Showing 211 items matching "building fitting"

-

Working Heritage Crown Land Collection

Working Heritage Crown Land CollectionDecorative object - Light fitting, Mint Light Fitting

A decorative architectural element made of iron that is badly corroded historic building, former royal mint, architecture -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Artist's impression of The Shrine in the Surrey Gardens

The photo comes from a souvenir brochure printed for the dedication of The Shrine on 7 April 1918, a copy of which is also held in the collection.. The Shrine was opened on Sunday 7 April 1918. Mrs C H D Steele, President of the local Patriotic League, is credited with the idea of building The Shrine as a fitting memorial to the WW1 soldiers of the district. The Surrey Hills Progress Association coordinated raising funds from local residents. John Kendrick Blogg carved the beautiful honor roll in Indian teak and Australian white mahogany and the design of the Shrine was by John Stevens Gawler, architect of Gawler & Drummond. Both men donated their services. It was one of the first WW1 memorials to be built and is noted for its use of Australian motifs, wattle blossom and gum leaves. The boomerang over the full width of the monument was said to be symbolic of both those who did and did not return. Surrey Hills Progress Association coordinated fundraising to build the memorial. There is a bound copy of a history of The Shrine by Robin Doble in the collection.Black & white photo of the artist's impression of The Shrine in the Surrey Gardens. surrey gardens, john kendrick blogg (mr), surrey hills progress association, john stevens gawler, gawler and drummond, the shrine, war memorials, sarah margaret russell (miss), sarah margaret steele (mrs), mrs charles henry dillon steele -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Eltham Community and Reception Centre, 2 October 2006

The Eltham Community and Reception Centre was Australia's first public mud-brick building. Commissioned in 1977 by Eltham Shire Council, led by Shire president (and architect) Robert Marshall, architects Whitford and Peck were asked to design a multipurpose facility in mud-brick and timber. The official opening was performed by the Hon. R.J. Hamer; E.D., M.P., Premier of Victorai on Saturday, April 22, 1978. Architects: Whitford & Peck Pty Ltd Quantity Surveyor: D.J. Cant & Associates Structural Civil Engineers: Charlett & Moore Pty Ltd Landscape: Peter Glass, Dennis Edwards Mech Elec: Lobley Treidel & Partners Pty Ltd Acoustics: Riley Barden & Kirkhope Builder: L.U. Simon Pty Ltd Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p177 The Wiggles performed there, so has the ABC’s Play School. New citizens have made their vows, volunteers have been honoured, school children have performed, weddings celebrated and people mourned at funerals. Since 1978 the Eltham Community and Reception Centre at the corner of Pitt Street and Main Road, has provided a beautiful and quintessential Eltham environment for people from all over Melbourne. Recognised as Australia’s first public mud-brick building, the centre was built partly on the site of the parsonage of the former Methodist Church (now the Uniting Church).1 Commissioned by the Eltham Council headed by President