Showing 321 items

matching heating

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clothes Iron, last quarter of the 19th century

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today.Clothes Iron, wedge shaped, cast iron painted black with cylindrical handle small funnel through centre of handle.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry equipment, sad iron, domestic object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Clothes Iron, last quarter of the 19th century

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today.Clothes Iron, wedge shaped, cast iron painted black with cylindrical handle small funnel through centre of handle.Noneflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry equipment, sad iron, domestic object -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Flat Iron, 1890-1935

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today. Flat iron cast iron with traces of original black finish on handle. Noneflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry, clothes ironing, sad iron, tailors goose -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Gas lamp wall bracket, Late 19th to early 20th Century

Gas lamps worked by heating something called a 'mantle' with a gas flame. The mantle then glowed brightly, lighting up the room. Lamps had either two chains, for a ceiling-mounted lamp or a tap for a wall-mounted burner to turn off the gas. These chains or taps could also adjust the flow of the gas and hence the brightness of the mantle. Before Carl Auer von Welsbach invented the gas mantle in the 1890s, all gas lights in homes and street lights had simple gas jets that pointed upwards. In the home, these lights were covered with glass globes and had an overall ornate look making the lamp ascetically pleasing and protecting the flame from being blown out. However, this arrangement was extremely inefficient: To get as much light as possible, the gas had to be turned fully up, resulting in large sheets of flame rising towards a ceiling. Also, because the lamp had to be point upwards, the illumination was directed upwards, i.e. at the ceiling rather than where it was needed. So the usable light for a given amount of gas was minimal but the invention of the gas mantle eventually changed this. It enabled gas lights to have a small flame and to direct their light downwards. The item is significant as it is part of a very ornate gas lamp wall bracket from the late 19th to early 20th century. Its provenance is currently unknown and at this time cannot be associated with a historical event, person or place and the item is assessed as a collective asset.Gas lamp wall bracket; part of a gas lamp. A single burner fancy wall mounted bracket, brass, ornate and decorative, featuring a Lamassu - figure with the body of a lion , wings of an eagle and human head. It was recovered from the wreck of the Loch ArdNoneflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, gas lamp, brass lamp, gas burner bracket, domestic artifact, gas lighting, gas lamp bracket -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Lights, porcelain, wall, electric light switch; Door Knob Porcelain, early 20th C

Both the Light switch and Door knob were used in Box Cottage during the late 19thC and early 20thC by the Box and Rietman families. William and Elizabeth Box purchased the two ten acre Lots of land with the Cottage in 1868 where they raised their family of 12 children and developed a flower garden producing seedlings. August and Frieda Rietman rented the Cottage 1917 with 1 acre of land and purchased it in 1935 where they raised 2 children while August established Rietman's Landscaping Pty Ltd making pressed concrete garden furniture. Porcelain is a ceramic material made by heating materials, generally including kaolin, in a kiln to temperatures between 1,200 and 1,400 °C The toughness, strength and translucence of porcelain, relative to other types of pottery, arises mainly from vitrification and the formation of the mineral mullite within the body at these high temperatures. Porcelain and other ceramic materials have many applications in engineering, especially ceramic engineering. Porcelain is an excellent insulator for use at high voltage, especially in outdoor applications, see Insulator (electricity)#Material. Examples include: terminals for high voltage cables, bushings of power transformers, insulation of high frequency antennas and many other components. Both the Light switch and Door knob were used in Box Cottage during the late 19thC and early 20thC by the Box and Rietman families. William and Elizabeth Box purchased the land with Cottage in 1868 and raised their familya) An electric light switch that would be attached to a wall. An Ivory Porcelain Base Single Light Switch with antique Brass top b) A porcelain door knob Both items used in Box Cottage early 20th Ca) On base BRITISH MADE / ENGLAND / 4 / 6959 lights, porcelain, electricity, early settlers, moorabbin, cheltenham, bentleigh, box william, box elizabeth, rietman august, rietman frieda, market gardeners, flower gardens, seedling nurseries, world war 1 1914-18, war memorials, sculpture, pottery, pressed concrete, door handles, door knobs -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen Equipment, sad iron with Mrs Potts handle, c1900

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. Mrs Florence Potts invented in 1871 a detachable handle made from walnut wood with a metal latch to release the handle. These wooden handles prevented burned hands and were sold to grateful women all over the world. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer.Mrs Florence Potts invented this type of detachable walnut wood handle with a meta release latch for sad irons in 1871 and it sold widely throughout the world to grateful women including those in Moorabbin Shire. The family of Ms May Curtis were early settlers in Moorabbin ShireA) A sad iron, made of cast iron , has a special handle invented in 1871 by Mrs Florence Potts of Iowa, USA. B) The detachable handle made of walnut wood to prevent burned hands, was attached to the iron by a metal latch.A) UNITED/ N0 / 50 / AUSTRALIApotts florence, iowa usa, melbourne, moorabbin, sad irons, kitchen equipmentn fireplaces, walnut wood, sewing, laundry, table ware, linen, pioneers, early settlers, washing days, craftwork -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Flat Iron, 1890-1935

Blacksmiths started forging simple flat irons in the late Middle Ages. Plain metal irons were heated by a fire or on a stove. Some were made of stone. Earthenware and terracotta were also used, from the Middle East to France and the Netherlands. Flat irons were also called sad irons or smoothing irons. Metal handles had to be gripped in a pad or thick rag. Some irons had cool wooden handles and in 1870 a detachable handle was patented in the US. This stayed cool while the metal bases were heated and the idea was widely imitated. Cool handles stayed even cooler in "asbestos sad irons". The sad in sad iron (or sadiron) is an old word for solid, and in some contexts this name suggests something bigger and heavier than a flat iron. Goose or tailor's goose was another iron name, and this came from the goose-neck curve in some handles. In Scotland people spoke of gusing (goosing) irons. At least two irons were needed on the go together for an effective system, one would be in use, and the other re-heating. Large households with servants had a special ironing-stove for this purpose. Some were fitted with slots for several irons, and a water-jug on top.An early domestic object that gives an insight into how the ironing of clothes was done before the electric type irons we use and take for granted today. Flat iron cast iron with stand None item too badly corrodedflagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, iron, flat iron, laundry, clothes ironing, sad iron, tailors goose -

