Showing 274 items

matching structural

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Plain Sewing Sampler, 1897

A "Plain Sewing Sampler" or "Darning Sampler" was intended to showcase the wide range of sewing techniques and skills a girl or woman had. These skills might include hand sewing techniques such as darning, patching, hemming, mending, structural sewing (making pleats, inserting gussets, joining fabric with seams) making buttonholes and embroidery. Samplers could also be intended for practicing a particular technique. There were several articles printed in Australian newspapers around 1889 referring to the "Plain Sewing Movement". In 1889 a Melbourne branch of the "London Institute for the Advancement of Plain Needlework" was formed by a group of ladies led by Lady Loch and Lady Clarke with the purpose of teaching "plain needlework' to women and girls. "Plain Sewing" included fundamental stitches and techniques that were essential for practical clothing construction and maintenance. Several years later in 1891, another meeting was held at Clivedon (the residence of Lady Clarke) to look into the possibility of improving the teaching of sewing in the state schools. This meeting was attended by several school inspectors and the committee of "the Melbourne Institute for the Advancement of Plain Needlework". This "Plain Sewing Sampler" was donated from the estate of Susan Henry OAM nee Vedmore (1944 - 2021). Susan's family (Harold and Gladys Vedmore) immigrated to Australia from Wales in 1955 and settled in Warrnambool. Susan was well known in the Warrnambool community for her work supporting children and families across the district - particular those with disabilities, or those who were homeless, unemployed or isolated. Susan was the founding trustee of the "Vedmore Foundation" - a Warrnambool philanthropic trust set up to support a range of charitable and not-for-profit causes by providing grant assistance. In 2021, she was awarded a Medal of the Order of Australia for services to the community. It has not been possible to identify the lady (with the initials L. L.) who made this item in 1897 but it was thought to possibly be a female relation in her maternal (or possibly, paternal) grandmother's family. It has many of the same elements and techniques that were taught by the "Plain Sewing Movement" that originated in England at the end of the nineteenth century.This item is a rare example of the handcraft skills learnt by women and girls in the late 1890's to construct and maintain practical clothing for their families.A cream cotton sampler made from three smaller rectangular shapes, displaying a wide variety of plain sewing techniques including hand stitched seams (french, bound and herringboned), inserted patch, buttonhole, button, gathering, a gusset, frills, pintucks, a placket, cross stitch initials and date (L L and 1897) and decorative embroidery.L L/1897flagstaff hill maritime museum and village, warrnambool, shipwreck coast, needlework, textiles, plain sewing sampler, darning sampler, handwork, sewing, great ocean road, susan henry oam, vedmore trust, hand sewing, sewing techniques -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTextile - Plain Sewing Sampler, 1897

A "Plain Sewing Sampler" or "Darning Sampler" was intended to showcase the wide range of sewing techniques and skills a girl or woman had. These skills might include hand sewing techniques such as darning, patching, hemming, mending, structural sewing (making pleats, inserting gussets, joining fabric with seams) making buttonholes and embroidery. Samplers could also be intended for practicing a particular technique. There were several articles printed in Australian newspapers around 1889 referring to the "Plain Sewing Movement". In 1889 a Melbourne branch of the "London Institute for the Advancement of Plain Needlework" was formed by a group of ladies led by Lady Loch and Lady Clarke with the purpose of teaching "plain needlework' to women and girls. "Plain Sewing" included fundamental stitches and techniques that were essential for practical clothing construction and maintenance. Several years later in 1891, another meeting was held at Clivedon (the residence of Lady Clarke) to look into the possibility of improving the teaching of sewing in the state schools. This meeting was attended by several school inspectors and the committee of "the Melbourne Institute for the Advancement of Plain Needlework". This "Plain Sewing Sampler" was donated from the estate of Susan Henry nee Vedmore (1944 - 2021). Susan's family (Harold and Gladys Vedmore) immigrated to Australia from Wales in 1955 and settled in Warrnambool. Susan was well known in the Warrnambool community for her work supporting children and families across the district - particular those with disabilities, or those who were homeless, unemployed or isolated. Susan was the founding trustee of the "Vedmore Foundation" - a Warrnambool philanthropic trust set up to support a range of charitable and not-for-profit causes by providing grant assistance. In 2021, she was awarded a Medal of the Order of Australia for services to the community. It has not been possible to identify the lady (with the initials L. L.) who made this item in 1897 but it was thought to possibly be a female relation in her maternal (or possibly, paternal) grandmother's family. It has many of the same elements and techniques that were taught by the "Plain Sewing Movement" that originated in England at the end of the nineteenth century.This item is a rare example of the handcraft skills needed by women and girls in the late 1890's to construct and maintain practical clothing for their families.A cream flannel sampler made from three smaller rectangular shapes, displaying a wide variety of plain sewing techniques including hand stitched seams (french, bound and herringboned), darned patches, inserted patches, pleats, buttonholes, buttons, a gusset, pintucks, a placket, cross stitch initials and date (L L and 1897) and decorative embroidery.L.L. / ?? Yr 1897flagstaff hill maritime museum and village, great ocean road, warrnambool, sewing, plain sewing, sewing sampler, plain sewing sampler, darning sampler, hand sewing, textiles, susan henry oam, vedmore foundation, sewing techniques -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph, Surrey Hills Post Office

The post office opened at this location in 1912. It was demolished in 2000. Post office history in the area: Until 1883 when the railway came through to Surrey Hills, this was essentially a rural community of scattered farms. Land subdivisions soon occurred along the railway line and limited postal services followed soon after, although a ‘permanent’ home for the post office was two decades away. George Sim Junior is acknowledged as our first postmaster; he opened a post office on 1 October 1884 in his father’s general store at 619-621 Canterbury Road, a few doors down from the Surrey Hills Hotel on the corner of Union Road. Over the next 20 years, the Surrey Hills Post Office moved several times into temporary, shared accommodation – in 1889 into Woodhead’s Corner Store at 364 Canterbury Road; then in 1895 to No 376, Hansen’s Exchange Building, part of Hansen’s Terrace (demolished) and in 1901 to 109 Union Road, on the corner of Windsor Crescent. Following Federation in 1901, the new Commonwealth Government established the Postmaster-General's Department to provide postal services to the nation. Many of the post offices constructed in the following years reflected a growing sense of Australian pride and nationalism. It was 1914 when building commenced on the ‘purpose-built’ post office at 609 Canterbury Road, Surrey Hills. Described as “a polychromatic Federation Freestyle building”, it served as the local post office for nearly 85 years until sold by the Commonwealth Government in c1999, after which the post office moved to the current, less prominent site at 100 Union Road. For nearly 10 years under private ownership, the building was successfully adapted for use as the base for two businesses, Gargoyles and Dragons and later the Surrey Sculpture Studio, and fortuitously the historic integrity of the building was maintained. However although renovated in the 1990's, structurally sound and of historic significance, it was not protected under local or commonwealth heritage legislation and was demolished soon after sale. This is an early image of a demolished building which should have been protected. In 1991, when the City of Camberwell conducted a heritage study, (which still informs the basis of the City of Boroondara’s heritage guidelines for this part of the municipality,) the post office was owned by the Commonwealth Government. As such, it could not be considered for heritage listing by the local authorities. Some years later, the Commonwealth and Australia Post rather belatedly recognized not only that post offices have heritage and social value, but also that the architecture of post offices as community buildings is important. A heritage management scheme was developed for the buildings they own or control under the Environment Protection and Biodiversity Act 1999. Unfortunately, the Surrey Hills Post Office had been sold and demolished before this was finally enacted in 2004. Black and white image, perhaps from a post card, of Surrey Hills post office at 609 Canterbury Road. The building is flanked by a picket fence. There is a woman, a dog and a man in front of the entrance. The man is in uniform - possibly a postal employee.post offices, canterbury road, businesses, surrey hills post office, surrey sculture studio, gargoyles and dragons -