Robert Marshall, architects Whitford and Peck were asked to design a multipurpose facility in mud-brick and timber. Following public consultation, it was agreed to build a centre for dances, exhibitions, films, plays or concerts. The results – at a cost of around $620,000 – captured the Eltham rustic style. The building – in soft tones of mud-brick and timber and immense floor-to-ceiling windows – overlooks the Diamond Creek and sporting fields. Eltham’s strong artistic heritage is reflected in the centre. Although the lighting is not ideal for a gallery and labels cannot be placed on walls, the centre hosts the Nillumbik Art Awards and displays around ten to 20% of the Nillumbik Shire Art Collection, usually for around a year at a time.2 On permanent display, close to the entrance, is local artist Clifton Pugh’s White Choughs in the Landscape. Further to the right is the Walter Withers Gallery, named after a local member of the Heidelberg School of artists. As part of the Eltham Gateway opposite the Eltham Hotel, the centre stands on what was once part of the Eltham Town Centre along this section of Main Road, then known as Maria Street. On the same site once stood the house and flour mill owned by Henry Dendy, best known as the founder of Brighton, although he lived longer in Eltham. Beside the drive is a wheel-rim tool with accompanying plaque, illustrating a technology important during the horse-powered age and now almost completely gone, as has the blacksmith’s shop that had housed it nearby. The implement is a platform for fitting iron tyres to the wooden rims of cartwheels. Beneath it is a capsule placed in 1985 to commemorate Victoria’s 150 years, which is to be opened in 2035. Although the plants, forming part of the landscaping by Peter Glass and Denis Edwards, are largely indigenous and other native species, some exotic plants are protected as an important link with the site’s past. Planted at the front around 1920, is a large Peppercorn tree with two joined trunks growing from the base, and close by is a Bhutan Cypress (Cupressus torulosa). Three other Peppercorn trees fringe the drive. The building includes two halls – the larger seating 250 people – and a large foyer overlooking trees and ovals. Both halls have retractable rear walls providing varying spaces as required, and guests can use several external decks. A site for outdoor theatre has been carved out of the natural slope outside the entrance. The Bricklayers Union refused to use the traditional mud-bricks, which weigh more than 22kg. As a result the mud-bricks were redesigned to reduce their weight and were laid back-to-back to produce a wall of normal thickness.3 The centre’s massive timber frame is reminiscent of timber bridge construction, with infill panels of mud-brick.4 In accord with the rustic style are colossal rough-sawn posts, bolts and steel brackets. The combination of mud-brick, exposed feature timber framing and creative design in this centre, characterises Eltham’s innovative buildings and the social movement behind them from the 1940s to the 1970s.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham community and reception centre, mudbrick construction -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Property Binder, 1184 Main Road, Eltham

