Showing 182 items

matching wool production

-

National Wool Museum

National Wool MuseumFolder, sample

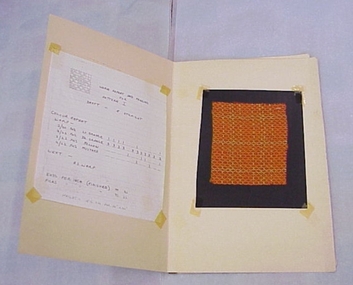

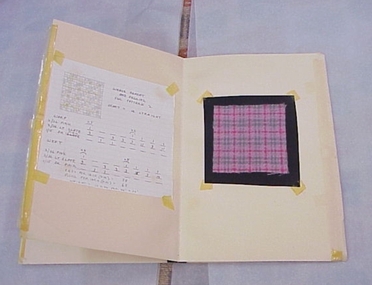

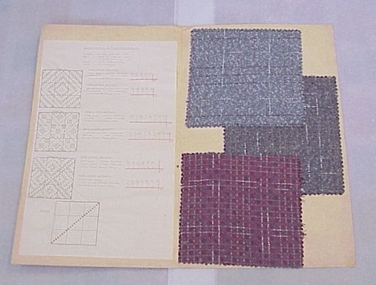

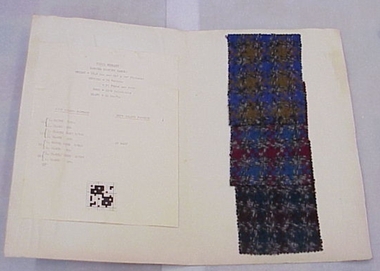

Weaving sample folder: "RANGE 2 WOOLLEN UPHOLSTERY FABRICS", "C. URQUHART". Booklets contains the following 2 paged inserts: "WEAVE REPEAT AND PATTERNING FOR PATTERN 1" sheet with orange patterned cloth; "WEAVE REPEAT AND PATTERNING FOR PATTERN 2" sheet with brown patterned cloth; "WEAVE REPEAT AND PATTERNING FOR PATTERN 1" sheet with yellow/green patterned cloth.RANGE 2 WOOLLEN UPHOLSTERY FABRICS C. URQUHART WEAVE REPEAT AND PATTERNING FOR PATTERN 1 WEAVE REPEAT AND PATTERNING FOR PATTERN 2 WEAVE REPEAT AND PATTERNING FOR PATTERN 3textile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

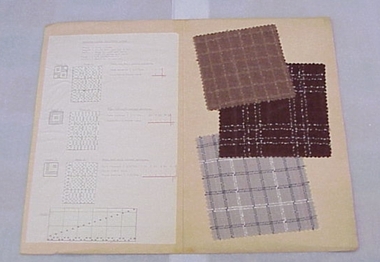

Weaving sample folder: "RANGE 4 LADIES WORSTED COSTUMING", "C. URQUHART". Booklets contains the following 2 paged inserts: "WEAVE REPEAT AND PEGGING FOR PATTERN 1" sheet with ochre/red/brown patterned cloth sample; "WEAVE REPEAT AND PEGGING FOR PATTERN 2" sheet with pink/grey patterned cloth sample; "PATTERN REPEAT AND PEGGING FOR PATTERN 3" sheet with orange/yellow/grey patterned cloth sampleRANGE 4 LADIES WORSTED COSTUMING C. URQUHART WEAVE REPEAT AND PEGGING FOR PATTERN 1 WEAVE REPEAT AND PEGGING FOR PATTERN 2 PATTERN REPEAT AND PEGGING FOR PATTERN 3textile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