Melton City Libraries

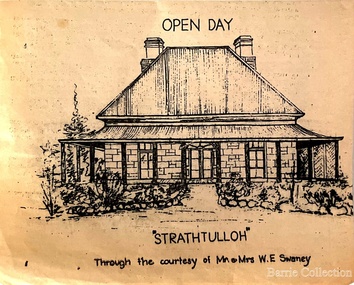

Melton City LibrariesDrawing, Open Day at Strathtulloh, Unknown

"Strathtulloh, 1402-1600 Greigs Road, Melton South, is significant as an early property in Victoria, retaining different eras of pioneering dwellings, ranging from a ruin to a fine Colonial style homestead. The property has close historical association with the early settlement of the Melton district, and was owned by the Henty family in the 1840s. The Strathtulloh property was alienated by the Crown in 1840 to Charles James Garrard, who sold it in 1848 to Charles and Stephen Henty, whose sister Jane and her husband Samuel Bryan lived there in the late 1840s. In 1853 the property then passed to William Tulloh, after whom the homestead was named. A primitive bluestone ruin of near the Toolern Creek, built of vesicular bluestone and mud mortar, is of unknown origin. It has commonly been assumed to pre-date 1840, and to have belonged to the original holder of the Exford lease, Dr Watton or Port Phillip Association member Dr Cotterill. This is unlikely, as the 1841 census records Dr Watton, and everyone else in the district, as living in a ‘wood’ dwelling. It may instead have been the residence of Garrard, and the Bryans, in the 1840s and an early map names a site near here as ‘Bryan’s outstation’. It is assumed that the two-level stone building that became the kitchen is the earliest intact building on the site, and was the first homestead; it is likely to date to the 1840s or 1850s. The main homestead is a substantial villa constructed of random coursed bluestone, with a verandah facing three sides, attic bedrooms with dormer windows, a fan light over the front door, a hipped roof originally clad in slate, and a large cellar. Although demonstrating characteristics of pioneering construction, such as unworked log beams, pit sawn beams, hand-sawn lintels and colonial door locks, documentary evidence shows that it was built c.1869. The homestead has now been structurally repaired and decoratively restored; a sympathetic new semi-detached rear extension was added in the early years of the 21st century. The former kitchen building has also undergone minor repairs and alterations". Strathtulloh Homestead at 1402-1600 Greigs Road, Melton Southlocal architecture -

The Beechworth Burke Museum

The Beechworth Burke MuseumPhotograph, 1960s

This photo was taken in the 1960s from a northeast position looking down towards Lake Sambell, the caravan park, and the surrounding area. This photo was taken during a period of rejuvenation for the lake area including the opening of the caravan park in 1959 and the swimming pool area in 1961 (this pool is just visible in the centre of the photo). The popularity of caravanning in Australia exploded during this post-war period of the late 1950s and 1960’s. This popularity was driven by multiple factors, including: the stopping of fuel rations, the accessibility of car ownership through the manufacturing of affordable cars, technological developments in caravan design, and the increase in prosperity and leisure time for many Australians. Lake Sambell is an artificial lake that was developed on the previous site of the Rocky Mountain Mining Company workings and was officially opened by Minister for Lands, Mr Baily, on October 5, 1928. The disused and unattractive remains of the mine were converted into a recreational area intended for swimming, boating, and fishing. The lake is named after Mr L.H. Sambell, shire engineer and secretary of the Forward Beechworth Committee, who advocated for the enhancement of Beechworth into a tourist destination and was central to the planning and establishment of the lake. Funding for the project was raised by both competition funds and donations. Since the construction in 1928 several engineering issues have arisen. In 1939 the water levels were low, and the lake was considered both an eyesore and ‘mudhole’, Beechworth Shire Council sort funding to raise the height of the lake six feet to improve the quality of water. Throughout the 1940s the Beechworth Swimming Club tried to raise awareness and funds to address the structural engineering issues and improve swimming facilities at the lake. R.E. Carter, similar to L.H. Sambell, was a shire engineer who advocated the importance of positioning Beechworth as a tourist destination. Carter held the position from 1954-63 and organised many improvements to the Lake Sambell area including the caravan park in 1959, the lake swimming pool in 1961, water skiing and boating facilities, and increased the lake surface are in 1964. These improvements were financed mainly by grants from the Tourist Development Authority. This photograph is of historical significance as it documents Lake Sambell and the surrounding area in the 1960s after a phase of enhancements to improve the appearance and usability for both the people of Beechworth and tourists. It is also of social significance in providing an insight into the increase in leisure time and access to travel during a period of post-war prosperity.Black and white rectangle photograph printed on matte photographic paper and unmounted.Reverse: 1 / [logo KODAK/ VELOX/ PAPER] / C798 / 3535lake sambell, lake sambell caravan park, lake sambell swimming pool, caravan park, caravanning 1960s, rocky mountain mining company, l.h. sambell, r.e. carter, beechworth swimming club, forward beechworth committee, minister of lands, tourist development authority, lake swimming, swimming, boating, fishing, water skiing, beechworth 1960s, lake sambell fishing, lake sambell boating -