Falls Creek Historical Society

Falls Creek Historical SocietyFunctional object - Peacock Hand Warmers

These mid-1960s Peacock and Gold brand lighter fuel hand warmers were used in Falls Creek to keep out the cold. The concept behind the hand warmer is that through combustion (ignition) of lighter fluid (light petrol distillate) it becomes a catalytic heater, relying on a catalysed chemical reaction to break down molecules and create heat. The devices could get quite hot, not hot enough to set paper on fire, but hot enough to give a nasty burn if sustained contact against your skin occurred. The construction of the device is very simple. There is very fine rolled wire mesh which fits on top of the reservoir body. After you fill the reservoir with lighter fluid, vapor pressure builds up. The device ignites by heating the grill with a match or lighter until it glows red. There is no open flame. The hand warmer also had a velvet bag to place it in after igniting to prevent direct skin contact. They were able to generate heat for up to a whole day. The Japanese company Yamato Shokai Ltd was founded in 1923 in the city of Osaka. Destroyed during air raids in 1945, the factory was rebuilt in 1946. They manufactured the Peacock brand pocket-warmer and sold it internationally.These items are significant because they were commonly used at Falls Creek.The pocket warmer is a small, relatively flat device with a tank at the bottom and a burner mechanism a t the top. "PEACOCK/MADE IN JAPAN" is engraved near the burner. The warmer fits into a metal case which features a series of ventilation holes in the shape of a peacock's tail. JAPANESE PAT. 237413.483177 MADE IN JAPANhand warmers, ski equipment 1960s -

Marysville & District Historical Society

Marysville & District Historical SocietyPostcard (item) - Black and white postcard, KITCHENER HOUSE MARYSVILLE, Unknown

A black and white postcard of Kitchener House in Marysville.A black and white postcard of Kitchener House in Marysville.Dear June, we are having a lovely time. Rather cold/ in the mornings, as the house has no central/ heating. The meals are everything to be desired/ and plenty of it. Yesterday lunch time Margaret/ had three servings of sweets and was coming/ up for one more before I stopped her. We played/ in the snow on Lake Mountain and were/ taken to Steavensons Falls. We are saving/ the Eildon Weir trip to do on our way/ home. I took the girls horse riding and/ for an hour I walked behind and had to/ hit the horses on the rump to make them move./ 7/6 an hour each too. We hope children/ are free from any ills and hoping to see/ you all soon will close how Love Myrtle marysville, victoria, australia, kitchener house, mount kitchener house, mt. kitchener house, accommodation, postcard, souvenir -

Royal Australasian College of Surgeons Museum and Archives

Royal Australasian College of Surgeons Museum and ArchivesSamovar

Donated by Sir Henry Newland.The samovar stands 41cm high, and is 39cm wide across the handles. It is made of Sheffield plate, and dates from the late 18th century. It is supported on a square base with four cast lion’s feet attached by elaborate mounts at the corners. The main vessel or tank is circular, and set on a short columnar stand. These elements are heavily fluted. There are two elaborately decorated solid cast silver handles attached to the sides of the tank. A long spout with a cast ivory handled tap extends from the bottom of the tank. The lid is plainer, with a fluted and scalloped edge, and is capped with a finial. Inside the tank is a cylindrical immersion container for hot coals, a primitive type of heating element. There is a crest, probably that of the original owner, engraved on the shoulder of the tank above the tap. A samovar is a Russian tea urn but the College’s samovar is not a tea urn, as it does not include the stand or the teapot. Undoubtedly it was intended to provide hot water for tea, and the absence of a matching teapot indicates a cultural difference between the English and the Russians, in the way in which they went about brewing tea. It is a showpiece, intended for use and display in the reception rooms of the house. In the 18th century tea was still a rare and exotic import from the Orient, so the serving of tea was an important act of hospitality and a statement of social status.Sir Henry Newland was the College President 1929-1935Antique sheffield plated samovar with shell design and pressed rib border, finely worked casted handles, spout with swivel top, with tapered centre column, square shaped base with cast lions feet -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Maufactured Objects, 1 box of Bryant & May waterproof safety matches, 20thC

‘Strike anywhere’ or ‘Waterproof’ matches are still used today all around the world, including many developing countries and are widely used for camping, outdoor activities, emergency/survival /military situations, and stocking homemade survival kits. Anton Schrötter von Kristelli discovered in 1850 that heating white phosphorus at 250 °C in an inert atmosphere produced a red allotropic form, which did not fume in contact with air. It was suggested that this would make a suitable substitute in match manufacture although it was slightly more expensive. Two French chemists, Henri Savene and Emile David Cahen, proved in 1898 that the addition of phosphorus sesquisulfide meant that the substance was not poisonous, that it could be used in a "strike-anywhere" match, and that the match heads were not explosive. British company Albright and Wilson, was the first company to produce phosphorus sesquisulfide matches commercially. The company developed a safe means of making commercial quantities of phosphorus sesquisulfide in 1899 and started selling it to match manufacturers. Bryant and May was a United Kingdom (UK) company created in the mid-nineteenth century specifically to make matches. Their original Bryant and May Factory was located in Bow, London. They later opened other match factories in the United Kingdom and Australia. On 15th December 1909, Bryant & May, Australia’s first match factory at Church Street, Richmond, Victoria. was opened by The Honorable Alfred Deakin, Prime Minister of Australia, and Mrs. Deakin The Bryant & May Ltd factory in Church St Richmond is a listed building and has been converted to apartments following the closure of the Company 1980. Bryant & May's Ltd were influential in fighting against the dreadful disease known as Phossy jaw which was caused by white phosphorus used in the manufacture of the early matches. They were also the object of the 'Match Girls Strike' in London 1888, which won important improvements in working conditions and pay for the mostly female workforce working with the dangerous white phosphorus. The public were slow to purchase these red phosphorus sesquisulfide safety matches because of the higher price1 box of unused Bryant & May safety matches 'Greenlite' waterproof Greenlites / waterproof / matches / CONTENTS 47 / MADE IN AUSTRALIA BY BRYANT & MAY / E 2994 photograph of a man and woman beside a camp fire on the beachsafety matches, bryant & may pty ltd, phossy jaw disease, early settlers, moorabbin, bentleigh, cheltenham, lights, lamps, tobacco, white phosphorous, red, phosphorus sesquisulfide, swedish match pty ltd, pitt william, savens henri, cahen emile david , richmond victoria, -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Ironing board, 1910-1930

