Showing 2824 items matching "c.c.45"

-

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1953-1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red children's wool jumper with green and white geometric tartan/plaid pattern on front. Has long sleeves with ribbed cuffs and ribbed crew neck and closes with four red plastic buttons at back neck. Coloured pattern is worked in lines on top of finished fabric in surface crochet in pattern of green, white, green[white label at back neck with blue stitching] ALL WOOLknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Grey wool Jumper with Blue and grey cable design on front. Vertical cable pattern is two sets of intertwining grey blue cable pairs on a purl stitch background in alternating rows of blue and grey. Front panel of jumper has five cable panels separated by smooth stocking stitch panels. Jumper has long sleeves and crew neck with thick ribbed collar and cuffs. Style B/110, Colourway Silver/Denim, Size 8 .2) 2 Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Brown/Woodgrain, Denim/Blue Shadow and Pebble/Oyster.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2) [blue sample label] STYLE B/110 Crew Neck Wool Pullover SIZES: 2 4 6 8 10 PRICE: $10 [amended to $11 in blue pen] $[written over in blue pen so as to be illegible] [handwritten in blue pen] $12.55 SIZES: 12 14 PRICE: [printed] $12.30 [handwritten over top in blue pen] $13.15 COLORS: Silver/Denim, Brown/Woodgrain, Denim/Blue Shadow, Pebble/Oyster. Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Brown and Grey children’s jacket with brown accents at pockets and shoulder, centre front zip, curved pocket detail.Style B/117, Colourway Woodgrain/Pebble, Size 8 .2) Sample tags stapled together with manufacturing information, including sizes and colours available, as well as knit swatch samples for colourways Green/Silver, Burgundy/Denim, Navy/Denim, and Rust/Pebble.1) [white label at back neck with green and black printed writing] ROBERT BLAKE Size 8 / knitwear HEIGHT 130cm MADE IN AUSTRALIA .2 [blue sample label] STYLE B/117 Jacket. Zip. Birdseye. Wool. SIZES: 2 4 6 8 10 PRICE: $11.75 [amended to $12.80 in blue pen] $13.85 [amended to $15.05 in blue pen] SIZES: 12 14 PRICE: [printed] $14.95 [amended to $16.15 in blue pen] COLORS: Woodgrain/Pebble Green/Silver [drawn through in black pen] Burgundy/Denim, Navy/Denim, Rust/Pebble Dec on Del. [cream brand label] [OBVERSE] ROBERT BLAKE [REVERSE] ROBERT BLAKE KNITWEAR MELBOURNE, AUSTRALIAknitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, children's knitwear -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Grey children’s cardigan with embroidered flowers and human figures in folk costume, and crocheted design around neck in green, yellow and red. Left panel has embroidered figure of man with blue lederhosen and yellow shirt, black shoes and hat, hat has red accent. Right front panel depicts woman wearing red skirt with white stripe, white shirt, and green headscarf with black stockings and shoes. Flowers are embroidered in pink, white and blue with green and yellow accents for stems and flower centres. Cardigan closes in front with five marbled grey plastic buttons[Label at back neck with blue lettering woven into label] KATHRYN REGD / 22 ALL WOOL CREATED BY ROBERT BLAKEchildren's knitwear, knitwear, clothing, children's clothing, cardigan, manufacturing, fashion textile production, machine knitting, embroidery, embroiderer, folk art, folk embroidery -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Royal blue double breasted cardigan 'Reefer Jacket' with short sleeves in a textured rib stitch with six chrome metal buttons in two rows down centre front. Style 319/J .2 is sample tag with manufacturing information, including sizes and colours available.1) [white label at back neck with blue stitching] KATHRYN REGD. CREATED BY ALL COTTON / 24 / ROBERT BLAKE .2) [sample label] [OBVERSE] STYLE: 319/J – Reefer Jacket – Combed Cot. SIZE: 22” 24” 26” 28” 30” 32” PRICE: 20/- 21/- 22/6 24/- 26/- 27/6 COLOR: NAVY ONLY. [REVERSE] KATHRYN Garments are • PRE-SHRUNK • STANDARD MEASUREMENTS • FIT EXACTLY • LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNEknitwear, children's knitwear, clothing, children's clothing, cardigan, manufacturing, fashion textile production, machine knitting, fashion cotton -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1975

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Orange jumper with multicoloured heathered tweed effect, white stripe accent on neck, upper arm and sleeve cuffs, two patch pockets mounted on diagonal outlined in thread matching accent colour .2 Sample tags with manufacturing information, including sizes and colours available, as well as knit swatch samples in colourways Blue Tweed/Sky/Magnolia and Cream Tweed/Magnolia/Pine.1) [tag stitched into back neck] KATHRYN REGD PURE NEW WOOL/ SIZE 6 HEIGHT 120cm MADE IN AUSTRALIA .2) [blue sample label] STYLE 589/Pullover S.47. Wool Tweed. SIZES: 2 4 6 8 PRICE: $9.80 [amended to $10.75 in blue pen] $0.35 [handwritten in blue pen] $11.40 COLORS: Pink Tw/Ochre/Mag, Blue Tweed/Sky/Magnolia Cream Tweed/Mag/Pine. [Crossed out in black ink] March on Del.children's knitwear, children's clothing, clothing, knitwear, jumper, manufacturing, fashion textile production, machine knitting, heathered yarn, tweed yarn, flecked yarn, colourwork -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1970

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Children’s jumper with fair isle pattern in shades of cream and orange. Pale orange tweed yarn on chest and shoulders is flecked throughout with red, yellow, blue and green. Vent at centre front closes with three cream plastic buttons. .2 is a swing tag with manufacturer care instructions retail tags size 8 .3 is a sample tag with manufacturing information, including sizes, prices, and colours available .4 is a swatch sample for Magnolia/Navy/Blue Tweed colourway[tag stitched into back neck] KATHRYN REGD PURE NEW WOOL/ SIZE 8 HEIGHT 190cm MADE IN AUSTRALIAchildren's knitwear, children's clothing, knitwear, clothing, jumper, manufacturing, fashion textile production, machine knitting, variegated yarn, variegated, colourwork, stranded colourwork, fair isle, fair isle colourwork, fair isle knitting -

National Wool Museum

National Wool MuseumTextile - Children's Jumper, Kathryn Knitwear, c.1955-1966

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Pale Blue embroidered jumper featuring a Koala on a tree branch, with green and red foliage and a yellow butterfly embroidered on centre front chest. Jumper has long sleeves and a round collar with ribbed collar and cuffs.[Label at back neck with blue lettering woven into label] KATHRYN REGD ALL WOOL / 24 /CREATED BY ROBERT BLAKEknitwear, children's knitwear, clothing, children's clothing, jumper, manufacturing, fashion textile production, machine knitting, embroidery, embroiderer, koala, australiana -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Brown children’s cardigan with embroidery of four baby chicks in yellow and red on green grass at bottom of front panels. Closes at centre front with three brown plastic buttons[Label at back neck with blue lettering woven into label] KATHRYN REGD / 20 ALL WOOL CREATED BY ROBERT BLAKEchildren's knitwear, children's clothing, clothing, knitwear, manufacturing, fashion textile production, machine knitting, embroidery, embroiderer, chickens, chicks, baby animals, cute animals -

National Wool Museum

National Wool MuseumTextile - Children's Cardigan, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Red cardigan embroidered with decorative tuck stitches and floral motifs on front panel, crochet around collar in blue, white and green. Closes at centre front with 5 plastic buttons[Label at back neck with blue lettering woven into label] KATHRYN REGD ALL WOOL / 20 /CREATED BY ROBERT BLAKEchildren's knitwear, knitwear, children's clothing, clothing, cardigan, manufacturing, fashion textile production, machine knitting, embroidery, hand embroidery, floral embroidery, floral motif, tuck stitch -

National Wool Museum

National Wool MuseumTextile - Diaper Set, Kathryn Knitwear, c.1960

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Cotton is a common material for knitwear worn in the warmer months, as it is very breathable and absorbs moisture easily. While we mostly associate knitwear with keeping us warm in the cold, the market for Australian knitwear would be very limited without options to wear all year round. The decoration on this garment was embroidered by hand by a skilled worker at the Kathryn Knitwear factory. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.White diaper set. Short sleeved white top with two inverted box pleats along whole length, stitched at shoulder and mid chest. Embroidered in half cross stitch with two blue dogs on front. Closes in centre back with three plastic pearlescent buttons. White baby diaper shorts with ribbing at waist and leg holes .3 is a sample tag with manufacturing information, including price, size and colours available .4 is a swing tag with manufacturer care instructions.1 [label at back neck of top] Kathryn Reg’d / All Cotton / 18 .3 [sample label] [Obverse] STYLE: 314. Diaper Sat [sic] – Emb top. Combed Cotton. SIZE: 18” PRICE: 26/- COLOR: BLUE. LEMON. WHITE. [reverse] KATHRYN Garments are •PRE-SHRUNK •STANDARD MEASUREMENTS •FIT EXACTLY •LAUNDER PERFECTLY Designed and Manufactured by ROBERT BLAKE, MELBOURNE .4 [retail label] [obverse] Kathryn PRE-SHRUNK KNITWEAR Style: 314 [handwritten] DESIGNED & MANUFACTURED BY Robert Blake MELBOURNE [reverse] IMPORTANT. Special care should be taken with white and pastel shades. Rinse thoroughly. Do NOT dry in sunlight. WASHING INSTRUCTIONS 1.Wash frequently to AVOID HEAVY SOILING 2.Wash garment BY HAND, in lukewarm Velvet Soap suds. ON NO ACCOUNT RUB SOAP ON GARMENT. 3.Squeeze suds gently through garment but DO NOT RUB. Rubbing will cause garment to thicken. 4.RINSE AT LEAST TWICE IN CLEAN WATER TO REMOVE ALL SOAP. 5.To dry, roll garment in a towel to remove excess moisture, turn garment inside out and pull it lengthwise, then safety-pin to line through shoulder tape. 6.To keep Brushed Wool garments like new brush frequently with nylon brush.children's knitwear, children's clothing, knitwear, clothing, manufacturing, fashion textile production, embroidery, embroiderer, hand embroidery, dog embroidery, animal embroidery, animal motif, dog motif, dog, animal, baby clothes, baby knitwear, baby clothing -

National Wool Museum

National Wool MuseumTextile - Children's Clothing Set, Kathryn Knitwear, c.1965

Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Wool has been renowned for its excellent properties for thousands of years, by people from all over the world. Not only good for thick winter woollens, it can help keep you cool in summer, as well as being durable and resistant to water, fire, ultraviolet light, stains and odour. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Three-piece brown and yellow outfit consisting of jumper, pants and hat. Jumper is long sleeved with a high crew neck and five yellow stripes above ribbing along bottom. Pants are brown with wide legs that dramatically taper into the ribbed cuff at bottom. Body of hat is brown and tapers into a long point and has a brown and yellow pompom at the tip. The hat is shaped with a tuck at the back neck near cuff..1 [Label at back neck of jumper with blue lettering woven into label] KATHRYN REGD / 24 ALL WOOL CREATED BY ROBERT BLAKEknitwear, clothing, children's knitwear, children's clothing, manufacturing, fashion textile production, machine knitting, clothing set, pom poms, wool -

National Wool Museum

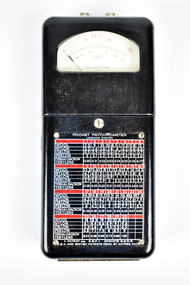

National Wool MuseumInstrument - Psychrometer, Electronova S.A, c.1965

Kathryn Knitwear Collection A Psychrometer is an instrument used to measure humidity using two thermometers, one of which is wet and one is dry. A similar example is housed at laboratoire d'histoire des sciences et des techniques (LHST). Inventory number 603.0509 Kathryn Knitwear, founded by Robert Blake, manufactured high quality children’s knitwear in Melbourne from the 1940s – 1980s. Robert Blake began manufacturing children’s knitwear in his bedroom in Strathmore using a hand powered machine in the late 1940s. The operation moved to Ascot Vale and Essendon, before eventually establishing a factory in Moonee Ponds in the early 1950s. The business continued to expand, necessitating a move to a new factory in Broadmeadows. By 1962, the Broadmeadows factory was producing an average of 20,000 garments per month, which increased to 24,000 by 1964. Robert Blake’s Son, Brendan recalls that “The Kathryn brand was famous around Australia, anywhere children needed to keep warm and dress smartly. It also won a number of wool fashion awards”, including the 1969 Wool Awards, which was held by the Australian Wool Bureau and published in Women’s Weekly. The Kathryn range was designed for durability, comfort and care, without sacrificing style. They used patterning techniques that increase stretchiness, comfort and fit, as well as integrating decorative elements into the fabric to prevent them from being bulky, uncomfortable or tight. Making longevity of style a priority, Brendan Blake remembers that “there was one particular garment that was in the range for at least thirty years”. He also recalls “In the past, when women have found out that I was associated with Kathryn Knitwear, they would often relate to me the story of a garment they had purchased or received as a gift and, when their child had grown out of it, they would hand it on to another child. Several ladies have told me of purchasing garments for their daughters’ glory box, or saving a particular garment after their daughter had grown out of it. Brendan Blake: “At the peak of their operation they employed approximately two hundred people, mainly women and girls. A family would often seek to send their daughter to work in this company because they knew they would be looked after and safe. One lady wrote to me telling me that working at the Moonee Ponds Factory prior to getting married was the happiest time of her life.” In 1963, workers at the Kathryn factory earned £13 per week, which was 8 shillings and 8 pence higher than the minimum weekly wage for female workers in the textile manufacturing industry (£12 11s 4d). By 1970, the Kathryn Knitwear brand expanded from children’s knitwear into womenswear under the brand name ‘Lady Kathryn’, and for boys and men under ‘Robert Blake’. Continuing to diversify their distribution, they also began exporting ‘Kathryn’ garments to New Zealand, the Pacific Islands, and Japan. ‘Kathryn Knitwear’ was well-known for their early adoption of modern materials and techniques that had broad appeal to their customer base. This is shown in their early use of the acrylic fibre ‘Orlon’ in the 50s and 60s and ‘Superwash’ wool in the 1970s. Many of Kathryn Knitwear’s styles, particularly those that were long running staples of the brand, were available in both wool and Orlon to suit the consumer’s preference. Far from the humble origins of one man in his bedroom with a hand-cranked machine; at its closure in 1980, the Broadmeadows factory of ‘Kathryn’ housed more than 100 machines, including 53 sewing machines and 45 knitting machines. Robert Blake was “a passionate advocate for wool and Australian Made” throughout his whole life. A strong thread that ties through the lifespan of Robert Blake and Kathryn Knitwear is a balance between adopting new innovations without sacrificing the core values of durability, comfort, care and style that had made the brand so well known. Their legacy forms an integral part of both Australian social and manufacturing history.Black metal measuring instrument with clear window to view gauge for displaying humidity. Reference table listing values for different fibres is printed in red and white on a black metal plate that is screwed onto the front of the psychrometer. The instrument is housed in brown leather case with zip. It includes a printed paper instruction book with black text and greyscale figures.psychrometer, measuring instrument, humidity, textile manufacturing, fashion textile production -

Federation University Historical Collection

Federation University Historical CollectionLetter - Correspondence and envelope, Ballarat School of Mines Invoices in Envelopes, c1905, c1905

A number of mostly sealed and addresses envelopes containing invoices from the Ballarat School of Mines. .1) C. Laidler, invoice from 8 shillings 8 pence for chemical apparatus, 17 July 1905 . .2) Mr Kofoed of the Asylum for Insane Wendouree - invoice .3) Sealed envelope addressed to Mr D. Bonan .4) Sealed envelope addressed to Mr R.E. Holdsworth .5) Sealed envelope addressed to Mr O'Bern .6) Sealed envelope addressed to Mr Meade .7) Sealed envelope addressed to Mr Macartney .8) Sealed envelope addressed to Mr Arthur Loveland .9) Sealed envelope addressed to Mr William Harris .10) Sealed envelope addressed to Mr Hamilton .11) Sealed envelope addressed to Mr G.F. Johnson .12) Sealed envelope addressed to Mr Bieske Esq .13) Sealed envelope addressed to Mr C. Stevenson .14) Sealed envelope addressed to Mr Dempster .15 Addressed envelope to Mr H. Bryant, and invoice from the Ballarat School of Mines for chemistry apparatus, 21 November 1905 .16) Sealed envelope addressed to Mr A.C.S. Leathes .17) Addressed envelope to Mr F.J. Martell School of Mines and an invoice from A. Ruddock, house painted and decorator .18) Sealed envelope addressed to Mr R.J. Webster .19) Sealed envelope addressed to Mr L. Thompson .20) Sealed envelope addressed to Mr Tregurtha .21) Sealed envelope addressed to Mr Baker .22) Sealed envelope addressed to Mr K. McTaggart .23) Sealed envelope addressed to Mr John W. Nettle .24) Sealed envelope addressed to Mr E. Pollard .25) Sealed envelope addressed to Mr R. Nevett .26) Sealed envelope addressed to Mr J. Smart .27) Sealed envelope addressed to Miss M. Janssen .28) Sealed envelope addressed to Mr Bantle .29) Invoice from the Ballarat School of Mines to Mr McTaggart for Chemistry Apparatus .30) Sealed envelope addressed to Mr Eklund 31) Sealed envelope addressed to Mr Fitzgerald .32) Sealed envelope addressed to Mr Fraser .33) Sealed envelope addressed to Mr B. Humffray .34) Sealed envelope addressed to Mr Fairley .35) Sealed envelope addressed to Mr Lowenthal .36) Sealed envelope addressed to Messrs Martin and Simmons .37) Envelope addressed to Mr Daly with an invoice for chemistry apparatus, 21 November 1905 .38) Sealed envelope addressed to Mr Elliott .39) Sealed envelope addressed to Mr E. Evans .40) Sealed envelope addressed to Mr W.E. Eyres .41) Sealed envelope addressed to Mr Kingston .42) Sealed envelope addressed to Mr Robin .43) Envelope addressed to Mr James Martin, and invoice for term fees for the Ballarat School of Mines. .44) Sealed envelope addressed to Mr Lounda .45) Sealed envelope addressed to Mr Richardson .46) Sealed envelope addressed to Mr Danton .47) Sealed envelope addressed to Mr Lennonballarat school of mines -

Bendigo Historical Society Inc.

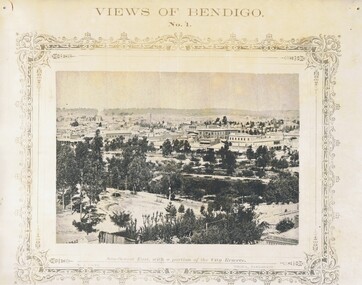

Bendigo Historical Society Inc.Photograph - NICHOLAS CAIRE VIEWS OF BENDIGO

Full set (52 photos) of Nicholas Caire ''Views of Bendigo'' photographs. 1) Sandhurst East with a portion of the City Reserve. 2) New Chum line of reef. 3) Sandhurst-North part as seen from the top of the Masonic Hall. 4) The Hustler's line of reef seen from Redan Hill. 5) Battery of stampers for crushing quartz 6) View of Sandhurst as seen from the top of the New Masonic Hall. 7) Excavation of quartz reef near Ironbark Hill. 8) St. Paul's Church, tower and belfry. 9) View of the Camp Reserve as seen from the Court House. 10) View of North Old Chum showing surface excavations. 11) View as seen from the Camp Hill near the lodge. 12) Garden Gully amalgamated claims. 13) Shamrock Hotel, Sandhurst. 14) View as seen from Court House showing the willows & East Pall Mall. 15) Wesleyan Church, Golden Square. 16) Savings bank, Sandhurst. 17) The Bendigo district hospital. 18) Interior of the Wesleyan Church, Golden Square. 19) View of Golden Square township. 20) The Town Hall, City of Sandhurst. 21) The City Hotel, Sandhurst. 22) Pall Mall, Sandhurst. 23) Sandhurst City Market. 24) Pall Mall, Sandhurst looking west. 25) View from Camp Hill looking north - east 26) View of Charing Cross, Sandhurst. 27) View of Sandhurst as seen from Knipe's Castle. 28) Township of Long Gully. 29) View taken from St. Paul's tower. 30) View of the Sandhurst cemetery at back creek. 31) Kock's pioneer quartz crushing plant, Long Gully. 32) The New Masonic Hall, Sandhurst. 33) The Bendigo benevolent asylum and industrial school. 34) Bendigo flat as seen from Wattle Hill. 35) View of Old Chum Hill. 36) New Chum Gully as seen from Specimen Hill. 37) Township of Eaglehawk. 38) View from St. Paul's tower looking south west. 39) View of the railway tunnel through the Big Hill, near Mt. Herbert. 40) View taken from St. Paul's looking south. 41) Scene taken from St. Paul's tower looking eastward. 42) View of Sandhurst from St. Paul's tower looking north-west. 43) The great extended Hustler's co's. quartz mining claim. 44) View from the Big Hill showing the line of railway to Melbourne. 45) View from St. Paul's Church tower looking westward. 46) View from St. Paul's Church tower looking north-west. 47) Scene near the Big Hill ranges taken from Mr. Buick's residence. 48) View from St. Paul's Church tower looking north eastward. 49) Township of Eaglehawk 50) View of Mitchell Street, Sandhurst. 51) Botanical gardens near the White Hills. 52) View Point, Sandhurst.bendigo, streetscape, various views, nicholas cairne -

Melbourne Tram Museum

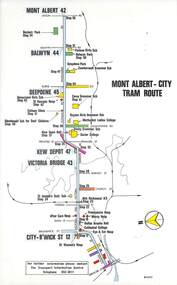

Melbourne Tram MuseumMap, Melbourne & Metropolitan Tramways Board (MMTB), Set of 15 tram route maps, 1977 to 1979

Series of 15 colour route maps for various tram lines or groups of tram lines for the MMTB. Some have the Transport Information Centre telephone printed on them, others have a label stuck on. Some are finished with a plastic laminate finish on either one or both sides. Show the major cross streets, parks, schools, other tram routes, major stop numbers and railway lines. Two copies of each held unless noted otherwise. .1 - Mont - Albert City - R11/77, shows routes 43. 47. 45. 44 .2 - Malvern, East Malvern, Carnegie and East Brighton Tram Routes (from St Kilda Junction) - R1/79 - shows routes 5, 3, 67, 66, 61, 62 and 64. .3 - Swanston St tram guide - R1/79 - lists all routes and route numbers that branch or cross Swanston St between Grattan St and St Kilda Junction. .4 - St Kilda Rd Tram Routes R12/77 - details South Melbourne Beach, route 1 and route 2 and St Kilda Beach routes 15, 16 and 55 otherwise shows were the various routes branch off St Kilda Road. Copy 1 has "P14909" in pencil in the bottom right hand corner. .5 - Kew - St Kilda Beach - R1/79 - Route 69. .6 - Footscray - Moonee Ponds - R3/81 - Route 82 .7 - Flinders St tram routes - R5/78 - North Balwyn, East Burwood, routes 48, 40, 41, Hartwell, 28, 74 and 75 .8 - William St tram routes - Route 55, 56 and 63 - South Melbourne Depot and Domain. copy 2 has "P14913" in bottom right hand corner. .9 - Toorak Camberwell and Glen Iris tram routes with Camberwell Junction and Malvern Town Hall, R1/79, routes 8, 7, 6, 72 and 73 shown. .10 - Swanston St tram routes - R12/77 - shows all the Swanston St routes, including East Coburg and Moreland. .11 - Bourke St tram routes - R4/77 - East Brunswick Blyth St and East Preston Tyler St and intermediate routes, routes 95, 96, 97, 90, 89 and 88. .12 - as for .11, dated 1/85, showing extension to La Trobe University - has Metropolitan Transit logo. Only 1 copy held. Also shows route 92 and 87. .13 - Batman Ave tram routes - R9/77 - Wattle Park, North Richmond and Prahran - routes 70, 71, 78 and 79. .14 - City route guide - R9/77 - showing all route numbers and destinations that passed through the CBD. .15 - Elizabeth St tram routes - R12/77 - Essendon Airport, West Maribyrnong, North Coburg lines, routes 50, 58, 60, 54, 57, 52. 49, 59, 18, 20 and 19. Copy 1 has "P14905" in pencil in bottom left hand corner.trams, tramways, maps, route guide, route numbers, routes, mont albert, route 43, route 47, route 45, route 44, route 42, malvern burke rd, east preston, carnegie, east brighton, south caulfield, route 5, route 3, route 67, route 62, route 64, route 66, glenhuntly tram depot, swanston st, st kilda rd, south melbourne beach, st kilda beach, route 1, route 2, route 15, route 16, route 55, kew- cotham road, route 69, route 79, route 82, footscray, moonee ponds, flinders st, north balwyn, kew, east burwood, burwood, hartwell, richmond, route 48, route 40, route 41, route 28, route 74, route 75, route 56, route 63, william st, west coburg, toorak, camberwell, glen iris, malvern town hall, route 72, route 73, route 7, route 8, bourke st, route 6, route 95, route 96, route 97, route 90, route 89, route 89, east preston, east brunswick, la trobe university, clifton hill, route 92, route 87, route 70, route 71, route 78, route 79, north richmond, prahran, wattle park, essendon airport, west maribyrnong, north coburg, route 50, route 58, route 60, route 54, route 57, route 52, route 49, route 59, route 18, route 20, route 19, batman ave -

Melbourne Tram Museum

Melbourne Tram MuseumEphemera - Timetable/s, Melbourne & Metropolitan Tramways Board (MMTB), "MMTB Timetables set of 39", 1960

Set of 39 MMTB Tram timetables, 2 fold sheets, , providing timetables for specific routes, route numbers, day of week giving information on tram times at departure time points, sections and fares, where applicable all night bus services. All signed by B. H. Misson, Traffic Manager. All sponsored by Kays Rent a Car and Motor Drome, 18-30 Mount Alexander Road, Flemington. The only one missing is Point Ormond. Not dated, based on fares - 1960 and possibly after Point Ormond had closed. .1 - Route 1, 21 - East Coburg - City .2 - Route 4, 4A, 4B - Carnegie - City .3 - Route 4D, 14 - East Malvern - City .4 - Route 5, 5A - Malvern Burke Road - City .5 - Route 6, 6A, 6B - Glen Iris - City .6 - Route 7, 7A, 7B, 7D - Camberwell - City .7 - Route 8, 8A - Toorak - City .8 - Route 9, 9A - Northcote via St Georges Road - City .9 - Route 9, 9B, 10, 12 - Sth Melbourne Beach, St Kilda Beach - City .10 - Route 10,11 - West Preston - City .11 - Route 15, 16 - St Kilda Beach - City .12 - Route 15, 22 - Moreland - City .13 - Route 18, 19, 20 - North Coburg - City .14 - Route 27, 28 - Hawthorn - Spencer St .15 - Route 42, 44, 45 - Mont Albert - City .16 - Route 48, 40, 41 - North Balwyn - Spencer St .17 - Route 49 - Essendon (Matthews Ave) - City .18 - Route 50, 54, 57, 58, 60 - West Maribyrnong - City .19 - Route 55, 56 - West Coburg - City .20 - Route 59 - Essendon Aerodrome - City .21 - Route 61, 62, 64, 65 - East Brighton - City .22 - Route 69 - Kew Cotham Road - St Kilda Beach .23 - Route 70, 71, 76 - Wattle Park - City .24 - Route 74, 75, 76 - Burwood - City .25 - Route 77, 80 - Prahran - City .26 - Route 78, 79 - North Richmond - Prahran .27 - Route 82 - Moonee Ponds - Footscray .28 - Williamstown Road - Footscray - Tram and bus .29 - Ballarat Road - Footscray - Tram and bus .30 - Russell St - - Footscray - Tram and bus .31 - East Brunswick - City .32 - Domain Road - City .33 - West Heidelberg - City .34 - Sunshine - City via Ballarat and Footscray Roads .35 - Sunshine - City via South and Dynon Roads .36 - Sunshine Park - City .37 - Garden City - City (Victoria St) .38 - Queens Bridge - Fisherman's Bend via Ingles St .39 - Queens Bridge - Fisherman's Bend via Lorimer St and Princes Bridge - Fisherman's Bend via Williamstown Rd.All have the route number in ink on the front cover - see image 5691i.jpg for standard cover.trams, tramways, mmtb, timetables, melbourne, fares, route 1, route 22, route 4, route 4a, route 4b, route 4d, route 14, route 5, route 5a, route 6, route 6a, route 6b, route 7, route 7a, route 7b, route 7d, route 8, route 8a, route 9, route 9a, route 9b, route 10, route 11, route 12, route 15, route 16, route 22, route 18, route 19, route 20, route 27, route 28, route 42, route 45, route 44, route 48, route 40, route 41, route 49, route 50, route 54, route 57, route 58, route 60, route 52, route 56, route 59, route 61, route 62, route 64, route 65, route 69, route 70, route 71, route 76, route 74, route 75, route 76, route 77, route 80, route 78, route 79, route 82, williamstown rd, ballarat rd, russell st, route 96, domain rd, west heidelberg, sunshine, garden city, queens bridge, fishermen's bend -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageFurniture - Shelves, A. Englander & Searle, Late 19th Century (1898)