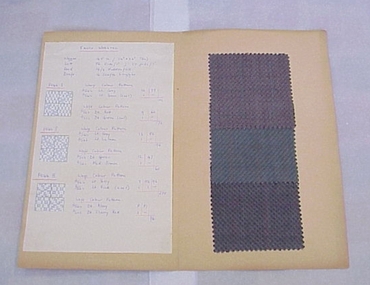

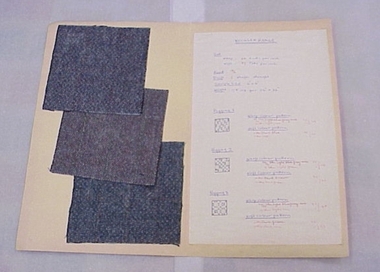

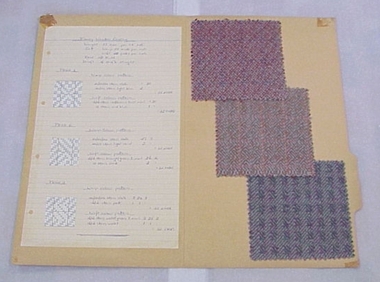

Weaving sample folder: "H.A. WILKINSON" contains "FANCY WORSTED" pattern sheet and 3 cloth samples.FANCY WORSTED (ink) H.A. WILKINSON (pencil)textile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

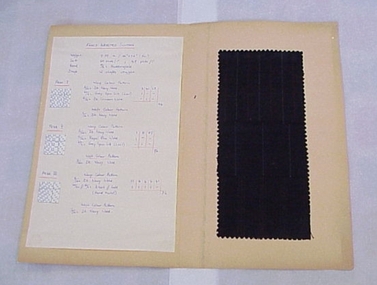

Weaving sample folder: "H.A. WILKINSON" and contains "FANCY WORSTED SUITING" pattern sheet and 3 black patterned cloth samples.FANCY WORSTED SUITING (ink) H.A. WILKINSON (pencil)textile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

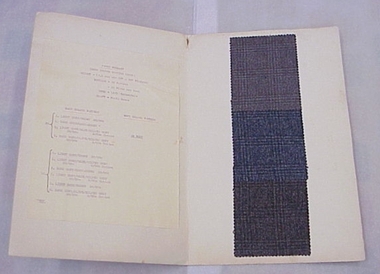

Weaving sample folder: JOHN YANG (1967) RANGE 2 and contains "LADIES COATING OR FURNISHING FABRICS" pattern sheet and 3 patterned cloth samples (light grey, medium grey, red).JOHN YANG (1967) RANGE 2 (ink) LADIES COATING OR FURNISHING FABRICStextile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

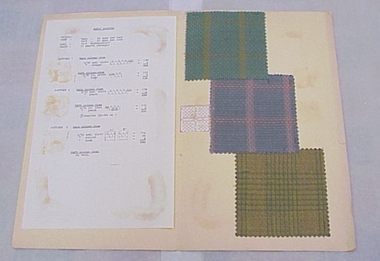

Weaving sample folder: "JOHN YANG (1967) RANGE 6" contains "WORSTED LADIES SKIRTING RANGE" pattern sheet and 3 checked cloth samples (light brown, medium brown, grey).JOHN YANG (1967) RANGE 6 (marker) WORSTED LADIES SKIRTING RANGEtextile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

Weaving sample folder: "K. NILA" contains "WOOLLEN RANGE" pattern sheet and 4 cloth samples (blue, brown, green and light brown).K. NILA (ink) WOOLLEN RANGE (ink)textile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

Weaving sample folder: "L. BOENUDA" contains "FANCY WORSTED" pattern sheet and 3 cloth samples (1 blue, 2 green).L. BOENUDA (ink) FANCY WORSTEDtextile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

Weaving sample folder: 3 "FANCY WOOLLEN" patterns with 3 cloth samples.5651 (ink/smudge) FANCY WOOLLENtextile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

Weaving sample folder: "E.C. McINTOSH 1963" contains "Fancy Woollen Coating" pattern sheet and 3 patterned cloth samples.E.C. McINTOSH 1963 (ink) Fancy Woollen Coating (ink)textile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumFolder, sample

Weaving sample folder: "FANCY WOOLLEN" patterns and 3 cloth samples5651 (ink) FANCY WOOLLENtextile production weaving, textile production, weaving -