Newspaper article: A sustainable award, Diamond Valley Leader, 1 November2006, Architect and building Llewellyn Pritchard won resource Efficiency Housing Award, finalist in HIA Greensmart Building of the Year Award. House – Environmental Leader (Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p186) In 2006 environmental awareness was mushrooming in the community, which is reflected in the award-winning house at Main Road near Wattletree Road, Eltham. At first sight, the building appears a mix of a classic Eltham mud-brick house and an avant-garde building style. The crown of solar panels stretching along the width of the curved roof, indicates that this is no ordinary house. In fact it signals a new building trend of minimal impact on the environment. Yet it utilises the environment with high technical expertise to achieve comfort and cut running and maintenance costs. In recognition of this, its designer/builder, Conscious Homes, won the 2006 National HIA Greensmart Resource Efficiency Award. For Conscious Homes director, Llewellyn Pritchard, this house reflects a philosophy, strengthened by his connection with Aboriginal culture, through his foster siblings. Pritchard believes the sustainable way indigenous Australians lived and their spiritual connection with land, demonstrates how humanity is part of the ecology. His interest in environmental design stemmed from growing up in bushy Eltham Shire, with its mud-brick tradition. This was followed by studying Architecture at RMIT in the early 1980s, and learning about passive solar design. Pritchard says this house demonstrates that environmental sustainability is not about sacrifice, but about exceptional levels of occupant comfort, savings in running costs and modern fittings and appliances.1 The solar panels on the north roofs are intentionally obvious to make a statement about what the building is doing. But inside the systems are hidden and interactive with conventional services, such as the underground water tank. The house is water and energy self-sufficient and at 12 squares is much smaller than conventional houses, to minimise resources. Yet it accommodates his family of four with three bedrooms, a living/dining and kitchen area and a bathroom/laundry. Importantly the building is designed to last hundreds of years, by being able to be modified as the need arises, such as for commercial use. In this way the structure minimises its environmental impact. The solid double mud-brick walls (which are insulated) include steel beams and supporting frame, allowing the future removal or alteration of any section. The materials are local, recycled and of low toxicity where possible.2 Inside and out, the mud-brick is rendered and sealed with a combination of cement and sand and a mud-based coating in a soft golden hue increases its life. Inside, the golden-brown timber is plantation Mountain Ash and the concrete floors throughout – of local stone aggregate with a clear seal – have a natural looking random stone appearance. The house sustains a stable temperature of around 20 degrees, assisted by the concrete slab floor. The many large double-glazed windows and highlights (windows set high on walls) provide cross-flow ventilation. The north-facing living area maximises heating from the lower winter sun and is cooler in summer, because the sun is higher. Heating comes from a solar hydronic slab system. All appliances and fittings are high efficiency energy or water rated. Appliances in the timber kitchen include a gas stove and a dishwasher, using the building’s own power and water. French doors open from the living area to a deck, concealing the treatment system for all waste water. This is pumped through sub-soil drippers to the indigenous garden beds and no-dig vegetable patch. Below the carport is the 80,000-litre rainwater tank and at the back, the boiler room houses the solar boiler, water tank access, domestic water supply pump, filter gear and hydronic slab heating controls. The solar system is backed up with gas, which is needed to heat water only in winter. Gas used is less than one quarter of that for an average home with ducted heating. Excess power is fed back to the grid and the building uses about one quarter of the mains electricity of an average home. Other local builders have followed Pritchard’s lead in resource efficiency for minimal environmental impact.main road, eltham, businesses, llewellyn pritchard, hia greensmart building of the year award., efficiency housing award, conscious homes australia pty ltd -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern was possibly made for casting a part for Craftman Marine, makers of engines for boats and other machines. It is part of a set that is stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block with a corner cut diagonally. A five-sided shape has been carved into the centre, with one side curved inwards and slightly shallower than the other sides. The cut-out area is painted black. Three holes are drilled in the cut-out side to align the pattern with another piece of work. A wooden slat is fixed across the diagonal side. The back of the pattern has a handwritten inscription, possibly by two writers. The pattern is part of a set of foundry patterns from Briggs Brass Foundry and is connected to Craftman Marine.In black handwriting: "1 # H AL" Handwritten in a different hand: "CRAFTMAN MARINE" Written the the first hand: BRIGGS" (or "BRICK")flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912, craftman marine, craftsman marine -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; thick square mostly unopainted wooden block with a solid half-cylinder added to the top, which has rounded shoulders. A disc is added to the front, aligned with the curve at the top. The top curve has orange paint and the dial is pink. Three holes are drilled in the back, in a triangular configuration. It is similar in shape to a mantle clock or an early-style radio. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that is stored in a strong wooden crate and may be part of another similar pattern. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; unpainted, square wooden block with a semi-circle of dowel added to the centre of the side with rounded corners. Three short dowel pegs are inserted on one flat side; one below the semi-circle and one near the lower corners in an overall triangle configuration. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Newspaper - Bendigo's Upper Court within the Bendigo Court House

Laminated newspaper article - Bendigo Advertiser Friday November 27, 1987. "Bendigo's Upper Court is the jewel. Within the Bendigo Court House, the upper court is used for both Supreme and County Court sittings. Detailed description of the fittings, purpose and use of the upper court room. newspaper, bendigo's historic buildings, bendigo law courts -

Bendigo Historical Society Inc.

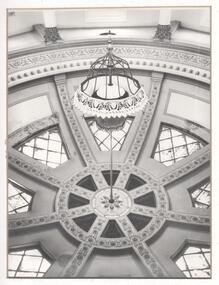

Bendigo Historical Society Inc.Photograph - CHANDELIER-LIKE LIGHT SUSPENDED FROM DOMED ROOF

Black and white photo: ornate dome shaped roof, diamond shaped leadlight inserts, chandelier-like light fitting suspended on rod. On bottom right of mount 'Photograph R. BallR. Ballbuildings, commercial -

Federation University Historical Collection

Federation University Historical CollectionDocument, List of Subjects

School of Mines Ballarat is predecessor of Federation University Foolscap sized list of Subjects from Ballarat School of Mines with handwritten names.8S3S in large writng on the back school of mines ballarat, practical chemistry, mr. walker, theoretical chemistry, theoretical agricultural chemistry, practical agricultural chemistry, technical chemistry, metallurgy, alfred mica smith, metallurgical calculations, metallurgy of gold and ore dressing, assaying practical, assaying dry, mr. murphy, ore dressing practical, mining, mining geology, mineralogy, geology, petrology, botany, applied mechanics, mr hart, mine surveying, land surveying, steam and gas engines, mr gilchrist, elementry electricity & magnetism, electrical technology, mr sutherland, turning and fitting, mr connon, engineering drawing, mr kerr, geometry, algebra, trigonometry, physics, conics, calculus, mr whitington, building construction, plane and solid geometry, plumbing grade, mr hall, mr mullins, carpentry, wool classing, materia medica, mr gutheil, technical arithmatic, mr hutchison, telegraphy, mr williams, sloyd, mr slater, photography, mr campbell, manual training, cyanide, mr deane, mr brittain, mr martell, english, astronomy, list of subjects -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; rectangular wooden block made from laminated sections of wood painted black. A half-cylinder shape was carved into the long side, and a dowel shape was placed at the lower side. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; pair of U-shaped carved blocks, unpainted. The blocks have opposing metal pins and holes to hold them together. One block has a disc shape carved into the base. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Moorabbin Air Museum

Moorabbin Air MuseumManual - Modern Mechanics flying manuals, Modern Mechanics Flying Manual 1930

... Technical details on aircraft fittings & building an aircraft, circa ...Technical details on aircraft fittings & building an aircraft, circa 1930Old manual stapled inside paper cover non-fictionTechnical details on aircraft fittings & building an aircraft, circa 1930aircraft fittings & aircraft construction -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Door

... Door Building-fittings Costumiers "Misses Wilson Costumiers ...Wooden door with brass sign inscribed "Misses Wilson Costumiers" with brass knocker on top. Door has brass doorknob and key hole. Door has panels front and back. Inside door has brass knob and small brass plate under."Misses Wilson Costumiers"door, building-fittings, costumiers -

Flagstaff Hill Maritime Museum and Village

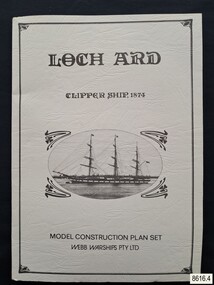

Flagstaff Hill Maritime Museum and VillageDocument - Ship Model Plans, Webb Warships Pty Ltd, Loch Ard Clipper Ship, 1874; Model Construction Plan Set, 1978

The plans are presented in a keepsake folder. They show marks of sections copied and assembled together. Overall, the plans are similar to those drawn by Mr P Webb to the order of the Loch Ard Shipwreck Centenary through Mr P Williams, the organizer of the Centenary competition. “The details were based on all available information which resulted in considerable historical research…and received favourable comment from model makers because of their attention to detail…In excess of 650 sets of plans were sold before entries closed…Many plans were probably purchased by collectors and interested persons for historical reference. An illustrated historical story sheet…was prepared and enclosed with the plans…” (‘Loch Ard Shipwreck Centenary 1878-1978 Report’, November 1978). An example of the attention to historical detail on the plans is the inclusion of the following useful information about the original vessel … Tonnage….1,693 G.R.T., 1,624 N.R.T. Dimensions, Builders….Charles Connell & Co., Ltd., Scotstoun, 1873. Owners….General Shipping Co., Glasgow, (Aitken Lilburn & Co., Ltd.), and the ship’s fate. The plans, in conjunction with the scale Ship Model of the LOCH ARD also on display, are of interpretive significance to Flagstaff Hill Maritime Village. The plans provide historical and technological context to artefacts from the shipwreck, increasing understanding and appreciation of those objects. Flagstaff Hill’s collection of artefacts from LOCH ARD is significant for being one of the largest collections of artefacts from this shipwreck in Victoria. It is significant for its association with the shipwreck, which is on the Victorian Heritage Register (VHR S417). The collection is significant because of the relationship between the objects, as together they have a high potential to interpret the story of the LOCH ARD. The LOCH ARD collection is archaeologically significant as the remains of a large international passenger and cargo ship. The LOCH ARD collection is historically significant for representing aspects of Victoria’s shipping history and its potential to interpret sub-theme 1.5 of Victoria’s Framework of Historical Themes (living with natural processes). The collection is also historically significant for its association with the LOCH ARD, which was one of the worst and best known shipwrecks in Victoria’s history.Model ship plans for building the LOCH ARD. The three sets of plans are presented in a textured cream card folder with the supplier’s details and an oval cameo drawing of the LOCH ARD. The plans are detailed and drawn to scale. They and printed on good quality paper with details, scale and legends. Sheet 1: Sails and Rigging Sheet 2: Lines, Decks and Details Sheet 3: Masts and Spars Details include deck fittings, the wheel, lights and the shipping company’s house flag. The ship model plans are copyrighted in 1977 and 1978 to Webb Warships Pty Ltd. The folder has details of four locations; Australia, USA, UK and New Zealand. Sheet has a handwritten inscription.On Folder: "LOCH ARD CLIPPER SHIP, 1874, MODEL CONSTRUCTION PLAN SET, WEBB WARRIORS PTY LTD." "CONTENTS COPYRIGHT (C) 1978, WEBB WARSHIPS PTY LTD" "WEBB WARSHIPS PTY LTD, PO BOX 50, WILLIAMSTOWN, VICTORIA 3016, AUSTRALIA" Handwritten inscription on sheet 3: "834" "THE FLOATING DRYDOCK, PO BOX 16066, PHILADELPHIA, PENNA. 14114, USA" "SAMBROOK MARINE (PLANS), 84 BROAD ST. TEDDINGTON, MIDDLESEX, UK" "BYMODELS, PO BOX 3037, FORBURY, DUNEDIN, NEW ZEALAND" flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, ship model plans, loch ard model plans, sailing ship, loch ard centenary, webb warriors pty ltd, 1977, 1978, centenary competition -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Foundry Patterns set, Briggs Brass Foundry, Early 20th century

The wooden crate contains a set of patterns or moulds that were once used at Briggs’ Brass Foundry for making sand moulds. The traditional method of sand casting is over 2000 years old. It is part of a crafted process used to make brass and copper alloy goods suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-corrosive and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry display was one of the early ‘working craft’ shops at Flagstaff Hill. It included a historic Cornish chimney that was set up as a working model, telling the story of heat from furnaces to smelt metal, which would then be poured into the sand moulds. This chimney is made from specially curved bricks and is about two-thirds of its full height when originally located at the Grassmere Cheese factory. HISTORY of BRIGGS BRASS FOUNDRY: - The family business was founded in 1912 by Herbert Harrison Briggs (1963-1931) with his son George Edward Briggs, trading as Briggs & Son Foundry at 70 Wellington Street, Collingwood. Younger son Cyril Falkiner McKinnon Briggs joined the foundry in 1922, and it was renamed H H Briggs & Sons Foundry. Both sons ran the firm after Herbert’s death in 1931, making products mainly for marine purposes. They became Bell Founders in 1936 and were known for their specialty of high-quality ship bells. They produced miniature varieties of these and other decorative items such as small propellers. The firm became known as Briggs Marine Foundry. The great-granddaughter of Herbert Briggs inherited the Briggs Brass Bell, similar to the one at Flagstaff Hill. Cyril became the sole family member of the firm in 1965. The Briggs Marine was an exhibitor at the 1965 Boat Show, where he advertised as “non-ferrous founders” and “Bell Specialists”. The foundry relocated to Chesterville Rd, Moorabbin. Cyril passed away in 1967. It is thought that either Cyril or his business partner Frank Lee donated the objects from the Briggs’ Foundry around the time when the business moved to Moorabbin. However, Flagstaff Hill hadn’t been thought about until 1972. The donated items were registered in the Collection in 1986 but they could have been in storage from an earlier date. In October of that same year, Briggs Marine restored Schomberg Bell, a shipwreck artefact from the collection at Flagstaff Hill. Peter Oram, who had worked for the previous owners of Briggs Marine as a fitter and turner, took over the firm in 2014, reviving some of the old casts for current use. The business is now located at Seaford in Victoria and is part of Alliance Casting & Engineering Solutions (Alliance Casting Pty Ltd). In 2016 the original Collingwood Foundry building was repurposed as a thriving business hub named The Foundry. The crate and its patterns are significant for their association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. The patterns are associated with the long-running firm, Briggs Brass Foundry, that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine is also associated with the Schomberg Bell in Flagstaff Hill, restoring the bell to is former state to show an example of the bell from a luxury mid-19th century vessel. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. Wooden rectangular crate with removable wooden lid. Inside is a set of wooden patterns of various shapes and sizes for making sand moulds in a metal foundry. The crate is made from thick wooden planks nailed together. The extended wooden struts on the long sides form a frame to hold the wooden lid. A pair of metal handles are at each short end of the crate, fixed with strong metal bolds. Between each pair of handles is an inscription stamped into the wood. The underside of the crate has red paint splashes. There are insect holes in the wood but no sign of current infestation. Stamped: "H.33 / II" (H may be N or a square B)flagstaff hill maritime museum and village, great ocean road, shipwreck coast, pattern, mould, foundry, brass foundry, metal foundry, crate, box, wooden container, briggs, traditional method, trade, sand cast, cast, brass alloy, copper alloy, marine equipment, marine tools, marine fittings, briggs' bronze, copper tin zinc lead, non-corrosive, briggs family, brassware, metalware, foundering, metalwork, maritime, casting, cornish chimney, curved bricks, grassmere cheese factory, 1912, herbert harrison briggs, h h briggs, george edward briggs, briggs & son foundry, collingwood, cyril falkiner mckinnon briggs, cyril briggs, h h briggs & sons foundry, bell founders, schomberg bell, alliance casting & engineering solutions, collingwood foundry, ship chandlers, marine products, flagstaff hill, warrnambool, maritime museum, maritime village, briggs & son brass foundry, briggs marine, moorabbin -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century.Pattern; hexagonal wooden shape painted orange. The thick carved wooden shape is in halves forming a hole when locked together with the dowel pegs and opposing drilled holes. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; round wooden shape with a wide concave centre and a round flat handle in the middle, painted dark brown. The underside has a large wooden disc added to the centre. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden pattern is part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; an unpainted, rectangular wooden frame with a top and sides, similar to a small rectangular stool. A solid half-cylinder shape was added under the horizontal 'seat' with another smaller half-cylinder attached to it, end-to-end. A string is tied between two metal loops attached to the back. There are two X marks stamped into the back. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.Stamped: "X" "X"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageEquipment - Pattern, Briggs Brass Foundry, Early 20th century

The wooden patterns are part of a set that are stored in a strong wooden crate. It was used at Briggs’ Brass Foundry for making sand casts. It may fit together with one of the other patterns with a similar outline. The traditional craft of sand casting is over 2000 years old. The handcrafted process produces brass and copper alloy goods that are well suited to marine use; bells, boat hooks, cowls, propellers, handles, lids, rowlocks, hooks, letters, bolts, rail holders, brackets, deck plates, flanges, rudder guides, portholes and covers. Briggs’ Bronze mixture is a copper-based alloy made from local ingots of copper, tin, zinc and lead in carefully measured quantities. The finished product is non-ferrous and can last indefinitely. The crate of patterns was donated by the Briggs family in the early years of Flagstaff Hill, along with other related items such as brassware, tools and machinery. The donated items were displayed in a simulated Brass Foundry in the Village along with other working crafts, trades and services found in a Maritime town. The items were on show from the completion of the building in 1986 until 1994 when the building was repurposed. The patterns represent the trades of foundering and metalwork, both supporting maritime industries such as shipwrights and boatbuilders. Farmers, manufacturers and other local industries also needed the castings made by foundries. The Brass Foundry included a historic Cornish chimney set up as a working model, to tell the story of smelted metal heated in furnaces then be poured into the sand moulds. This chimney was made from specially curved bricks and is now about two-thirds of its full height when originally located at the Grassmere Cheese factory. The craft of sand-casting from carved wooden patterns to create metal is an example of skills from the past that are still used today. The foundry pattern set is significant for its association with brass foundries locally and generally in coastal areas of Victoria. Marine industries such as ship and boat building rely on good quality castings for their machinery, equipment and fittings. Briggs Brass was especially formulated using non-ferrous metals to ensure their longevity. The patterns are associated with the long-running firm Briggs Brass Foundry that specialised in cast goods for the marine industry, ready to supply the needs for once-off or mass-produced items. Their products would have been fitted to sail and steam vessels along coastal Victoria including Warrnambool. Briggs Marine was also a bell-founder specialist and is also associated with the Schomberg Bell at Flagstaff Hill, having restored it to is former state as a fine example of the bell from a luxury migrant vessel from the mid-19th century. Pattern; a pair of blocks that form a rectangle with a carved centre hole and disc shape inside. The block is made from laminated pieces of wood with cut corners. Both sides have four drilled holes in a square configuration but in different positions. The cut faces and the space carved into them are painted red; one piece has two dowel pins that fit into two drilled holes on the other. The pattern is part of a set of foundry patterns from Briggs Brass Foundry.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, briggs' bronze, traditional method, trade, sand cast, cast, brass alloy, copper alloy, pattern, mould, foundry, brass foundry, metal foundry, casting, sand mould, sand casting, marine equipment, marine tools, marine fittings, copper tin zinc lead, non-ferrous, non-corrosive, brassware, metalware, foundering, metalwork, maritime, bell founders, ship chandlers, marine products, biggs, briggs family, herbert harrison briggs, h h briggs, george edward briggs, cyril falkiner mckinnon briggs, cyril briggs, briggs & son brass foundry, h h briggs & sons foundry, briggs marine, alliance casting & engineering solutions, grassmere cheese factory, cornish chimney, curved bricks, collingwood, moorabbin, collingwood foundry, moorabbin foundry, 1912 -

Melbourne Tram Museum

Melbourne Tram MuseumPhotograph - Black & White Photograph/s, late 1920's

Black and white photograph, sepia toned of an W class (383 or 363), east bound in Flinders St, prior to the fitting of route number boxes, c1928-1930.. In the background is Hartley's Sports store with a large crowd milling out onto the street, the City Auction Mart and to the east, The Empire Arcade building. No known details of the photographer or date.trams, tramways, flinders st, w class, tram 363, tram 383 -

Whitehorse Historical Society Inc.

Whitehorse Historical Society Inc.Functional object - Door and name plate

... Cottage and Museum Complex. buildings fittings museum business ...Saved from a house in Nicholson Street, Nunawading owned by the Jenkinson's. Mrs Jenkinson died in Strathdon Nursing Home, Forest Hill and was buried on her 100th birthday. Plaque made in 1922. Door and plaque is now in fitted on a shopfront display in the Schwerkolt Cottage and Museum Complex.Wooden door with brass sign inscribed 'N. Jenkinson Piano & Theory'. Brass door knob and door ringer inset panels'N. Jenkinson Piano & Theory'buildings, fittings, museum, business, music -

Wodonga & District Historical Society Inc

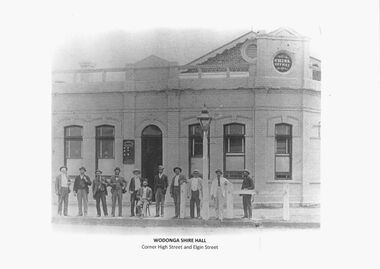

Wodonga & District Historical Society IncPhotograph - Wodonga Civic Buildings Over Time

Wodonga Shire was created in 1876 when the colonial government agreed to ratepayers' petitions to have their part of the local government district severed from the Yackandandah Shire to form a new municipality. After meeting for 14 years in rented remises, in the Prince of Wales Hall, Wodonga Council built its first Shire Hall on the corner of High and Elgin Streets in 1890. The date on the façade of the building, 1876, represents the date of the formation of the Shire. In 1957 the second Shire Office was built in Woodland Grove by A.B. and M. A. Chick. These offices were considered more than adequate for future needs. The façade featured floor to ceiling windows and several different meeting rooms in addition to the council chamber, which featured an impressive “horse shoe” table. It also included a kitchen equipped with modern fittings and a President’s room. In the late 1960s the area between Hovell and Havelock Streets as far as Jack Hore Place was zoned for civic purposes. In 1969 plans for a civic centre providing a library, theatre and senior citizens’ rooms. It was opened on 22 April 1971. In 1973, the Council engaged Bruce Marshall to design new offices beside the Civic Centre. Jennings Industries were contracted to complete the offices. The Governor, Sir Henry Winneke, laid the foundation stone of the new offices on 10 March 1976. The Civic Centre was demolished in 2011 to make may for a new $10 million community and entertainment centre which opened in August 2012.These photos are significant because they depict the different buildings which have housed the centre of local government in Wodonga since its inception as an independent shire in 1876.A series of photographs depicting the different buildings used to house the Wodonga Council and Civic buildings over time.wodonga civic buildings, wodonga council, shire of wodonga, rural city of wodonga -

Wodonga & District Historical Society Inc

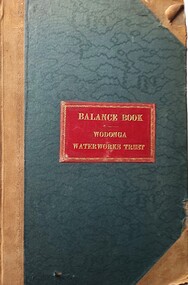

Wodonga & District Historical Society IncFinancial record - Wodonga Waterworks Trust Balance Book

Wodonga Waterworks Trust was established in 1897 to control and improve water supply to Wodonga. This included focus on the water quality which had often been a problem. After lobbying the Victorian Department of Water Supply for several years, the first official meeting of the newly constituted Wodonga Waterworks Trust was held on Wednesday 20th October 1897. The Board initially consisted of all Wodonga Shire Councillors, together with Mr Samuel Mason Jr., as the nominee of the Government. Councillor McFarlane was appointed as the first Chairman. This Record Book contains documentation of expenditure of the Wodonga Waterworks Trust from 1908 through to the early 1950s. This includes the official record of payments of £2,897/ 18 /- and £130 to contractor A. A. Hargrave for Erection of the Water Tower. Other payments related to the Water Tower include entries for pumps, gears, pipe laying, pipes, the pump station and related fittings. Construction of the Water Tower was completed in early 1924 and after thorough testing throughout that year, the completed new water system for Wodonga was officially opened on 4th December 1924.This item is significant because it contains financial records related to the construction of one of the oldest and most significant buildings in Wodonga.This large ledger contains both hand written and typed notes documenting financial reports of the Wodonga Water Trust over 40 years. The cover is dark green with brown binding. In the centre of the cover is an red rectangle with text and a border printed in gold.On front cover within gold border BALANCE RECORD WODONGA WATERWORKS TRUSTwodonga waterworks trust, wodonga water tower, a. a. hargrave -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Door, 1871 or earlier