Showing 274 items

matching yarns

-

National Wool Museum

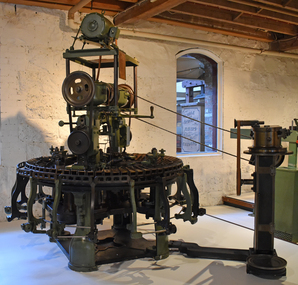

National Wool MuseumMachine - Axminster Carpet Loom, Brintons Ltd (UK), c. 1910

The Axminster Carpet Loom has been set up as a focal point in the centre of the National Wool Museum. The loom was originally built by Brintons in England around 1910 and was initially operating in Geelong in 1960. Brintons designed and built most of their own looms and ancillary equipment. When superseded in 1975 the loom was donated to the Melbourne College of Textiles for weaving training. The College has now donated the loom to the National Wool Museum and Brintons engineering staff has restored it to full working condition. This loom is known as an Axminster gripper loom. The gripper system was invented by Brintons in 1890 and operates using a gripper shaped like a birds beak. This grips the yarn, the yarn is then cut and the gripper swings down to place the tuft into the woven backing. This particular loom also uses a jacquard system for weaving colours. In jacquard weaving, punched cards are used to instruct the loom as to which colour to use. The system was invented by Joseph Jacquard, a silk weaver from Lyon, and was introduced in 1804. It revolutionised pattern weaving as it had the capacity to create intricate patterns through the use of the cards. By 1833 there were approximately 100,000 power-looms used in Great Britain that had been influenced by Jacquards invention. Joseph Jacquard died in 1834. Charles Babbage was later to adapt Jacquards punch-card system to produce a calculator that was the forerunner of todays methods of computer programmingAxminster carpet loom featuring over 1000 Jacquard punch cards and over 100 bobbins of different colours of wool.loom carpet wool, geelong woolbrokers' association, geelong, auction -

Eltham District Historical Society Inc

Eltham District Historical Society IncJournal - Newsletter, Newsletter, No. 265 August 2022, Aug 2022

Contents: • Our Local History by Jim Connor • Our Next Meeting – 2.00pm Saturday 13th August 2022 • Heritage Excursion – A Tour of Montsalvat - Saturday 10th September • Gordon Ford by Barry Pearce • OM:NI Eltham by Jim Connor • A Yarning Circle – A Gathering Place by Jim Connor • Annie Chases a Tinkler; October 3, 1902, Evelyn Observer, and South and East Bourke Record, p. 2 • Health Inspector Report from Eltham Shire Council meeting – 1932 • J.H. Clark - photographer by Peter Pidgeon • Harcourt Hill by Carlota Quinlan • Eltham Cemetery Stories by Liz Pidgeon o Margaret Sweeney, nee MeehanThe Shire of Eltham Historical Society was formed in October 1967. The first newsletter of the Society was issued May 1978 and has been published continuously ever since on a bi-monthly basis. With the cessation of the Shire of Eltham in late 1994, the Society's name was revised to Eltham District Historical Society and this name first appeared with issue No. 103, July 1995. The collection of the Society's newsletters provides a valuable resource on the history of the Society's activities, office bearers and committee members, guest speakers and subjects of historical interest pertinent to the former Shire of Eltham and the Eltham District.A4 newsletter distributed to members (Digital and A4 photocopy)newsletter, eltham district historical society -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

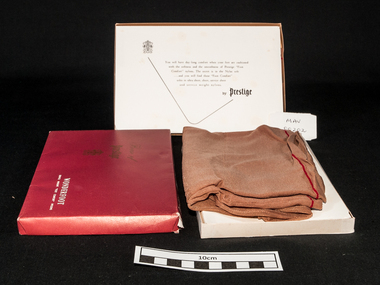

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's nylon stockings 'Prestige Wonderfoot'', mid 20thC

Prestige Limited was formed in 1922 by George Foletta to manufacture fine silken hosiery. The company had acquired the Atlas Knitting and Spinning Mills Pty Ltd which had been established in 1920 and produced "Prestige hosiery" from 1921. Prestige Limited merged with Holeproof Hosiery Company (Australia) Pty Ltd in 1964. Both were taken over by Pacific Dunlop in 1968. The Prestige name was dropped in 1978/79. George Gotardo Foletta (1892-1973), hosiery and knitwear manufacturer, was born on 30 January 1892 at Northcote, Melbourne, eldest son of Victorian-born parents Henry Gotardo Foletta, a stonemason of Swiss extraction, and his wife Gertrude, née Bright. Henry repaired the depression-ravaged fortunes of his family by starting a successful fancy goods commission-agency.....George persuaded the demoralized board to restructure around a quality-first marketing policy. By 1924, when George A. Bond & Co. Ltd ( Sydney) was liquidated, Prestige was back in the black. About this time the company became the first Australian knitter to make fully-fashioned silk stockings, outselling the best imported brands and giving Prestige dominance of the local hosiery market. With the arrival of British-trained Leslie Gough in 1926, Prestige entered its period of greatest expansion. By 1933 it was spinning its own silk yarn, had diversified into lingerie and commenced business in New Zealand; three years later it was spinning imported rayon filament into hosiery yarn.A pair of unworn lady's brown nylon 'service weight' stockings made by 'Prestige' Pty Ltd. in the original boxBox Lid: House of / Prestige / ‘monogram’ / WONDERSOFT / SERVICE WEIGHT “FOOT COMFORT’ NYLONS. Box inside lid : ‘monogram’ / You will have day long comfort when your feet are cushioned / with the softness and the smoothness of ‘Prestige “Foot Comfort” nylons. The secret is in the Nylon soles / …and you will find these “ Foot Comfort” / soles in ultra sheer, sheer, service sheer / and service weight nylons. / by Prestigeclothing, stockings, nylons, prestige hosiery pty ltd, melbourne, bentleigh, cheltenham moorabbin -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

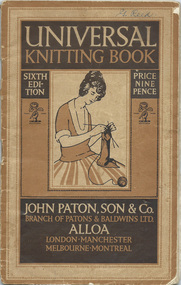

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Booklet - 'Universal Knitting Book' Paton, John Paton, Son & Co. 6th Edition 1923, c1923

Gladys Reed was a member of the Ormond Choral Society c 1950. who performed plays and musicals the City of Moorabbin and she was skilled in hand knitting, crochet and dressmaking. Her garments were used by her family and the Ormond Choral Society . Patons' & Baldwin Ltd began as two separate companies: J & J Baldwin and Partners, founded in the late 1770s by James Baldwin of Halifax, West Yorkshire, England, and John Paton Son & Co., founded in 1814 by John Paton of Alloa, Scotland. Both men had formed their businesses using the spinning mule developed by Samuel Crompton. They mainly produced yarns for commercial knitting machines. The two companies merged in 1920 and diversified into producing wool for home knitters, as well as publishing knitting patterns under the "Patons Rose" and "Baldwins Beehive" trademark. By the mid-1930s, the company had establishments across Scotland and Northern England, Canada, New Zealand, Launceston, Tasmania, Australia. The company branched out into various related lines of business, and the development of new products such as nylon and Terylene. In 1961, the company was merged with J & P Coats Ltd. The Patons trademark is still in use today.The yarn production facility at Alloa was closed in 1999 and the large factory in Launceston, Tasmania, Australia,closed in 1997. In 1952 J. & P. Coats and the Clark Thread Co. merged.and in 1961 a merger with Patons and Baldwins created Coats Patons. In 2015 the business returned to the market as "Coats Group".Patons' knitting books have been used by hand knitters in many countries since they were published early in 20thC Gladys Reed and other residents of the City of Moorabbin used these pattern guides to make clothing for their families and community c1950A printed paper booklet with 64 pages of knitting and crochet patterns, instructions, photographs bound by 2 metal staplesFront Cover ; UNIVERSAL/ KNITTING BOOK / SIXTH / ED / ITION / PRICE / NINE / PENCE / Photo of lady knitting / Trade Mark / JOHN PATON, SON & CO. / BRANCH OF PATONS & BALDWINS LTD. / ALLOA / LONDON, MANCHESTER / MELBOURNE / MONTREAL Written top right ; G Reed Back Cover ; Trade Mark / Registered / THIS TRADE MARK / IS YOUR GUARANTEE / WHEN BUYING / PATONS' ALLOA / KNITTING WOOLS knitting, crochet, craftwork, john paton son & co., baldwin j &j ltd, aloa scotland, launceston tasmania, melbourne, knitting mills, knitting books, coates j&p ltd, early settlers, moorabbin shire, mechanics institute cheltenham, ormond choral society, postworld war 11 settlers, housing estates moorabbin 1950, bentleigh, ormond, moorabbin, cheltenham, drama societies, musical society cheltenham, clark judy, reed gladys, reed george -

Ballarat Tramway Museum

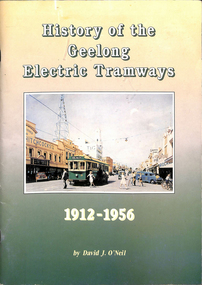

Ballarat Tramway MuseumBook, David J. O'Neil, "History of the Geelong Electric Tramways", Jul. 1994

Eighty page book with heavy card covers A4 size. Colour covers with colour photo of No. 31 at Moorabool and Little Malop Streets, 1950. Contains index, notes on early Geelong Transport, Tramways, opening, decorated trams, Football and trams, People of the tramways, Conductresses, Tramway's staff, Yarns and Truthful (?) stories, The Tramway's Union, Closure, Tram car fleet disposal. Contains many black and white photos, stories and one map and plan of depot. Written by David (Dave) J. O'Neil On rear cover has a "Highton Newsagency" label with price of $24.95. Item scanned 28/4/2019 - btm1293i1.pdf to btm1293i3.pdf - three sections - text searchable when opened using a pdf editor.trams, tramways, geelong, provincial tramways, conductresses -

National Wool Museum

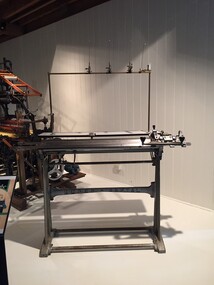

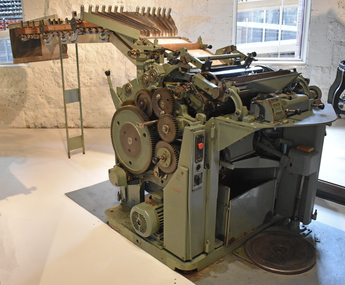

National Wool MuseumMachine - Knitting Machine, Coppo, 1960s

The knitting machine is a recently designed instrument, especially when it is compared with its ancient counterpart, the loom. It enables the creation of many metres of fabric very quickly. A knitting machine is composed of a series of needles which mimic the process of manual knitting. The mechanism engages numerous mechanical elements simultaneously and enables the creation of many metres of fabric very quickly. In addition, a knitting machine can be setup to produce unique bolts of fabric. The density of the fabric may be modified and a knitting machine can produce double-faced effects. A doubled-faced effect creates colour combinations through the introduction of an additional colour to the knitting pattern. This knitting machine is a Coppo brand. It contains over five hundred needles and was produced in the 1960s. It is a representation of the best available in the world at that time. Originating from Italy, it was designed for commercial use. Through both precision and capacity, Italian artisans were seen to be the best in the world of textiles and knitwear. Through emigration, globalisation and the regularly available quantities of wool, Australia came to compete on this stage. The owner of this particular machine migrated from Italy in 1959. When she did, she brought with her a Dubied knitting machine. She later replaced it with this Coppo. When in Australia the owner began work as a piece worker, knitting jumpers and worked for some of the iconic names in the Australian knitting trade including ES Poratt and Alpin Manufacturing. The owner’s role progressed from a piece worker to a wool garment designer and she won many Wool Industry Awards in the 1970s and 1980s. Her high quality of work using and her individual custom designs were spoken about by many of her customers and she had a very large private clientele. She designed and knitted fully fashioned tailored jumpers for people for around 30 years.Knitting table sits on a stand with wide metal legs. Legs contain lettering 'COPPO torino'. Legs are connected via three thin metal poles as well as a metal band and the bed of knitting table at top. The connecting metal band has the lettering 'SUPER - COPTAL' attached. The Knitting table itself contains two beds and a bench at the rear. Attached to the bench is a thin metal structure for the elevation of yarn. It has four crane esk structures above on this metal structure. The bench is covered in a pale grey laminate in the imitation of wood. Attached to the knitting bed is a sliding contraptions containing two handles at the front followed by a complex semi-circle sliding mechanism used to move the knitting mechanism front and back.Left Stand. Lettering: Coppo Torino Right Stand. Lettering: Coppo Torino Centre Stand. Lettering SUPER - COPTALcoppo, knitting machine, design, italy, wool, business, migrants -

National Wool Museum

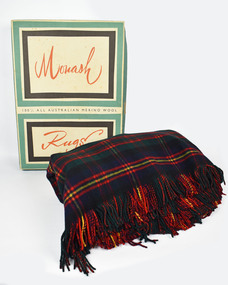

National Wool MuseumTextile - Rug, Returned Soldiers and Sailors Mill, 1963

The Returned Soldiers and Sailors Mills was located near the Barwon river on Pakington Street, Geelong, where its building still stands. The mill was established in October 1922 with capital acquired from War Gratuity Bonds. The mill produced fine grade woollen products with its speciality being ‘Retsol’ travelling rugs. The mill first began to run into financial troubles with the ‘Credit Squeeze’ or the ‘Holt Jolt’ of the early 1960s. This saw import restrictions lifted which triggered the start of a minor recession and a rise in unemployment. Included in these troubles was the RS&S Mill which saw the number of employees gradually decrease and business declining with cheaper imports beginning to grab an expanding part of the market share. The mill was eventually purchased by Godfrey Hirst in 1973 who tried to continue operations without success and in June 1975 textile production at the site ceased. Outside of financial considerations contributing to the closure of Woollen Mills in this period was the declining need for heavier fabrics as in-home heating and insulation improved. This need had been replaced for a demand for ever softer, finer and lighter worsted fabrics for more casual clothing. Modern day textile production requires fewer steps in the processing of materials for this use. This meant large factory complexes such as early woollen mills like the RS&S mills were no longer required. Compared to modern textile production which can spin a fine yarn out of synthetic fibre or imported cotton easily, spinning fine yarn from medium quality wool at a textile factory was cumbersome and no longer financially viable to suit new consumer demands. This rug provides context to this statement. It was gifted to Shirley and Gordon Green as a wedding present in November 1963 by one of Gordon's colleagues in the wool industry. Living in areas such as Neutral Bay, the Hornsby area and later in life retiring to the Central Coast, the blanket was too heavy for use in these weather conditions and hence it stayed in its original box for nearly 60 years. Top and bottom of rug has frilled edges. Pattern is titled the 'Clan Cameron' and is repeated in a 7x7 grid. Front of rug has a red background with 4 vertical and horizontal lines. All is surrounded by a yellow boarder. Label is stitched into the bottom right corner. Reverse of rug also has a repeating 7x7 grid. Blue background with thick green horizontal stripe. Yellow and red boarder to the grid with 4 red vertical and horizontal lines making up the interior. Rug measure 1550 x 2040mm, approximately the same size as a queen size mattress.Wording, Bottom right corner. THE GEELONG R.S&S. WOOLEN MILLS/ PURE/ WOOL/ AUSTRALIA/ The John Monash Rug (cursive)/ The Clan Cameron (cursive)rs&s mills, textile manufacture, rug, clan cameron, sydney greasy wool exchange -

National Wool Museum

National Wool MuseumClothing - Shirt, 1925-1938

Male wool shirt made in Bradford, U.K. The shirt is cut from first fabric woven from 100% traceable Australian wool. Bradford Mills differ to Australian mills in that the entire process of producing worsted material does not take place at the one firm/factory. Rather it is split between many firm/factories specialising in their task in the production of worsted material. For example, the wool goes from merchants to combers to produce tops, the tops to spinners to produce yarn and then the yarn is sold to manufactures who weave it into cloth. After the weaving is done the cloth has to be sent to the dryers and finishers, who scour, dye and finish the cloth. Finally, the finished cloth is purchase by a fresh set of merchants, who will later sell the cloth elsewhere in England or abroad. At each these steps a new firm is handling the wool/cloth making it hard to track lineage of wool through this process and hence hard to guarantee 100% Australian wool. This shirt was purchased and worn by the donor’s husband, George H. Gerber, an Australian Wool Buyer. The shirt was purchased on one of George’s trips to Bradford in the U.K. on company business. Gerber was a second-generation Wool Traders in his family. His father, also named George H. Gerber, worked for Kreglinger & Furneau. He worked for them in Boston, U.S.A. before he died from the Spanish Flu in 1918. The company then promised a job to his oldest son (donor’s husband) once he finished school. Thus, George came to be trained as a Fine Wool Classer by Kreglinger & Furneaux (Aust.) Pty Ltd where he was employed as a Wool Buyer all his working life. He retired in 1969 as the head of their Australian office when the company was taken over Also of note, the shirt was sold with 2 add-on collars. Having additional collars was advantageous as changing only the collar increased the number of days the shirt could be worn without washing. Cream coloured shirt with black and red single thread verticle stripes.“Grandpa” collar (with 1 of its 2 supplied add-on collars included). French cuffs. Sold with 2 add-on collars, hence both ends of the collar have buttonholes to take a stud, and a partially-opened button-hole is at the centre of the neck on the outside of the collar for a second stud.Letering label on shirt: GENT’S OUTFITTER Herbert Winfield 23 CHEAPSIDE, BRADFORDbradford, u.k, kreglinger & furneaux (aust.) pty ltd, 100% australian wool -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings "Holeproof', mid 20thC

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. A unused pair of lady's silk stockings in original box. 'Holeproof' 'Truly Yours' Candlelight, size 10Box Cover: Truly Yours / by / Holeproof Side Holeproof 'Candlelight' Size 10clothing, stockings, nylons, holeproof hosiery pty ltd, lingerie, melbourne, bentleigh, cheltenham moorabbin, brunswick milwaukee usa, wisconsin -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific Brands. An unused pair of lady's nylon stockings in original box. 'Holeproof' 'For you', 'Precious' size 91/2Box Cover : For You / HOLEPROOF/ SUPERFINE EXQUISITE SHEERS Side : Precious 9 1/2 Package : 60 GUAGE / SHEER NYLON / BY / HOLEPROOF / 9 1/2 Card : Especially / For You / fromclothing, stockings, nylons, holeproof pty ltd, milwaukee usa, hosiery, fashion, melbourne, bentleigh, cheltenham moorabbin, brunswick, lingerie -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Clothing - Clothing, lady's stockings 'Holeproof', c1950

Holeproof Hosiery was a Milwaukee, Wisconsin textile firm that was founded in 1901.With extensive advertising the brand name became recognized worldwide. The business produced men's and women's hosiery, underwear, lingerie, and men's pyjamas. Holeproof Hosiery began making nylon hosiery in January 1940, starting production on 8 of its 230 machines. The hose were made of a synthetic yarn composed of derivatives of coal and iron manufactured by Du Pont. In the late 1920s, a successful hosiery manufacturer, Staley & Staley Ltd, started making ladies hosiery under licence from the Holeproof Hosiery Company in Milwaukee, USA. The company went public in 1929 and opened the first Holeproof mill at Brunswick, Victoria in 1930, becoming the first manufacturer to produce and market Australian-made self-supporting socks. During the 1930s, Holeproof revolutionised the Australian market by promoting their products as a sought-after fashion accessory. The Australian company is still in business today, owned by Pacific BrandsAn unused pair of lady's stockings, in original box, 'Holeproof', 'Beauty Fit', ' Nocturn' Size 81/2 - 9 Box Cover : HOLEPROOF / Beauty Fit / LADDERPROOF MESH SHEERS STRETCH Inside Wrapper ; HOLEPROOF / Beauty Fit / LADDERPROOF STRETCH NYLONS 8 1/2 - 9clothing, stockings, nylons, hosiery, melbourne, bentleigh, cheltenham moorabbin, brunswick, holeproof pty ltd, lingerie, fashion -

National Wool Museum

National Wool MuseumMachine - French Comb, Schlumberger & Cie, 1964

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. Machine has been completely rebuilt and set up by Nick Sokolov of Comb Research and Development with the help of Bruce Hill and others. NSC Schlumberger Comb PB25L machine No 3953, year of manufacture 1964. A rectilinear version of the Noble Comb, this machine separated long and short fibres. Donated to the National Wool Museum by Port Phillip Wool Processing Pty Ltd in 1993.French comb machine. 1962 Shlumberger and Co, France Model PB 251 NO. 3953.french comb, wool processing, textile industry, factory, machine, comb, restoration, fibres -

National Wool Museum

National Wool MuseumTaxidermy Sheep, Bilby Bill, c1980

Originating in New Zealand, the Drysdale, represented by Bilby Bill, was developed in the 1930s at Massey University (Canterbury) by crossing a coarse haired Romney and the hardy Cheviot breed. First imported to Australia in 1975, the Drysdale, due to a genetic abnormality, produces coarse, long staple fleece. This same gene also gives them their horns, something that generally does not occur in the parent breeds. Their fleece grows very fast, up to 25cm every six months; as such shearing is carried out twice a year. The coarse and hard wearing wool is mostly used for the manufacture of carpets. The Drysdale is a medium to large stocky sheep, weighing approximately 55kg and produces about 6 to 8kg of fleece per animal annually, which is 35 to 45 microns in diameter. The yarn used on the National Wool Museum’s Axminster Gripper Loom to make the Manor House Rug is spun from the wool of Drysdale sheep.Taxidermied male Drysdale sheep. Medium sized animal with white body coloration. Large horns protruding from the top of the skull. drysdale, sheep, new zealand -

National Wool Museum

National Wool MuseumSpinning Wheel, 18th century or early 19th century

The spinning wheel was owned by Amy Penfold (donor Jan Dawson's mother) who presumably purchased the spinning wheel in the 1930s at an antiques auction. Amy lent the spinning wheel to her friends who spun (as Amy could not spin herself) In Yass, New South Wales during the early years of the Second World War. Amy's friends would spin lightly scoured semi greasy wool worked into yarn and knitted into particularly warm and water-resistant socks for sailors on minesweepers serving during the Second World War. Jan received the wheel in the early 1960s after her mother past away at which time the wheel was no longer operable. When Jan came to live in Melbourne, she sought the assistance of Spinners and Handweavers who assisted her in creating a new bobbin and restored the broken pieces of the wheel back into working order which we find it in today. With the loom are three bobbins. One bobbin is attached to the loom while of the two loose bobbins; one is a reproduction and one is an original. From these two the differences in construction can be observed. Large 12 spokes pinning wheel finished in dark tinted varnish on wood. Ornate upright posts.Additional two bobbins. One original and slightly damaged other is a reproduction and in excellent condition. -

![Manual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions](/media/collectors/510b3f7f023fd725b4cd52cc/items/54065ed29821f50e3cc9ea4b/item-media/601344e16061d010347e22d5/item-fit-380x285.jpg) National Wool Museum

National Wool MuseumManual, [Hattersley] Standard Loom Tuners Handbook: Setting instructions

This handbook contains the setting instructions for a Standard Hattersley Loom developed by George Hattersley and Sons Ltd. The Hattersley loom was developed by George Hattersley and Sons of Keighley, West Yorkshire, England. The company had been started by Richard Hattersley after 1784, with his son, George Hattersley, later entering the business alongside him. The company developed several innovative looms, of which the Hattersley Standard Loom – developed in 1921 – was a great success. The Hattersley Standard Loom was designed and built in 1921. Thousands of models were expected to be sold, which would bring considerable financial success to the company. After the recapitalisation boom of 1919, cotton yarn production peaked in 1926 and further investment was sparse. Rayon, an artificial silk, was invented in the 1930s in nearby Silsden, and the Hattersley Silk Loom was adapted to weave this new fabric. An example of this type of loom can be seen on Vic Collections here ( https://victoriancollections.net.au/items/54065d0f9821f50e3cc9c122 ) and is also on display within the National Wool Museum in Geelong, Victoria. A copy of this manual may be available by contacting the National Wool Museum Collection Team. Book, 64pp. Red and black loose leaf, soft cover, printed black ink. "[Hattersley] Standard Loom Tuners Handbook: Setting instructions " - George Hattersley and Sons LtdTHE BRUCE WOOLLEN MANUFACTURING CO LTDtextile industry - history textile machinery weaving textile industry - education, george hattersley and sons ltd, weaving looms, weaving machinery, textile industry - history, textile machinery, weaving, textile industry - education -

Whitehorse Historical Society Inc.

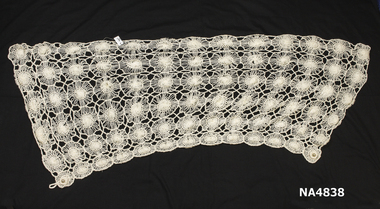

Whitehorse Historical Society Inc.Clothing - Cape, 1997

I have lived in Box Hill now City of Whitehorse since 1970 I have belonged to Box Hill Spinners and Weavers Inc. since 1990.During the 90s' Box Hill Spinners and Weavers participated in the Annual Sheep and Woolcraft Show, at that time held in the Melbourne Showground. As well as submitting individual entries we always entered the Group Competition, known as the '5 articles' the entry had to have 5 separate articles made by a group and displaying different woolcraft techniques . In 1997 our Box Hill entry focused on 'The Planets' featuring five capes. The red one representing Mars the red planet. It was woven. The dark cape represented Jupiter. It was also woven. the Neptune cape was felted in blue and greens. The Earth cape featured knitting and crochet. My contribution was the Venus cape featuring spinning from raw merino fleece and silk. Once completed this wool/silk yarn was fashioned using hairpin lace. I was adept at spinning by this time but knew nothing about the old technique of hairpin lace. Box Hill Spinners and Weavers won First Prize. Margaret Dimelow.Cream coloured cape spun from raw merino fleece and silk, technique is hairpin lacecostume, female -

4th/19th Prince of Wales's Light Horse Regiment Unit History Room

4th/19th Prince of Wales's Light Horse Regiment Unit History RoomPoem, The Horses Stay Behind, 1919

During WW1 Australia sent 39,348 Walers overseas to the AIF. Many Light Horsemen enlisted with their horses with a government promise that they would be able to bring their horses home with them. On the outbreak of peace, costs became important and it was deemed too costly to have horses repatriated to Australia - except for one horse, "Sandy", owned by General W T Bridges who died at Gallipoli in 1915 Quarantine was offered as a reason for not permitting the walers to return to Australia. However, the horses would have had a long sea voyage, giving time for problems to emerge. Many of the fit horses were sold to the Indian ArmyFramed print of poem "The Horses Stay behind". In days to come we'll wander west and cross the range again; We'll hear the bush birds singing in the green trees after rain; We'll canter through the Mitchell grass and breast the bracing wind: But we'll have other horses. Our chargers stay behind. Around the fire at night we'll yarn about old Sinai; We'll fight our battles o'er again; and as the days go by There'll be old mates to greet us. The bush girls will be kind. Still our thoughts will often wander to the horses left. I don't think I could stand the thought of my old fancy hack Just crawling round old Cairo with a Gyppo on his back. Perhaps some English tourist out in Palestine may find My broken-hearted waler with a wooden plough behind. No; I'd better shoot him and tell a little lie: "He floundered in a wombat hole and then lay down to die" May be I'll be court-martialled; but I'm damned if I'm inclined To go back to Australia and leave my horse behind. Trooper Bluegum -

Federation University Historical Collection

Federation University Historical CollectionArticle - Article - Women, Ballarat College of Advanced Education: Anne Stewart; Librarianship Storyteller

Anne completed her secondary education at Presentation College Windsor. She left Melbourne to study Librarianship at Ballarat College of Advanced Education and completed a Graduate Diploma of Librarianship in 1981 and a Graduate Diploma of Education in 1986. During her studies Anne E. Stewart produced weekly shows on 3BBB Community Radio Ballarat, `As the assistant children's librarian at Geelong in 1987 Anne E. Stewart drove the Jolly Jumbuck storytelling van to various local sites, gathered the children and told a story. A keen community player Anne E. Stewart has fulfilled a number of pro bono roles such as the President of the Australian Storytelling Guild (Vic Branch), and Council President of the Daylesford Primary School. Anne E. Stewart is a senior writer for the 'Swag of Yarns' and has worn the prestigious storytellers Cape at Dromkeen, an institution that nurtures and develops children's literature. Returning to her alma mater in 2007 Anne E. Stewart developed a ghost tour through the historic Ballarat School of Mines (SMB) campus. Established in 1870, and incorporating a former gaol, the SMB ghosts came to life as she enthralled numerous groups visiting the campus on Open Day 2007, 2008 and 2009. In 2009 Anne E. Stewart was a principal teller at the Scottish International Storytelling Festival at Edinburgh.women of note, ballarat college of advanced education, anne stewart, presentaion college windsor, librarianship, graduate diploma of librarianship, graduate diploma of education, community radio, geelong library, jolly jumbuck van, storytelling, australian storytelling guild, daylesford primary school, swag of yarns, cape at dromkeen, children's literature, ghost tours, school of mines ballarat -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Liz Pidgeon, Heritage Excursion; The 1901 Eltham Railway Walk, 3 May 2014, 3 May 2014

EDHS Member Doug Orford stands by a yarn bombing installation. ewsletter No. 216, May 2014 May Excursion – The 1901 Eltham Railway Walk The railway from Heidelberg to Eltham was opened in 1902. Over the previous year railway construction cut a curving swathe through Josiah Holloway’s 1851 Little Eltham subdivision. The survey plans for the railway show the owners and occupiers of land within Little Eltham affected by the railway alignment and for some distance each side. The plans show houses and other buildings but development at that time was rather sparse. Copies of these plans from the State Library of Victoria collection have been provided to the Society by Alan Sheehan. For our walk on 3rd May we intend to follow the railway from the Eltham Station to Ryans Road, which was the boundary of the adjoining Montmorency Farm. The return will be by way of nearby streets. Along the way we will discuss the details shown on the railway plans as well as more recent railway documents and photographs. At the conclusion and if time permits we can inspect the historical display at the Eltham Station. The walk is about 3 km in length and will take about 2.5 hours. It will start at 2 pm at the Eltham Railway Station car park (east/Main Road side) (Melway Ref. 21 J5).Born Digitalheritage excursion, activities, eltham district historical society, eltham railway station, eltham library, trestle bridge, yarn bombing, doug orford -

National Wool Museum

National Wool MuseumMachine - Noble Comb, Prince Smith & Sons, Burlington Shed, Keighley, 1915

Combing removes the short or broken fibres and draws out the long fibres into even strands suitable for spinning. The process is necessary to produce long and soft strands needed for worsted yarn. These machines remove the short fibres and blend the remaining long fibres together to form the top. The short fibres that are removed, known as the noil, are used in the woollen system. The long fibres are drawn together, ready for spinning. To retain as many of the valuable long fibres as possible, a skilled operator always needed to be on duty in the factory to precisely set the machine. A Nobel Comb separates short (Noils) fibres while also blending long (Tops) fibres together. The long fibres are used for worsted materials while the short fibres are used for woollen fabrics. Woollen materials are soft, bulky and fuzzy, such as a picnic blanket; whereas worsted materials are fine, smooth and crisp, such as a suit jacket. The Valley Worsted Mills in Geelong, now the Little Creatures Brewery, ran 12 noble combs up until 1981. Gold plaque on display with machine until 2018 read: G.H. Mitchell & Son, Adelaide have celebrated 125 Years of involvement with the Australian Wool Processing Industry by contributing the funds necessary to restore The Carding Machine, Noble Comb & The Gill Box.Noble Comb with plates - 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box). 'Prince Smith & Sons, Burlington Shed, Keishley' (One plate located on each gear box).wool manufacturing, noble comb, textile industry, geelong, little creatures brewery, valley worsted mills, fibres, wool, factory -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationFlags & Pennants, navigational, signal

The 41 alphabetic and numeric visual signalling flags (including substitute and answering pennants) have either square or pointed ends. They are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations. Some of the flags are marked with inscriptions, for example “B”. Attachments to the flags include hemp rope and metal clips. Each flag has its own galvanised canister and lid, each of which is painted grey and marked with a letter, number or word. The flags were used for communicating messages to passing ships. Knowledge of visual signalling was mandatory for all lightkeepers and all lightstations maintained a set of flags. Although used for centuries, visual flag signalling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages. The signal flags and canisters at Gabo Island form a complete set and are not historically linked to the lightstation and their provenance is unknown. It is known however that they originate from a lightstation in Victoria and for some years were on loan from AMSA to the Queenscliff Maritime Museum, where they were held in storage and not displayed. Three of the six lightstations that Parks Victoria manages have sets of signal flags in their collections. Forty navigational signal alphabet flags & numeral pennants. Flags are made of wool. -

Parks Victoria - Gabo Island Lightstation

Parks Victoria - Gabo Island LightstationFlag canisters

The 41 alphabetic and numeric visual signalling flags (including substitute and answering pennants) have either square or pointed ends. They are made of bunting, a coarse fabric of worsted (open yarn wool) in various colour combinations. Some of the flags are marked with inscriptions, for example “B”. Attachments to the flags include hemp rope and metal clips. Each flag has its own galvanised canister and lid, each of which is painted grey and marked with a letter, number or word. The flags were used for communicating messages to passing ships. Knowledge of visual signalling was mandatory for all lightkeepers and all lightstations maintained a set of flags. Although used for centuries, visual flag signalling formally developed in the nineteenth century and was published internationally as a system in 1857. By the early twentieth century it had developed into an effective means of conveying all kinds of short range visual messages. The signal flags and canisters at Gabo Island form a complete set and are not historically linked to the lightstation and their provenance is unknown. It is known however that they originate from a lightstation in Victoria and for some years were on loan from AMSA to the Queenscliff Maritime Museum, where they were held in storage and not displayed. In three of the six lightstations that Parks Victoria manages have sets of signal flags in their collections. Forty-one galvanised canisters with separate lids. The canisters are painted a grey/white colour and have either numbers, letters or words painted on the lid and on the cannister in black paint. There are variations in the style of canister and in the style of the inscriptions. -

National Wool Museum

National Wool MuseumClothing - Tabard, Jun Tomita, 1970s

This tabard is one of a small number that were produced/woven by Japanese master weaver Jun Tomita during the period that he was resident artisan at the Jam Factory in Adelaide. The tabard incorporates Ikat/Kasuri woven central panels. Tomita was born in 1951 in Toyama prefecture, and is based in Kyoto, the textile centre of Japan. The technique he uses kasuri (the Japanese term for ikat) is selectively pre-dying yarns before weaving to create pattern. The other decorative features of this garment are based on Japanese family crest designs (kamon). The pointed shoulders of this garment are reminiscent of the stiffened shoulders of kataginu, the upper part of the kamishimo ensemble that was formal wear for samurai men. Tomita was at the Jam factory from 1976-78 and he has works in numerous public collections, including: - Stanthorpe Art Museum, Art Gallery of South Australia / Australia - Oslo National Gallery / Norway - National Museum of Israel / Israel - Stedelik Museum, Museum of Rotterdam / The Netherlands - Denver Art Museum, St. Louis Art Museum, Long House Foundation - Cooper-Hewitt Museum of Art/USA - Victoria and Albert Museum, UK - Toyama Prefectural Museum of Art, Japan The donor purchased this tabard from an exhibition held at Wool House in Parkville Victoria, which was sponsored by the Australian Wool Board to promote the use of Australian Wool in textiles and fashion at that time, around April/May in 1977. At that time (1976-1977) the donor owned and run a retail/display shop for craft products such as ceramics, artworks and jewellery. The donor subsequently retained this in storage with some other items since the business closed.Double sided reversible tabard featuring woven centrals panels. One side is navy blue with white and blue detail panels, one side is grey with green, brown and cream central panel detail.textile, tabard, japan, art, clothing, weaving, fashion, design, ikat, kasuri -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Caulking Tool, Ward & Payne Ltd, Late 19th century

Caulking is the traditional technique used on wooden vessels built with butted or clinker-built planks to fill the gaps between these planks while still allowing the wood to flex and move. This involved driving the irons, hammered in with the mallet, deep into the seams to open them up. After this, spun yarn, oakum (hemp) or cotton was driven deep into the gaps. The hemp or cotton was soaked in creosote or pine tar to make the joins watertight. Caulking also played a structural role in tightening up the hull or deck by reducing the longitudinal movement of the neighbouring planks. The subject item was made by Ward & Payne of the Limbrick Works at Hillsborough, Sheffield England manufacturers of hand-forged tools. Their trademark registered in 1850 was a Letter "W" & "P" stamped into the steel. The firm was established by David Ward (1767-1822) in 1803 the company became David Ward & Sons, in 1837 after Ward's son Edward joined the firm. In 1845 Henry Payne the founder's son-in-law became a partner but died in 1850 after which the company reverted to the Ward family. The business then concentrated on making carving tools, chisels and gouges. In 1882 David Ward's grandson David Ward Jr. (1835-1889) purchased land and built a factory at Sheffield North known as the "Limerick Wheel". For a time Wards operated from both 106-114 West Street Sheffield and at Limbrick Road, Hillsborough on the river Loxley. By 1911 they had expanded into making spades, forks, sheep shears and many other types of edged tools including drills and wood planes. In 1967 Wilkinson Sword purchased all the company's share capital and continued to sell Ward & Payne tools until 1970 when a fire burned the factory down and housing development was built on the site. The subject item is significant as it gives a snapshot of the technological development of sailing ships and their operation before steam-powered vessels took over around the world. Tools such as the subject item demonstrate the traditional craftsmanship and skill of the shipwright and the aesthetic quality of the timber ships designs of the time. Caulking tool with square end"WARD Sheffield"flagstaff hill, warrnambool, flagstaff hill maritime museum, shipwreck coast, flagstaff hill maritime village, james s steele, caulking iron, caulking tool, shipwright tools, ward & payne sheffield, forged tools -

National Wool Museum

National Wool MuseumAudio - Talking Wool, August 1994

Part of a collection of books, manuals, photographs, letters and clothing relating to the working life of Stuart Ascough. Stuart's career in the wool industry spanned over 43 years from 1960 to 2003 in various roles including Topmaking Plant Manager at Courtaulds Ltd. in Spennymore, U.K., Operations Manager at Port Phillip Mills in Williamstown Victoria, Marketing Executive, Early Stage Wool Processing at the International Wool Secretariat Melbourne, Australia and General Manager of Victoria Wool Processors Pty. Ltd. in Laverton North, Victoria. Throughout his career Stuart travelled extensively, and in the 1990s worked at many topmaking mills in China on quality improvement projects. He also provided technical advice and training at mills in India, Ukraine, Lithuania, Kyrgyzstan, Russia, Latvia, Byelorussia and other parts of Europe and Asia.Cassette tape featuring image of a woman in black and white clothing.front: Talking Wool / Brought to you by / PURE NEW WOOL / AWRAP / ANZ spine: Talking Wool / August / 1994 / 5 back: Contents / SIDE ONE / AWRAP and IWS Intergrate Activities / by Mac Drysdale, Chairman, AWRAP, / Chairman, IWS / Changes to Quality Arrangements / by John O'Connor, General Manager, / International Market Development, AWARP / Pitti Filati Yarn Fair, Florence / by Terry Hennessey, General Manager, / National Marketing, AWRAP / Menswear in the US / by Judith Pinder, Associate Product Manager, / Menswear, IWS - Americas / SIDE TWO / Review of R & D Functions / by Mac Drysdale, Chairman, AWRAP / China Wool Product / by Bill Jones, Co-ordinator AWRAP/AIDAB / (Australian International Development Assistance / Bureau) China Wool Project / AWRAP in India / by Stuart Ascough, International Market Executive / (Early Stage Processing) / Produced by SG Communications Pty Limited. / ACN 063 021 796 © Copyrightstuart ascough, international wool secretariat, victoria wool processors, port phillip mills pty ltd, topmaking, career, wool industry, training, technical advice, mills, cassette tape, audio -

National Wool Museum

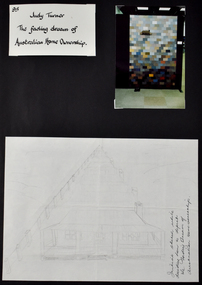

National Wool MuseumDocument - The Fading Dream of Australian Home Ownership, Design and Photograph, Judy Turner, 1989

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Folio page depicting three items attached to a black card background. One item is a title written in black ink on white background, another is a photograph of a quilt, the third shows a hand drawn sketch of a house with a verandah.Front: [handwritten] 95 / Judy Turner / The fading dream of / Australian Home Ownership. / Initial sketch while / deciding how to depict / the Fading Dream of / Australian Home Ownership.quilt, wagga, home, house, housing affordability, design -

National Wool Museum

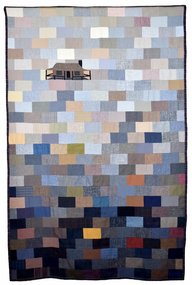

National Wool MuseumTextile - Quilt, Judy Turner, The Fading Dream of Australian Home Ownership, 1989

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Quilt featuring block pieces in tones of grey, blue, tan and brown, graduating in light to dark tones from top to bottom. The top third features a house with a verandah.quilt, wagga, home, house, housing affordability, design -

National Wool Museum

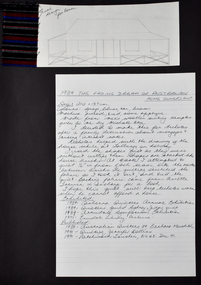

National Wool MuseumDocument - The Fading Dream of Australian Home Ownership, Design and Fabric Sample, Judy Turner, 1989

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Folio page depicting three items attached to a black card background. One item is a red, blue, black and white textile sample, another is a hand drawn sketch of a house, the third shows hand written text on lined paper in black ink.Front: [handwritten] Final / design / for housequilt, wagga, home, house, housing affordability, design -

National Wool Museum

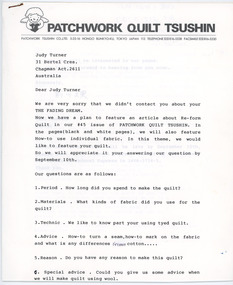

National Wool MuseumDocument - The Fading Dream of Australian Home Ownership, Letters, Judy Turner et al, 1991

‘The Fading Dream of Australian Home Ownership’ was made by Judy Turner in 1989 for her son Nicholas (then 14 years) after a family discussion about mortgages and rising interest rates (17% at the time), out of concern for his generation. “Perhaps this will keep my son warm when he can’t afford a house”, wrote Judy at the time. As a quilting teacher for over thirty years, Judy was well aware of the ‘wagga’ tradition of making do with what you have and reusing resources to make something useful. The quilt was made using approximately 270 different men’s woollen suiting samples. The fabrics in the quilt were a gift from Micheal Haze who was a travelling men’s ware salesman and friend of the artist’s late husband. The suiting samples were used just as they were, without cutting, and are stacked liked house bricks. The pieces have been machine pieced and tied. The quilt has woollen backing, with no batting. Judy’s son Nicholas, always interested in drawing, and keen to see what his mother was making, helped with the drawing and design of the house. The quilt has been exhibited in Canberra, Armidale and Sydney and featured in publications in Australian and Japan. Judy’s work has been exhibited Nationally and Internationally, including in Japan, Korea, Germany, Switzerland and the United States of America. Judy’s work has featured extensively in publications around the world, and has received many awards. Her work is held in public and private collections across Australia and the USA. As well as a successful career as an artist, Judy spent three decades imparting skills to the next generation as a patient and skilled teacher. ARTIST STATEMENT The medium of my artistic practice is quilt making and my focus is the use of colour and speedy, accurate and efficient methods of making successful quilts. In 1995 I developed an original technique of applying woollen yarn to a woollen background, focusing on the subtle blending of colour to express an idea. Author of Awash With Colour (1997) and co-author with Margaret Rolfe of Successful Scrap Quilts (2002).Two typed letters held together with a staple. The first letter has a grey printed letter head which includes a logo of a person with wings holding a heart.[printed] PATCHWORK QUILT TSUSHINquilt, wagga, home, house, housing affordability, design -

Warrnambool and District Historical Society Inc.

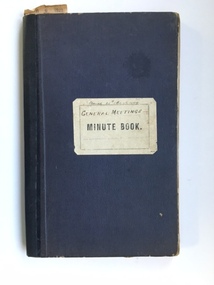

Warrnambool and District Historical Society Inc.Document - Minutes Books, Woollen Mills 1909- 1923 1933-1945, C 1909 C 1933-1945

The minutes book of the Warrnambool Woollen Mill are an important record of the beginnings of one of Warrnambool's major industries for close to one hundred years. They record the struggle in the early days of 1909 and 1910 to raise the capital. Also mentioned is the support which had been given by local people of small means who were prepared to back the enterprise while those with financial means had been rather more reserved. Apart from a Mr Vidler all the initial directors were initially working in an honorary capacity. They lamented the fact that local banks held half a million pounds on fixed interest so there was no shortage of money. The first directors were appointed in March 1909 : Jas. Worland, W H Philpott, G S Mackay, E H Price, S McDonald, J C Beeching, W Rogers ,J Marfell, J Deany, Jas Duirs, Jas. Ponting, H Jessen, S Nettleton, J Blain, J Gooden, Drs. Holmes, Henderson and Powell. Mr J E Bennett was secured as first manager of the mill in 1910 Over the ten year period of this book there is much discussion on possible returns and share prices as well as decisions relating to the operation of and production from the mill. Within four years they were using more yarn than they were producing. Electricity was connected around 1914 and by 1915 shareholders were receiving eight percent return on their investment and were also contributing to the first world War effort by supplying blankets. Assets continued to accumulate and building was also continued with sandstone being quarried from the site and rain water tanks and asphalt floors installed, all contributing to savings. By 1917 The Warrnambool Woollen Mill was considered to be one of the states best investments and it continued to prosper through the years. The second minutes book likewise records similar events and circumstances for the period 1933-1945. This like wise is an interesting period, covering the period of the second World War. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries. These minutes books hold an important information regarding the establishment and early operation of one of Warrnambool's major industries. The mill itself has strong connection to the Warrnambool community and many of the names mentioned as directors and shareholders have held positions within the community as businessmen and city officials. These minutes add another dimension to their contribution to Warrnambool..1Navy blue hard card cover with cloth spine. White label glued to front cover.186 pages.There are handwritten entries in black ink which are interspersed with reports from newspaper. .2 Pale grey cloth cover on early Kalamazoo filing system 612 pages of typed minutes . .1There are dates from 1910 through to 1923. Minutes have been signed by chairman of directors, M Saltau.label on front cover has blue stamp, The Warrnambool Woollen Mill Company. hand written above in black ink "opened 24th March 1909." .2 dated from May 1933 to September 1945. Signatures include M Saltau, James Disckson and Fletcher Jones.warrnambool, warrnambool woollen mill, first minutes book warrnambool woollen mill, minutes book, warrnambool woollen mill 1909, minutes book warrnambool woollen mill 1945