Ironing is the use of a machine, usually a heated tool (an iron), to remove wrinkles from fabric. The heating is around 180–220 °Celsius, depending on the fabric type. Ironing works by loosening the bonds between the long-chain polymer molecules in the fibres of the material. While the molecules are hot, the fibres are straightened by the weight of the iron, and they hold their new shape as they cool. Some fabrics, such as cotton, require the addition of water to loosen the intermolecular bonds. Many modern fabrics developed in or after the mid-twentieth century require little or no ironing. Permanent press clothing was developed to reduce the ironing necessary by combining Wrinkle resistant polymers with cotton. The first known use of the iron for removing wrinkles in clothes is known to have occurred in China, and the electric iron was invented in 1882, by Henry W. Seeley. Seeley patented his "electric flat iron" on June 6, 1882 (U.S. Patent no. 259,054). On 15 February 1858 W. Vandenburg and J. Harvey patented an ironing table that facilitated pressing sleeves and pants legs. A truly portable folding ironing board was first patented in Canada in 1875 by John B. Porter. The invention also included a removable press board used for sleeves. In 1892 Sarah Boone obtained a patent in the United States for improvements to the ironing board, allowing for better quality ironing of shirt sleeves.A domestic item with an interesting history of development, significant as it shows the progress and the evolution of a domestic item designed to make housework more efficient.Wooden Ironing board with press board for sleeves, board is folding.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill-maritime-museum, flagstaff-hill-maritime-village, domestic item, ironing board, ironing, clothes, wrinkles in clothes, henry w. seeley, w. vandenburg and j. harvey -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, spirit-fuelled sad iron, c1920

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Late in the 19thC designers experimented with heat retaining fillings for these irons. William Coleman began selling Kerosene lanterns in 1900 in Kingfisher, Oklahoma, USA. He moved to Wichita, Kansas in 1902 and the company became world wide. The company also produced a range of cooking stoves and domestic irons. This spirit- fuelled flat iron was very popular in 1920s - 30s These sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin ShireA) spirit- fuelled, sad iron with chrome plated sole c1920, and metal trivet The iron is blue enamel with a white speckled body, with a hemispherical tank for the Coleman 'Lighting Petrol' that provided the heat for smoothing the material B) Coleman Fuel measuring can and funnellMetal Trivet/stand " COLEMAN" ; Petrol can " COLEMAN" / MEASURING CAN / for INSTANT LIGHTING IRON/ with printed instructionssad iron, kitchen equipment, coleman william, kansas, oklahoma, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, petrol fuelled irons, spirit flat irons, coleman lamp stove co. ltd. -

Federation University Art Collection

Federation University Art CollectionCeramic, Tony Nankervis, Three Lidded Woodfired Cylinders by Tony Nankervis, 1986

Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire."(https://www.strathnairn.com.au/studios/artist-in-residence/montessa-maack-ursula-burgoyne-jen-lyall-and-vicki-grima-5ndd6, accessed 09 July 2021)Tony NANKERVIS Tony Nankervis taught ceramics from 1984 when the university was the Northern Rivers College of Advanced Education from 1984. before moving to Southern Cross University (SCU) in 1994. He retired from full time teaching in 2004. Nankervis was a pioneer of the long wood-fired ceramics technique in Australia: a technique he has been practising since the late 1970s Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire. There are particular qualities that only come from firing in that way, he said. "If you see some of these older ceramics, particularly from Asia, the surface qualities are discernible from the surfaces generated by post-Industrial fuels." (https://www.scu.edu.au/engage/news/latest-news/2004/leading-australian-potter-who-paints-with-fire-retires-from-lecturing-at-scu-after-19-years.php, accessed 09 July 2019)Three Lidded Woodfired Cylinders ceramics, jan feder memorial ceramics collection, tony nankervis, tony nankervic -

Federation University Art Collection

Federation University Art CollectionCeramic, Tony Nankervis, Dry Glazed Lidded Form by Tony Nankervis, 1986

Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire."(https://www.strathnairn.com.au/studios/artist-in-residence/montessa-maack-ursula-burgoyne-jen-lyall-and-vicki-grima-5ndd6, accessed 09 July 2021)Tony NANKERVIS Tony Nankervis taught ceramics from 1984 when the university was the Northern Rivers College of Advanced Education from 1984. before moving to Southern Cross University (SCU) in 1994. He retired from full time teaching in 2004. Nankervis was a pioneer of the long wood-fired ceramics technique in Australia: a technique he has been practising since the late 1970s Nankervis prefers the pre-Industrial Revolution method of firing pottery, involving heating the kiln by burning wood for five days, to the modern, quicker methods using gas or electricity. The distinctive surfacing in wood-fired ceramics is generated by the ash and volatile salts from the burning wood. "Because the wood ash and salts blush the ceramic pieces in the kiln, the finished work tends to take on the nature of the firing process," he said. "One colleague has described the process as painting with fire. There are particular qualities that only come from firing in that way, he said. "If you see some of these older ceramics, particularly from Asia, the surface qualities are discernible from the surfaces generated by post-Industrial fuels." (https://www.scu.edu.au/engage/news/latest-news/2004/leading-australian-potter-who-paints-with-fire-retires-from-lecturing-at-scu-after-19-years.php, accessed 09 July 2019)Presented by the artistLidded Raku fired box, dry glazedceramics, jan feder memorial ceramics collection, tony nankervis, tony nankervic -

Melbourne Legacy

Melbourne LegacyDocument - Press Release 1975, Melbourne Legacy, Rising prices worrying you?, 1975

A press release from Melbourne Legacy in 1975 which relates a story of how Legacy works. The information was intended to be used by press and magazines etc. The title 'Rising prices worrying you?' and makes the point that the average cost of a family is rising, and now Legacy is a family of 107,000 people. Throughout Australia Legacy was supporting 80,000 widows and 27,000 children of deceased ex-servicemen who died in or since, the two World Wars, and the conflicts in Korea, Malaya and Vietnam. 'Legacy counsels these families in their daily life, that costs nothing for Legacy members give freely of their time' 'What does cost money, and plenty, is providing the tangible things these fatherless families need. Help with education up to an including tertiary studies. Firewood and other forms of heating in the colder climates. Maintenance of residences where country children can live, with all provided, when they have to come to the city for reasons of welfare, study or employment. Housing projects to care for aged widows, in both city and country areas. Subsidising nursing home beds for the infirm. An impressive list? In the calendar year of 1974 if cost Legacy in Australia almost $2.5 million and with rising prices, the coming year is going to cost considerably more. This is where Legacy seeks your help.' Note that in the 1970s inflation and cost of living was rising quickly.A record of how Legacy promoted their work in the 1970s.Pink foolscap page x 2 with black type of a press release in 1975.Rising prices worrying you?'press release, case studies -

The Beechworth Burke Museum

The Beechworth Burke MuseumGeological specimen - Brown coal

This particular specimen was recovered from the Lal Lal Coal and Iron Mine in Victoria, 19km from Ballarat. Brown Coal was discovered here in 1857, just alongside the Geelong to Ballarat Railway line. This discovery of lignite (brown coal) was the first in Victoria, which would bring important benefits to the region and state, both of which had previously been reliant on coal imports. In the 1860s, iron ore was found just 5km from Lal Lal, and the area was converted into an Iron Ore Mine. The Lal Lal Iron Mining Company took over operations in 1874, who then peaked iron production in 1884. This mine continued operations until June 1884, when the blast furnace was extinguished and never recommenced. The blast furnace at Lal Lal is considered one of the most important and highly significant sites ion early industrial history in Australia, as it is the only remaining best furnace from the nineteenth century in the Southern Hemisphere. The furnace ruins are 17 metres high, and are clearly visible today on Iron Mine Road, Lal Lal, near the Bungal Dam. This specimen of Lignite (brown coal) is significant, as it was mined from the area where brown coal was first discovered in Victoria, leading to an important and controversial future of the mining and use of brown coal in this State. The Victorian Heritage Database has listed the Lal Lal Coal Mine with local significance, with their Statement of Significance stating: "The Lal Lal coal mine is historically significant as the site of the first discovery of lignite (brown coal) in Victoria, and one that promised important benefits to regional and state industries that were reliant on coal imports at the time. The significance of the stie is reduced by the poor state of preservation of the coal mining and processing fabric". This specimen is part of a larger collection of geological and mineral specimens collected from around Australia (and some parts of the world) and donated to the Burke Museum between 1868-1880. A large percentage of these specimens were collected in Victoria as part of the Geological Survey of Victoria that begun in 1852 (in response to the Gold Rush) to study and map the geology of Victoria. Collecting geological specimens was an important part of mapping and understanding the scientific makeup of the earth. Many of these specimens were sent to research and collecting organisations across Australia, including the Burke Museum, to educate and encourage further study.A hand-sized light-weight, soft and combustable sedimentary rock specimen, that is dark brown in colour. The specimen has jagged edges, as though parts of the rock have crumbled away. Brown coal, or Lignite, is formed naturally from compressed peat, and is typically found in natural basins. The stages to the formation of coal ('coalification') begin with plant material and wood, which will decay if it is not subjected to deep burial or heating, and turn into Peat. Peat, when sufficiently compressed naturally, will turn into Brown Coal (Lignite), and finally into Black Coal (sub-bituminous, bituminous and anthracite). Each successive stage has a higher energy content and lower water content. It is brownish-black in colour. Brown Coal has a high moisture content, between 50 and 75 percent, and a low carbon content. Some Brown Coals may be stratified, with layers of plant matter, which means little coalification has occurred beyond the peat natural processing stage. When Brown Coal is submerged in dilute nitric acid or boiling potassium hydroxide solution, it reacts to produce a reddish solution, of which higher-ranked coals do not. When brown coal is pulverised and burned in boilers, the steam is used to drive turbines, which generates electricity. It is the lowest rank of coal, as when burned, it creates a relatively low heat content, which in turn does not create a great output of steam. burke museum, beechworth, indigo shire, beechworth museum, geological, geological specimen, mineralogy, brown coal, brown coal specimen, lignite, lal lal, lal lal coal mine, lal lal iron mine, ballarat, blast furnace -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Photograph - BENDIGO GAOL, FROM COMMISSIONER'S GULLY, c.1880

Sepia photograph of the Bendigo Gaol looking across from Barnard Street, Mining dam in foreground. . Conifers along Northern bank of creek with gaol buildings in the background. All buildings are of masonry. Inscriptions: '37' in red ballpoint ink top RH corner. On back of mount: stamped in circle 'Royal Historical Society of Victoria, Bendigo Branch' In blue ballpoint ink above circly '1959' In red ballpoint ink above circle '37'. In blue ballpoint ink in one corner '1880'. Inclusions in storage envelope: Bendigo Gaol, J Lerk, 28/02/2000. The Bendigo Gaol looking across Commissioner's Gully c1880. The grey granite cell blocks contrast with the red brick exterior walls. Photograph courtesy Bendigo Historical Sociery (No. 136, texta on back). Machine printed inclusion worded as above entry. Another inclusion written in pencil states ' Bendigo Gaol about 1880. Granite from Big Hill was used to construct the cell blocks about 1860. Prisioners did not have heating, beds, seats or eating utensils. A public meeting in 1862 called for the debtor's quarters at the gaol to be lit with gas, handsomely furnished throughout and that inmates be provided with a bottle of wine, one bottle of brandy daily and tobacco and pipes availabe at liberty. (from Butcher, 'Annals of Bendigo 1862, Vol. 1, 76B).buildings, government, watch house, sandhurst -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Platform Scales

Thaddeus Fairbanks (1796 –1886) was an American inventor. of heating and cook stoves, cast iron ploughs, and other items. His greatest success was the invention and manufacture of the platform scale, which allowed the weighing of large objects accurately. Fairbanks was born in Brimfield, Massachusetts, on January 17, 1796, the son of Joseph Fairbanks (1763–1846) and Phebe (Paddock) Fairbanks (1760–1853). His uncle was Ephraim Paddock, the brother of Phebe Paddock. In 1815 he moved to St. Johnsbury, Vermont, and set up a wheelwright's shop above his father's gristmill. In 1820 he married Lucy Peck Barker and In 1824 he built an iron foundry. his brother Erastus joined him to establish E. and T. Fairbanks, a partnership to manufacture heating stoves, cast iron ploughs a design for which he patented in 1826. In 1830 Fairbanks and Erastus became interested in the raising and processing of hemp. Fairbanks went on to patent a hemp and flax dressing machine and became the manager of the St. Johnsbury Hemp Company. He also built a set of scales that would measure large loads of hemp accurately, as there were no reliable scales at the time. Upon the success of building these scales, his brothers recommended that he make and sell these for general use. Fairbanks' most famous invention then became the platform scale for weighing heavy objects. These are commonly known as the Fairbanks Scales, for which he patented his original design in 1830. Before this time, accurate weighing of objects required hanging them from a balancing beam as a result, particularly heavy or ungainly objects could not be weighed accurately. A platform scale, if large enough, could weigh an entire wagon. By placing a full wagon on the scale, unloading it, and then placing it on the scale when empty, it became possible to easily and accurately calculate the weight and value of farm produce and other loads. In 1834 Fairbanks and his brother formed "E. and T. Fairbanks and Company" to manufacture and sell these platform scales. These scales were well known in the United States and around the world resulting in the company doubling in volume every three years from 1842 to 1857. There was a temporary slow down during the American Civil War, however, the business took off again after the war. Their partnership was incorporated in 1874 into a firm known as "Fairbanks Scale Company". These platform scales revolutionized weighing methods of large loads and have been in use ever since. Portable platform scales are found in almost every hardware store, physician's office, and manufacturing factory throughout the United States and the world. The first railway track platform scale patent was granted to Fairbanks on January 13, 1857, as Patent No. 16,381. In 1916 the company was purchased by ”Fairbanks, Morse and Company”. Ownership of the company has since changed several times, but Fairbanks Scales continue to be made in St. Johnsbury Vermont to this day. Fairbanks had received 43 patents in his lifetime with the last one at the age of 91. He died on April 12, 1886, and is buried at St. Johnsbury, Vermont, at the Mount Pleasant Cemetery. An early example of the first type of platform scale that revolutionised the weighing of goods throughout the world made in the USA around the turn of the 19th century. Commercially built platform scale on wheels. Cast iron base supports iron weighing platform with wooden floor. At back, square hollow wooden post supports a hooded rod which bears the weight of the platform and which hooks onto a brass balancing arm, marked in pounds up to 50. There is a cylindrical sliding weight and on the end a loop for a metal weight holder. The holder is designed for three circular pieces of metal with a slit to the centre. The weights used are 50, 100 and 200 lbs.Embossed to base Fairbanks Patent No 11 1/2, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, platform scales -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Platform Scales, Thaddeus Fairbanks, 1880-1910

Thaddeus Fairbanks (1796 –1886) was an American inventor. of heating and cook stoves, cast iron ploughs, and other items. His greatest success was the invention and manufacture of the platform scale, which allowed the weighing of large objects accurately. Fairbanks was born in Brimfield, Massachusetts, on January 17, 1796, the son of Joseph Fairbanks (1763–1846) and Phebe (Paddock) Fairbanks (1760–1853). His uncle was Ephraim Paddock, the brother of Phebe Paddock. In 1815 he moved to St. Johnsbury, Vermont, and set up a wheelwright's shop above his father's gristmill. In 1820 he married Lucy Peck Barker and In 1824 he built an iron foundry. his brother Erastus joined him to establish E. and T. Fairbanks, a partnership to manufacture heating stoves, cast iron ploughs a design for which he patented in 1826. In 1830 Fairbanks and Erastus became interested in the raising and processing of hemp. Fairbanks went on to patent a hemp and flax dressing machine and became the manager of the St. Johnsbury Hemp Company. He also built a set of scales that would measure large loads of hemp accurately, as there were no reliable scales at the time. Upon the success of building these scales, his brothers recommended that he make and sell these for general use. Fairbanks' most famous invention then became the platform scale for weighing heavy objects. These are commonly known as the Fairbanks Scales, for which he patented his original design in 1830. Before this time, accurate weighing of objects required hanging them from a balancing beam as a result, particularly heavy or ungainly objects could not be weighed accurately. A platform scale, if large enough, could weigh an entire wagon. By placing a full wagon on the scale, unloading it, and then placing it on the scale when empty, it became possible to easily and accurately calculate the weight and value of farm produce and other loads. In 1834 Fairbanks and his brother formed "E. and T. Fairbanks and Company" to manufacture and sell these platform scales. These scales were well known in the United States and around the world resulting in the company doubling in volume every three years from 1842 to 1857. There was a temporary slow down during the American Civil War, however, the business took off again after the war. Their partnership was incorporated in 1874 into a firm known as "Fairbanks Scale Company". These platform scales revolutionized weighing methods of large loads and have been in use ever since. Portable platform scales are found in almost every hardware store, physician's office, and manufacturing factory throughout the United States and the world. The first railway track platform scale patent was granted to Fairbanks on January 13, 1857, as Patent No. 16,381. In 1916 the company was purchased by ”Fairbanks, Morse and Company”. Ownership of the company has since changed several times, but Fairbanks Scales continue to be made in St. Johnsbury Vermont to this day. Fairbanks had received 43 patents in his lifetime with the last one at the age of 91. He died on April 12, 1886, and is buried at St. Johnsbury, Vermont, at the Mount Pleasant Cemetery. An early example circa 1900 of the first type of platform scales used in a grocery store. This design for accurately measuring goods that were sold over the counter revolutionised the weighing of goods throughout the world. Platform scale metal black with removable tray & pan. Has horizontal brass arm with a brass slide weight black removable weight hook and 2 x 2 lb. weights. Fairbanksflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Ships, South Warrnambool Primary School Centenary Committee, Unloading coal at Warrnambool Breakwater, 1977

This photograph was framed and mounted then presented to the South Warrnambool school by the South Warrnambool Centenary Committee in 1977 on the school's centenary year. The school was decommissioned and closed in the 1990s. In the photograph, people unload the coal from the ship beside the Breakwater and load it into the row of tramway carts. The coal would be sold to businesses and householders for the purpose of fuel for warmth, cooking, heating water and running machinery. The image shows the early days at the Port of Warrnambool. The building of the Warrnambool Breakwater had only just been completed. Steamships and sailing ships were frequent visitors to the port. Steam Navigation companies were plentiful, carrying passengers and freighting cargo such as coal, timber, food, livestock, furniture, hardware and haberdashery between Melbourne and the ports along the southwest coast of Victoria, including Warrnambool. The carts would take their loads into the township for distribution. The ship carrying the coal is thought to be the "S.S. Chillagoe" previously named "Speculant". In 1903 the Chillagoe was registered at the Port of Melbourne, and it sailed between Melbourne and Newcastle, New South Wales, where coal was mined and sold in significant quantities. In March 1890 a tragedy occurred when coal was being unloaded at the Warrnambool Breakwater. A local young man, David Ferrier, was working in the hold of the steamship Kurrara as its delivery of coal was being unloaded. A basket of coal fell from a sling onboard and came down upon Ferrier, breaking his back. He was not expected to live. In September 1890 there was a strike of coal workers but the Geelong Advertiser reported that a Warrnambool firm of coal merchants had recently received some large cargoes from Newcastle.The photograph is historically significant as it is connected with the local areas of the Warrnambool Breakwater, Lady Bay, and the South Warrnambool Primary School. The scene shows a moment in time when a steamship was unloading a shipment of coal onto tram carts on the Breakwater, which had only just been completed that year. The photograph was taken about 13 years after the opening of the South Warrnambool School, which was decommissioned around 20 years after it celebrated its centenary.. Photograph, black and white, in a gilded rectangular wooden frame, behind glass. The maritime scene shows figures on ships beside the Warrnambool Breakwater jetty and figures on the jetty, standing next to rail carts containing coal. There is a steamship further out on Lady Bay. A card below the photograph has an inscription and there is a pencil inscription on the back of the frame. The coal ship is thought to be the SS. Chillagoe. The photograph was taken in 1890 and was presented to the South Warrnambool School in its centenary year, 1977, by the South Warrnambool Centenary Committee.Typewritten on card: "UNLOADING COAL AT WARRNAMBOOL BREAKWATER"- 1890 - "Presented to Sough Warrnambool School by the SOUTH WARRNAMBOOL CENTENARY COMMITTEE - 1977 - " Handwritten in pencil on the back:"Speculant" as "SS Chillagoe" at Breakwater"flagstaff hill, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, warrnambool breakwater, 1890, tramway, steamship, sailing ship, coal, cargo, port of warrnambool, unloading coal, chillagoe, speculant, newcastle, kurrana, david ferrier, coal strike -

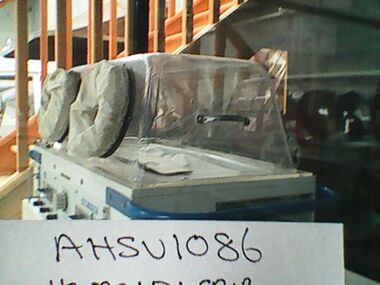

Ambulance Victoria Museum

Ambulance Victoria MuseumHumidicrib, CIG, Port-O-Cot, The Commonwealth Industrial Gases Limited

Humidicribs are used to transport sick babies from small hospitals to major hospitals for specialist care. They work by maintaining normal body temperature and provide oxygen if needed during ambulance transit. Known by a variety of commercial names, earlier humidicribs were ones heated with water bottles. Not part of an ambulances standard equipment, humidicribs are kept in ambulance stations and carried if babies needed to be transported. In the early days before humidicribs came into use and when air ambulances did not exist, many more babies died during emergency transits than do today Manufactured by the Commonwealth Industrial Gases Limited (better known as CIG), Australian-made Port-O-Cot brand humidicribs came replaced timber home-made humidicribs. They had electrical heating and easy to control oxygen flow and humidity control equipment. CIG also noted that noted that: Once the baby has been placed inside, the cot need not be opened, all nursing operations being carried out through the iris armholes. Even though the baby is in complete isolation nursing is a straight forward matter… The iris armholes allow nurses to feed, weigh, take temperatures, change napkins or, in fact, carry out any procedures without changing or disturbing the atmosphere within the cot. Happily for ambulance officers and nurses, the new Port-O-Cots were also much lighter and easy to carry than their old timber ones! metal box with carry handles and Perspex opening top. Carry handles at each end.PORT-O-COTinfant -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, A blue Harris electric train heads towards Union Road, Surrey Hills

The Harris blue electric trains were introduced in c1955 and followed the 'Red Rattlers'. They had a long life and were named after Norman Charles Harris, Chairman of Commissioners of the Victorian Railways, between 1940 and 1950. The first 30 7-carriage trains, known as the first series, were constructed in the United Kingdom by Gloucester Railway Carriage and Wagon Company, and delivered between 1956 and 1959. Another 30, the second series, were built by Martin & King in Melbourne, and delivered between 1961 and 1967. The trains had either two or three sets of hand-operated dual sliding doors per carriage side. Later they were fitted with power doors. Initially, until late 1978, the interiors were split into smoking and no-smoking compartments. In 1978 smoking on trains was abolished. Carriages were also designated as First or Second class until 1958, when one class travel was introduced. they had florescent lights but no heating. Most of the early carriages did not have end doors and gangways between carriages, but safety concerns led these being incorporated in the sets delivered from mid-1966. With the exceptions of the last few carriages built, all Harris trains contained asbestos insulation. The first sets contained blue asbestos, and the later sets contained white asbestos in the linings for insulation of noise and temperature. Due to the presence of asbestos, they began to be withdrawn from the mid-1980s and most were disposed of in the 1990s, by being buried at Talbot Quarry in Clayton, some having been wrapped in plastic. No original Harris trailer cars remain. A coloured photograph of a blue Harris electric train heading towards Surrey Hills station from Mont Albert station. The electricity sub-station and Lorne Parade are on the RHS of the photo and Beresford Street on the LHS. The grey, smoggy appearance of the sky suggests a winter's morning.surrey hills, trains, lorne parade, beresford street, norman charles harris, gloucester railway carriage and wagon company, martin & king, talbot quarry, harris blue train -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Manufactured Glass, milk bottles 600ml, c1970

There are two distinct types of milk consumption: a natural source of nutrition for all infant mammals and a food product for humans of all ages that is derived from other animals. Milk is a key contributor to improving nutrition and food security particularly in developing countries. Improvements in livestock and dairy technology offer significant promise in reducing poverty and malnutrition in the world. Pasteurization is used to kill harmful micro-organisms by heating the milk for a short time and then immediately cooling it. In the past, milk was always packaged in glass milk bottles The first glass bottle packaging for milk was used in the 1870s. The first company to do so may have been the New York Dairy Company in 1877 with a small glass lid and a tin clip. Lewis P. Whiteman holds the first patent for a glass milk bottle c1884,which was sealed with a waxed paper disk. The Express Dairy Company in England began glass bottle production in 1880. Melbourne Glass Bottle Works Spotswood 1880 - 1990. Milk cartons first came to Australia in 1958, when the Model Dairy in Melbourne began packaging milk in 150 ml and 500 ml cartons. At the time, 160,000 new glass bottles were needed in Melbourne alone every week to keep up the delivery of 1.3 million bottles of milk a day c1970, the blow-moulded disposable plastic milk bottle was introduced. In 1987, only about 2% of milk was still being sold in glass bottles. Glass milk bottles are now rare. Metric measures were introduced throughout Australia with Decimalisation 14/2/1966.3 x clear glass milk bottles c 1970 600ml ( 2 shown in photograph)PASTEURISED / 600 ML MILKmelbourne glass bottle works, spotswood melbourne, milk, dairy, dairy produce, dairy farmers, market gardeners, pioneers, early settlers, moorabbin, cheltenham, pasteur louis, pasteurization -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Domestic object - Kitchen equipment, gas-fuelled flat iron, c1900 - 30

Sad-irons or "solid" irons were made by blacksmiths and used to smooth out material by pressing the hot iron over it. A piece of sheet -iron was placed over the kitchen fire and the irons placed on it could be heated whilst remaining clean of ash.. The women used 2 irons - one heating while the other was used. Thick cloth or gloves protected their hands from the hot irons. The handle was removed from the cool iron and re- attached to remove the hot iron from the fire. The cool iron was replaced on the fire or stove to heat again. These irons were cleaned with steel wool to prevent them marking the material. If the iron was too hot the material would scorch. Most homes set aside one day for ironing and some large households had an ironing room with a special stove designed to heat irons. However, most women had to work with a heavy, hot iron close to the fireplace even in summer. Thomas Fletcher (1840-1903). By 1880s he had a gas appliance manufactory in Thynne Street, Warrington. By 1895 the company had become Fletcher Russell and Co Gas Engineers, his firm having merged with Alexander and William Russell of Pendleton Iron Works. Circa 1950, the firm merged into Radiation Ltd which was later acquired by 'TI New World'; 1902: Fletcher, Russell & Co. Ltd., Palatine Works, Warrington In 1880 gas -fuelled irons were connected by rubber tubing to the gas light-fittings of the house or to gas canisters. However , not many houses had access to a gas supply until much later and this iron was popular in 1920’sThese sad irons remind us of the difficult circumstances experienced in their daily routines by the pioneers and early settlers of Moorabbin Shire The family of Miss M Curtis were early settlers in Moorabbin Shire.A gas-fuelled flat iron, made in USA , It would have been attached to a gas hose fitting that was also used at night for light in the house. There is a small chimney to allow for air and to try to control the amount of heat in the iron. A 'shield' is under the leather covered handle to protect the user's hand from the heat, however it is made of copper metal - a heat conductor.FLETCHER RUSSELL CO. / LIM/ PATENT/ WARRINGTON on right side of handle 'Registered' on left side of handle ' Fletcher Russell Co L / Warrington, Manchester / & London.sad iron, kitchen equipment, fletcher russell co. ltd., england, warrington, manchester, pioneers, early settlers, market gardeners, sewing, craftwork, clothing, moorabbin, brighton, bentleigh, fireplaces, stoves, domestic gas supply, gas-light, gas cannisters -

Wodonga & District Historical Society Inc

Wodonga & District Historical Society IncDomestic object - Electric Toaster, Hecla Electrics Pty Ltd, c1940s

Hecla produced a wide range of appliances for domestic use, beginning with heaters and later branching out to a wider range of kitchen appliances Hecla was established by Clarence William Marriott, a young Melbourne metal worker. He began manufacturing Australia's first carbon filament electric radiators in 1899. He originally worked for his father James Marriott who commenced business in Melbourne as an art metal worker in 1872 and was, in 1907, appointed as the official art metal worker to the Victorian Government producing items including the ornate iron gates and gas lamp standards outside Melbourne's Parliament House. With the invention of nickel chromium wire after 1900, C.W. Marriott began making more efficient heating elements using this new material in 1916. After being influenced by the eruption of Mount Hekla in Iceland, on 19 December 1918, Clarence registered the brand name "HECLA" with an erupting volcano as its logo. The company Hecla Electrics Pty Ltd was officially registered in 1922. In 1928 the company adopted the advertising slogan, 'By Hecla, it's Good'. The Hecla range rapidly expanded to include electric heaters and radiators, electric foot warmers, electric kettles, ceramic & metal electric jugs, immersion hot water elements, electric fans, electric coffee percolators, electric toasters, electric grillers and stoves, electric irons and electric frypans, clocks and curling wands. Electric blankets were introduced shortly after WWII.In 1930, a controlling interest in Hecla Electrics Pty Ltd was acquired by General Electric Corporation. Clarence William Marriott died in June 1967 in Melbourne, Victoria.This item is representative of a common domestic appliance used throughout Australia. It was manufactured by a pioneering Australian company.A small chrome steel toaster manufactured by Hecla Australia. It has a door on either side which flips down to insert or remove a slice of bread on each side, Each door has two black Bakelite knobs. The electric element is placed down the centre of the cavity. A detachable electric cord is included.240 Volts, 600 Watts. Cat. No. T4 Submitted to Electrical Approval Board Ref Application A1/AD01 SECV 240 Volt 600 Watt MANFED. IN AUSTRALIA SOLID BRASSelectrical appliances, hecla corporation australia, clarence william marriott, domestic appliances -

Montmorency–Eltham RSL Sub Branch

Montmorency–Eltham RSL Sub BranchUniform - Coat, US Cold Weather, M-65, US Cold Weather Coat

In 1951 - in the context of the Cold War - the Menzies government established the 'National Service Act 1951', which called-up men for compulsory military training for a period of 176 days. The 14th Battallion was located in Victoria. The coat has historic significance in the wider context of Australia’s involvement in the Cold War (particularly in Vietnam) and in the establishment of a National Service Scheme. Olive green army man coat with four outside pockets - two on the chest, two at the bottom; each pocket has one metallic button attached. Coat has a metallic zip as well as metallic buttons; two velcro scratches at the wrist level. Extra removable padding inside, which is attached with plastic buttons. Two identical inscriptions on right and left shoulder reading '14 National Service Battalion'. Two identical inscriptions on right and left shoulder - reading '14 National Service Battalion' Manufacturing details on the inside reading: Coat, Cold weather, Man's, Field M-65. Olive green colour. Style 8120/8542 DSA 102-81-C1204. 1. Wear as outer garment or as under-layer in cold-dry climate. 2. Wear button-in liner for added insulation. 3. Adjust closures and drawcords to ventilate; avoid over-heating of body. 4. When hood is used, lower extension shall be worn over neck opening, preventing water. 5. Brush snow or frost from garments before entering opening. 6. For fast drying, remove liner from coat. 7. Do not expose to high temperature of a stove. 8. Lubricate slide fasteners with wax. 9. For cleaning and restoring of water repellency return to laundry for machine washing in accordance with established procedures for quarpel garments. 10. Do not starch. Do not remove this label. Black ink pen inscription on manufacturing label reading '3/715875' and 'N.Wain'war, army, coat, man's coat, australian army, military uniform, national service scheme, cold war, vietnam war -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Stove, Cox and Rizzetti Stove Works, ca. 1918-1930s

Cast iron stoves burn solid fuel such as wood or coal, and are used for cooking and warmth. The stoves have a firebox with a grate where the fuel is burned. The hot air flows through flues and baffles that heat the stove top and the oven. Before cast iron stoves were invented, cooking and heating were carried out in outdoor open fires, and later, in fireplaces inside the home. In 1642 the first cast iron stove was manufactured in Lynn, Massachusetts, where molten cast iron was poured into a sand mould to make rectangular plates that were then joined together to make a box. Benjamin Franklin invented the more efficient Pennsylvania stove in 1744, and this efficient design is still used today. After the mid-19th century cast iron stoves were produced with burners in different positions, giving varied temperatures, so a wide variety of foods could be cooked at the same time at the most suitable heat, from slow cooking to baking scones. In contemporary times people the new wood-burning stoves had to meet the anti-pollution standards now in place to protect our environment. By the 1920s gas cookers were being introduced for domestic use, and by the 1930s electric home cookers were being offered to householders. PLANET STOVES In August 1925 the firm Cox and Rizzetti, Stove Works, and also Sydney Road, South Melbourne, advertised in the Brunswick and Coburg Leader of November 11, 1925 as "formerly with Harnwell and Sons" and as "specialists in solid cast iron Planet stoves ... which merit an inspection from builders and householders". The firm continued in business and was mentioned as sponsors in the King Island News in 1971. Harnwell and Sons was listed in the Victorian Government Gazette of 1894. It is curious that the firm was mentioned in an article in the Sunrasia Daily of June 14, 1934 titled 'Planet Stoves' as a manufacturer of Planet Stoves. This Planet No 3 stove is an uncommon example of cooking equipment used in kitchens in the early 20th century, as the firebox is above the oven rather than beside it. The cast iron combustion stove is significant as part of the evolution of domestic cooking. Previously cooking was mostly carried out in outdoors in open fires, and later in fireplaces indoors. Cast iron stoves are still used today and have additional features such as thermostats to monitor and maintain temperature, water heating pipes connected, and environmentally approved anti-pollution fittings. Stove; a compact, blackened cast iron combustion cooker, installed within a fireplace and enclosed by bricks on both sides. The upright rectangular stove has a flat top with three round, removable cook plates and a flue connected at the back. The front has three doors with round knob handles; a swing-down firebox door above a sliding ashtray, and two side-hinged oven doors above a sliding opening. Inside on the side walls are two pairs of runners. Behind the pair of doors is an oven with two pairs of rails and two removable metal shelves. The stove has cast inscriptions on the chimney flue and on the front of the right hand side stove door. The model of the stove is The Planet No 3, made in Melbourne.Chimney flue, "[within rectangle] THE / PLANET" Stove door, "(within oval) PLANET / No 3"flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, stove, cast iron stove, combustion stove, wood-burning stove, wood stove, wood oven, solid fuel stove, cooker, the planet, planet, planet no. 3, kitchen equipment, baking, domestic cooking, cooking equipment, food preparation, planet stove, planet cooker, cooking range, slow combustion stove, antique, range cooker, cox and rizzetti, harnwell and sons, melbourne manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Bolster Sham, Eliza Towns, Late 19th century to early 20th century

This bolster sham is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes and household linens - adding her own handmade embroidered or crocheted decorative trim. Most beds during the late 19th and early 20th century had a feather, hair or spring mattress covered by a blanket and topped with an under sheet, an upper sheet, several blankets and a bedspread. A flat bolster could be placed either under the pillows or on top of the pillows with a decorative sham. Washing pillows and quilts by hand would have been a very onerous task (involving heating water and handwashing in a tub or using a copper) and so it became the practise of many housewives to cover the pillows and bolsters with an outer slip (or sham) of washable material which could be easily removed and washed when needed. If the bolster was kept under the pillows it wouldn't need to be very decorative but many shams or slips that were "on show" were often highly decorated with embroidery, pintucks, ribbons or lace. This bolster sham is machine made and quite plain with the exception of some pintucking and eyelet lace on each end which suggests that it would mostly be hidden under the top pillows with just the decorative edges on display.This item is an example of the needlework skills of women in the early 20th century - combining machine stitching with hand embroidery to personalise and embellish a practical domestic object. It is also significant as an example of an early 20th century innovation that helped make the working lives of housewives a little bit easier.A long white cotton rectangular bolster sham, machine sewn, with seven ties and two buttons (plus one missing button) to enable it to be folded over lengthwise and closed. It has two pull string ties near each end to enclose a bolster and is finished with a decorative edge of pintucks and handmade eyelet lace and embroidery.flagstaff hill maritime museum and village, eliza towns, sham, bedding, great ocean road, shipwreck coast, warrnambool, household textiles, sewing, bolster sham, housework, pillow sham, charles towns, nhill, haberdashery, needlework, manchester, handmade, household linen -

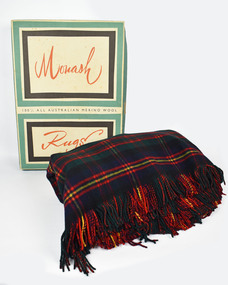

National Wool Museum

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange