Showing 751 items

matching machine made

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

... increasingly machine made, which greatly reduced the production time... increasingly machine made, which greatly reduced the production time ...This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper with flared lower. Push-up base with pontil mark and embossed inscription. Base is uneven, glass composition has imperfections.Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

... increasingly machine made, which greatly reduced the production time... increasingly machine made, which greatly reduced the production time ...This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Neck has seams and shoulder seam from 3-piece mould. Body tapers towards base. Push-up base with pontil mark and embossed inscription. Base is uneven. Mouth has remnants of the seal in it and tape remnants around its outside. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

... increasingly machine made, which greatly reduced the production time... increasingly machine made, which greatly reduced the production time ...This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, olive green glass, handmade. Tall slim, Gallon style liquor bottle. Applied double collar lip; square upper with flared lower. Neck is slightly bulged and there is a mould seam where shoulder joins base. Body tapers inward to base. Uneven base with deep push-up centre with small pontil mark. Scratches and imperfections in glass. Also encrustations on surface. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

... increasingly machine made, which greatly reduced the production time... increasingly machine made, which greatly reduced the production time ...This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, olive green glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Mouth has remnants of tape and wire seal. Mould seam around shoulder. Body tapers slightly inward to the base. Push-up base has pontil mark and is embossed in large letters. Base is uneven. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

... increasingly machine made, which greatly reduced the production time... increasingly machine made, which greatly reduced the production time ...This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from an unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, Tall slim gallon style. Applied double collar lip; upper is straight, lower is flared. Lip has bumps around the top. Neck has slight taper towards shoulder, which has a shoulder seam from the mould. Body tapers inwards towards base. Push up base has a pontil mark. Base is embossed.Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageBolt Cutter, 1878

... for the machine that would make clay bricks. This machine made forty... for the machine that would make clay bricks. This machine made forty ...Cyrus Chambers was a self-described mechanic who started out winding bobbins in his father's woollen mill and went on to invent machines that changed their industries. Cyrus Chambers came from Quaker parents the ninth of thirteen siblings, he once said a year before his death. “I believe I have succeeded because, first, I was industrious; second, because I made a study of the subject that was before me.” At age 7, Chambers went to work in his father’s mill. His job was to monitor bobbins—wooden spindles around which thread was wound and to remove and replace them as they became full. "There was no child labour law at that time," he later recalled. Chambers loved machinery and always regarded himself as a mechanic rather than an inventor. At age 16, Chambers was sent to learn dentistry with an older brother, (Edwin) who was already in the field and willing to take him on as an apprentice. Chambers was talented at working with small parts. He used his brother's dental instruments to build a miniature high-pressure steam engine of silver. It ran at 3,000 revolutions per minute and weighed less than a half-ounce. At that time it was the smallest engine that had ever been constructed. The engine was displayed at the 1876 Centennial and is now in a permanent collection at the Franklin Institute USA. Chambers major invention was the paper folding machine and came from reading that school teachers made less than the young girls who were employed to fold book pages as they came off the press. He told friends that his first efforts were to make the machine that would fold newspapers after demonstrating his device he met with Horace Greeley of the New York Tribune who advised Chambers would never invent the machine that would be able to fold his newspaper or books. In less than a year Chambers had built a full-size machine capable of folding large newspapers and books and was installed at J B Lippincott & Co folding pages for the "Comly Speller" this machine ran successfully for twenty-five years until the printing works burnt down. Chambers then went into partnership with a brother and they established the firm "Chambers, Brother & Co" at a plant in Philadelphia. It was also observed in 1910 and a fact that there was not a periodical or newspaper printed or recently published book that had not gone through one of Chambers inventions. Chambers went on to produce many mechanical inventions and improvements to existing tools and machinery most notable was his invention for the machine that would make clay bricks. This machine made forty bricks per hour and by the end of Chambers life after many improvements, it could make more than four hundred. Although there were a large number of bold cutters made of this patent at Cyrus Chamber’s foundry in Philadelphia, the item is associated with a notable American inventor of the nineteenth century. This particular patent for a bolt and rivet cutter won Chambers the prestigious Elliott Cresson Medal. This cutter is just one of the many inventions and mechanical improvements that Cyrus Chambers made during his lifetime, contributing to the ongoing development of mechanical improvements that were occurring in American industry of the time and therefore a notable addition to the Flagstaff collection.Cast iron bolt cutter with removable tempered steel cutter. Chambers New No. 2.Raised embossed lettering on cast body of cutter "New No 2" on one side, "Chambers Bros & Co" on the other sideflagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, cyrus chambers, bolt cutter, paper folding machine, brick making machine, elliot cresson, elliot cresson medal, franklin institute, gold medal, rivet cutter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

... increasingly machine made, which greatly reduced the production time... increasingly machine made, which greatly reduced the production time ...This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. However, this bottle is rare, in that the base has been embossed then over-embossed with the same text, letters overlapping. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is a rare find, in that the base has been over-embossed with the same lettering, letters overlapping one another. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, over embossed, brown glass, handmade, rare. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Mouth has sealing tape remnants around top. Mould seam around shoulder. Body tapers inwards to push-up base. Top edge of lip has application faults. There is also a rectangular indent in the upper edge of lip. Base is embossed and over embossed, with the letters overlapping each other. Embossed on base "6 TO THE GALLON", then over-embossed with the same "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable, over embossed, rare -

NMIT (Northern Melbourne Institute of TAFE)

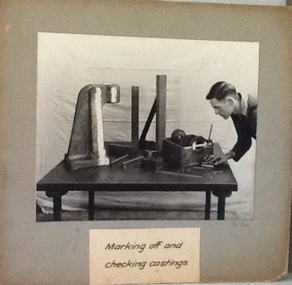

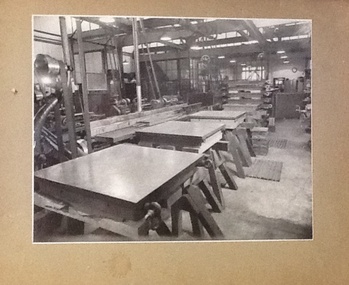

NMIT (Northern Melbourne Institute of TAFE)Photographs - Collingwood Technical School, Allan Studios, Mounted photographs of Trade School CTS, circa 1940, Early 1940s

... castings 2. Examples of other machine parts, etc., being made.... Examples of other machine parts, etc., being made in Youth ...Collingwood Technical School trained apprentices in many trades. These photographs depict some of the machines and machine parts built in class. Captions : 1. Marking off and checking castings 2. Examples of other machine parts, etc., being made in Youth Employment classes in engineering machine shop. 3. Cutting the traversing screw for a 5 ¼ inch lathe. 4. Grinding lathe spindle. 5. Cutting helical flutes in a shell end mill. 6. Arbor Press. Another valuable machine produced by Youth Employment and senior technical evening students. 7. Milling angular slides of lathe saddle. 8. 5 ¼ inch lathe product of Collingwood Technical School. These are high quality professional photographs taken circa 1940. 8 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work.Each photograph has a hand written caption on the front. Also handwritten in black pen "Allan Studios".collingwood technical school, cts, apprentices, students, lathes, machinery, machine parts, nmit, -

NMIT (Northern Melbourne Institute of TAFE)

NMIT (Northern Melbourne Institute of TAFE)Photographs - CTS 1940-1943, Collingwood Technical School. Defence Training Scheme, 1940-1943

... vises made in technical schools. 4.View of engineering machine... / rectifying machines, and two types of milling / machine vises made ...Collingwood Technical School trained apprentices in many trades. CTS was also invlved in Training Schemes during the late 1930s and during World War II. These photographs depict some of the machines and machine parts built in class. These are high quality professional photographs taken circa 1940-1943. At this time , CTS was part of the Defence Training scheme. These photographs are a visual record of this scheme.6 black and white photographs mounted on brown card. Photographs depict various aspects of lathe work undertaken during the Defence Training Scheme, 1940-43. Also a smaller photograph of a Moultar Thread Milling Machine 1941.Each photograph has a hand written caption on the back. Captions: 1. Finished surface plates for R.A.A.F. / standing on trestle after scraping. Stack of / others in background waiting for scraping. 2. Lathe bodies in foreground, with machined / parts of lathes in middle distance, and milling / cutters, gauges and bearings in background. 3. Frames of glass splitting machines, thread / rectifying machines, and two types of milling / machine vises made in technical schools. 4.View of engineering machine shop. Carbon dioxide / freezing box in foreground, and stack of / surface plates for RAAF in middle / distance. 5.Fan geared lathes, 6 inch centres, with / self-contained motor drives, made for / cartridge factory. To be used for making / this 6.Freezing of cast iron surface plates / in layers of solid carbon dioxide / blocks. Smaller photograph has a handwritten note on the reverse: 'this photograph shows how, with the aid of a 3ft. extension mounted in front of the tool box, on which Mr. Grubb sen. is seated, these large milling machine bases ... machinists at Collingwood Technical School. A Strang, Principal 21.4.1941'. collingwood technical school, cts, apprentices, students, defence training scheme, lathes, machinery, machine parts, nmit, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings "Holeproof', mid 20thC

... of its 230 machines. The hose were made of a synthetic yarn... of its 230 machines. The hose were made of a synthetic yarn ...Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. A unused pair of lady's silk stockings in original box. 'Holeproof' 'Truly Yours' Candlelight, size 10Box Cover: Truly Yours / by / Holeproof Side Holeproof 'Candlelight' Size 10clothing, stockings, nylons, holeproof hosiery pty ltd, lingerie, melbourne, bentleigh, cheltenham moorabbin, brunswick milwaukee usa, wisconsin -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

... of its 230 machines. The hose were made of a synthetic yarn... of its 230 machines. The hose were made of a synthetic yarn ...Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. An unused pair of lady's nylon stockings in original box. 'Holeproof' 'For you', 'Precious' size 91/2Box Cover : For You / HOLEPROOF/ SUPERFINE EXQUISITE SHEERS Side : Precious 9 1/2 Package : 60 GUAGE / SHEER NYLON / BY / HOLEPROOF / 9 1/2 Card : Especially / For You / fromclothing, stockings, nylons, holeproof pty ltd, milwaukee usa, hosiery, fashion, melbourne, bentleigh, cheltenham moorabbin, brunswick, lingerie -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

... of its 230 machines. The hose were made of a synthetic yarn... of its 230 machines. The hose were made of a synthetic yarn ...Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific BrandsAn unused pair of lady's stockings, in original box, 'Holeproof', 'Beauty Fit', ' Nocturn' Size 81/2 - 9 Box Cover : HOLEPROOF / Beauty Fit / LADDERPROOF MESH SHEERS STRETCH Inside Wrapper ; HOLEPROOF / Beauty Fit / LADDERPROOF STRETCH NYLONS 8 1/2 - 9clothing, stockings, nylons, hosiery, melbourne, bentleigh, cheltenham moorabbin, brunswick, holeproof pty ltd, lingerie, fashion -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing Machine, Early 20th century

... Sewing Machines Limited. The switch was made with the government... front of machine body has large, decorated gold lettering “A. N... to a tariff of two pounds per head for every machine head made ...Ward Brothers (George and Samuel) registered a company (Australian Sewing Machines Limited Pty Ltd) with the head office address in Errol St, North Melbourne, and Prahan. The earliest newspaper advertisement for this company was in 1897. Around this time the Ward Brothers first imported sewing machines from England and Wertheim placed their decal on them and mounted them in their own Australian made cabinets. David Ward later imported machines from Beisolt & Locke in Germany and registered name A.N.A. (All Native Australian), his shop was in Collingwood Melbourne. Some of these machines had Ward Brothers decals on them as well. The three brothers sold under the same name as Ward Brothers. The early Ward Brothers logo had a map of Australia with a picture of all three brothers on it. In 1911 all three of the Ward Brothers decided to share a stall in the yearly Melbourne exhibition. The A.N.A was the machine that got rave reviews. It was at this time that the Australian Sewing Machine Company Pty Ltd decided to add the A.N.A logo to their logo to cash in on the new found celebrity status that the A.N.A has gained. To cut a long story short. David Ward took his brothers to court to prevent this from happening. This was a long drawn out affair that took quite a few years. The settlement was decided out of court and nothing was disclosed of the deal that was made. David seemed to have left the scene, then the remaining Ward Brothers and A.N.A. combined and then became “Wardana”. There are many Ward Brothers sewing machines in displays, they originated from Japan, England, America, and Germany. It seems that where ever they got the best deal for sewing machines or parts is the direction they went. This is where the Bendigo sewing machine company came into the picture. All imported sewing machines into Australia drew a government tax. Bendigo Cording's Traction Company was given proposed two-pound tariff protection that gave the company a significant price advantage for its machines. As a result, the Ward Brothers purchased a huge number of Bendigo shares to get cheaper machines for their sewing machine cabinets. Ward Brothers then placed one of their company officials on the Board of “Bendigo Sewing Machines Limited” and the rest is history. Ward Brothers had shops Australian wide and in most of the major country towns. History for “Bendigo Sewing Machines Limited” Cordings Traction Company owners (H. Keck MLC, W. Wallace, and W. Ewing) operated their business out of the former W. Webb & Co. building in Queen St. Bendigo. Around 1923-1924 they decided to switch from traction engines to manufacturing sewing machines. The actual date is not known but that year's financial report made note of both Cordings and Bendigo Sewing Machines Limited. The switch was made with the government of the day agreeing to a tariff of two pounds per head for every machine head made completely in Australia. The change from traction engines to sewing machines went well. Government representatives visited the factory in Bendigo to inspect and ensure that the sewing machines were Australian made as a result they agreed on granting the two-pound tariff to the company. After the first 12 months, they built 30, the following 12 months the company had produced 1500 machines probably due to the involvement of the Ward brothers. However, the government proposed a new condition to the tariff agreement which was that the company must produce 20% of Australia's requirements for sewing machines. In 1924 after having had produced 1500 machines resulting in reaching their financial limit for tariff support. According to the government, the requirement was 15,000 machines for the next year had to be produced to qualify for the tariff. The company had already reached its production limit and unfortunately folded. There were several attempts to regain government assistance to save this new industry but it was to no avail. Even a promise to open another factory in Sydney was offered but unfortunately wasn't accepted. An item fabricated in Australia from a majority of imported parts from either Germany, America or England giving a snapshot into the early manufacturing industries that were operating at the time of Federation. Sewing machine, treadle, in timber cabinet. Branded Ward Bros, A.N.A., Australian Sewing Machine Coy. Decorative carved timber cabinet, hinged, fold-out laminated timber top and five drawers; two small on each side with handles and one long, shallow, between side drawers without handle. Thread is on bobbin in a rocket shuttle (both in good condition) plus spare empty shuttle (rusty). Brass ‘Half Yard’ ruler inlaid across front, measuring scale in inches and centimetres. Two metal shuttle cover plates (or throat plate / slide plate); front one is impressed with a gauge for needle and thread. Gold trim and decals on flatbed and machine front and back, serial number under shuttle cover, brand on decals and on round metal plate on back of machine. Front right of machine has a bobbin winder. Treadle belt shows signs of wear and laminate on timber machine cover is peeling slightly.Decal coat of arms on right front of machine: kangaroo on left, man with broad-brim hat, holding pick-axe on right, in centre, top “SEWING MACHINE / THE / A. N. A.” then below it, the rising sun, then below that is state of Victoria shield with the Southern Cross constellation. Wheat sheaves around edge on left and flowering plant on right. Gold ribbon banner at bottom with script “WARD BROS.“ Decal of map of Australia on flatbed of machine. States and capital cities are marked and named (no northern territory), portrait of two men. In centre of map are interwoven letters “A. N. A.” and written in script “WARD BROS.” Decal across front of machine body has large, decorated gold lettering “A. N. A.” Decal across the top of machine “THE AUSTRALIAN SEWING MACHINE COY. PTY. Ltd.” Steel shuttle cover at front has an impressed gage listing cotton and needle sizes and number of stitches. Brass disc on back of machine “A. N. A.” in centre. Brass ruler across front of machine has carved or pressed words in the timber. In centre “INCHES” above ruler and “CENTIMETRES” below ruler, and on right above ruler is “HALF YARD” Decal across back of machine’s body “A.N. A. / MADE IN U.S.A.” Stamped into metal under shuttle cover is “219415” (2 and 5 are partially there, first 1 could instead be a 7) flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, ward bros., australian sewing machine co., a.n.a., treadle sewing machine, rocket shuttle sewing machine, home industry, clothing, wardana, australian sewing machine company, all native australian, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Hinge, 1800s to early 1900s

... and manufacturing boomed. Hinges could be made by machines quickly... and manufacturing boomed. Hinges could be made by machines quickly ...This flat hinge was recovered from an unknown shipwreck in the coastal waters of Victoria in the late 1960s to early 1970s. It is part of the John Chance Collection. The size of the hinge indicates that it was used for a large item such as an entry door, gate or perhaps a ship fitting. The blue-green patina on the metal is caused by a reaction from its exposure to external elements such as the sea water. The hinge is likely to have been in the water for over 100 years, as the more widely known shipwrecks along Victoria’s Shipwreck Coast date from 1837 to 1940. Before the Middle Ages metal was expensive and took a lot of effort to work with As time went on, methods were discovered for working more easily with metals, and ways were found for combining different metals to make alloys that made the metals stronger and more durable. Hinges forged by blacksmiths began to be common in homes. In the Victorian Era steam power was introduced and manufacturing boomed. Hinges could be made by machines quickly and in great number. All sorts of applications were found to take advantage of the features of hinges. They continue to be developed and used in a huge variety of ways. Although the hinge is not linked to a particular shipwreck, it is recognised as being historically significant as an example of hardware either as part of the ship’s fittings or imported for use in Colonial Victoria in the 19th to early 20th century. The hinge is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Hinge; heavy bronze flat hinge, hand forged. Flat with narrow, arrow shaped end that lares outward to wider straight end. Attached to the wide end is a rectangular, upward curved knuckle. There are five formed holes along the hinge, two are oval shaped and three are round. The hinge has a blue-green patina.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, hinge, hardware, flat hinge, door fitting, ship’s fitting, 19th century metalwork, forged hinge -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Nightgown, Eliza Towns, circa 1890's

... ". Eliza probably had a treadle sewing machine and would have made...". Eliza probably had a treadle sewing machine and would have made ...This nightgown is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes as well as clothes for her children - adding her own handmade embroidered or crocheted decorative trim. This nightgown is machine sewn by Eliza Towns and she has added a detailed design of pintucks and broderie anglaise lace to the front yoke and cuffs as a decorative element. The 1800's bought a shift in attitude towards modesty as the Victorian era progressed and by the mid to late 1800's it had become more acceptable ladies to wear simple, modest nightgowns. They tended to have a very loose fit and were usually made of linen, cotton or flannel, which had the advantage of providing warmth and also being easy to wash - a necessity for a garment worn next to the skin. Although the basic design of the nightgown was fairly simple, the wearer was free to add various types of trim e.g. lace, crochet, pintucks, embroidery etc.This item is an example of the needlework skills of women in the late 19th century - combining machine stitching with hand embroidery to personalise and embellish a practical item of clothing. It is also significant as an example of a practical solution to the difficulties that women of this era faced with regard to the washing of clothes and household linens.Lady's long, white, cotton nightgown with a V shaped bodice decorated with bands of nine pintucks alternating with strips of broderie anglaise lined with pink ribbon. The opening front placket and neckline are bordered with a simpler broderie anglaise lace. The long sleeves are gathered into cuffs with a matching V shape, pintuck and broderie anglaise design. The front placket fastens with three cream buttons although one is missing. The back of the nightgown has gathered fabric on a plain, narrow V shape yoke. A narrow gusset has been added to the both sides at the bottom of the nightgown.Noneflagstaff hill, flagstaff hill maritime museum and village, warrnambool, great ocean road, shipwreck coast, victorian era clothing, victorian era nightgown, nightgown, nightdress, eliza towns, nhill, wimmera, textiles, clothing, machine sewing, hand sewing, pintucks, broderie anglaise, sewing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Corset cover, Eliza Towns, Mid to late 19th century

... machine and would have made many of her own clothes as well... machine and would have made many of her own clothes as well ...This corset cover is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes as well as clothes for her children - adding her own handmade embroidered or crocheted decorative trim. This corset cover is an excellent example of an everyday clothing item with the decorative trim favoured by women in the late Victorian era. Eliza Towns has added pintucks, embroidered feather stitch and a highly decorative hand crocheted lace trim to the neckline, sleeves and front of the bodice. Corset covers (sometimes called camisoles) began to appear in women's fashion around 1840 and continued through the late Victorian decades into the Edwardian era. The long chemise was considered too bulky to cover the corset and so the corset cover was developed to be short and light and was worn over the corset and under the bodice of the outer garment. A woman would dress into her chemise and drawers first, followed by her corset and finally her corset cover as a final layer under her dress. Corset covers served several purposes. They provided protection against sweat (and the need to regularly wash the corset), helped smooth the lines of the corset and increased a woman's modesty.This item is an example of the needlework skills of women in the late 19th century - combining machine stitching with hand embroidery and crochet to embellish an item of personal underclothing. It is also significant as an example of a practical solution to the difficulty of hand washing a corset in the Victorian era.A short (waist length) corset cover of fine cotton. Short sleeves fall from a square neckline and are gathered into a wide crocheted lace trim with a band of embroidered feather stitch. The same crocheted lace design and feather stitching are also on the square neckline which is finished with a drawstring ribbon. The bodice has a front opening with five buttons and is bordered on each side with four pintucks. It has a drawstring ribbon at the waist and an extra layer of fine cotton lining has been added to strengthen the corset cover under the arms. The back has two bands of three pintucks running vertically from the neckline to the waist.flagstaff hill, flagstaff hill maritime museum & village, warrnambool, great ocean road, shipwreck coast, nhill, wimmera, eliza towns, underclothing, corset cover, camisole, machine sewing, hand sewing, crocheted lace, pintucks, feather stitch, embroidery, underwear, victorian era underclothing, victorian era corset cover -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Combination Undergarment, Eliza Towns, Late 19th century

... had a treadle sewing machine and would have made many of her... had a treadle sewing machine and would have made many of her ...This item of underclothing, called a "combination" is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes as well as clothes for her children - adding her own handmade embroidered or crocheted decorative trim. Combination undergarments combined the chemise and drawers into one garment. The combination is divided, or bifurcated, from the waist to the crutch for easier urinating. This one-piece type of underwear was worn by females from the 1860s and into the early 1900s. The 19th Century garments had front button closures like this one, and those made in the 1900s more often had back closures. Combination underwear was popular because the all-in-one design had far fewer gathers and bulk, making the other clothing look much smoother. Their primary use was to protect clothing from perspiration and because they were made with cotton or linen, were easy to wash. Although they were worn under the corset, next to the skin (and therefore not meant to be seen), they were often decorated with lace and embroidery. Although these combinations are made with a plain cotton fabric, Eliza Towns has incorporated pin tucks, hand embroidery and crocheted lace to embellish her garment. The collection of women’s late-19th-century undergarments is an example of clothing that women would include in their wardrobes. The garments add to the study of the evolution of women's fashions and practicality for the early Australian settlers. The careful needlework in these handmade garments and hand-worked lace trims reflect the maker’s dedication to making even serviceable garments beautiful to look at and wear.Women’s white cotton and lace all-In-one combination undergarment. The handmade underwear is a combined chemise and bloomers. It has three buttons in the front and a handmade drawstring cord around the square neckline. It is trimmed with crocheted lace (with a floral design) on the neckline, sleeves and pants. It had pintucks and feather stitching on the bodice and the left and right sides are divided from the waist to the crutch. The back of the garment is plain with a gathered section at the lower back.flagstaff hill maritime museum and village, maritime museum, maritime village, warrnambool, great ocean road, victorian era, combination undergarment, all-in-one underwear, combination, ‘combinations’, one-piece underwear, one-piece undergarment, chemise and bloomers, combination chemise and bloomers, divided, bifurcated, split, chemise and drawers, women’s underwear, ladies’ underwear, undergarment, women’s clothing, women’s fashion, lingerie, 19th-century undergarment, handmade clothing, handmade lace, crocheted lace, towns family, nhill, eliza towns -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageClothing - Child's dress, Eliza Towns, Late 19th century

... machine and would have made many of her own clothes as well... had a treadle sewing machine and would have made many of her ...This child's dress is one of several linen and clothing items that were made and belonged to Mrs. Eliza Towns and donated to Flagstaff Hill Maritime Museum and Village. Eliza was born Eliza Gould in 1857 in South Melbourne (Emerald Hill) and in 1879 married Charles Towns. In the early 1880's they moved to Nhill in western Victoria and remained there for the rest of their married life. Charles was a jeweller and later became an accountant and for many years was involved with the Shire Council, the local show committee (A & P Society), the Hospital Committee and the Board of the local newspaper (the Nhill Free Press). They had three children and lived a life that would be regarded as comfortably "middle class". Eliza probably had a treadle sewing machine and would have made many of her own clothes as well as clothes for her children - adding her own handmade embroidered or crocheted decorative trim. A photograph of their youngest child, Alice, taken in circa 1903 depicts her wearing the dress. The dress would have been only worn on special occasions (such as a formal family photographic portrait) as most young girls in that era would have smocks or pinafores for everyday wear. The age of the dress is in question as it may have been made by Eliza for her eldest daughter, Dorcus, who was born in 1884. This dress has some machine sewing at the neck, waistband and pintucks but much of the dress is handsewn and richly embroidered with Broderie anglaise. Broderie anglaise (also known as eyelet lace) is a form of cutwork embroidery. The foundation fabric is cut to make decorative holes which are sewn with overcast or buttonhole stitches to create a lace like effect. Designs often involve floral motives that are enhanced with simple embroidery stitches such as stem stitch and satin stitch and scalloped edges finished with buttonhole stitches. It was commonly used to trim baby clothes, dresses, nightclothes, underclothes and household linens - particularly in the Victorian and Edwardian eras. This item is an example of the needlework skills of women in the late 19th century - combining machine stitching with hand embroidery to personalise and embellish a child's special dress.Child's white dress made of cotton and lawn, with a skirt of hand embroidered circular cutwork (broderie anglaise), a scalloped hem edged in buttonhole stitch and a gathered waist. The lined bodice has three panels of hand embroidered broderie anglaise (eyelet lace) inserted in a V shape with pintucks and bordered with a broderie anglaise lace frill. The short sleeves also have an inserted broderie anglaise lace strip, three pintucks and a broderie anglaise lace frill. The skirt is semi lined with fine lawn. The dress has a back opening with one button and two ties. The neckline is decorated with two rows of hand embroidered broderie anglaise lace.flagstaff hill, flagstaff hill maritime museum & village, warrnambool, shipwreck coast, great ocean road, nhill, wimmera, eliza towns, dorcus towns, child's dress, machine sewing, hand sewing, broderie anglaise, cutwork, embroidery, eyelet lace, clothing, handmade, charles towns, alice towns -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

... . Krupp's main products are machinery and machine components made.... Krupp's main products are machinery and machine components made ...60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

Bendigo Military Museum

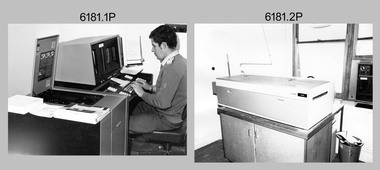

Bendigo Military MuseumPhotograph - Personnel and Equipment, Army Survey Regiment, Fortuna, Bendigo. c1979, c1979

... machine, ‘Editwriter’ Model 7500, SGT Jim McDonald. .2) - Photo... machine, ‘Editwriter’ Model 7500, SGT Jim McDonald. .2) - Photo ...This is a set of 23 photographs of cartographic, aero-triangulation and lithographic equipment, and personnel at the Army Survey Regiment, Fortuna, Bendigo circa 1979. Photos .8P to .23P were taken in Lithographic Squadron’s printing, Camera, proofing rooms and external buildings. Cartographic Squadron’s SGT Jim McDonald operated the Editwriter type setting machine, as shown in photo .2P for a couple years in a room on the top floor of Fortuna Villa. This is a set of 23 photographs of cartographic, aero-triangulation and lithographic equipment, and personnel at the Army Survey Regiment, Fortuna, Bendigo, c1979. Black and white photos are on photographic paper and mounted on manilla card. They were scanned at 300 dpi. .1) - Photo, black & white, c1979, Typesetting machine, ‘Editwriter’ Model 7500, SGT Jim McDonald. .2) - Photo, black & white, c1979, Processor Model ACP101 & dual disk module (attached to Editwriter). .3) - Photo, black & white, c1979, Duplicating machine, stencil process electric ‘Gestetner’. .4) - Photo, black & white, c1979, Comparator photogrammetric stecometer, modified ‘Carl Zeiss’, CPL Jack Elverd. .5) - Photo, black & white, c1979, Point transfer device ‘Wild PUG IV. .6) - Photo, black & white, c1979, Zoom transfer scope, stereo ‘Bausch & Lomb’ .7) - Photo, black & white, c1979, Stereoplotter analytical automatic, ‘APC/3-1’. .8) - Photo, black & white, c1979, Prophylaxis unit, ‘Densply/Cavtron’ .9) - Photo, black & white, c1979, Machine punch register (made by Bendigo Ordnance Factory). .10) - Photo, black & white, c1979, Plan printer 122cm (48”) wide. ‘Admel Bruning’ Model - 5003A. .11) - Photo, black & white, c1979, Metal halide printing lamp. ‘Violight 5000 HV’ .12) - Photo, black & white, c1979, Densitometer transmission or reflection, ‘Macbeth’ Model – TR 524 MD. .13) - Photo, black & white, c1979, Machine whirling vertical type ‘Payne VLW’. .14) - Photo, black & white, c1979, Densitometer reflection, ‘Macbeth’ Model – RD917. .15) - Photo, black & white, c1979, Densitometer reflection, 240V ‘Cosar’ .16) - Photo, black & white, c1979, Printer contact ‘Hohlux’ Model RP-II, LCPL Martin Van der Maele. .17) - Photo, black & white, c1979, Frame printing vacuum vertical. .18) - Photo, black & white, c1979, Frame printing vacuum flip top 91cm x 117cm. .19) - Photo, black & white, c1979, Printer reduction stereo plotter diapositive ‘Wild’ Model – U3A modified and U4A modified to U4A plus. .20) - Photo, black & white, c1979, Printing press offset rotary lithographic 3 colour ‘Ultra-MAN-III’ .21) to. 23) - Photo, black & white, c1979, Camera cartographic consolidated super 100 32” x 32”The three personnel appearing in this set are identified. Most items have a full description, NSN, serial number, and the Repairer’s name, address and phone details and contact name. Just the full description is documented.royal australian survey corps, rasvy, army survey regiment, army svy regt, fortuna, asr -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageScale, 1920

... weighing machine, No.387, made in England by George Salter and Co... weighing machine, No.387, made in England by George Salter and Co ...Inventor Biography: Percival Everitt was a Norfolk-born engineer and regarded as the father of the coin-op industry. in 1884 he patented one of his many inventions the coin-operated scales. For many people, it was their first exposure to coin-operated machines. As a young man in 1877, Everitt invented a hay and corn pitcher, a turnip thinner in 1878 and an “Automatic Travelling Anchor” in 1880. But he hit his stride in 1883 with the first postcard-vending machine over a hundred of which he distributed around London. Everitt went on to invent the one penny scale which prompted the formation of the Weighing Machine Company in 1885. Further inventions followed a blow tester in 1887 also the machine for testing a person grip in 1888 and the dispensing machine that opera glasses could be hired from in 1889 also the fortune-telling machine in 1890. He also invented a mechanism to shut coin slots when vending machines were empty, but then as now vandals posed a problem by jamming paper into the slot. Everitt sadly did not make his fortune he died suddenly in February 1893, in his late forties with £71 to his name. Penny Slot Weighing Machine: When the Australian colonies federated to form the Commonwealth of Australia in 1901 their post and telegraph departments were merged to form the national Postmaster General's (PMG) Department. The subject scale is an automatic public weighing machine, No.387, made in England by George Salter and Co. of West Bromwich. The Australasian Automatic Weighing Machine Co. Ltd in 1923 tendered for the right to place Automatic Weighing Machines on railway and tram premises throughout New South Wales subsequently for five-year terms in return for a fixed payment per machine and a portion of the revenue to the NSW Government. The company also made arrangements with the Postmaster General's Department to place machines outside post offices across the country. Weights were measured in stones and pound's up to 20 stone (127 kg) and average weights were shown separately for men, women, boys and girls by various heights in feet and inches. The subject item has had its scale change by the Eastern Scale Company to metric and it is believed to have occurred shortly after April 2000 as the company was first registered and began trading on this date. This weighing machine was originally installed by the Australasian Automatic Weighing Machine Co. Ltd at Warrnambool Post Office and was made by the firm, George Salter and Company, in West Bromwich, England to the Percival Everitt patent. Salter advertised that these machines were suitable for hotels, pleasure gardens, theaters, exhibition halls, clubs, baths and places of public resort. The company had been established in 1760 by the brothers, Richard and William Salter, manufacturing springs and pocket steelyards (spring balances). After several generations, the company was taken over by a nephew, George, and in 1884 the Salter trademark was registered to show a Staffordshire knot pierced by an arrow. The company's expanded range of products included the first coin-operated public weighing machines in the 1880s and in 1895 the first English made typewriter. When the last George Salter died in 1917, the company passed into the hands of other relatives but continued to grow before being bought out by Staveley Industries in 1973. Despite several subsequent mergers, the Salter name continues today on home ware products such as digital scales.A very rare example of a penny in the slot weighing machine imported into Australia and used in public places the item is significant as it gives a snapshot into community life at the time where the public could go and get weighed given there were no personal weighing machines or equipment that people could use at home. So if they needed to post a letter or go on a train journey they could use a machine to check their weight. Whats interesting is that this patent by Percival Everitt was the worlds first slot machine and the start of casino, arcade and other types of slot machines. Personal weighing scale metal large silver painted penny coin operated. Weight measurements are in stones and pounds. Australian Automatic Weighing Machine 60 lb Everitt Patent. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Wedding Dress, Mary Box (nee Closter), circa 1918