National Wool Museum

National Wool MuseumBlanket, Travel rug

'Retsol' brand travel rug produced by the Returned Soldiers and Sailors Mill, Geelong. Retsol rugs were one of the specialities of the RSS Mill. This one was owned by Mrs A.T. Lucas who gave it to Running Stitch.RETSOLtextile production, textile mills, returned soldiers and sailors mill running stitch group, retsol rugs, running stitch collection, blankets, lucas, mrs a. t., geelong -

National Wool Museum

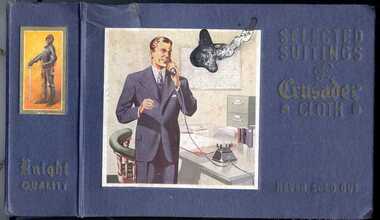

National Wool MuseumSample Book, "Selected Suitings of Crusader Cloth" sample book

This book dates from the 1940s and was part of the Running Stitch collection of quilts, probably because it was common for women to acquire these books from travelling salesmen. This sample book is an example of the type made by textile mills and given to tailors to sell fabric for made to measure suits. With little money to spare during the austere years of the war, women often acquired these books from tailors when the fabrics were no longer available. They made use of the fabric sample pieces to make quilts. The Australian Woollen Mills was an example of a woollen mill which went into worsted production making good quality English-type suiting. They were very successful until the 1960's when the oversupply of worsted fabrics from Europe and Asia led to the decline of the industry in this country. This book was displayed in the Running Stitch exhibition "Wool Quilts Old and New" of 1985 where it was catalogue entry number 40.Australian Woollen Mills Crusader fabric sample book, c.1940sKnight / QUALITY SELECTED / SUITINGS / of / Crusader / CLOTH / NEVER SOLD OUT Crusader / CLOTH / Makes the best suits "Crusader" / WORSTEDaustralian woollen mills pty ltd running stitch group, cloth - worsted, running stitch collection -

National Wool Museum

National Wool MuseumSign

Advertising sign (probably a point of sale sign) for Federal Woollen Mills blankets.Advertising sign for Federal blankets.Federal / THE SUPERIOR BLANKET / 100% PURE WOOL / NEW "DEEP-NAP" FINISH GIVES / NEW DOWNY LIGHTNESS ... / NEW WONDERFUL WARMTH / MADE IN AUSTRALIA BY / FEDERAL WOOLLEN MILLS / MAKERS OF / Federal / Fabricstextile production, federal woollen mills ltd, sign -

National Wool Museum

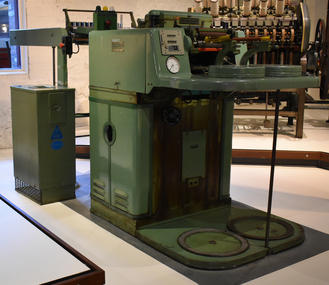

National Wool MuseumMachine - Gill Box, Deutscher Spinnereimaschinenbau Ingolstadt, 1963

This machine uses a series of combs attached to bars that move with increasing speed away from a starting point. This draws-out and aligns the wool fibres to produce a gilled top. The gilling process is also used in other positions along the worsted production line. A gill box draws and combs the fibres prior to spinning. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Gill box. Green painted steel.Deutscher / Spinnereimaschinenbau / Ingolstadt / 1963deutscher spinnereimaschinenbau ingolstadt, gilling, gill box, textile industry, wool processing, factory, machine, mills, spinning, fibre, comb -

National Wool Museum

National Wool MuseumTextile - Yarn Display

Samples of woollen yarn mounted on a board. From the Collins Bros' Mill, used by textile designs for creating patterns and design for sale to the publicSample display. Numbered cards of woollen yarn mounted on a wood display board. The woollen yarn is multi-coloured. yarn production, collins bros mill pty ltd -