Parks Victoria - Point Hicks Lightstation

Parks Victoria - Point Hicks LightstationCorbel

In architecture a corbel serves a decorative as well as structural function as a solid piece of stone, wood or metal that is built into a wall and juts out like a bracket to carry a weight. The smoothly shaped corbel was formerly built into the external wall of the lighthouse facing the sea. It consists of two cupped, rounded forms, one bigger than the other, which are attached to a damaged flat base. Made of cast concrete, it is the same fabric as the lighthouse and shows evidence of white paint on its surface. An early architectural drawing of the tower shows the corbel as a projecting, decorative moulding underpinning the balcony floor associated with the auxiliary light. It indicates the original corbel was a much larger architectural feature which started as a solid rectangular block and terminated with a smaller block and then two tapering, rounded forms. Prepared in mid-1888, the architectural drawings for the lighthouse by Victorian Public Works Department architect, Frederick Hynes, were amended in 1888-89 to provide for an auxiliary light, which comprised an arched opening and door in the tower wall below the lantern room and small balcony. In the late nineteenth century all of Victoria’s lightstations installed a red auxiliary light to serve as a danger warning to mariners sailing too close to shoare. Existing lightstations, like Cape Otway, built a pavilion below their lighthouse facing out to sea, but newly constructed towers like Point Hicks and Split Point incorporated them into their designs. The efficacy of auxiliary lights became a controversial issue and all were discontinued on 1 January 1913. The Point Hicks balcony was removed from the face of the tower in 1971 after it was found to be badly rusted. This resulted in the complete removal of the corbel, from which the rounded moulding and part of the base survives. The auxiliary light and door were subsequently removed in 1975 and glass blocks now fill the opening. Cape Schanck Lightstation retains four cast iron brackets from its auxiliary light balcony which are currently stored in the lighthouse on the ground floor. No other architectural fabric associated with the auxiliary light has been identified at Point Hicks Lightstation. The fragment of corbel has first level contributory significance for its historic and architectural values as a relic of the auxiliary light and as an original moulding from the fabric of Victoria’s first concrete lighthouse.A masonary corbel. -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, William Marple & Sons, Early 20th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. William Marples junior joined his father's joinery making business in 1821. In 1860 William's sons joined him and the firm became William Marples and sons. Over the years they acquired John Moseley & Sons a London plane maker and Thomas Ibbotson & Co a Sheffield edge tool maker. Growing to become the most prolific and best known Sheffield tool maker. Their large factory was known as the Hibernia Works. Their trademark was a shamrock that appeared on some of their tools, in 1961 they had about 400 employees. In 1962 the record Tool Company and William Ridgway acquired a fifty percent interest in the company and in 1972 the companies merged with several others to form Ridgway Tools Ltd. After 116 years at its Hibernia Works, the company was moved to Dronfield. A 1982 takeover by A G Bahco of Sweden was short-lived and in 1985 Record Ridgway returned to British ownership first as Record Marples Woodworking Tools Ltd. In 1988 then as Record Holdings PLC in 1993. In 1998 the company accepted a bid from American Tool Corporation, subsequently trading as Record Irwin. The Irwin company itself was acquired by Newell Rubbermaid in 2002 and renamed Irwin Industrial Tool Co. Both the Marples and Record names were re-branded "Irwin" However the name has since been resurrected as Irwin/Marples and applied to wood chisels and table saw blades now made at their new facility in Udine, Italy. As a footnote, William Marples was the uncle of Robert Marples and Joseph Marples, both of whom established competing tool making businesses in Sheffield. The Robert Marples firm disappeared early in the 20th century. After several changes in the company's ownership tools are now made under the Ridgway name but in China. A tool made by a company with a long family history of tool making in Sheffield England, with a member of the Marples family, Joseph Marples establishing a competing tool company which continues today to manufacture quality products for the joinery and shipwrights trades.Caulking tool straight wide blade, Stamped "W Marples & Sons" & James S Steele tool box.flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, caulking tool, caulking iron, james s steele -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Gas Fitting, Before 1878

The artefact is a short cross-section of part of a functional part of a brass fitting that suspended a gas lamp, providing structural support, and internally, supplying the gas for its ignition. It combines elegant design with the elements required for safe and efficient delivery of gas. It was recovered from the LOCH ARD shipwreck site. There are similar artefacts in the Flagstaff Hill collection. The LOCH ARD left Gravesend (London) on 2 March 1878, bound for Melbourne, with a crew of 37, 17 passengers, and a diverse and valuable cargo of manufactured goods, luxury items, and refined metal. Some of the cargo was intended for Melbourne’s first International Exhibition to be held in 1880. At 3 am, 1 June 1878, the ship was wrecked against the high limestone cliffs of Mutton Bird Island on Victoria’s south west coast near Port Campbell. Only two people survived the disaster — Tom Pearce, a male crew member, and Eva Carmichael, a female passenger. The cargo proved too difficult to salvage in the vessel’s exposed condition and was largely written off. The manifest of goods in the LOCH ARD’s holds included “Fittings gas (4 cases)”. The gas lighting of streets, public buildings, and the dwellings of wealthier private citizens, was already well advanced in the cities and major towns of the Australian colonies. In 1841 Sydney was the first to be gas lit with 23 street lamps, 106 hotel lamps, and 200 private residences connected to the Darlinghurst “gasometer” by an underground network of metal pipes. “The dim days of oil and tallow are gone by!” pronounced one newspaper, flushed with civic pride. The 1850s Gold Rush promoted a similar attitude of confidence and affluence in the Colony of Victoria. In 1855 Melbourne was connected to its own system of subterranean gas pipes despite the same high rates of 25 shillings per 1000 cubic feet being charged, (reduced to 15 shillings in 1865 with cheaper sources of coal). By1858 Kyneton had its own gasworks to light the town (fuelled by eucalyptus leaves) and Geelong followed suit in 1860. Had the LOCH ARD reached its intended destination in 1878, it is probable that the 4 cases of brass gas light fittings on board would have found a ready market.The gas fitting is significant for its association with the LOCH ARD shipwreck, which is of State significance and is listed on the Victorian Heritage Register S417. The fitting is an example of a late 19th-century plumbing and light fitting.A pressed brass gas light fitting, recovered from the wreck of the LOCH ARD. The elegant and functional fitting extends from an ornate 8cm diameter ceiling flange, and comprises two short lengths of fluted column pipe with a brass joiner that are severed (cut off) at the end. Within this decorative outer layer of 3cm diameter is a full length brass tube liner, which is in turn protecting a narrow 0.75cm copper gas pipe that also runs full length. The artefact is generally unrestored with reddish/cream sandstone concretion, but is in good condition.warrnambool, shipwreck coast, flagstaff hill, shipwrecked coast, flagstaff hill maritime village, flagstaff hill maritime museum, shipwreck artefact, maritime museum, gas lamps, gas lighting, gas works, brass fittings, gas pipes, loch ard, 1878 shipwreck, victorian affluence, colonial gas lighting -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, VR Commissioner's Special train, steam locomotive D3-639 crossing the Echuca-Moama Road Rail Bridge over the Murray River from Moama, NSW to Echuca, Victoria, 1962

VR Commissioner's Special train, steam locomotive D3-639 crossing the Echuca-Moama Road Rail Bridge over the Murray River from Moama, NSW to Echuca, Victoria. Commissioner Edgar Henry Brownbill on footplate, 1962. Commissioner Edgar Henry Brownbill was in office 1957 to 1967. George Coop advises - "The train on the Eltham/Moama bridge is actually the Commissioner’s Special on one of its inspection tours of the VR rail system. This was a very grand special train with accommodation for the Commissioner and staff in carriages also used once for the Royal Train and other State purposes. You can just see the Commissioner of the day, dressed in his suit and wearing engine drivers gloves, standing in the loco cab doorway. A good ‘hands on’ impression is created amongst local staff if can be seen that the boss is no ‘desk jockjey’. The observation car on the back was originally made for the ’Spirit of Progress’. I climbed up onto the bridge iron plate work to get this view. It was safe enough as the cantilevered pedestrian walkway was still on the east side at the time." "I was resident in Echuca from Jan. ’59 to approx. May ’64. At that time the single Echuca/Moama bridge was a combined road/rail bridge. The rail gauge was 5’3” and still is, I believe, on the new bridge that sits just upstream of the old one. This rail line into NSW has always been 5’3" gauge because it has no connection with any NSW tracks. The old Echuca/Moama bridge, locally called the ‘Iron Bridge’ has, over years, undergone some structural changes. The two lattice iron hoops arcing over the roadway have been raised and lowered and changed design. Presently a pedestrian walkway is cantilevered off the west (or downstream) side of the bridge. It used to be on the eastern side. Guess changes went in when new rail bridge only was built on the eastern side as well." Image dated as c.1963 based on same image in Port of Echuca collection (possibly frame 32 of film) (print 19.5 x 24.5cm) On reverse in pencil: "Brown card" in black pen: "Commissioners special. F. Brown on Footplate. George C.L. Coop c1963". https://victoriancollections.net.au/items/59d575b921ea6e1278d78042 However based on frame no. 10, date set as 1962Digital TIFF file Scan of 35mm Ilford FP3 black and white negative transparencyd3-639, d3-class steam locomotive, echuca-moama road rail bridge, edgar henry brownbill, george coop collection, murray river, vr commissioner's special train -

Robin Boyd Foundation

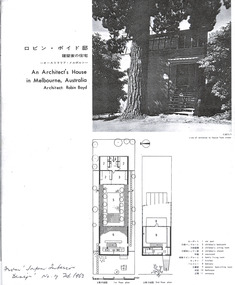

Robin Boyd FoundationArticle, Japan Interior Design, An Architect's House in Melbourne, Australia. Architect: Robin Boyd, Feb-62

This Japanese journal features a photographic article on Boyd's Walsh Street home. It was written by a Japanese architecture student who visited Walsh Street with a group of 6 such students in 1961. A translation of the text follows. ________________________________________________________ "An Architect’s House in Melbourne, Australia Author: Tamon Okubo This house was built by architect Robin Boyd as an experimental work. Although in a residential area of Melbourne, the site is a 40 x 126 ft rectangle in a corner of a former park with high rise buildings on either side. Due to its location, the design focuses on protecting the privacy of the house from the outside and on the composition of the interior space, creating a somehow introverted plan. However, the interior is not completely closed from the outside; it is cleverly designed to provide both views of the rooves of nearby houses as well as the mountains in the distance. Firstly, the couple’s room and the children’s rooms are in separate buildings. These two independent structures are connected by a courtyard. The ceiling of the courtyard is partly open, so one can look out from the second-floor terrace of the couple’s room. The walls on both sides of the courtyard are of opaque glass to ensure privacy from outside. In both buildings brick walls with three-inch steel pipe inserted into the brick cavities form the structure and separate each room. The roof is connected to pairs of 3/4-inch thick cables, spaced four feet apart, attached to the brick walls of both buildings and supported by wooden posts that separate the glass panels in the rooms. The cables are not tightly strung together but are loosely suspended from the front structure, where the entrance is, to the rear one. The upper cable in the courtyard is covered with vine. The materials used are insulation board for the roof, raw timber for the structural materials, native jarrah for the timber sections of the interior walls and white eucalyptus for the joints. Robin Boyd – A Brief Personal History 1919 Born in Melbourne, Australia 1947 As an architect, was the first director of the Small Homes Service, a public housing research institute established to provide homes for needy Australians. 1960 Wins the American Institute Architects Prize (the Japanese architect, Kenzo Tange, was awarded the same prize in 1959). In the same year he was elected an honorary member of the Institute. Mr Robin Boyd is currently writing a book on the history of Australian architecture, The Walls Around Us, as well as a book on Kenzo Tange. He is a frequent visitor to Japan to exchange ideas with Japanese architects and is quite a Japanophile. " This is a photocopy of the article from Japan Interior Design No 17. Pages 4-5 are glued together, and pages 6-7 are glued together, p8 p9, p10 are separate. There is writing on it (not Robin Boyd's hand). Geoffrey Serle, Robin Boyd's biographer, may have given it to Patricia Boyd.walsh st library -

Eltham District Historical Society Inc

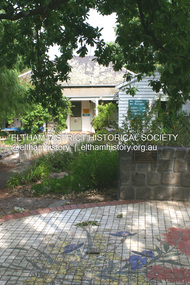

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Eltham Living and Learning Centre, 26 January 2008

In 1857, tanner John Pearson purchased three and a half acres of land in Little Eltham, at the western end of Pitt Street, with a 70-foot frontage to Maria Street (Main Road) and stretching down to the Diamond Creek for £100. He contracted Benjamin Oliver Wallis to build house for him. Wallis, a mason by trade who originated from the Cornish village of Newlyn, migrated to Melbourne in 1853 and was shortly engaged by Richard Warren to build the Eltham Hotel, which opened in 1854. When Warren fell into financial difficulty in 1858, Wallis purchased the hotel. That same year, Pearson constructed a tannery below the house with access to the water in the Diamond Creek. When Pearson became bankrupt in 1867, Wallis similarly acquired the house from Pearson’s creditors in 1868 and lived there until his death in 1896. For some of this time the house was in the name of Wallis’s son Richard but following his death in 1888, ownership reverted to his father. It was purchased by retired teacher Richard Gilsenen in 1899. Gilsenen was made acting head teacher at the Eltham State School in 1906 following the sudden death of head teacher John Brown. In the 1950s the house was bought by retired engineer Dr Alfred Fitzpatrick and his wife Claire who made various modifications to house goats and poultry as well as structural modifications to the house. In the early 1970s, Eltham Shire Councillors Frank Maas and Don Maling proposed an extended communities’ activities program be set up and the Commonwealth Grants Commission was approached for financial assistance. In 1974 a $50,000 Commonwealth Grant was received by the Shire Council to acquire the Fitzpatrick property as part of the planning to establish an extended communities’ activities program. The Fitzpatricks moved next door and Claire taught at the new Living and Learning Centre, which began in 1975, one of the first community education centres in Victoria. Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p59 It’s a centre for sharing knowledge and friendship and it stands on the former hub of Eltham’s original township near Pitt Street. The Eltham Living and Learning Centre, with around 2000 participants a year, began in 1975 as one of the first Community Education Centres in Victoria. Classes ranging from macramé to wine making to environmental living have enriched the lives of thousands of people through the generosity of tutors sharing their skills free of charge. The centre’s heart is the brick cottage, built in 1858 by tanner John Pearson. He bought the three and a half acre (1.4ha) allotment fronting Maria Street (now Main Road) and stretching down to the Diamond Creek. The allotment formed part of a 316 acre (127.8ha) subdivision, owned by Josiah Holloway, called Little Eltham, north of the original Eltham Reserve.1 The allotment then passed through the hands of several speculators before it was sold to Pearson for £100 in 1857. Mr Pearson’s children attended the Eltham Primary School from 1864 to 1867. But creditors took possession of the property when his tannery folded in 1867. It was then sold to publican Benjamin Wallis, who owned the Eltham Hotel at the corner of Pitt Street and Main Road. In 1899 the property was bought by Richard Gilsenan, who became acting head teacher of the Eltham Primary State School in 1906. In the 1950s, retired engineer Dr Alfred Fitzpatrick and his wife Claire bought the property, and made structural changes. Claire, a journalist and community campaigner, modified and built pens for goats and poultry, a stable, a garage and planted fruit trees and a vegetable garden. In the early 1970s a young woman called Carina Hack approached Gwen Wesson at the Diamond Valley Learning Centre (Victoria’s first Community Education Centre) about starting a community centre. Following Wesson’s suggestion, Hack spoke to Shire President Alistair Knox ‘one bleak rainy afternoon, sipping hot drinks and discussing life’.2 Eltham Shire Councillors Frank Maas and Don Maling proposed a community activities program and the council received a $50,000 Commonwealth Government Grant for this venture.3 The Fitzpatricks sold their property to the council and moved next door and Claire taught at the new centre, which Hack named. Eltham obviously wanted such a centre as Hack recalls. ‘During the next two months we had about 50 volunteers working day, night and weekends, scrubbing down, plastering and painting walls, replacing floors, repairing fences, recycling furniture, sewing curtains and cushions, donating furniture, toys, equipment, clean-ing and gardening…’4 The first enrolment day saw a queue stretching up the driveway nearly to the gate and the first sessions attracted 270 people a week. Soon the outbuildings were converted into pottery studios and a large workshop. From 1979 the Eltham Art and Craft Market was held in the centre’s grounds and the Friends of the Centre ran it from 1980. A former program coordinator, Margaret Johnson, remembers enrolment day in the late 1970s and 1980s, when hundreds of people would queue – and some even camped overnight! Overnighters were greeted in the morning with fresh tea and toast. Another tradition was The Enrolment Day Cake with Recipe, given to volunteers. ‘One happy Enrolment Day fell on February 14 and let’s just say that St Valentine found some willing participants, paying $2 for a kiss.’5 Meanwhile the participants’ children could play at the Council Eltham Lower Park house in Hohnes Road, later in Susan Street. But the centre has had difficulties too. In 1990 a fire destroyed the stable and the police suspected arson. However the pavilion was built in its place.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, benjamin oliver wallis, claire fitzpatrick, don maling, dr alfred fitzpatrick, eltham living and learning centre, frank maas, john pearson, richard gilsenen, tannery -

Federation University Historical Collection

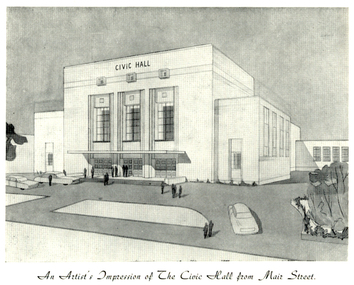

Federation University Historical CollectionProgramme, The Opening of Civic Hall, 1956, 1956

The City of Ballarat unanimously resolved to erect a Civic Hall in Mair Street in 1951. The architects, Gordon Murphy, of Melbourne, and H.L. and L.J. Coburn, of Ballarat, were commissioned in 1952. The Council constructed the foundations and footings for the building under the supervision of the former City engineer, Mr L.H. Finch, in 1953. These footings are of massed concrete. The design for the building took advantage of the cross fall of the land, providing for the Small Hall to be entered from the Doveton Street frontage through a foyer under the Main Stage, the structure is steel with brick panels, with accommodation for 1,592 persons in the Main Hall and 440 persons in the Lower Hall. The front facade faces Mair Street, set back from the building line to provide for the entrance drive-ways and kerbed gardens. Tenders were invited on a firm price basis. A young Ballarat master Builter, Walter Benbow Trahar was the successful tenderer, the contract price being 139,841 pounds. the work was commenced in 1953 and has proceeded in spite of material and labour difficulties until its completion. The following statistics are of interest:- * The foundations contained 200 cubic yards of concrete. * The constructional steel work weighs approximately 270 tons. * The reinforcing steel 47 tons. * Reinforced concrete in the structure, 1,100 cubic yards. * The approximate number of bricks in the building, 580,000. * The flooring is of selected kiln-dried hard wood and totals 40,000 lineal feet. * The dimensions of the Main Auditorium, 100ft by 86 ft, including the side promenades each 82ft by 13ft. *The Main stage, of reinforced concret with parquette finish measures 62 ft by 40ft. *The floor area of the Lower Hall is 74 ft by 38 ft, and has a stage dimensions of 40ft by 20 ft. * Each hall has independent heating and ventillating systems. Where possible the material in the building was furnished from local business houses. The public address installation, which provided for additional microphones, is on the main Stage. There is inter-communication throughout the building connecting the front office, with the bioscope box, the stages in both the large and lower halls, and the Hallkeeper's residence. Local craftsmen have completed the painting, plaster work, and the electrical installation; local produced materials being used in the construction of the buildings with the exception of the timber for the Main Floor, the roofing and the structural steel. The City of Ballarat Councillors in 1956 were Councillors N. T. Callow, F.J. Cutts, K.C. Webb, W.E. Roff, O.W. Curnow, F.T. Woodward, Allan C. Pittard, A.W. Nicholson, J.A. Chisholm, G.L. Scott, F.W. Oliver, A.D. Mason. The Town clerk was H.R. Maddern and the City Engineer was G. Murrowood. A City of Ballarat Council meeting of 25 September 2013 voted to demolish the Ballarat Civic Hall. The Council heard from nearly 50 members of the public during a marathon six-hour meeting. Councilors John Birt, Des Hudson, Amy Johnson, Josh Morris, Peter Innes, John Philips supported the motion to demolish Civic Hall. Councillors Samantha McIntosh, Vicki Coltman and Belinda Coates voted against the motion.Six page souvenir Program of citizens' entertainment on the occasion of the Opening of Ballarat Civic Hall on in August 1956. The front cover features the City of Ballarat Coat of Arms. The programme starts with a message from the Mayor, Cr Neil T. Carrow. It includes the Concert Programme directed by James H. Davey, an asrtist's impression of the Civic Hall from Mair Street, and information relative to the New Civic Hall. The programme features images of the City of Ballarat Coat of Arms, Cr N.T. Callow, , James H, Davey, and an artist's impression of the Ballarat Civic Hall. Mayor Neil Callow's Message: "To-day, our citizens witness the fulfilment of the most extensive Municipal undertaking in the City's period of recent prosperity and development. Their Hall now fills a requirement of which they have been deprived since the Coliseum building was destroyed by fire over 20 years ago. The building has been designed as an all purpose structure and I am hopeful the citizens will use it and enjoy it to its fullest extent. Your Council and its Architects have planned as broadly as possible for the benefit of all to-day and for years to come. We are proud of the work executed by a Ballaarat Master Builder whose work is a monument to the City's craftsmen. I feel I should also remind this assembly that the women of Ballaarat, back in 1951, provided funds which have been applied in the purchase of a Grand Piano and two Upright Pianos which are now installed in this building. The sincere hope of myself and your Councillors is that this Hall and its amenities will prove of immense value to the development of the cultural and artistic tastes of this community and that it will be freely used for these and many other purposes. From now on this magnificent building and its furnishings and equipment will be available to all. I strongly exhort you to use and protect it. My hope is that the citizens will, for many years to come, enjoy the amenities which it has to offer. ballarat civic hall, civic hall, architecture, finch, art deco, city of ballarat, coat of arms, city of ballarat coat of arms, callow, shugg, lemke, oates, gullan, tuuri, john, robertson, sorrell, antonio, gordon murphy, walter benbow trahar, trahar, coburn, h.l. coburn, l.j. coburn, n.t. callow -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Henry Kennedy Pottery, Late 1800s to early 1900s

This bottle was made in Scotland and recovered decades later from a shipwreck along the coast of Victoria. It may have been amongst the ship's cargo, its provisions or amongst a passenger's personal luggage. It is now part of the John Chance collection. Stoneware bottles similar to this one were in common use during the mid-to-late 19th century. They were used to store and transport. The bottles were handmade using either a potter's wheel or in moulds such as a plaster mould, which gave the bottles uniformity in size and shape. The bottle would then be fired and glazed in a hot kiln. Makers often identified their bottles with the impression of a small symbol or adding a colour to the mouth. The manufacturer usually stamped their bottles with their name and logo, and sometimes a message that the bottle remained their property and should be returned to them. The bottles could then be cleaned and refilled. The Barrowfield pottery was founded in 1866 by Henry Kennedy, an Irish native, in the Camlachie district east of Glasgow, close to the Campbellfield and Mount Blue potteries. It is believed that Kennedy started with just one kiln but by 1871 was employing forty men and six boys and such was the success of the enterprise that by 1880, no less than eight kilns were in operation and a year later one hundred and the pottery was employing eighteen people. Stoneware bottle production was a mainstay of the pottery and over “1500 dozen” were being turned out daily along with other wares, including 30-gallon ironstone containers. With so many kilns in operation, six hundred saggars were required every week but, unlike some potteries, these were made on the premises from Garnkirk and Glenboig fire clays. Pottery production reaches a high scale which presented a high risk of fire and Barrowfield was no exception. In April 1884 heat from a kiln set fire to the roof resulting in significant structural damage, the loss of unfinished wares alone amounting to £10,000 a very substantial sum in 1884. The pottery recovered from this reverse but then Henry Kennedy died in July 1890. The terms of his will indicated that he and his sons John and Joseph were partners and this was reflected in a change of title in the 1891-92 Post Office Directory to Henry Kennedy & Sons. Despite the growth of the business there was still space enough, however, to allow china, earthenware and glass retailers Daniel and John McDougall to commence production of their Nautilus wares there in 1894, the success of which allowed them to soon move to permanent quarters at the empty Saracen Pottery, Possil. In around 1900 John Kennedy left to resurrect the liquidated Cleland Pottery and although Barrowfield remained listed as Henry Kennedy & Sons, brother Joseph was in control. In 1911 Henry Kennedy & Sons Ltd was formed, with two of the four directors being the Kennedy brothers. The pottery’s growth to this point was reflected in the eighteen kilns the largest pottery kilns then recorded in Scotland. However, the disruption of the First World War and the combined effects of subsequent economic depression, US prohibition, hygiene regulations and competition from alternative materials posed severe challenges for stoneware potteries in the post-war years as they competed with each other for diminishing markets. Competitors such as Eagle and Caledonian Potteries fell by the wayside and finally, Barrowfield closed in 1929. This stoneware bottle is historically significant for its manufacture and use in the late 19th to the early 20th century. The bottle is also significant as it was recovered by John Chance, a diver, from a wreck on the coast of Victoria in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value. Stoneware was produced at Barrowfield pottery for the domestic and export markets, with South America being a large market. Barrowfield stoneware can be found throughout the world. Its longevity and abundant production makes the subject item a significant addition to the Flagstaff Hill Maritime Museum collection.Bottle, salt glazed stoneware, beige, some discolouration above base. Chip on base and on neck. Inscriptions stamped near base.Makers lozenge stamped, H Kennedy Barrowfield Pottery GLASGOW at base.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, h kennedy pottery, stoneware, ironstone, pottery, barrowfield glasgow -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Woodburn residence, mudbrick adobe (1949), Eltham Heritage Tour, 24 May 1992, 24/05/1992

ELTHAM HERITAGE TOUR The Society excursion on 24th May 1992 was arranged by David Bick, leader of the team carrying out the Shire's heritage study. David selected a number of sites or buildings identified in the study, some of them lesser known components of the Shire's heritage. The tour commenced at the Eltham Shire Office at 10.00 am. Travel was by private car and mini-bus with stops at about twelve locations for commentary by David.It included a short walk in Hurstbridge and lunch at Kinglake. Highlights of the tour included: - 10 am Leave from Shire Offices - 3 Important Trees - A Physical Link to Eltham's First Settlers - Toorak Mansion Gates - A Surviving Farm House - An Intact Circa 1900 Main Street - First Settlers - Gold Miners, and Timber-getters - An Early Hotel - A Pioneering Homestead - Changing Eltham Shire - 20th Century - 4 pm Afternoon Tea and Finish Tour Extract from ELTHAM CULTURAL HERITAGE TOUR (Newsletter No. 85, July 1992, by Bettina Woodburn) "In some respects Eltham is a 'back-water' and it has its own distinctive flavour. On the outskirts the homes date from the 1960's, 70's and 80s with a sprinkling of 'earth homes', mud-brick or pise, rammed dirt. Crossing Main Road into Beddoe Street and Thompson Crescent a very pleasant drive past pines and old fence lines, front lawns unfenced, the occasional ·old farm building, we eventually looked down on a huge circular roof of a 1992 adobe home. Other distinctive places included the Pauline Toner Butterfly Reserve, Gordon Ford's splendid garden at Fulling in Pitt Street, cypress hedges and old houses in Bridge Street and in every direction Eltham's special feature - a totally treed horizon. We were now in the part of the Shire closest to Melbourne - Montmorency - not on the way to anywhere, with no through road going across it, developed in the 1950's and 1960's with conventional gardens, now converted to native plants. The rail looped between Greensborough and Eltham and a shopping street (Were Street) served the area, growing up the hill from the station. It was a typical outer Melbourne suburb with lawns and roses with patches of originality. The shopping precinct still has 1950 characteristics - walls which sloped back, projecting roofs, the original shop fronts are nearly all tiled below the old windows. There's an air of past times about the School, the Dairy, the Butcher's (now a milk bar) and the Castlemaine stone face of the Commonwealth Bank. The final stop for the tour was at the mud-brick Woodburn residence, adobe of 1949 with additions. After War Service, Bill Woodburn had commenced an Architecture course at Melbourne University and after second year in the Christmas vacation, with his wife, Betti, built the two bedroom house - with amazing saving of costs. In the three and a half months they made over 3000 bricks (external walls 18" x 12" x 4", internal walls 12" x 9" x 4"), sifted top soil for mortar and laid them, on concrete foundations and slab floor, made all the structural window frames, door frames and roof members to carry 'super six' asbestos sheets, laboured for the electrician and plumber, did all the glazing and, still without electricity, moved in in March 1949. Rooms have been added, at first with glass walls, later using concrete blocks, to accommodate three daughters and a son. The house not only grew from the earth, but also with the family."Record of the Society's history and activities and highlighting various aspects of the Heritage Study undertaken by David Bick used to create the future heritage overlay for the Shire of Eltham and later Nillumbik Shire.Roll of 35mm colour negative film, 4 stripsKodak Gold 100 5095shire of eltham historical society, activities, heritage tour, woodburn house -

National Wool Museum

National Wool MuseumClothing - 35 Life, Canwen Zhao, 2022

Canwen Zhao was awarded the $10,000 We The Makers Acquisitive Prize for '35 Life' in 2023. Artist Statement: "35life" is a sustainable fashion project that transforms second-hand clothing materials into urban street outdoor-style products. Highlighting prominent Chinese classic red and green colours not only conveys eastern aesthetics but also adds a sense of unity to the clothing collection. The high-saturation and high-brightness full-colour palette keeps the clothing consistently "fresh," allowing any trendy colours to seamlessly integrate into the project's designs, thus extending the lifespan of the garments. Additionally, all clothing items can quickly transform into a stylish bag for convenient daily carrying and home storage. These bags are made from leftover fabric generated during the production process and serve as original packaging for sale. This approach not only reduces excessive packaging but also enhances the chances of resale in the second-hand market. The project draws inspiration from the traditional Chinese cultural concept of "huo feng ding," meaning "exchange the old for the new." it's also influenced by the designer's personal experience with health issues, making the designs suitable for individuals who can't be exposed to sunlight for extended periods, adapting to the changing urban lifestyle. 35life aims to provide visually pleasing and comfortable dressing experiences for urban dwellers who are busy with work and experience high levels of stress. Unlike traditional design patterns, this project adopts a unique design approach. It selects 3-5 pieces of raw materials based on their colours, and then disassembles them through structural lines. While retaining most of their functionality, these materials are rearranged and assembled on a flat surface before being shaped on a dress form. Subsequently, various ways of creating storage bags are derived from the initial clothing prototypes. After refining the designs, the final products are developed, and similar materials are used to create samples. Therefore, under this design methodology, even for the same garment, it is impossible to produce two identical pieces of clothing. Each garment is truly one-of-a-kind, which enhances its rarity and contributes to the longevity of the fashion pieces. The project includes various types of clothing, each with unique storage methods. This yellow look, named "elegant beach sunscreen monarch," draws its fashion inspiration from traditional Han Chinese attire and its storage concept from the Chinese cultural concept of "jiu jiu gui yi." the design employs flat pattern cutting, utilizing materials from the second-hand market such as beach towels, children's waterproof clothing, and women's dresses. Similar colours and patterns are reassembled through cutting and combining. For the sleeves, quick-drying, sun-protective sport fabric forms the base, overlaid with discarded silk fabric dyed with turmeric and plant dyes. This not only ensures functionality but also adds a sense of elegance. The length can be adjusted using drawstrings. Artist Bio: Zhao Canwen is a multidisciplinary fashion designer with a strong passion for integrating art, history, culture, and sustainable design. With over 15 years of experience in painting, she draws inspiration from ancient Chinese philosophy and aesthetics, which gives her a unique sense of beauty. After 8 years of fashion and art training, she possesses a keen insight into current trends and tends to combine art with commercial needs. Zhao's design style is diverse, characterized by a multidimensional approach, a focus on colour application, and storytelling through details.Outfit consisting of six pieces: - Orange plastic eye wear with green paint - Pair of red and green metal clip on earrings - Red beaded phone case with attached beads on string - Pair of red and green painted running shoes - Yellow and green hooded garment with red piping and zips - Brown bag with green beaded handlessustainable, fashion, we the makers, art, culture, design, chinese philosophy, prize -

Puffing Billy Railway

Puffing Billy RailwayV. R. Krupp 1888. IV. Rail, 1888

60lbs rail that was used throughout the Victorian rail network. In 1887 Gibbs, Bright and Co. had a contract with Victorian Railways for railway and canal construction and supply of Krupp Rails. Gibbs, Bright and Co were merchant bankers and shipping agents and merchants who where also Directors of the GWR ( Great Western Railway ) and the Ship The "Great Britain" in England Gibbs, Bright and Company had principally been involved in shipping and trading, mainly in the West Indies, but following the discovery of gold in Victoria they established an office in Melbourne and soon became one of the leading shipping agents and merchants in the Colony. They expanded into passenger shipping and soon established offices in Brisbane, Sydney, Newcastle, Adelaide and Perth as well as launching passenger services between England, Mauritius and New Zealand. Gibbs, Bright also held a number of financial agencies from British mortgage, finance and investment companies as well as representing several British insurance companies in Australia. In addition they conducted a growing import business as well as an export business that included livestock, dairy produce, wool and flour. Also the company played a substantial part in the development of Australia's mineral resources, starting with lead in 1895, and later venturing into tin, gold, copper, cement and super phosphates. In Australia, after WWI, many of the larger companies were managing their own import and export so Gibbs, Bright and Company tended to focus its Agency business on smaller companies while expanding their interest into other markets such as timber, wire netting, zinc, stevedoring, road transport, marine salvage, gold mining as well as mechanical, structural, electrical and marine engineering. The Company's shipping interests continued to grow as well and still formed a major part of its business. In 1948 the parent company in England took the major step from tradition when they changed the business from a partnership into a private limited company. The name was the same, Antony Gibbs and Sons Limited, and in practice the effect of the change was very little. Some of the firm's branches and departments had already become limited companies and the formation of a parent company simplified the structure. The Australian operation was in time changed to Gibbs Bright & Co Pty Ltd in 1963. In 1848 Alfred Krupp becomes the sole proprietor of the company which from 1850 experiences its first major growth surge. In 1849 his equally talented brother Hermann (1814 - 1879) takes over the hardware factory Metallwarenfabrik in Berndorf near Vienna, which Krupp had established together with Alexander Schöller six years earlier. The factory manufactures cutlery in a rolling process developed by the brothers. Krupp's main products are machinery and machine components made of high-quality cast steel, especially equipment for the railroads, most notably the seamless wheel tire, and from 1859 to an increased extent artillery. To secure raw materials and feedstock for his production, Krupp acquires ore deposits, coal mines and iron works. On Alfred Krupp's death in 1887 the company employs 20,200 people. His great business success is based on the quality of the products, systematic measures to secure sales, the use of new cost-effective steel-making techniques, good organization within the company, and the cultivation of a loyal and highly qualified workforce among other things through an extensive company welfare system. From 1878 August Thyssen starts to get involved in processing the products manufactured by Thyssen & Co., including the fabrication of pipes for gas lines. In 1882 he starts rolling sheet at Styrum, for which two years later he sets up a galvanizing shop. The foundation stone for Maschinenfabrik Thyssen & Co. is laid in 1883 with the purchase of a neighboring mechanical engineering company. In 1891 August Thyssen takes the first step toward creating a vertical company at the Gewerkschaft Deutscher Kaiser coal mine in [Duisburg-]Hamborn, which he expands to an integrated iron and steelmaking plant on the River Rhine. Just before the First World War he starts to expand his group internationally (Netherlands, UK, France, Russia, Mediterranean region, Argentina). info from The company thyssenkrupp - History https://www.thyssenkrupp.com/en/company/history/the-founding-families/alfred-krupp.htmlHistoric - Victorian Railways - Track Rail - made by Krupp in 1888Section of VR Krupp 1888 Rail mounted on a piece of varnished wood. Rail made of ironpuffing billy, krupp, rail, victorian railways -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Alan King, Ellis Cottage, Diamond Creek, 23 January 2008

Built by William Ellis in 1865 of local uncut stone about 30cm thick, the cottage is now a museum and home to the Nillumbik Historical Society. Ellis Cottage is historically significant for its association with the Ellis family, who were pioneers of the Diamond Creek district and the benefactors of the notable Nillumbik Cemetery gateway. It illustrates the development of farming in the area. Ellis Cottage is historically and technically significant for its rare use of uncut local stone for building purposes. Covered under Heritage Overlay, Nillumbik Planning Scheme. National Estate Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p79 Ellis Cottage, built by William Ellis, is a memorial to the courage of pioneers in the Diamond Valley area.1 Now a museum and home to the Nillumbik Historical Society, it is a fine example of an early settler’s house in Diamond Creek – and one of the few original buildings standing from the middle of the 19th century. It is a poor man’s cottage – typical of the dwellings of those who had to work hard to wrest a living in this district, because most of the land was not fertile enough for major forms of farming. The pretty stone cottage at 10 Nillumbik Square, built in 1865, is made of local uncut stone about one foot (30 cm) thick. It once stood near the centre of the 147 acres (59.4ha) Ellis bought in 1850. The property extended from Diamond Creek to Reynolds Road and from Perversi Avenue to the Wattle Glen School. It stood in the electoral parish of Nillumbik. The Nillumbik township (later called Diamond Creek) was not created until 1867. In 1912 the property was cut in half by the new railway to Hurstbridge. Ellis paid £147/10/- for the land - about three times what a Victorian farmer would usually earn in a year. Despite the poor quality soil Ellis became a very successful farmer with an orchard, vegetables and a dairy herd. Five years later, in 1855, Ellis bought 70 acres (28.3ha) from neighbour, Hugh Larimour. In 1857 Ellis bought 208 acres (84ha) at Yarra Glen. In 1877 he bought 122 acres (49.3ha) at Diamond Creek and later bought land at Greensborough and Woodstock. Ellis was born in 1815 at Blackawton, a small Devonshire village, and became a tenant farmer. It is not known why Ellis came out to Australia or settled in Diamond Creek. In 1847 he married Margaret Child at the Melbourne Presbyterian Church. Ellis and Child had no children and 18 years after the wedding, while probably living in Kangaroo Ground, Ellis built this small cottage. The simple cottage has a central hall and two rooms on each side. To maximise the small space the ceiling cavity was designed large enough to provide sleeping accommodation accessed via a ladder. Each room was heated by an open fireplace and the one in the kitchen was large enough to roast a sheep. A large cellar under the front room probably stored farm produce. Water came from a well as reticulated water did not arrive at Diamond Creek until 1914. In 1870 Ellis’ 22 year-old nephew Nathaniel joined him from England.2 Until 1890 they developed Ellis Park, praised in The Evelyn Observer, May 30,1890 as a model farm. Ellis had become wealthy, and on his death in 1896 his estate was valued at £9000. In his will he left £100 to construct memorial gates at the Nillumbik Cemetery where he was buried.3 Ellis left the farm to his second wife Louisa. As he had no children, upon her death the farm passed to Nathaniel, but he did not take it up. The farm was sold and leased several times until 1967, when engineer Phillip Lovitt bought the property and carried out major structural works. The Shire of Diamond Valley bought it in the 1980s and in 1989 restored it with the Nillumbik Historical Society. The stone walls of the cottage had been plastered with mud and straw mortar, which were removed as they were riddled with vermin. Doors, windows and a floor were replaced and the original roof of timber shingles had been replaced with slate. The well was too deeply cracked to be restored, so was used for a flower bed. Two mature Italian Cypresses at the entry are also heritage protected as they relate to similar trees planted at Shillinglaw Cottage and other early buildings in Nillumbik Shire.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, ellis cottage, diamond creek, nillumbik historical society, william ellis -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph - Digital Photograph, Marguerite Marshall, Eltham Community and Reception Centre, 2 October 2006

The Eltham Community and Reception Centre was Australia's first public mud-brick building. Commissioned in 1977 by Eltham Shire Council, led by Shire president (and architect) Robert Marshall, architects Whitford and Peck were asked to design a multipurpose facility in mud-brick and timber. The official opening was performed by the Hon. R.J. Hamer; E.D., M.P., Premier of Victorai on Saturday, April 22, 1978. Architects: Whitford & Peck Pty Ltd Quantity Surveyor: D.J. Cant & Associates Structural Civil Engineers: Charlett & Moore Pty Ltd Landscape: Peter Glass, Dennis Edwards Mech Elec: Lobley Treidel & Partners Pty Ltd Acoustics: Riley Barden & Kirkhope Builder: L.U. Simon Pty Ltd Covered under Heritage Overlay, Nillumbik Planning Scheme. Published: Nillumbik Now and Then / Marguerite Marshall 2008; photographs Alan King with Marguerite Marshall.; p177 The Wiggles performed there, so has the ABC’s Play School. New citizens have made their vows, volunteers have been honoured, school children have performed, weddings celebrated and people mourned at funerals. Since 1978 the Eltham Community and Reception Centre at the corner of Pitt Street and Main Road, has provided a beautiful and quintessential Eltham environment for people from all over Melbourne. Recognised as Australia’s first public mud-brick building, the centre was built partly on the site of the parsonage of the former Methodist Church (now the Uniting Church).1 Commissioned by the Eltham Council headed by President Robert Marshall, architects Whitford and Peck were asked to design a multipurpose facility in mud-brick and timber. Following public consultation, it was agreed to build a centre for dances, exhibitions, films, plays or concerts. The results – at a cost of around $620,000 – captured the Eltham rustic style. The building – in soft tones of mud-brick and timber and immense floor-to-ceiling windows – overlooks the Diamond Creek and sporting fields. Eltham’s strong artistic heritage is reflected in the centre. Although the lighting is not ideal for a gallery and labels cannot be placed on walls, the centre hosts the Nillumbik Art Awards and displays around ten to 20% of the Nillumbik Shire Art Collection, usually for around a year at a time.2 On permanent display, close to the entrance, is local artist Clifton Pugh’s White Choughs in the Landscape. Further to the right is the Walter Withers Gallery, named after a local member of the Heidelberg School of artists. As part of the Eltham Gateway opposite the Eltham Hotel, the centre stands on what was once part of the Eltham Town Centre along this section of Main Road, then known as Maria Street. On the same site once stood the house and flour mill owned by Henry Dendy, best known as the founder of Brighton, although he lived longer in Eltham. Beside the drive is a wheel-rim tool with accompanying plaque, illustrating a technology important during the horse-powered age and now almost completely gone, as has the blacksmith’s shop that had housed it nearby. The implement is a platform for fitting iron tyres to the wooden rims of cartwheels. Beneath it is a capsule placed in 1985 to commemorate Victoria’s 150 years, which is to be opened in 2035. Although the plants, forming part of the landscaping by Peter Glass and Denis Edwards, are largely indigenous and other native species, some exotic plants are protected as an important link with the site’s past. Planted at the front around 1920, is a large Peppercorn tree with two joined trunks growing from the base, and close by is a Bhutan Cypress (Cupressus torulosa). Three other Peppercorn trees fringe the drive. The building includes two halls – the larger seating 250 people – and a large foyer overlooking trees and ovals. Both halls have retractable rear walls providing varying spaces as required, and guests can use several external decks. A site for outdoor theatre has been carved out of the natural slope outside the entrance. The Bricklayers Union refused to use the traditional mud-bricks, which weigh more than 22kg. As a result the mud-bricks were redesigned to reduce their weight and were laid back-to-back to produce a wall of normal thickness.3 The centre’s massive timber frame is reminiscent of timber bridge construction, with infill panels of mud-brick.4 In accord with the rustic style are colossal rough-sawn posts, bolts and steel brackets. The combination of mud-brick, exposed feature timber framing and creative design in this centre, characterises Eltham’s innovative buildings and the social movement behind them from the 1940s to the 1970s.This collection of almost 130 photos about places and people within the Shire of Nillumbik, an urban and rural municipality in Melbourne's north, contributes to an understanding of the history of the Shire. Published in 2008 immediately prior to the Black Saturday bushfires of February 7, 2009, it documents sites that were impacted, and in some cases destroyed by the fires. It includes photographs taken especially for the publication, creating a unique time capsule representing the Shire in the early 21st century. It remains the most recent comprehenesive publication devoted to the Shire's history connecting local residents to the past. nillumbik now and then (marshall-king) collection, eltham community and reception centre, mudbrick construction -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, A Mathieson and Son, Early 20th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. The subject item was made by Alexander Mathieson & Sons but the company was established in 1792 when John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker”. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over by Mathieson and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. In the 1851 census, Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his father's name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, but it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. In the Company's later years both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as a tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 and took a rather different approach to engineer, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medalThe firm Alexander Mathieson & Sons were one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide. The subject item is of further significance as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Caulking tool Off-set. Stamped on blade "Mathieson & Son Glasgow" also stamped in handle, James S Steele tool box.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, james s steele, caulking iron, caulking tool, offset caulking tool, alexander mathieson & sons, shipwrights tools, ship building, clinker hull caulking, sailing ships -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined