Showing 2190 items

matching back to warrnambool

-

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph, c. 10/02/1911

Photograph of the wreck of the barque SPECULANT, wrecked at Cape Patton, Victoria. The barquentine SPECULANT was a steel, three-masted sailing ship built in 1895 in Inverkeithing, Scotland, registered in Warrnambool, Victoria and wrecked at Cape Paton, Victoria, 10th February 1911. The SPECULANT had been involved in the timber trade between the United Kingdom and Russia, until sold to its Warrnambool owners and timber merchants Messrs. P.J. McGennan & Co. (Peter John McGennan) in 1902 for 3000 pounds and had her sailed to Warrnambool as her new port. Peter John McGennan was born in 1844 and worked as a builder and cooper in Holyhead, Anglesea, Wales. He immigrated to Australia in 1869 as a free settler and arrived in Warrnambool in 1871 and undertook management of a property in Grassmere for Mr. Palmer. Peter met his wife Emily in South Melbourne and they married in 1873. They had ten children including Harry who lived to 1965, and Andrew who lived until 1958. (The other children were their four brothers - John who was killed in the Dardenalles aged 35, Frederick who died aged 8, Peter who died aged 28, Frank who died aged 5 weeks - and four sisters - Beatrice who died age 89, Edith who died aged 49, Blanche who died aged 89 and Eveline who died aged 48.) In 1874 Peter starting a boating establishment on the Hopkins River. In 1875 he opened up a Coopers business in Kepler Street next to what was Bateman, Smith and Co., moving to Liebig Street, next to the Victoria Hotel, in 1877. In 1882 he then moved to Lava Street (which in later years was the site of Chandlers Hardware Store). He was associated with the establishment of the Butter Factory at Allansford. He started making Butter Boxes to his own design and cheese batts for the Butter Factory. In 1896 established a Box Factory in Davis Street Merrivale, employing 24 people at its peak, (it was burnt down in 1923); and in Pertobe Road from 1912 (now the Army Barracks building). Peter was a Borough Councillor for Albert Ward from 1885 to 1891, he commenced the Foreshore Trust (including the camping grounds along Pertobe Road), and he was an inaugural Director of the Woollen Mill in Harris Street, buying an extensive share-holding in 1908 from the share trader Edward Vidler. They lobbied the Town Hall to have a formal ‘Cutting’ for the waters of the Merri River to be redirected from its natural opening south of Dennington, to its existing opening near Viaduct Road, in order to have the scourings from the wool at the Woollen Mill discharged into the sea. He sold Butter Boxes around the state, and had to ship them to Melbourne by rail. Peter’s purchase of the SPECULANT in 1902 enabled him to back-load white pine from Kaipara, New Zealand to Warrnambool to make his butter boxes then, to gain profitability, buy and ship potatoes and other primary produce bound to Melbourne. (McGennan & Co. had also owned the LA BELLA, which had traded in timber as well, until she was tragically wrecked with the loss of seven lives, after missing the entrance channel to Warrnambool harbour in 1905. It appears that the SPECULANT was bought to replace the LA BELLA.) In 1911 the SPECULANT had been attempting to depart Warrnambool for almost the entire month of January to undergo docking and overhaul in Melbourne. A month of east and south-easterly winds had forced her to remain sheltered in Lady Bay, Warrnambool apart from one morning of northerlies, when an attempt was made to round Cape Otway; she had to return to shelter in Portland after failing to make any headway. With only 140 tons of sand ballast aboard, the ship would not have been easy to handle. Captain Jacobsen and his crew of nine, mainly Swedes, decided to make for Melbourne, leaving Portland Harbour on 5th February 1911. By the 9th they had reached Cape Otway, where they encountered a moonless night, constant heavy rain, and a heavy sea with a south-easterly wind blowing. After safely rounding Cape Otway the course was changed to east, then north-east to take the vessel to a point six miles off Cape Patton, following the orders of Captain Jacobsen, who told the crew to be very careful with the steering, as the wind and sea was running to leeward. The patent log (used to measure speed) had been out of order for the last four months as no-one in Warrnambool was able to fix it: it was intended to have it repaired in Melbourne. In the meantime the crew measured the vessel's speed by looking over the side and estimating wind strength. This compounded the difficulties of imprecise positioning, as the strong cross wind and sea were acting on the lightly laden vessel to steadily drive it towards the shore. At 3.30am on Friday 10 February 1911 Captain Jacobsen and the first mate were looking over the side of the vessel when they heard the sound of breakers and suddenly struck the rocks. The crew immediately knew they had no chance of getting the SPECULANT off, and attempted to rescue themselves by launching the lifeboat, which was instantly smashed to pieces. One of the crew then volunteered to take a line ashore, and the rest of the crew were all able to drag themselves to shore, some suffering hand lacerations from the rocks. Once ashore they began to walk along the coast towards Lorne, believing it was the nearest settlement. Realising their mistake as dawn broke they returned westwards to Cape Patton, and found a farm belonging to Mr C. Ramsden, who took them in and gave them a change of clothes and food. After resting for a day and returning to the wreck to salvage some of their personal possessions, at 10am on Saturday they set out for Apollo Bay, a voyage that took six hours, sometimes wading through flooded creeks up to their necks. The Age described the wreck as "listed to starboard. All the cabin is gutted and the ballast gone. There is a big rock right through the bottom of her, and there is not the slightest hope of getting her off". A Board of Marine inquiry found that Captain Jacobson was guilty of careless navigation by not taking steps to accurately verify the position of the vessel with respect to Cape Otway when the light was visible and by not setting a safe and proper course with respect to the wind and sea. It suspended his certificate for 6 months and ordered him to pay costs. The location of the wreck site was marked for a long time by two anchors on the shoreline, until in 1970 the larger of the two anchors was recovered by the Underwater Explorers' Club and mounted on the foreshore at Apollo Bay. The bell from the wreck was also donated to the Apollo Bay Surf Lifesaving Club but is recorded to have been stolen. Rusting remains of the wreck can still be found on the shoreline on the southern side of, and directly below Cape Patton. Parts of the SPECULANT site have been buried by rubble from construction and maintenance works to the Great Ocean Road, as well as by naturally occurring landslides. Peter J McGennan passed away in 1920. The Gates in the western wall of the Anglican Church in Henna Street/Koroit St are dedicated to him for his time of community work, which is matched with other prominent Warrnambool citizens; Fletcher Jones, John Younger, J.D.E (Tag) Walter, and Edward Vidler. After Peter J McGennan's death Harry, Andrew and Edith continued to operate the family business until July 11th 1923 when the company was wound up. (Andrew lived in Ryot Street Warrnambool, near Lava Street.) Harry McGennan (Peter and Emily’s son) owned the Criterion Hotel in Kepler Street Warrnambool (now demolished). His son Sid and wife Dot lived in 28 Howard Street (corner of Nelson Street) and Sid managed the Criterion until it was decided by the family to sell, and for he remained Manager for the new owners until he retired. Harry commenced the Foreshore Trust in Warrnambool around 1950. The McGennan Carpark in Pertobe Road is named after Harry and there are Memorial-Stone Gates in his memory. (The Gates were once the original entrance to the carpark but are now the exit.). Peter’s great-grandson, also called Andrew, is a Security Officer in Warrnambool. The Patent Log (also called a Taffrail log) from the SPECULANT, mentioned above, and a number of photographs, are now part of the Collection at Flagstaff Hill Maritime Village. The SPECULANT is historically significant as the largest ship to have been registered in Warrnambool, and is believed to have been the largest barquentine to visit Melbourne. It is evidence of the final days of large commercial sailing vessels involved in the Victorian and New Zealand timber trade. The SPECULANT is listed on the Victorian Heritage Register VHR S626Black and White photograph of the Barquentine Speculant, on rocks at Cape Patton. On front in white hand writing "Speculant wrecked 10/2/11 Cape Patten"."Speculant wrecked 10/2/11 Cape Patten".flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, la bella, speculant, cumming and ellis, international timber trade, p. j. mcgennan and co. warrnambool, peter mcgennan, capt. james jacobsen, warrnambool maritime history, h. pengilley apollo bay, cape patton victoria, warrnambool historical photograph -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePostcard

Back and White postcard of the sailing ship Scottish Hills. (SH 275 Ships S)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, post card, scottish hills, postcard, sailing ship, postcard -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChair

Chair wooden Spindle Back Bent with a pressed foliage pattern to the top rail. The seat also pressed and all supported on four splayed legs with a supporting circular rail. Height 900 mm, Width 470 mm, made from black wood, circa 1880, one of the spindles is broken, bad wood borer damageflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Tilley Heater, John Tilley, 1930s

The Tilley lamp & heaters derives from John Tilley’s invention of the hydro-pneumatic blowpipe in 1813 in England. W. H. Tilley were manufacturing pressure lamps at their works in Stoke Newington in 1818, and Shoreditch, in the 1830s. The company moved to Brent Street in Hendon in 1915 during World War I, and started to work with paraffin (kerosene) as a fuel for the lamps. During World War I Tilley lamps were used by the British armed forces, and became so popular that Tilley became used as a generic name for a kerosene lamp in many parts of the world, in much the same way as Hoover is used for vacuum cleaners. During the 1920s the company had diversified into domestic lamps, and had expanded rapidly after orders from railway companies. After World War II fears about the poisonous effect of paraffin fumes, and widely available electricity, reduced demand for domestic use. The company moved from Hendon to Ireland in the early 1960s, finally settling in Belfast. It moved back to England in 2000.Item is significant as it was an early form of portable heating used in a domestic situation or any small room that required to be heated. This item fell out of use when electricity and electric heater became more available and affordable. Tilley kerosene pressure heater with large reflector dish. Fuel tank painted cream and wooden handle.Tilleyflagstaff hill, warrnambool, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kerosene heater, tilley lamps, john tilley, pressure heater, domestic use -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Fire Box, Late 19th to early 20th century

Item used in the late Victorian to early Edwardian period as an insert into a house fireplace allowing the burning of coal or wood as fuel to heat a home.An item that is significant as it gives an insight into daily domestic life in the home regards heating.Fire box insert & tray black metal Embossed design to casting at back of box flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Early 20th Century

Enamel cookware became very popular because people wanted a way of coating iron to stop metallic tastes or rust getting into food: something acid-resistant and easy to clean without laborious scouring, something more durable than the tin linings used inside copper. Enamelware dates back to 1760 in GermanyThis object is significant as an example of an item in common use in the 19th and early 20th centuries.Large light blue enamel bowl.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, enamel, kitchenware, washing -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Cookie Cutters, Probably late 19th or early 20th century

The use of cookie cutters dates back to at least Roman times, as some were found in the ruins of Pompeii. They were buried by the eruption of Mount Vesuvius in 79 AD.Cookie cutters have been used to create attractive shaped biscuits and cakes for many years.Set of five metal cookie cutters.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cookies, cutters, biscuits, cakes -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSpokeshave

James S Steele tool boxSpokeshave metal straight handled. Has No 64 stamped on back of handle 225mm long 45mm wideflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSpokeshave

James S Steele tool boxSpokeshave metal with raised handle SCH+T 51 stamped on back of handle. 240mm long 60mm wide Black in colour. Has a pattern handleflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageNail, circa 1810

This copper nail, sometimes known as a ‘Dumpy Bolt’ or spike, was salvaged from the hull of the wreck of the “George III”. It dates back to at least 1810. It was found by an abalone diver on the south east coast of Tasmania. The nail would have been used to hold the layers of the ship’s keel frame and the planking together. The nail has been passed from the abalone diver to an interested business man on a trip to the south of Hobart, on again to the business man’s close friend who then donated it to Flagstaff Hill Maritime Village. The metal of nails such as this one, after being in the sea for a long time, become affected by the natural reaction of the sea water, causing it to degenerate and thin, and the stress from the force of the sea over the years alters its shape. Iron nails had been used on ships previously, but they quickly corroded in the salt; ships needed regular, costly and time-consuming maintenance to replace the iron nails. Towards the end of the 18th century the British Navy trialled the use of copper nails, finding them to be very successful. Merchant ships began to adopt this process in the early 19th century, although it made ship building very expensive and was more often used for ships such as the “George III” that sailed on long voyages. The three masted sailing ship “George III” was a convict transport ship built in Deptford, England, in 1810. On 14th December 1834 she left Woolwich, England, bound for Hobart Town, Van Diemen’s Land (Tasmania), under Captain William Hall Moxey. She was carrying 220 male convicts plus crew, guards and their families, totalling 294 persons (another 2 were during the voyage). Amongst the cargo were military stores including several copper drums of gun powder. On 27th January 1835 the “George III” was near the Equator, about half way into her journey. A fire broke out and the gun powder was in danger of explosion, threatening the whole ship. Two convicts braved the heat and smoke, entered the store and seized the gun powder drums, suffering burns for their efforts but saving a probable disaster. The fire destroyed some of the provisions and food was scarce. Many became ill with scurvy and some died during the journey. Nearing the end of their journey on 10th April 1835 the “George III” was headed through the D'Entrecasteaux Channel, south east Tasmania, between the mainland and Bruny Island. She was sailing in the moonlit night to hasten her arrival in port due to the great number of sick on board. She struck uncharted rocks, known only to the local whalers, between Actaeon Reef and Southport Lagoon and within hours began to break up. The ship’s boats were used to first rescue the women and children. Firearms were used to help quell the panic of the convicts below decks and some were killed by the shots. Many convicts, including the sick, were drowned. In all, 133 lives were lost including 5 of the crew, guards and their families. It was the third worst shipping disaster in Tasmanian waters. A monument in honour of the prisoners who perished in the “George III” has been erected, noting the date of the wreck as “Friday 10th April 1835.” (NOTE: there are a few differences between sources regarding dates of the shipwreck, some saying March and others April 1835. There are also differences in the figures of those on board and the number of lives lost.) The copper nail is significant as an example of sailing ship construction; fasteners used in the early 19th century on ships carrying convicts to Australia. The nail is also significant for its association with the ship “George III”. The “George III” is registered on the Australian National Shipwreck Database, ID 7195 as an Historic Shipwreck. She is the third worst shipwreck in Tasmanian waters. She is also associated with Early Australian History and the transportation of convicts to Australia. The incident of the fire on board and the bravery of the convicts in making the gun powder safe is an example of the social character of the people in early Tasmanian colonisation. Copper nail (also called a Dumpy bolt or spike) from the convict ship George III, wrecked in 1835. Nail is long, bent in an ‘L’ shape about 3/5ths along, tapering from both ends to the bend. Both ends are flat and do not taper to a point, nor have a thread. The shorter end has been polished, showing bright copper. There is pitting along the nail and virdigris is evident on the longer, unpolished end. The nail is displayed with the longer section resting on a wooden board between two ‘U’ shaped uprights, the shorter section upright. flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, george iii, ship construction, ship nail, 1835 shipwreck, 19th century shipwreck, william moxey, d'entrecasteaux channel, convict transportation, copper nail, dumpy bolt, spike, keel nail -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageWood Samples, 1891

The timber display case was presented to Mr Richard Standcombe Harris of Warrnambool (1831-1923). He was a councillor (1875-1891) and predominant businessman. Mr C F Loggin had met Mr Harris while on a trip to Stratford upon Avon in the United Kingdom. Upon his return to Warrnambool, Mr Harris donated the item to the Warrnambool Museum and Art Gallery, (established 1886) where Joseph Archibald was Curator: he catalogued the case in 1894. THE LETTERS IN THE CASE The two letters contained within the display case confirm the authenticity of the oak wood sample. The first letter in the case includes the text; "[Stamped Header on banner] High Street, Stratford on Avon [Hand written] Sept. 22nd / 91. Mr. R. S. Harris, Dear Sir, Enclosed you will find [underlined next 3 words] every authentic proof of the Oak from Shakespeare's House (Birth place). I regret very much Sir, that you made a short-day at S. on A. I should have been delighted to have had the honour, & pleasure, of showing you around our Beautiful Country. You did not give [next 3 words underlined] me or yourself a fair chance. But however I hope that we may again some day have more time to go quietly around. With kind regards, and wishing you, Sir, a pleasant voyage, I remain, Dear Sir, Yours very truly, C.F. Loggin. P.S. A paper will be always acceptable to be as how you Jolly Warrnamboolites are desporting yourselves. “ The second letter includes text; “[Printed Letterhead with stamped impression] The Trustees and Guardians of Shakespeare’s Birthplace Incorporated by Act of 54 and 55, Vict. 1891 Secretary and Librarian - Richard Savage Shakespeare’s Birthplace Stratford-upon-Avon [handwritten] 22 Sept 1891 This piece of oak is a portion of what was cut away at at the restoration of Shakespeare’s Birthplace in 1857-58. C. F. Loggins Chemist 3 High Street Richard Savage Sec. – Shakespeare’s Birthplace Mr C F Loggin was connected with the Shakespeare Trust as the person who had originally donated a scion of Shakespeare's mulberry tree to the "Shakespearean Birthday Committee" in 1842. (The scion that was given to the Shakespearean Birthday Committee, from which the Mulberry sample is derived, still grows today in "New Place" garden.) Mr Richard Savage was the Secretary and Liberian of the then renamed “Trustees and Guardians of Shakespeare’s Birthplace when the display case was given to Mr Harris in 1891 by Mr Loggin. WILLIAM SHAKESPEARE Shakespeare was born in 1564 in Stratford-upon-Avon, where he also grew up. He married at 18 years and he and his wife, Anne Hathaway, had three children: They moved to London where he became successful as an actor, writer, and part-owner of a playing company. He later returned to Stratford and purchased his last home, which he called "New Place" in 1602 where he later died in 1616. For the next 150 years, it was known that there existed a black mulberry tree in the garden. At the time there was a fashion for planting mulberry trees. It was the early 17th century after King James had come to the throne, and he imported tens of thousands of saplings in an attempt to get landowners to start a silk industry in England. Unfortunately for posterity, Shakespeare's mulberry was felled around 1756, by the then owner of “New Place" the Reverend Francis Gastrell, who was apparently tired of continual visits by pilgrims asking to see the tree, so he chopped it down. Gastrell had applied for local permission to extend the garden but the application was rejected and his tax was increased. Gastrell retaliated by demolishing the house in 1759, this greatly outraged the local inhabitants. Gastrell was eventually forced to leave town having provoked the wrath of Stratford residents for committing such an act. Today only the garden remains where “New House" used to stand with a scion from the original mulberry tree still growing there. The wood from the felled mulberry tree at “New House" was purchased by an enterprising local clock-maker Thomas Sharp and he spent the next 40 years or so years making souvenirs from the wood. These became early tourist souvenirs and subsequently developed into a profitable sideline for various other makers, including George Cooper and John Marshall. These objects range from relatively small domestic wooden objects, such as snuff boxes and weight scales to large tea caddies and even tables. C. F. Loggin donated a scion or cutting from Shakespeare's mulberry tree to the Shakespeare Birthplace Trust in 1862, he was a chemist who lived and worked in Stratford. There is a note on the frame of the donation that the mulberry sample is from this scion, research shows that from Richard Savage's diary notes that there must have been a lot of wood taken from that scion over the years which was planted in the garden of “New Place” and is still growing there today. The "Trustees and Guardians of Shakespeare’s Birthplace" (1847 -1964) was formed after the house where Shakespeare is believed to have been born fell into disrepair. Subsequently in 1846 after the death of Thomas Court's widow the last owner. Interest in the house was revived when PT Barnum, the American showman, wanted to buy it and ship the house back to America. In response to this, the Shakespeare Birthday Committee was established (by a private Act of Parliament) with the help of such luminaries as Charles Dickens, the Committee of Trustees raised the necessary £3,000 and purchased the house the following year. Once the Committee had acquired the building, restoration work began. Originally the Birthplace formed part of a terrace with later houses built either side. The first stage in its conservation was their destruction. At the time it was thought necessary to avoid the risk of fire spreading to Shakespeare's birthplace. Reconstruction was carried out by the Shakespeare Trust between 1857 and 1864 that restored the outside of the building to its original 16th-century state. It is from this restoration that the donated piece of oak is derived, originally from a beam that was in the house. Communication from The Shakespeare Birthplace Trust, dated April 11th, 2019, confirms that the pieces displayed in this case have good provenance. The wood samples are significant for their association with the history of William Shakespeare. The display case and its content is significant to Warrnambool local history for its association with the establishment in 1886 of the Warrnambool Museum and Art Gallery. However, it should be noted that the letters of authentication that accompany the wood samples are only applicable to the oak sample. None the less, all the pieces have very good provenance, with Richard Savage's certificate of authenticity for the oak, and the mulberry sample with the letter to Mr Harris from Mr CF Loggin having also been the donor of the scion of mulberry in 1862 to the Shakespeare Birthplace Trust. This scion was then established at Shakespeare's garden at "New Home" that had been demolished by Rev Francis Gastrell in 1759. Two wood samples associated with William Shakespeare, presented in a hanging, timber and glass display case with metal trim around the frame. The case also contains two letters and a label printed on a card that refers to the contents, their origins and the donor. A card label with a printed number and a round adhesive label are attached on the back of the case. The left round section of wood is from a donated scion (or shoot) derived from the original mulberry tree planted by William Shakespeare at his last home "New Place", Stratford-upon-Avon. The outer section is light brown coloured while the centre is dark grain. The right wood sample in the case is a section of oak rafter from the house where Shakespeare was born in 1564. The wood is mid brown with a distinct grain. The included letters, each dated 22/9/1891, refer to only the oak sample. - The letter on the left comprises two handwritten pages from Mr CF Loggin to Mr Richard Standcombe Harris. The paper has the printed letterhead address of High Street, Stratford on Avon. - The letter on the right is a handwritten certificate of authenticity signed by Mr CF Loggin and counter signed by Mr Richard Savage, Secretary and Liberian of the Shakespeare Trust. It is on the printed letterhead of The Trustees and Guardians of Shakespeare’s Birthplace Cardboard label inside the glass case “Shakespeare Section of Mulberry Tree, traditionally said to have been planted by Shakespeare in his garden, “New Place,” Stratford-on-Avon. PORTION OF OAK RAFTER from the house in which Shakespeare was born. (Presented by R S Harris 1891.) Printed label on the back of the case “3 2 “ The handwritten adhesive label “0566” flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shakespeare display case, wood samples, oak from shakespeare's birthplace, mulberry from shakespeare's home "new place", stratford-upon-avon, shakespeare's birthplace, the trustees and guardians of shakespeare's birthplace &c., shakespeare trust, shakespeare birthday committee, r.s. harris, brunswick, victoria, richard s harris, brunswick, victoria, c.f. loggins, chemist, 3 high street stratford-on-avon, richard savage, warrnambool museum and art gallery, thomas court, pt barnum, charles dickins, anne hathaway, black mulberry tree, reverend francis gastrell -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChair

Chair wooden ornate carving on top. Quilted embroidery seating with flower pattern. Red Cushion backrest. Round legs on front with roller casters. Back legs square. Seat is sprung. 1010mm x 470mmflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Chair

Chair wooden ornate carving on top. Quilted embroidery seating with flower pattern. Red Cushion backrest. Round legs on front with roller casters. Back legs square. Seat is sprung. 1010mm x 470mmflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChair

Chair wooden slatted blackwwod, plain legs with 3 upright supports at back.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTemplate

Ovalo Sash Template wooden, with brass plate/attachment one end maker J Budd London Has J Heath and 5/8 stamped on back flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFunctional object - Rowlock, early 20th century

This row lock was fitted onto the Warrnambool Lifeboat, which is also on-site at Flagstaff Hill Maritime Village. The construction of the lifeboat 'Warrnambool' began 15th September 1909 and was completed almost 12 months later 1st September 1910. It was built at the Government Dockyard in Williamstown, Victoria, along the lines designed by Great Britain's Royal Lifeboat Institution, and included whale back decks fore and aft, mast and centre board, and rudder and tiller hung from the stern post. It could be propelled by both sail and oar. At that time Captain Ferguson was Chief Harbour Master and Mr Beagley was a foreman boat builder. Mr Beagley built the lifeboat with his fellow workmen. It had all the latest improvements in shape, disposition of weight with watertight compartments, and it had space for a large number of people in addition to the crew. It appears that 'H Meiers' whose signature was on the plaque that was found concealed in the hull, was involved with the building of the lifeboat. His signature and the dates of the start and finish of the boat's construction are penciled on the raw timber 'plaque' found in the hull in the early 1990s when the lifeboat was being restored. It is interesting that the 'Melbourne Directory' of 1911, published by Sands and MacDougal, lists McAuley and Meiers, boat builders, Nelson Place foreshore, between Pasco and Parker Streets, Williamstown, It is quite possibly the business of the person whose name is inscribed on the lifeboat plaque. Flagstaff Hill's documentation also mentions that the keel was laid at 'Harry Myers, boat builders, Williamstown, Melbourne the name 'Myers' can also be spelled 'Meiers', which could be the same person as the Meiers in "McAuley and Meiers" (as mentioned in genealogy lines of Myers). The new lifeboat, to be named 'Warrnambool' was brought to town by train and launched at the breakwater on 1st March 1911 using the Titan crane (the old lifeboat built-in 1858, was then returned to Melbourne in 1911). This new lifeboat was stationed at Warrnambool in a shed located at the base of the Breakwater, adjacent to the slipway. The lifeboat ‘Warrnambool’ was similar in size to the old lifeboat but far superior in design, with new sea-going qualities such as greater maneuverability. The ‘self-righting, self-draining’ design was made the vessel difficult to capsize and even if the boat overturned it would right itself to an even keel and the water would drain away. The hull was built of New Zealand Kauri, using double diagonal planking, laid in two layers at right angles, with a layer of canvas and red lead paint between the timbers to help seal the planking. It has plenty of free board. The backbone timbers were made of Jarrah. The Warrnambool lifeboat was one of several rescue boats used at Port Fairy and Warrnambool in the early 1900s. In late 1914 the Warrnambool lifeboat and crew were used to help find what was left of the tragic wreckage of the Antares and were able to discover the body of one of the crewmen. Between 1951 and 1954 the lifeboat was manned under the guidance of Captain Carrington. He held lifeboat practice each month on a Sunday morning, to comply with the Ports and Harbour’s request that lifeboats be ready for action in case of an emergency. In the early 1960’s it ended its service as a lifeboat and was used in Port Fairy as a barge to help dredge the Moyne River. Flagstaff Hill obtained the Warrnambool lifeboat in 1975. In 1984 it was on display at Flagstaff Hill Maritime Village, Warrnambool. On 23rd May 1990, she was lifted from the water and placed in a cradle for restoration. The name 'WARRNAMBOOL could be seen faintly on the lifeboat before it was restored. It was during the restoration that Flagstaff Hill's boat builder discovered the 'plaque' inside the hull. A copy of the blueprint plans has the name “V.E.E. Gotch” printed on it. His advertisement in Footscray’s ‘Independent’ newspaper of Saturday 11th May 1901 states he is “Principal and Skilled member (Naval Architect) to the Court of Marine Inquiry of Victoria and holds classes for naval architectural drawing and arithmetic.” The subject row lock is significant due to its association the Warrnambool Lifeboat which was an integral part of an important service to the local community as a lifesaving vessel for a half-century. One of the lifeboats many achievements was when it was used to help retrieve the body of a shipwrecked crew member of the ship Antares. Rowlock from the Warrnambool Lifeboat.Noneflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, lifeboat warrnambool, life boat, life saving vessel, 1910 vessel, port fairy, boat builder plaque, rescue boat, beagley, government dockyard, williamstown, v.e.e. gotch, royal lifeboat institution, captain ferguson, non-capsizeable lifeboat, self-righting lifeboat, antares shipwreck, double diagonal planking, captain carrington, rowlock, lifeboat rowlock -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSaw

Mitre saw being a member of the Back family of saws. Wooden handle attached by 2 rivets. 255 mm l of blade Overall length 370mm. Blade width 87mm flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Chair, ca. 1900

The timber on this captain's chair has been worn smooth across the backrest. It is of solid construction. A captain's chair is typically a wooden armchair with a back that curves around to form the armrests. The style of chair was used in the 19th century and was a statement of status aboard a ship. This captain's chair is an example of the type of furniture used onboard a ship in the 19th and early 20th centuries.Captain's chair; an oak armchair with a low curved back that forms the armrests. It has six turned spindles, a fretted back, a solid saddle seat and is supported on four turned legs. The timber backrest feels smooth and well-worn. Circa 1900.flagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, wooden chair, captain's chair, armchair, 19th century furniture, nautical furniture, seating -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageChair

Chair wooden with missing round seat & plain legs. Has 6 turned back supports & decorative carving on back piece. Bracing ring under seat & on sides. Chair is reddish coloured woodflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, chair, wooden chair -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageSaw

Back saw wooden handled, three screws holding blade. Blade 356 mmL 95 mmWflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, back saw -

Flagstaff Hill Maritime Museum and Village

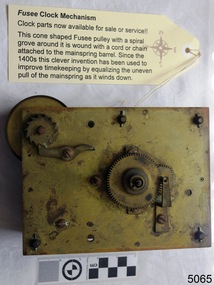

Flagstaff Hill Maritime Museum and VillageMachine - Fusee Clock Mechanism, early 20th Century

The origin of the fusee is not known. Many sources credit clockmaker Jacob Zech of Prague with inventing it around 1525. The earliest dated fusee clock was made by Zech in 1525, but the fusee appeared earlier, with the first spring-driven clocks in the 15th century. The idea probably did not originate with clockmakers, since the earliest known example is in a crossbow windlass shown in a 1405 military manuscript. Drawings from the 15th century by Filippo Brunelleschi and Leonardo da Vinci also show fusee mechanisms. The earliest existing clock with a fusee, also the earliest spring-powered clock, is the Burgunderuhr (Burgundy clock), a chamber clock whose iconography suggests that it was made for Phillipe the Good, Duke of Burgundy about 1430. Springs were first employed to power clocks in the 15th century, to make them smaller and portable.[1][5] These early spring-driven clocks were much less accurate than weight-driven clocks. Unlike a weight on a cord, which exerts a constant force to turn the clock's wheels, the force a spring exerts diminishes as the spring unwinds. The primitive verge and foliot timekeeping mechanism, used in all early clocks, was sensitive to changes in drive force. So early spring-driven clocks slowed down over their running period as the mainspring unwound. This problem is called lack of isochronism. Two solutions to this problem appeared with the first spring-driven clocks; the stack freed and the fusee. The stack freed, a crude cam compensator, added a lot of friction and was abandoned after less than a century. The fusee was a much more lasting idea. As the movement ran, the tapering shape of the fusee pulley continuously changed the mechanical advantage of the pull from the mainspring, compensating for the diminishing spring force. Clockmakers empirically discovered the correct shape for the fusee, which is not a simple cone but a hyperboloid. The first fusees were long and slender, but later ones have a squatter compact shape. Fusees became the standard method of getting constant force from a mainspring, used in most spring-wound clocks, and watches when they appeared in the 17th century. Around 1726 John Harrison added the maintaining power spring to the fusee to keep marine chronometers running during winding, and this was generally adopted. The fusee was a good mainspring compensator, but it was also expensive, difficult to adjust, and had other disadvantages: It was bulky and tall and made pocket watches unfashionably thick. If the mainspring broke and had to be replaced, a frequent occurrence with early mainsprings, the fusee had to be readjusted to the new spring. If the fusee chain broke, the force of the mainspring sent the end whipping about the inside of the clock, causing damage. The invention of the pendulum and the balance spring in the mid-17th century made clocks and watches much more isochronous, by making the timekeeping element a harmonic oscillator, with a natural "beat" resistant to change. The pendulum clock with an anchor escapement, invented in 1670, was sufficiently independent of drive force so that only a few had fusees. In pocketwatches, the verge escapement, which required a fusee, was gradually replaced by escapements which were less sensitive to changes in mainspring force: the cylinder and later the lever escapement. In 1760, Jean-Antoine Lépine dispensed with the fusee, inventing a going barrel to power the watch gear train directly. This contained a very long mainspring, of which only a few turns were used to power the watch. Accordingly, only a part of the mainspring's 'torque curve' was used, where the torque was approximately constant. In the 1780s, pursuing thinner watches, French watchmakers adopted the going barrel with the cylinder escapement. By 1850, the Swiss and American watchmaking industries employed the going barrel exclusively, aided by new methods of adjusting the balance spring so that it was isochronous. England continued to make the bulkier full plate fusee watches until about 1900. They were inexpensive models sold to the lower classes and were derisively called "turnips". After this, the only remaining use for the fusee was in marine chronometers, where the highest precision was needed, and bulk was less of a disadvantage until they became obsolete in the 1970s. Item is an example of clock mechanisms used until 1910 for many different styles of clocks and went out of fashion in the 1970s due to improvements in clock and watch making.Brass fusse clock movement, It has very heavy brass plates and wheels, high-count machined pinions, and a fusee. The mounting of the pendulum is missing and It has a recoil escapement. A fusee is a conical pulley driven through a chain by the spring barrel. As the spring runs down, the chain acts at a larger and larger radius on the conical pulley, equalising the driving torque. This keeps the rate of the clock more even over the whole run. It has motion work to drive an hour hand as well as a minute hand and the centre arbor is extended behind the back plate to drive some other mechanism.Inscription scratched on back"AM 40" flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, clock mechanism, fusee mechanism, horology -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Spoons, William Page & Co, Prior to 1878

These desert spoons are from the wreck of the Loch Ard, that sailed from Gravesend, London. The manifest listed an array of manufactured goods being exported to the Colony of Victoria. Included in the cargo manifest was a large number of hardware and cutlery items. These spoons are representative of similar items of silver electro-plated cutlery salvaged from the Loch Ard wreck site, comprising nickel silver electroplated spoons and forks of various sizes but all sharing the same general shape and design. Some of the pieces display their makers’ mark of William Page & Co Birmingham UK. Within the Flagstaff Hills cutlery collection donated from the Loch Ard, maker’s marks are often obscured by sedimentary accretion or verdigris after a century of submersion in the ocean. However sufficient detail has survived to indicate that the collection of samples of electroplated cutlery probably originated from the same cargo consignment from the Loch Ard and was made by William Page & Co. William Page was born in 1811 and died in 1885. He was active as a manufacturer of cutlery from 1829 with premises at 74 Belmont Rd, Dales End as a "close plater" (someone who works sheet metal), and he began electroplating in 1855. William Page & Co was also active from 1880 at Cranemore St, Cattle’s Grove also 55 Albion St, Birmingham, in 1936 the firm became Ltd. The firm used the trademarks "Asrista, Bolivian Silver, Silverite, Roman Silver, Roumanian Silver and Trevor Plate. In 1938 William Page was a supplier to the British Government, marking its products with the broad arrow symbol and was also present at Sheffield. History of the Loch Ard: The Loch Ard got its name from ”Loch Ard” a loch that lies to the west of Aberfoyle, and the east of Loch Lomond. It means "high lake" in Scottish Gaelic. The vessel belonged to the famous Loch Line which sailed many vessels from England to Australia. The Loch Ard was built in Glasgow by Barclay, Curdle and Co. in 1873, the vessel was a three-masted square-rigged iron sailing ship that measured 79.87 meters in length, 11.58 m in width, and 7 m in depth with a gross tonnage of 1693 tons with a mainmast that measured a massive 45.7 m in height. Loch Ard made three trips to Australia and one trip to Calcutta before its fateful voyage. Loch Ard left England on March 2, 1878, under the command of 29-year-old Captain Gibbs, who was newly married. The ship was bound for Melbourne with a crew of 37, plus 17 passengers. The general cargo reflected the affluence of Melbourne at the time. Onboard were straw hats, umbrellas, perfumes, clay pipes, pianos, clocks, confectionery, linen and candles, as well as a heavier load of railway irons, cement, lead and copper. There were other items included that were intended for display in the Melbourne International Exhibition of 1880. The voyage to Port Phillip was long but uneventful. Then at 3 am on June 1, 1878, Captain Gibbs was expecting to see land. But the Loch Ard was running into a fog which greatly reduced visibility. Captain Gibbs was becoming anxious as there was no sign of land or the Cape Otway lighthouse. At 4 am the fog lifted and a lookout aloft announced that he could see breakers. The sheer cliffs of Victoria's west coast came into view, and Captain Gibbs realised that the ship was much closer to them than expected. He ordered as much sail to be set as time would permit and then attempted to steer the vessel out to sea. On coming head-on into the wind, the ship lost momentum, the sails fell limp and Loch Ard's bow swung back towards land. Gibbs then ordered the anchors to be released in an attempt to hold its position. The anchors sank some 50 fathoms - but did not hold. By this time the ship was among the breakers and the tall cliffs of Mutton Bird Island rose behind. Just half a mile from the coast, the ship's bow was suddenly pulled around by the anchor. The captain tried to tack out to sea, but the ship struck a reef at the base of Mutton Bird Island, near Port Campbell. Waves subsequently broke over the ship and the top deck became loosened from the hull. The masts and rigging came crashing down knocking passengers and crew overboard. When a lifeboat was finally launched, it crashed into the side of Loch Ard and capsized. Tom Pearce, who had launched the boat, managed to cling to its overturned hull and shelter beneath it. He drifted out to sea and then on the flood tide came into what is now known as Loch Ard Gorge. He swam to shore, bruised and dazed, and found a cave in which to shelter. Some of the crew stayed below deck to shelter from the falling rigging but drowned when the ship slipped off the reef into deeper water. Eva Carmichael a passenger had raced onto the deck to find out what was happening only to be confronted by towering cliffs looming above the stricken ship. In all the chaos, Captain Gibbs grabbed Eva and said, "If you are saved Eva, let my dear wife know that I died like a sailor". That was the last Eva Carmichael saw of the captain. She was swept off the ship by a huge wave. Eva saw Tom Pearce on a small rocky beach and yelled to attract his attention. He dived in and swam to the exhausted woman and dragged her to shore. He took her to the cave and broke the open case of brandy which had washed up on the beach. He opened a bottle to revive the unconscious woman. A few hours later Tom scaled a cliff in search of help. He followed hoof prints and came by chance upon two men from nearby Glenample Station three and a half miles away. In a complete state of exhaustion, he told the men of the tragedy. Tom then returned to the gorge while the two men rode back to the station to get help. By the time they reached Loch Ard Gorge, it was cold and dark. The two shipwreck survivors were taken to Glenample Station to recover. Eva stayed at the station for six weeks before returning to Ireland by steamship. In Melbourne, Tom Pearce received a hero's welcome. He was presented with the first gold medal of the Royal Humane Society of Victoria and a £1000 cheque from the Victorian Government. Concerts were performed to honour the young man's bravery and to raise money for those who lost family in the disaster. Of the 54 crew members and passengers on board, only two survived: the apprentice, Tom Pearce and the young woman passenger, Eva Carmichael, who lost her family in the tragedy. Ten days after the Loch Ard tragedy, salvage rights to the wreck were sold at auction for £2,120. Cargo valued at £3,000 was salvaged and placed on the beach, but most washed back into the sea when another storm developed. The wreck of Loch Ard still lies at the base of Mutton Bird Island. Much of the cargo has now been salvaged and some items were washed up into Loch Ard Gorge. Cargo and artefacts have also been illegally salvaged over many years before protective legislation was introduced in March 1982. One of the most unlikely pieces of cargo to have survived the shipwreck was a Minton majolica peacock- one of only nine in the world. The peacock was destined for the Melbourne 1880 International Exhibition in. It had been well packed, which gave it adequate protection during the violent storm. Today the Minton peacock can be seen at the Flagstaff Hill Maritime Museum in Warrnambool. From Australia's most dramatic shipwreck it has now become Australia's most valuable shipwreck artifact and is one of very few 'objects' on the Victorian State Heritage Register.The shipwreck of the Loch Ard is of significance for Victoria and is registered on the Victorian Heritage Register ( S 417). Flagstaff Hill has a varied collection of artefacts from Loch Ard and its collection is significant for being one of the largest accumulation of artefacts from this notable Victorian shipwreck. The collections object is to also give us a snapshot into history so we can interpret the story of this tragic event. The collection is also archaeologically significant as it represents aspects of Victoria's shipping history that allows us to interpret Victoria's social and historical themes of the time. The collections historically significance is that it is associated unfortunately with the worst and best-known shipwreck in Victoria's history. Large conglomerated group of nickel silver plated dessert spoons with fiddle-back design handle, narrow stem with flared collar and elongated bowl (there are 8-10 spoons in the group). Inscriptions on the spoons. Made by William Page & Co, of Birmingham. The spoons were recovered from the wreck of the Loch Ard.Stamped “W” & “P” within a raised diamond outline, which is in turn contained within a sunken crown (The shape identifies the manufacturer as William Page & Co of Birmingham.)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, loch line, loch ard, captain gibbs, eva carmichael, tom pearce, glenample station, mutton bird island, loch ard gorge, dessert spoon, petrified timber, conglomerated cutlery, silverware, dining utensil -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTile, c 1914

This clay roof tile was part of the ANTARES cargo, a large consignment of tiles on its way to Melbourne. THE ANTARES In mid-November 1914, after the beginning of the First World War, a young local man went one evening to fish near the Bay of Islands, west of Peterborough. He later arrived home hurriedly and in an agitated state declaring: "The Germans are coming!" His family laughed and disbelieved him, as this young fellow was prone to telling fictional tales. About a month later, on December 13th 1914, local farmers Phillip Le Couteur and Peter Mathieson were riding in the vicinity, checking on cattle. Phillip Le Couteur saw what he “thought was the hull of a ship below the cliffs.” He rode to Allansford and contacted police. The next day, two Constables and Phillip Le Couteur returned to the site, where they dug a trench near the top of the cliff and sank a log in it. To this they attached a rope, which they threw down the cliff face. Constable Stainsbury and Phillip Le Couteur then made the dangerous descent down the rope on the sheer cliff face. They found wreckage strewn around a small cove and a portion of a man's body under the cliffs. The hull of the ship could be seen about 300 metres out to sea. Some of the wreckage revealed the name Antares and the remains of the ship's dinghy bore the name Sutlej. During the next two weeks and with the help of the Warrnambool lifeboat and crew, two more bodies were found. Later investigations proved that the tragic wreck was indeed that of the Antares, reported overdue on the 207th day of her voyage from Marseilles, France, to Melbourne. She was a three masted, 1749 ton iron clipper, built in Glasgow in 1888 and originally named and launched as the Sutlej. Bought in 1907 by Semider Bros. from Genoa, Italy, she was refitted and renamed Antares. It was later realised that the local lad who a month earlier had declared he had seen German guns being fired, had probably seen distress flares fired from the deck of the Antares the night she was wrecked. She was last sailed under Captain Gazedo and wrecked at what is now known as Antares Rock, near the Bay of Islands. She had been carrying a large cargo of roof tiles from France to Melbourne, consigned to Mullaly & Byrne. Many of them are now to be seen amongst the battered and scattered remains of the wreck. Some of the timbers were found to be blackened by fire. An Information Board has been erected on the cliff top near to the site of the Antares wreck, at the end of Radfords Rd, west of Peterborough. (Ref: Flagstaff Hill Maritime Village’s “Antares” fact sheet, Victorian Heritage Database, Information Board at Peterborough, Flagstaff Hill Significance Assessment 2010) The Antares was one of the last of the 'tall ships' to be lost along the south west coast of Victoria, and is the only wreck that took the lives of all people on board. She is listed on the Victorian Heritage Register VHS S34. The Antares is significant as a sail trader carrying an international inbound cargo. It is part of the Great Ocean Road Historic Shipwreck Trail. Piece of a clay roof tile recovered from the wreck of the Antares. Has a relief of a horse on back. Artefact Reg No A/7.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, antares, tall ship, peterborough, 1914 shipwreck, phillip le couteur, peter mathieson, constable stainsbury, sutlej, antares rock., bay of islands, clay tile, roofing tile, roof tile -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Butter Dish

The art of making glass can be traced back to 2600 BC in Mesopotamia. Egyptians practised making glass around 2500 BC. Artificial glass first appeared in the Egyptian or the Mesopotamian civilization, whereas they used tools made out of volcanic glass obsidian in the Stone Age. Ancient China, however, discovered how to make glass a little later. Glass beads are known to be one of the earliest products made out of glass. Their creation is thought to be primarily accidental. In the later Bronze Age, glassmaking came to a halt. Glass was a luxury material back then. Archaeological excavations suggest the use of glass in England during the middle ages. In the 10th century, stained glass found a place in cathedrals and windows of palaces. After the Renaissance, architectural methods changed substantially, leading to a decrease in stained glass as a building material. Domestic use of glass increased following the industrial revolution. Vessels, glass windows, and glass beads gained popularity in Europe during this period. During the 19th century, many people preferred glass windows and doors as a decorative option. In the late 19th century, some designers brought back stained glass in decorative windows. It was during this period that Mr Tiffany discovered several methods to make domed glass handicrafts. People discovered the true versatility of using glass as a building material only in the 20th century. With glassmaking technology receiving an industrial boom, you could produce several different types of glass. Toughened glass, laminated glass, bulletproof glass, and smart glass all boosted the use of glass in buildings. Today, several skyscrapers, small and big homes, and offices use glass in almost all aspects of construction and design. https://www.aisglass.com/glass-made-step-step-process/The invention and development of glass, both as domestic items and in building, has been nothing short of revolutionary. Prior to the use of glass for windows, the interior of buildings were extremely dark, even during sunny days. The use of glass domestic objects, that could be easily washed, led to improved hygiene.Moulded patterned glass butter dish. Base has been broken.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, glass, kitchen item, butter -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePencil Set

"Challenge" 6 piece pen and pencil set, consisting of best combined penholder and pencil case, superb seal top copying pencil, nickel silver refill case of leads, reversible pocket pen holder and natty charm pencil. Name on back of case D Hamilton, 16/9/04flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, pen and pencil set, d hamilton -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillagePhotograph - Maritime, John Murray, 1909-1917

The image in this photograph is the 'John Murray', which was owned by the Government of Victoria from 1909 to 1917 as a training vessel. It was built and registered in Glasgow, UK in 1877 as the 'Loch Ryan'. This photograph is a copy of the original photograph, which was owned by Dr J. Douglas, brother o the donor. The iron baque 'Loch Ryan' was a three masted, 1207 ton sailing ship built by James & George Thomson in Glasgow in 1877. It was purposed as a general cargo vessel and owned by the General Shipping Company, known as the Loch Line because the ships were named after Scottish lochs. The company had a fleet of 25 colonial clipper ships that traded between the UK and Australia between 1866 and 1909, mainly from Glasgow to Melbourne, Sydney and Adelaide. Many of the sips, including the Loch Ryan, had a distinctive white stripe on their dark coloured hulls. The 'Loch Ryan' was purchased in 1909 by the Victorian Government's Défense Department and converted for the purposes of a training in Williamstown. In 1910 it was renamed John Murray, whose namesake, John (Jack) Murray (1851-1916) was born near Koroit. He was the 23rd Premier of Victoria (1909-1912), and a Warrnambool Member of Parliament for twenty years. The government commissioned the ship from 1910-1917 for reforming juvenile offenders, training them as seamen for the Navy and Merchant Navy. The training project ceased after reports of the treatment of the boys. Although 411 did their training under this scheme, the success rate of them qualifying to serve on other vessels was less than twenty percent. In 1917 the John Murray was sold to the Government of Australia to serve during WWI. The ship was loaded with a cargo of dynamite and petroleum at San Francisco then departed for Melbourne when, during its passage, it was wrecked at Malden Island reef in the mid-Pacific Ocean on May 29th, 1918.The photograph of the John Murray , formerly the 'Loch Ryan' is significant for its connection with the Loch Line of the General Shipping Company of Glasgow, the same company that owned the Loch Ard, which was wrecked and tragically lost 52 lives. The photograph is also significant for its connection with Victoria's training ship John Murray, which aimed at reforming delinquent juveniles, to be suitable as seamen for Australia's Navy or Merchant Navy. The ship was the namesake of John Murray, so the photograph is also significant for its connection with Victorian and local Government, as John Murray was the 23rd Premier of Victoria and a Warrnambool Member of Parliament for over 20 years. He was born in the local town of Koroit. The photograph is significant as an image of the many clipper ships that traded between the United Kingdom and Australia, with goods collected from other countries along the way.Photograph, black and white, behind glass, matt, framed in black with gold trim. Image is the Government of Victoria's training ship "John Murray". Label attached to back of frame with inscription. Also a square white sticker with handwritten number.Text on label includes: "The "John Murray" / A training ship for delinquent boys about 1910 / Formerly the Loch Ryan / John Murray - Premier of Victoria and Member for Warrnambool for over 20 years / Donated by Elizabeth O'Callaghan / Original photo in possession of Dr J. Douglas / (Brother of Elizabeth O'Callaghan - nee Douglas)" Sticker; handwritten "57"flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, the john murray, loch ryan, john murray, loch line, general shipping company, government of victoria, training ship, juvenile reformation, delinquent boys, james & george thomson, iron barque, three masted ship, clipper ship, uk to australia trade, dynamite cargo, petroleum cargo, maldon island reef, 1909-1917 -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate

The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/Ceramics have evolved over thousands of years.White earthenware dinner plate. Crazing evident all over.Backstamped ‘Made in England S LTD’flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, ceramics, tableware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate, Johnson Bros