Showing 9084 items

matching handling

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Jug, 1900 - 1940

Stoneware is a rather broad term for pottery or other ceramics that is fired at a relatively high temperature. A modern technical definition is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory fire clay. Whether vitrified or not, it is non-porous, it may or may not be glazed. Historically, across the world, it has been developed after earthenware and before porcelain and has often been used for high-quality as well as utilitarian wares. As a rough guide, modern earthen wares are normally fired in a kiln at temperatures in the range of about 1,000°C (1,830 °F) to 1,200 °C (2,190 °F); stoneware's at between about 1,100 °C (2,010 °F) to 1,300 °C (2,370 °F); and porcelains at between about 1,200 °C (2,190 °F) to 1,400 °C (2,550 °F). Historically, reaching high temperatures was a long-lasting challenge, and temperatures somewhat below these were used for a long time. Earthenware can be fired effectively as low as 600°C, achievable in primitive pit firing, but 800 °C was more typical. Stoneware also needs certain types of clays, more specific than those able to make earthenware, but can be made from a much wider range than porcelain. A domestic item used to store food products as glazing makes the container non-porous, often used for pickling. Or larger containers for kitchen flour. Items age is difficult to determine given the same techniques for making stoneware are in use today. Stoneware containers were made by many potteries in Australia and England. They were in common domestic use before plastics were invented around 1940 to store goods so this subject item is probably from around 1900 to the 1940s.Item's significance and origin of manufacture is difficult to determine given it is not associated with a place, person, historic event, or manufacturer. Its significance lies with its use as a domestic object giving today a view into our social past. Stoneware jug badly cracked and repaired with handle and short neckNoneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, jug, stoneware jug, earthenware jug, kitchen storage -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wicker Basket, mid-20th century

This handmade basket is typical of baskets used for domestic purposes for many years. The basket is strong and easily carried for shopping, food gathering and many other everyday purposes.The cane basket is currently not associated with a historical event, person or place at this time and is being used to augment Flagstaff's village display.Wicker or cane basket, rounded rectangular shape with strong handle.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, basket, cane basket, shopping basket, wicker work -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sharpening Steel

A honing steel, sometimes referred to as a sharpening steel, whet steel, sharpening stick, sharpening rod, butcher's steel, and chef's steel, is a rod of steel, ceramic or diamond-coated steel used to restore keenness to dulled blade edges. They are flat, oval, or round in cross-section and up to 30 centimetres (1 ft) long. The steel and ceramic honing steels may have longitudinal ridges, whereas the diamond-coated steels are smooth but embedded with abrasive diamond particles. Non-abrasive honing rods such as smooth ceramic or ribbed steel are able to remove small amounts of metal via adhesive wear. In normal use, the rod is applied to the blade at a slightly higher angle than that of the bevel, resulting in the formation of a micro-bevel. The term "hone" is associated with light maintenance performed on a blade without the effort and precision normally associated with sharpening, so the name "hone" was borrowed. In the 1980s, ceramic abrasives became increasingly popular and proved an equal, if not superior, method for accomplishing the same daily maintenance tasks; manufacturers replaced steels with ceramic (and later, manufactured diamond abrasive) sharpening "steels" that were actually hones. Use Honing steels are used by lightly placing the near edge of the blade against the base of the steel, then sliding the blade away from yourself along the steel while moving it down – the blade moves diagonally, while the steel remains stationary. This should be done with the blade held at an angle to the steel, usually about 20°, and repeating on the opposite side at the same angle. This is repeated five to ten times per side. Steeling It is often recommended that steeling be performed immediately before or after using a knife and can be done daily. By contrast, knives are generally sharpened much less frequently. A traditional smooth honing steel is of no use if the edge is blunt, because it removes no material; instead it fixes deformations along the edge of a sharp blade, technically known as burnishing. There has long been speculation about the efficacy of steeling (re-aligning the edge) vs honing (removing minor deformation with abrasives); studies tend to favour abrasives for daily maintenance, especially in high-carbide-volume "stainless" steels (such as the popular CPM S30V steel, which tends to "tear out" when steeled rather than re-forming an edge.) Small honing steel for outdoor activities Usage trends Steels have traditionally been used in the West, especially in heavy-use scenarios (e.g. butchering, where the edge deforms due to forceful contact with bone). These scenarios also lead Western trends toward blades tempered to a lower level of hardness (and thus lower brittleness). In East Asia, notably Japan, harder knives are preferred, so there is little need for steeling intra-day, as the edge does not deform as much. Instead, the blade is honed as needed on a waterstone. While tradition has kept the practice of steeling alive in Western kitchens, the majority of honing steels sold are abrasive rather than smooth, and knives are harder and more frequently made of stainless steel, which does not respond to traditional steeling techniques as well as high-carbon/low alloy tool steels.The sharpening steel is essential to maintain the sharpness of carving and other knives.Steel knife sharpener with bone handle. Part of a carving set.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, sharpening steel, carving set, kitchen equipment -

Flagstaff Hill Maritime Museum and Village

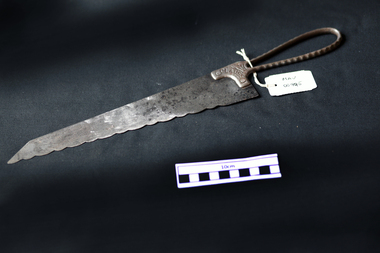

Flagstaff Hill Maritime Museum and VillageDomestic object - Knife

From the early days of our race, the knife represented one of the first and most important tools that enabled rise of our technology, military, culture, science and all other things that brought us to this point of modern civilisation. As a vital tool for survival, combat, construction and food preparation, the knife quickly became the most basic tool from which all others were born. In those ancient times, 500,000 years ago, sharpened stones started slowly evolving, becoming more and more like their modern counterpart. Before the time when fire enabled the melting of the various metals, and forging them into modern knives, their stone counterparts received several visual upgrades. Double bladed knives were most popular, and their wooden or stone hilts were decorated with animal skins and feathers. Those knives represented a great deal of pride for the warriors and elders who owned them, and that tradition continued to be practised with the arrival of the Bronze Age. The appearance of metallurgy brought the ability to create knives from softer types of metal. Even though knives from bronze did not provide durability over longer periods of time [easily dulled, and susceptible to corrosion), their sharpness and slim designed proved to be superior to any stone knife tool. As the centuries went on, iron and then steel became commonplace across the entire world. Knives created from those materials were much more durable and easier to maintain their sharpness after prolonged use. During medieval times in Europe, steel metallurgy managed to evolve knives from small single or double-bladed edges to larger sizes - swords, spears and axes. Even with all those advancements, the use of knives as an eating utensil continued to be used in some small circles. Even as early as the 15th century, wealthy circles of people started carrying personal knives, intended for double use - both eating and defending against threats. During those times the host were not obliged to provide their guest with any kind of eating utensil in addition to plates, so wealthy males used their eating knives for cutting their own meals, and the meals of nearby female guests. Slim double-bladed knives were good for cutting and piercing foods. As the use of forks became widespread in the whole of Europe by the late 17th century, most people used this kind of small knife on a regular basis (a combination of two knives, one for stabilising and other for cutting the meal). http://www.eatingutensils.net/history-of-cutlery/knife-history/The knife is one of the most important items that has enabled the development of civilisation over thousands of years.Carving knife with wooden handle and rusted slender metal blade.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, knife, kitchen equipment, dining -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBasket

Basket cane with 2 semi circular handles on top edgeflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Compass Saw, Mid to late 20th Century

A saw is a tool consisting of a tough blade, wire, or chain with a hard-toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power sources. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. In ancient Egypt, open (unframed) saws made of copper are documented as early as the Early Dynastic Period, circa 3,100–2,686 BC. Many copper saws were found in tombs dating to the 31st century BC. Models of saws have been found in many contexts throughout Egyptian history. As the saw developed, teeth were raked to cut only on the pull stroke and set with the teeth projecting only on one side, rather than in the modern fashion with an alternating set. Saws were also made of bronze and later iron. In the Iron Age, frame saws were developed holding the thin blades in tension. The earliest known sawmill is the Roman Hierapolis sawmill from the third century AD used for cutting stone.The subject item is believed to date from around the mid to late 20th century and is regarded as a modern item. The maker is unknown but the pattern or design and type of wood used indicate it is a tool of modern manufacture.Compass saw with wooden handle and metal blade. Small teeth. flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, wood cutting, wood saw, cross cut saw, cabinet makers tools, wood working tools, tool, compass saw -

Federation University Historical Collection

Federation University Historical CollectionMetalcraft, Planished Copper Basket

This work was most probably made by Keith Rash at the Ballarat Junior Technical School.Keith became a well-known Ballarat signwriter and amateur historian. Planished copper basket (flat base) with double rivetted handleScratched into base 'K.E. Rash"keith rash, metalwork, basket, ballarat junior technical school -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumBuckland District Board, 1862

Round hand stamp -wood handle brown - metal stampBuckland District Board - 1st meeting at Bright 1862 -

Bright & District Historical Society operating the Bright Museum

Bright & District Historical Society operating the Bright MuseumBuckland District Board, 1866

Round hand stamp -wood handle black - metal stampBright Shire -stamp black -

Federation University Historical Collection

Federation University Historical CollectionObject, Matsushita Electric Industrial Company Limited, Reel to Reel Tape Recorder

A white plastic 'National' audio tape recorder with brown handlesmodel RQ-700 Seriel number 3145tape recorder, audio -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTry Square

Try square metal and wood. Has a W stamped on handle. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageStereoscope

Stereoscope wooden with wooden eye shield with no handle or slide focusflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Bed Pan, R. Fowler, 1927-1935

The company R. Fowler Limited was established in Ultimo, Sydney, in 1837 when Enoch Fowler (1807-1879) came to Australia from Ireland and is known today as the oldest pottery still in operation in Australia. They were mostly known for producing bottles, jars, and pipes. The pottery was originally located at Abercrombie Place on Parramatta Street, Chippendale, NSW before they relocated to Glebe in 1847. Later the pottery manufactured building materials such as tiles, pipes, and chimney pots. As the business grew, they moved to Parramatta in the 1850s. Enoch's son Robert (1839-1906) had joined the company, and took over its management in 1873, changing the name to “R Fowler Sydney” in 1880. Robert, introduced the black under glaze trademark with the archer as shown on the subject item. He went on to opened further sites at Marrickville and Bankstown, with the company becoming R. Fowler Limited in 1919. The factory at Thomastown, Melbourne was opened in 1927. Fowler also owned a Pottery somewhere near Lithgow, where they produced clay pipes that look like salt-glazed Earthenware pipes. There have been numerous developments to the company over subsequent decades, and the company was still operating in 2002 but is now owned by Caroma Industries Ltd, manufacturing only sanitary fixtures. An item made by an Australian company during the first half of the 20th century and quite rare today. The item is significant as it gives a snapshot of the early development of manufacturing companies in Australia. This informs our social history in Australia marking Australia's evolution into an independent country and no longer a colony of England. Bed pan ceramic white glaze handle at one end.Marked R Fowler Ltd and trademark a person sitting with a bow and arrow "00"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageHandle

Handle brass with square end and square section punched out.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, handle brass, handle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBasket

Basket cane rectangular shape with rope handles and hinge lidflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, basket, cane basket -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageScraper

Box Scraper, triangular head, with bent stem. Wooden handle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, box scraper -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFry Pan

Fry pan black metal with handle attached by 3 rivetsflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageScrew Driver

Screw driver wooden handle. Has a screw blade that revolves.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, screw driver -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChisel

John Heath tool boxChisel with wood handle octagonal. Blade 87mmL x 4mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChisel

John Heath tool boxChisel with wood handle octagonal. Blade 97mmL x 5mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChisel

John Heath tool boxChisel with wood handle octagonal. Blade 99mmL x 3mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChisel

John Heath tool boxChisel with wood handle octagonal. Blade 74mmL x 3mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSurgical Instrument, Mayer & Meltzer Co

Forceps, Made by Mayer & Moltzer London. "HAS" scratched on handle.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, forceps, mayer & moltzer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageKnife

Butter knife. Antler handle curved. Blade has "in Sheffield". flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, butter knife -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFork

Small 3 tines fork with wooden handle. Length 6¾"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCorer

Apple Corer with turned wooden handle, cylindrical metal blade.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, apple corer -

Federation University Historical Collection

Federation University Historical CollectionAward - Trophy, Six Metre Henk Miller Line Special, 1981

Silver cup with handles relating to the Gippsland Advanced Institute EducationSix metre Henk Miller Line Special The GAIE Annual Raft Perpetual Trophy Hazelwood Pondage 1981 F Golly, S Corlett, G Honeychurch, M Jongerius, P Llewellyn, D Patching, D Wagner 1982 S Corlett, G Honeychurch, P Llewellyn, D Wagner, M Jongerius, D Patching, 1983 C Blowers, A Casser, P Coultox, I Namiltox, A Hassak, S Kallbacka, R Lestin, R Shellcot, T Stevens 1984 D Patching, P Llewellyn, G Honeychurch, N Bates, R Dathan 1985 G Honeychurch, P Llewellyn, G Martin, A Lonneveid, P newman 1986 James (Pas) Bennet Lindsay Fawell 1975 Meredith Annand, Ken Jeanes Tim Gallacher, Jeff Goodchild 1976 Ken Ken Jason, Chris Westaway, Karen Pearce, Charlie Wheelan 1977 Jeff Leamon, Chris Hobson 1978 Jeff Leamon, Ken Jeanes, Greg Vines, Vicki Whitesidef golly, s corlett, g honeychurch, m jongerius, p llewellyn, d patching, d wagner, s corlett, g honeychurch, p llewellyn, d wagner, m jongerius, d patching,, c blowers, a casser, p coultox, i namiltox, a hassak, s kallbacka, r lestin, r shellcot, t stevens, d patching, p llewellyn, g honeychurch, n bates, r dathan, g honeychurch, p llewellyn, g martin, a lonneveid, p newman, james (pas) bennet, lindsay fawell, meredith annand, ken jeanes, tim gallacher, jeff goodchild, ken jason, chris westaway, karen pearce, charlie wheelan, jeff leamon, chris hobson, jeff leamon, ken jeanes, greg vines, vicki whiteside, giae, gippsland institute of advanced education, churchill campus -

Federation University Historical Collection

Federation University Historical CollectionObject, University of Ballarat Insulated Cup, c2015

An insulated stainless steel cups with black plastic cover and handle. university of ballarat, cup, merchandise -

Red Cliffs Military Museum

Red Cliffs Military MuseumRazor, Service Shaving Razor WW11, (estimated); 1940 -1945

Razor is part of the A.J. Roddy CollectionAluminium & steel Service razor -No Blade. Handle finshed in knurlingA.S.& Co R45ww11, pow, a j, roddy -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Kitchen Equipment, Bread Knife 'Clauss', c1900

Clauss Cutlery’s long and vivid history started in early 1880’s when John Clauss and his younger brother Henrie established Elyria Shear Works in Elyria, Ohio. At one time the company was the largest manufacturer of scissors and shears in the world and was acquired by Acme United Corporation in 2004. John and Henrie Clauss, of German origin, started Elyria Shear Works from a one-room building in Elyria, Ohio Together with five employees, they began manufacturing scissors, shears, straight razors and serrated kitchen knives In August 1887, the Company moved to Fremont, Ohio to be near an accessible, abundant supply of natural gas which had recently been discovered. 1889, disaster struck as the plant was completely destroyed by fire, In 4 months Clauss built a new plant and was back in full operation and changed the company’s name to Clauss Shear Company. 1919 Clauss Shear merged with Henkel Company, to become Henkel-Clauss Company. Henkel Company was founded in 1906 to manufacture manicure and pedicure files, knives, shears and razors. After World War II, Clauss was unable to compete with European firms producing household scissors and shifted its focus to industrial scissors. In 1967 Clauss was taken over by Alco Standard Corporation who integrated Clauss into its existing structure to manufacture tools for industrial niche markets. Clauss made surgical scissors for eye operations, heavy duty metal cutting shears, poultry shears for gutting chickens and specialty items such as anti-acid, anti-magnetic tweezers for the electronics industry. Clauss had approximately 100 employees and produced about $18 million in annual revenues in the late 1980s, but profits continued to decline. In 2004, Acme United Corporation acquired the Clauss inventory, trademarks and brand names from Alco Industries for approximately $500,000A large Bread Knife with scalloped / serrated edge and looped handle Front : CLAUSS Back : FREEMONT / OHIOcutlery, knives, clauss shear company, ohio, freemont, market gardeners, early settlers, moorabbin, cheltenham,