panel, cream coloured with brown cotton band machined onto lower edge. Blue and gold embroidery on brown band.handcrafts, embroidery -

Whitehorse Historical Society Inc.

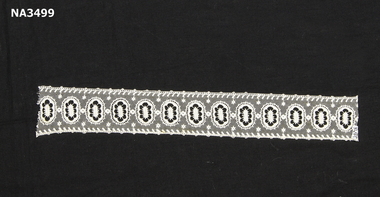

Whitehorse Historical Society Inc.Textile - Length of lace edging

... Mitcham melbourne manchester trimmings Machine embroidery on net ...Machine embroidery on netmanchester, trimmings -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine

Sewing machine, hand operated with transverse shuttle, spool wound by running on to a large wheel. Serial no. S6362996|Wooden cover with inlaid pattern on top, metal handle. Painted black gold leaf pattern on arm and plate.Wertheim written in gold on front and a pattern also around metal keyhole.|WERTHEIM FRANCFORT impressed on oval medallion depicting workman with hammer on shoulder.textile machinery, sewing, domestic items -

Whitehorse Historical Society Inc.

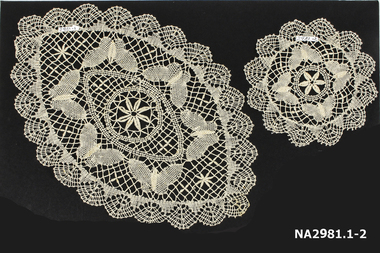

Whitehorse Historical Society Inc.Textile - Duchess Set, Doyley

... linen one oval and two round pieces, coffee coloured, machine ...From the estate of the late Jean Ord, mother of the donor.one oval and two round pieces, coffee coloured, machine made.domestic items, ornaments / decorative, manchester, table linen -

Whitehorse Historical Society Inc.

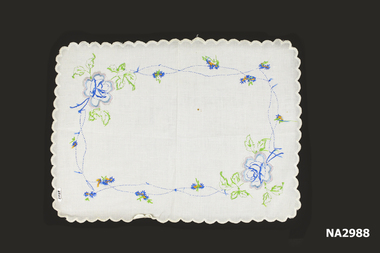

Whitehorse Historical Society Inc.Textile - Table Mat

From the estate of the late Jean Ord, mother of the donor.A large square table mat with scalloped machined edging. Decorated with large blue satin stitch roses in diagonal corners with green outline leaves. In the other corners are blue chain stitch daises with yellow centres and green chain stitch leaves all lined with blue stem stitch.manchester, table linen, handcrafts, embroidery -

Whitehorse Historical Society Inc.

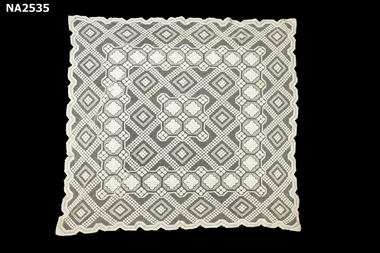

Whitehorse Historical Society Inc.Textile - Table Cloth, c1917

Purchased by Bruce Reynolds Aunt, Emily Templeman for her glory box in 1917.Cream cotton lace machine made all over pattern medallions, flowers and squares.manchester, table linen -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, 1941-42

Used by donor in family home.Portable electric singer sewing machine, rotating shuttle. There is a separate knee action control lever. Serial no. EG588844 .Black base with gold decoration. The wooden case top has 'Singer' on front. Motor K605945Singerdomestic items, sewing, textile machinery -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Textile - Table cloth and two napkins

From the Till collectionDark blue table cloth. Machine embroidered in blue and pink cotton plus two napkins.domestic items, table setting -

Whitehorse Historical Society Inc.

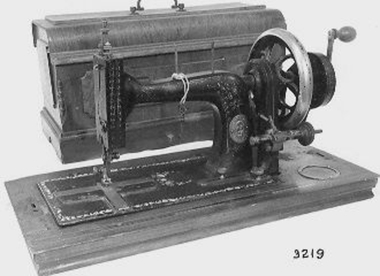

Whitehorse Historical Society Inc.Machine - Sewing Machine

WERTHEIM sewing machine transverse shuttle. Hand operated with thread winding attachment, uprights for reels of thread, tension adjuster and sewing mechanism. Serial no. S6005404|Handles folds into wheel for storage. Has a metal base with pearl insert on outer edge. originally painted black with gold scroll work - base is hinged to a wooden base. Wooden veneered cover stored separately. Aluminium label on body of machine with 'Werthiem Frankfort' around a figure sitting - all embossed.Wertheim Frankfort|Pes. Gesch and emblem on bobbin boxtextile machinery, sewing, domestic items -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Machine - Sewing Machine, c1880

Machine used by Francesca Schwerkolt, August Schwerkolt daughter -in - law. She was the grandmother of the donor.Hand and foot operated transverse shuttle sewing machine with ornate foot treadle. Wooden top with mechanism in centre. Base of mechanism has mother of pearl inlay. Ornate iron supports. Two drawers on either side with ornate handles. Centre drawerOn Sewing Mechanism - ' Syst 182/Manufactured in Germany/Specially for/Hugo Wertheim'|On Base - 'Griffin' in ironwork|'Wertheim' in ornate ironwork on sides|S No. 6778165domestic items, sewing, textile machinery