National Wool Museum

National Wool MuseumPhotograph Album, The Valley Worsted Mills, Geelong

Photograph album containing 15 photographs of the textile processes which took place at the Valley Worsted Mill which was established in 1923.Photograph album contains 15 photographic postcards of textile processes from the Valley Mill, c.1920s. Valley Mill, Geelong, c.1920s. Wool sorting at the Valley Mill, Geelong, c.1920s. Wool scouring at the Valley Mill, Geelong, c.1920s. Woollen carding at the Valley Mill, Geelong, c.1920s. Worsted carding at the Valley Mill, Geelong, c.1920s. Combing and drawing at the Valley Mill, Geelong, c.1920s. Woollen spinning at the Valley Mill, Geelong, c.1920s. Worsted spinning at the Valley Mill, Geelong, c.1920s. Winding at the Valley Mill, Geelong, c.1920s. Warping at the Valley Mill, Geelong, c.1920s. Weaving at the Valley Mill, Geelong, c.1920s. Mending at the Valley Mill, Geelong, c.1920s. Wet finishing at the Valley Mill, Geelong, c.1920s. Dry finishing at the Valley Mill, Geelong, c.1920s. Warehouse at the Valley Mill, Geelong, c.1920s.PHOTOGRAPHS THE / VALLEY WORSTED MILLS / GEELONG WOOL SORTING / WOOL SCOURING / WOOLLEN CARDING / WORSTED CARDING / COMBING & DRAWING / WOOLLEN SPINNING / WORSTED SPINNING / WINDING / WARPING / WEAVING / MENDING / WET FINISHING / DRY FINISHING / WAREHOUSE C.J. Frazer Photographer / Melbournetextile mills warehouses, weaving, textile production, textile mills, valley worsted mill, scouring, carding, combing, drawing, spinning, winding, warping, wet finishing, mending, milling, dry finishing, textile mills - warehouses -

National Wool Museum

National Wool MuseumCap

This cap was part of a media kit produced by Melba Industries, part of the Austrim Textiles Group. The kit was given away at a media launch to publicise the production of an Australian made, nylon wool pack called 'Jumbuck'. The packs will be made at the former Valley Mill in Geelong. This launch occurred on 21 July 2000 and was attended by Andrew Moritz, National Wool Museum Director, who collected this media kit for the museum collection.Part of media kit for launch of 'Jumbuck', Australian made nylon wool packs produced by Melba Industries (part of the Austrim Textiles Group) in Geelong.JUMBUCK / AUSSIE-MADE WOOL PACKS Melba Industries 80% WOOL / 20% VISCOSE / ONE SIZE FITS ALL / HAND WASH ONLY / MADE IN CHINAblack, mr lindsay - melba industries (an austrim nylex ltd company) austrim nylex ltd valley worsted mill, jumbuck wool pack -

National Wool Museum

National Wool MuseumBag, Paper

This bag contained a media kit produced by Melba Industries, part of the Austrim Textiles Group. The kit was given away at a media launch to publicise the production of an Australian made, nylon wool pack called 'Jumbuck'. The packs will be made at the former Valley Mill in Geelong. This launch occurred on 21 July 2000 and was attended by Andrew Moritz, National Wool Museum Director, who collected this media kit for the museum collection.Contained media kit from the launch of 'Jumbuck', an Australian made nylon wool pack produced by Melba Industries (part of the Austrim Textiles Group) in Geelong.JUMBUCK TM / AUSSIE-MADE WOOL PACKS FILDESFAST / LABELS BAGS PRINTING / Tel: 1800 351 185black, mr lindsay - melba industries (an austrim nylex ltd company) austrim nylex ltd valley worsted mill, jumbuck wool pack -

National Wool Museum

National Wool MuseumMedia Kit

This media kit was produced by Melba Industries, part of the Austrim Textiles Group. It contains three photographs, as well as other company information. The photos depict Mr Alan Jackson, the chairman of Austrim, Mr Tom Quick, the general manager of technical textiles at Austrim, and a shot of the new packs being made in the old Valley Mill. The kit was given away at a media launch to publicise the production of an Australian made, nylon wool pack called 'Jumbuck'. The packs will be made at the former Valley Mill in Geelong. This launch occurred on 21 July 2000 and was attended by Andrew Moritz, National Wool Museum Director, who collected this media kit for the museum collection.Media kit from launch of 'Jumbuck', Australian made nylon wool packs made by Melba Industries (part of the Austrim Textiles Group) in Geelong. Contents of media kit produced for the launch of 'Jumbuck', Australian made nylon wool packs made by Melba Industries (part of the Austrim Textiles Group) in Geelong.Media Kit / JUMBUCK TM / AUSSIE-MADE WOOL PACKS / The Aussie-Made Pack / For A Cleaner Clipblack, mr lindsay - melba industries (an austrim nylex ltd company) austrim nylex ltd valley worsted mill, jumbuck wool pack, jackson, mr alan ao - austrim nylex ltd quick, mr tom - austrim nylex ltd -

National Wool Museum

National Wool MuseumSpool

Spools used at Foster Valley Mill. Large bobbin to hold fine yarns like silk or mercerised cotton (slippery, shiny threads) Used in production ofmen's suiting fabric with a fine stripe or thread effect. -

Otway Districts Historical Society

Otway Districts Historical SocietyBook, Closed 50 Years Ago. Norman Houghton, 2012

June 2012 represented 50 years since the Colac to Beech Forest to Weeaproinah narrow guage railway was closed. The last goods train ran on 27 June 1962, and the last passenger excursion train on 30 June 1962. The railway was the lifeblood of the West Otways for several decades, enabling farmers and saw millers to bring into economic production the natural wealth of the region. Timber, butter, wool, livestock, potatoes, fodder and minerals flowed out for the benefit of Victorian consumers.Closed 50 years ago. The Colac to Beech Forest narrow guage railway. Commemorative booklet - 30 June 2012. Norman Houghton. Norman Houghton; Geelong (Vic); 2012. iv, 52 p.; illus., maps. Soft cover.colac; beech forest; weeaproinah; railway; -

National Wool Museum

National Wool MuseumTextile - Dyers Apron

Over time, apron design and function diversified, and many trades and professions developed their own versions. Aprons were practical for protecting the wearer’s clothing as well as signifying their trade or craft. Wool dyeing was an industrialised profession to aid in the mass production of synthetic dyed clothing. This dyer’s apron would have protected the wearer from the chemicals of the dyer’s trade. There are several ways that fabrics would have been dyed including direct application, exhaust methods, continuous methods and waterless dyeing methods. As seen folded in archive box.dying, wool, apron, wool dying -

National Wool Museum

National Wool MuseumPhotograph - Slide, Stuart Ascough, Carding Production Rates, 1990s

This slide is part of a collection of visual resources used by Stuart Ascough while conducting training, seminars, conferences and lectures in China, Australia, India, Russia and Taiwan. This item is part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.35mm colour transparency mounted in plastic slide mount showing printed data relating to carding production rates.wool, industry, australia, australian wool board international wool secretariat, topmaking, carding, factory, training, gill box -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

National Wool Museum

National Wool MuseumMillion Dollar Bale Wool Sample, 1995

The wool was shorn from sheep of the Wyndarra and Rockbank bloodlines. A flock of 290 sheep were kept undercover at Kadinia, the property of the Appledore family from Brim in the Wimmera district of Victoria. Their record-breaking wool was produced by giving the sheep a special diet and providing each one with a UV-protective coat. Around 180 fleeces were selected for the million dollar bale. The sale of the first bale of wool measuring below 14 microns was held in the Auction Room here at the National Wool Museum. Bidding began at $600/kg and steadily increased until there were only two bidders left. The bidders represented the Japanese firm Aoki International and Loro Piana of Italy. The hammer fell at $10,300/kg, with Aoki International paying $1,194,800 for the 116kg bale. The fleece was scoured (cleaned) at the Goulburn Wool Scour, New South Wales. The degree of preparation and care taken with the task was extreme. The Scour closed production three days before and was extensively cleaned. On the day of scouring 12 tonnes of 17 micron wool was washed to condition the water, then nine bales of extra super fine wool, worth over $300,000 was washed as a trial run. Toabo Agaki Japan was employed to process the scoured wool into suit cloth. Taobo required the scoured wool to contain 0.5% residual grease, 12% moisture and a yield of 83kg. These requirements were met. The entire staff of the Scour wanted to be part of washing the best wool in the world. Without asking for payment both the night shift and afternoon shift crews assisted the day shift in the task. The bale was fed into the scour in seven minutes and fitted into three bowls, half the scour. It completely disappeared into the dryer and the last wool was fed before the first wool was out. The clean wool was hand-packed into cardboard cartons and freighted to Japan. Aoki International, based in Yokohama Japan, cut three suit lengths from the cloth, then blended the remaining wool into an exclusive line of commercially-available suits. These suits are labeled Kadinia.Wool sample from the Million Dollar Balewool sales, million dollar bale -

National Wool Museum

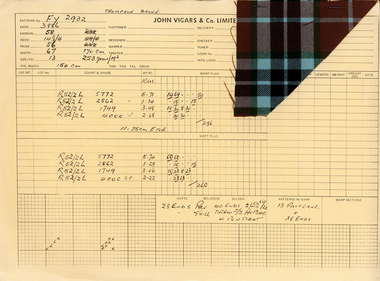

National Wool MuseumDocument - Mastercard, 1970-1975

Nino Corda was a Geelong based textile designer who worked at various textile mills between 1957 & 2003. He travelled the world in search of the latest fashions and techniques and developed timeless designs that were much loved by Australians. These items are on rotational display at the National Wool Museum’s ‘In the Factory’ exhibition. For many years, Nino also worked as part of the Honorary Staff of the National Wool Museum. His passion for the world of textiles provided energy and knowledge to the visitors and staff of the museum. Although Nino has now retired from his honorary position and has hung up his Australian Tartan vest, these items will continue to serve the community in sharing the stories of Australian Textile design. Once a pattern has been selected for mass production, a master card is produced. A mastercard shows exactly how to replicate the designs and colours depicted on the sample attached. “Ends” is the technical word to describe a vertical band and “picks” describes a horizontal band.Brown card with fabric sample stapled to the top right. Writing is present on the left and bottom of the card detailing the information applicable to the design of attached fabric. 14 individual Masetercards in collectiontextile calculations, textile design -

National Wool Museum

National Wool MuseumBook - Crochet and Knitwear Novelties, No 31, New Idea, c.1950s

Eighteen page black and white pattern book with colour front and back cover. Book contains black and white photographs and printed text. Front cover shows a colour image knitted items, a chicken tea cosy, knitted dolls outfit, and two crocheted textile items. front: [printed] FUN TO MAKE AND FUN TO GIVE / CROCHET AND KNITWEAR / Novelties / No 31 / 9 d. / A “NEW IDEA” PRODUCTIONfashion, women, knitting, crochet, home life, patterns -

National Wool Museum

National Wool MuseumBook - Crafts in Wool, Woman's World, c.1950s

Thirty six page book with black and white text and graphics. Front and back cover feature colour graphics, with the front showing a detail of brown and yellow textile with green text. front: [printed] CRAFTS / IN / WOOL / BY JESSE JENKINS / A WOMAN’S WORLD PRODUCTION / 1’3fashion, women, knitting, crochet, home life, patterns -

National Wool Museum

National Wool MuseumBook - Book of Correspondence, 1960s-1970s

Notes relate to blanket design, marketing, retail and production and repeatedly refer to ‘Phillips’. Refers to Physician Blankets, so possibly related to Collins Brothers Mill Pty Ltd. Note book with black cover, containing notes typed on pink, green and white paper, cut out and sticky taped into note book. Also contains some loose newspaper articles and wool samples. wool, victoria, working life, blankets, correspondence, scrapbook, letters, record keeping, woollen mill, collins bros mill pty ltd