Showing 1321 items

matching after the fires

-

Warrnambool and District Historical Society Inc.

Warrnambool and District Historical Society Inc.Artefact, China Plate, 1922 (painting)

... of the interior of St. John’s Presbyterian Church in Warrnambool after... in Warrnambool after it was destroyed by fire in 1920. John Forrester ...This plate was painted by J.J. Forrester in 1922. John James Forrester, the son of John Lamb Forrester and Maria Hexter, was an architect in Warrnambool in the early 20th century. He had an office in Kepler Street (1910) and in Koroit Street (1916). He lived in the house in Liebig Street that was formerly the first Savings Bank and was erected in 1860 (7A Liebig Street today). Forrester was a staunch member of the Presbyterian Church and was the co-architect for the re-building of the interior of St. John’s Presbyterian Church in Warrnambool after it was destroyed by fire in 1920. John Forrester was also a noted artist of his time and several of his works of art have survived. A landscape by him is in the possession of the Warrnambool and District Historical Society. This plate is one of two painted by Forrester that survive today.This plate, although damaged, is of interest because it was painted by John James Forrester, a Warrnambool artist from the early 20th century. This is a china plate showing a seascape painted by John James Forrester in 1922. It depicts a coastal scene of rocks, birds and sailing boats. The colours are in mauve/brown/ white tonings and are slightly opalescent. The plate has brown/grey handles with one broken and repaired. The plate is oval-shaped with a slight dip and a stand at the base. Front of plate: ‘J.J.F.’ On base: ‘J.J. Forrester 1922’ john james forrester, history of art in warrnamool, history of architecture in warrnambool, history of warrnambool, china painting -

Wooragee Landcare Group

Wooragee Landcare GroupPhotograph, 28th April 2004

... National Park and had survived after a bush fire in 2003 had burned... National Park and had survived after a bush fire in 2003 had burned ...This photograph was taken at Wooragee Hall on Wednesday the 28th of April 2004 called 'Queries about Quolls' and shows a Quoll Presentation by Andrew Murray at Mt Pilot, Chiltern Mt Pilot National Park. The photograph shows (L - R) Jerry Alexander, Unknown, Unknown, Mary Prowse, Tony Prowse. The event was hosted by the Wooragee Landcare Group and was led by Andrew Murray (of Parks Victoria), President of the South-East Forest Spotted-tailed Quoll Working Group and one of Victoria's leading authorities in quolls. As the name of the event would suggest, this session provided attendees with insight and general information on quolls, including the characteristics of quolls, the habitat of quolls and the techniques that can be used when searching for quolls which was part of a wider project aimed at protecting the endangered species of the tiger quoll, also known as the spotted-tailed quoll, an animal that once inhabited Mount Pilot-Chiltern National Park. This particular photo shows a group of attendees looking at a typical quoll nesting site in a rock crevice. According to an article included in the Wooragee Landcare group coordinators annual report 2004 and 2005 album (record 00001), Andrew Murray had been tasked to train a team of Department of Sustainability and Environment staff and volunteers from the local area (Beechworth and Wooragee) in the detection skills needed to establish whether the tiger quoll still inhabited the Mount Pilot-Chiltern National Park and had survived after a bush fire in 2003 had burned through the area where they would normally have been found. The Tiger Quoll is the largest of the quoll species. Largely resembling a cross between a possum and a cat, the quoll is distinctive due to the white spots that are often found all over its brown fur.This photograph is significant as it provides evidence of a project undertaken by the Wooragee Landcare Group to educate themselves and members of the public on the tiger quoll in the early 2000s in an attempt to better understand and protect the species. The Wooragee Landcare Group has been instrumental in the co-ordination of programs relating to biodiversity protection in the local area, providing great assistance to landholders.Landscape coloured photograph printed on gloss paperReverse: WAN NA 0ANA2N0 AN2 0 1636 / [PRINTED] (No.4) / 918wooragee, wooragee hall, wooragee landcare, wooragee landcare group, quoll, spotted-tailed quoll, tiger quoll, queries about quolls, south east forest spotted-tailed quoll working group, andrew murray quolls, mount pilot chiltern national park, quoll species, endangered quoll, andrew murray, beechworth, landcare group, mount pilot -

Kew Historical Society Inc

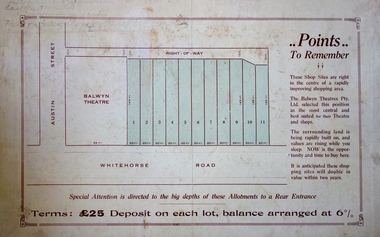

Kew Historical Society IncPlan - Subdivision Plan, Balwyn Theatre and Shop Sites, circa 1927-28, c.1927-28

... , this first Balwyn Theatre was destroyed by fire after a break... Theatre was destroyed by fire after a break-in. Following the fire ...The Kew Historical Society's map collection includes a substantial number of real estate subdivision plans, mainly of Kew but also of surrounding suburbs in Melbourne. Most of the subdivision plans date from the 1920s and 1930s when the districts old homes and local farmland were being split up to accommodate residential growth in the postwar period. These early plans were assembled by a local firm, Jas R Mather & McMillan, which had an office in Cotham Road. Many of the plans, and sometimes photos, were annotated by the agents. The ‘new’ Balwyn Picture Theatre was built and owned by Balwyn Theatres Pty Ltd in ca. 1928. By 1930, this first Balwyn Theatre was destroyed by fire after a break-in. Following the fire, a new cinema was constructed. This plan for a Cinema and eleven shops presumably dates from 1927/28 when the Company announced that this location in Whitehorse Road ‘was the most central and best suited [area] for their Theatre and shops’.Subdivision plans are historically important documents used as evidence for the growth of suburbs in Australia. They frequently provide information about when the land was sold as well as evidence relating to surveyors and real estate and financial agents. The numerous subdivision plans in the Kew Historical Society's collection represent working documents, ranging from the initial sketches made in planning a subdivision to printed plans on which auctioneers or agents listed the prices for which individual lots were sold. In a number of cases, the reverse of a subdivision plan in the collection includes a photograph of a house that was also for sale by the agent. These photographs provide significant heritage information relating house design and decoration, fencing and household gardens.The photograph may also be aesthetically significant depending on the importance of the photographic atelier.Subdivision plan showing the Balwyn Theatre and its adjoining shop sites in Whitehorse Road Balwyn. The 11 shop sites were noted for their depth (133 ft - 145 ft. [Map.0041]balwyn theatre -- balwyn (vic.), subdivisions -- balwyn (vic), subdivision plans -

Warrnambool and District Historical Society Inc.

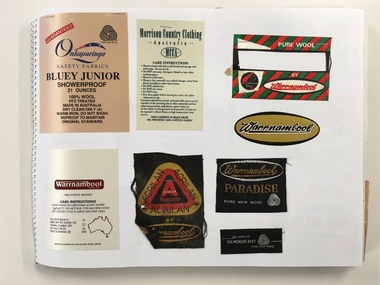

Warrnambool and District Historical Society Inc.Booklet, Scrap Book Warrnambool Woollen Mill, Late 20th century

... to the directors of the Warrnambool Woolen Mill Company. After being... to the directors of the Warrnambool Woolen Mill Company. After being ...In 1869, the Warrnambool Meat Preserving Company commenced their business on the site, where it operated until 1875 when it was sold to the directors of the Warrnambool Woolen Mill Company. After being destroyed by fire in 1882 it wasn’t until 1910 that the Warrnambool Chamber of Commerce was approached by Marcus Saltau and Peter McGennan to invest in a new mill. The original directors were James Dickson, P J McGennan, Robert Swinton, M Saltau, and J W Younger. In 1955 the Warrnambool Woollen Mill formed a partnership with the Wangaratta Woollen Mills. Dunlop bought the mill in 1968. From that time until its closure in 2000 it had a number of different owners, the last being the Smith Family Industries.This book contains a large number of labels some of which would have been sewn to the corner of the many blankets which were manufactured over the long history of the Woollen Mill.Some are cloth of a satin type. Some state care instructions and some have been made under other name brands such as Myer, Patersons and Nile. There is also a range of types of blankets such as travel and picnic rugs, baby blankets.Some are pure wool, others are a blend of synthetic and wool, mohair. In the latter stages of its operation, under the ownership of the Smith family , recycled woollen product was produced.This is an interesting collection of labels which were produced and collected over a long period of time and therefore provide a valuable insight into different styles and variety of the blankets produced by the Warrnambool Woollen mill which played a large part in the social and employment history of the city for nearly all of the 20th century. The different styles and colours provide a snapshot of design and artistic styles of the period. Large Spirax folder with yellow and white check patterned cover with dark blue writing.A Warrnambool label in gold,black and white is glued to front cover . Back cover is grey heavier card. The white pages have a large number of labels which relate to the Warrnambool Woollen Mill . Some are stapled and others are glued.Genuine drawing cartridge 48 sheets . Made in Indonesia.warrnambool, warrnambool woollenmill,warrnambool blankets warrnambool blankets labels, -

Eltham District Historical Society Inc

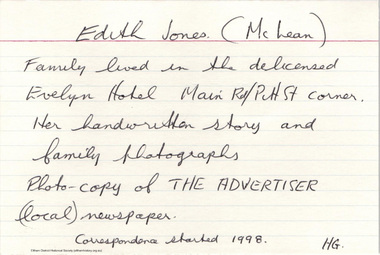

Eltham District Historical Society IncDocument - Folder, McLean, 1984-1999

... thinking they had survived. Two days after the fire Hector Mclean... thinking they had survived. Two days after the fire Hector Mclean ...References to McLean family, Hector John McLean and Louisa Frances (nee Green) and six daughters who lived in Eltham during the period 1930 to 1934 inclusive. Lived in the former Evelyn Hotel at the time it was destroyed by fire and being part of the Centenary Parade in 1934 where the family won the Group Section for their entry “Pioneers of Eltham” Reminiscences provided by Edith Jones (nee M1934 flood, ballroom, baptism, barber shop, bittern, boy scouts, bremner's flat, burgoyne's shop, cable tram, cemetery road, centenary celebrations, centenary parade, christening, coach house, collis grocery, dalton street, depression, dole, dorothy jean mclean, edith jones (nee mclean), eltham fire brigade, eltham high school, eltham higher elementary school, eltham lower park, eltham railway station, eltham state school no. 209, evelyn hotel, fire damage - buildings, flinders naval depot, fordham, gladys evelyn mclean, gold mining, gwenneth mae mclean, gwladys evelyn mclean, headmistress, hector john mclean, isherwood house and shop, louisa frances mclean (nee green), metery road, methodist church, miss finnin, miss grant cottage, motor bike races, mrs barrett, mrs bremner, mrs hurley, olive isabel mclean, parade, phoebe lillian mclean, picnic, pioneers of eltham, pitt street, research fire brigade, rev. r.g. arthur, shed, shops, st margarets church hall, st margaret's church, stables, state savings bank of victoria, susso books, todaro, vinnie willet, warrandyte bridge, warrandyte, wingrove park, yarra river -

Forests Commission Retired Personnel Association (FCRPA)

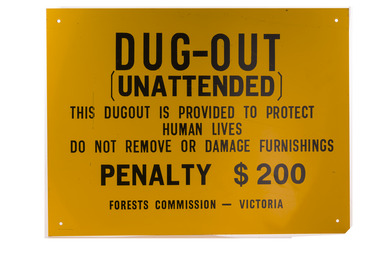

Forests Commission Retired Personnel Association (FCRPA)Dugout sign, Post 1966

... that remained in the forest after the 1939 fires. Many remote logging... that remained in the forest after the 1939 fires. Many remote logging ...Considered in terms of both loss of property and loss of life, the Black Friday bushfires on 13 January 1939 were one of the worst disasters to have occurred in Australia and certainly the worst bushfire up to that time. The fires burnt 2 million hectares, 69 sawmills were destroyed, 71 people died, and several towns and sawmills were entirely obliterated. Among those killed were four men from the Commission The subsequent Royal Commission conducted by Judge Leonard Stretton has been described as one of the most significant inquiries in the history of Victorian public administration. Its recommendations led to sweeping changes. In addition to building dams and water points, the Stretton Royal Commission recommended expanding and controlling the use of bushfire dugouts at forest sawmills. Well-constructed dugouts had saved the lives of many sawmill workers and their families during the 1939 bushfires. But in some locations, they had proved fatal. Dugouts became mandatory for those few sawmills that remained in the forest after the 1939 fires. Many remote logging coupes and FCV roading camps also had dugouts. The local District Forester was required to make annual pre-season inspections of all dugouts on State forests and those within the Fire Protected Area (FPA). Some were built privately on private land. Most were primitive construction with a log or corrugated iron roof covered with earth. A hessian bag often hung at the entrance to keep the heat and smoke out. But they were dark and damp with snakes and other creepy crawlies often lurking inside. By 1940-41 there were 19 new dugouts constructed by the Commission and a further 128 by forest licensees. Ten years later there were 8 new Commission dugouts and 21 new ones built by other interests. By 1960-61 the rate of new builds was declining but the Commission still managed 103 dugouts while 127 were looked after by others. However, as the forest road network improved and gave all-weather access to modern two-wheel-drive vehicles the reliance on dugouts receded.Large metal sign that was positioned near forest dugoutsbushfire, forest signs, forests commission victoria (fcv) -

Eltham District Historical Society Inc

Eltham District Historical Society IncDocument - Folder, Pugh, Clifton

... of buildings Phoenix I and Phoenix II after the 2001 bush fire... of buildings Phoenix I and Phoenix II after the 2001 bush fire ...The artist, Clifton Pugh, grew up in Briar Hill. He served in WWII and settled at Cottles Bridge, building his own house and forming Dunmoochin artist colony. He married three times and had two sons. He painted the portraits of many eminent people. Contents Newspaper article: "This is the house that Cliff built", The Age, 2 May 1964. Description of Clifton and Marlene Pugh's house.. Folder: Brief biography Clifton Pugh. Photocopy section of "Clifton Pugh: Patterns of a lifetime", Traudi Allen, Nelson, Melbourne 1981. Magazine article: "Clifton Pugh: His home is a work of art", Woman's Day, 16 January 1894. Describes Clifton Pugh's house at Hurstbridge. Newspaper article: "A guide to our orchids", Diamond Valley News, 14 February 1984. Clifton Pugh contributed to the book "A Year of Orchids". Newspaper article: "A family tradition is continued". Diamond Valley News, 28 February 1984. Clifton Pugh's childhood and career. Magazine article: "Clifton Pugh's bush paradise", Home Beautiful, May 1989. Clifton Pugh's house and studio. Clipping: "Clifton Pugh award winning artist". Clifton Pugh currently working on illustrations for a book, with Pam Blashki, on wood chipping ["A Kingdom Lost: A Story of the Devastation of Our Wilderness", published 1989]. Newspaper article: "Funeral drama shows the Pugh touch", The Age, 19 October 1990. Clifton Pugh's funeral at Montsalvat. Newspaper article: "Friends bid farewell to Pugh". Herald-Sun, 19 October 1990. Clifton Pugh's funeral at Montsalvat. Newspaper article: "Friends paint a lowing portrait". Herald-Sun, 19 October 1990. Funeral and obituary of Clifton Pugh. Newspaper article: "Montsalvat mourns passing of a great". Diamond Valley News, 23 October 1990. Clifton Pugh's funeral at Montsalvat. Newspaper article: "Loner who was a fair dinkum mate". Diamond Valley News, 23 October 1990. Obituary of Clifton Pugh. Newspaper article: "Pugh's last works", Tempo, The Age, 17 July 1991. Clifton Pugh was illustrating Helen Lunn's book 'The Digger's Mate' when he died. Newspaper article: "Dunmoochin's rich tradition to live on", Diamond Valley News, 29 October 1993. Dunmoochin Foundation Board to advertise lease of studios. Newspaper article: "Clean up for Cliff", Herald Sun, 8 December 1993. Preparation for exhibition of Clifton Pugh's work at LaTrobe University Art Museum. Flier: Exhibition "Clifton Pugh: A Retrospective", Montsalvat, 12 to 14 November 1999. Newsletter: "Dunmoochin: an edited version of the history prepared for the Heritage Study by David Bick", Eltham District Historical Society newsletter 140, September 2001 Newspaper article: "Hail rising of Phoenix", Diamond Valley Leader, 20 July 2005. Dunmoochin Foundation and official opening of buildings Phoenix I and Phoenix II after the 2001 bush fire. Newspaper article: "Legacy to the arts", Diamond Valley Leader, 10 August 2005. Dunmoochin Foundation and the rebuilding after the 2001 bush fire. Newspaper article: "Tiwi art to go on show", ?publication, ?2002. Shane Pugh, Johnny Young and Ian McKimmie organising exhibition of Tiwi art to mark 100th birthday of Strathewen hall. Flier: Exhibition "Clifton Pugh AO: Reflections of Dunmoochin". Briar Hill Primary School, 23 to 25 November 2007. Printout: "Dunmoochin", http://www.standrews.vic.edu.au/dunmoochin.html. 19 May 2004. Newspaper article: "Hail rising of Phoenix", Diamond Valley Leader, 20 July 2005. Rebuilding at Dunmoochin after bushfire. Newspaper article: "Legacy to the arts", Diamond Valley Leader, 10 August 2005. Rebuilding at Dunmoochin after bushfire. Newspaper article: "Artist's legacy on show". Dunmoochin one of four Cottles Bridge sites for a tour by Trust for Nature, 2 and 3 October no year. Newspaper clippings, A4 photocopies, etcclifton pugh, hurstbridge, adriane strampp, princess michael of kent, arthur boyd, john brack, charles blackman, fred williams, shane pugh, marlene pugh, professor jock marshall, briar hill victoria, cottles bridge victoria, turner family of briar hill, yandell family of briar hill, st helena church, st helena road, briar hill primary school, eltham high school, dunmoochin, campbell beardsell, david beardsell, ivanhoe boys grammar school, national gallery art school, hurstbridge grevillea, montsalvat, george dreyfus, kew city band, justus jorgensen, sir edward "weary" dunlop, prue acton, john howley, fay dunmore singers, derryn hinch, jeff kennett, tom uren, dennis gowing, matcham skipper, kyra skipper, gordon ford, hilary jackman, peter graham, robert marshall, john greaves, jenni mitchell, rodney roschollor, gough whitlam, sir john kerr, lionel murphy, manning clark, arts policy committee of victorian branch of the australian labor party, latrobe's art museum, rudy komon gallery, leonard french, jon molvig, rick armor, john olsen, latrobe university, donovan pugh, trevor welshman, australia council visual arts board, lesley alway, dailan pugh, paul barnett, helen nixon, helen lunn, a year of orchids book, campbell bearsdell, david bearsdell, johnny young, ian mckimmie, tiwi art, strathewen hall, rhonda noble, latrobe university art museum, traudi allen, clifton pugh patterns of a lifetime book, trust for nature, randall robinson -

Ballarat Heritage Services

Ballarat Heritage ServicesPhotograph - Photograph - Colour, Clare Gervasoni, Nimon's Bridge, 1999, 04/10/1999

... was rebuilt after the 1953 fire, the timber beams were replaced... was rebuilt after the 1953 fire, the timber beams were replaced ...Nimons Bridge was built in 1890, as part of the then Ballarat-Linton railway. The bridge is 17 spans with tall timber piers of four driven piles each, with triple sets of diagonal cross-bracing and walers and a single row of longitudinal horizontal bracing between piers. The spans are of a uniform twenty feet (6.1 metres), originally supported by four 21-inch x 9-inch (535 mm x 230 mm) Kauri timber beams per span, following the standard V.R. design of the period. When the superstructure was rebuilt after the 1953 fire, the timber beams were replaced with two 24-inch (610mm) deep rolled-steel-joists on each span. These are marked 'Lancashire Steel Co., Scotland' and are believed to have been second-hand. The deck of transverse-timber planks is 103.6 metres in length. Overall the bridge has an impressive appearance with its exceptionally tall triple-cross-braced piers creating a 'three-tiered' effect, with the deck 19.2 metres above the Woady Yaloak River. The Ballarat-Skipton line closed in 1985. Nimons Bridge has been recently restored, as part of the Ballarat-Skipton Rail Trail. How is it significant? Nimons Bridge is significant for technical, historic and aesthetic reasons at a State level. Why is it significant? Nimons Bridge is technically significant as Victoria's fourth-tallest timber trestle bridge when built, and as the third-tallest surviving example. It is also the second-largest composite bridge combining traditional timber piers with RSJ spans and a timber deck and falls within a select group of fewer than ten timber railway bridges with horizontal longitudinal bracing between the piers and three sets of double cross-bracing on its tallest piers, creating a visually striking 'three tiered' effect that enhances its viaduct form. Nimons Bridge is historically significant as having served initially the mining community at Linton, then the Western District agricultural area and in later years a kaolin quarry at Pittong. Nimons Bridge is historically significant as a representative of the 'light' branch line methodology that stimulated the explosion of railway construction in Victoria during the 1880s, and provides an interesting contrast with the more solid and vastly more expensive railway viaducts built in similar terrain on Victorian main lines, at Moorabool and Taradale, in the late 1850s. Approached by a deep cutting and high embankment at either end, the bridge represents a very cost-effective late 19th century engineering solution to the characteristic physiography of western Victoria with flat basalt plains intersected by deep wide valleys occasionally subject to severe flooding. Nimons Bridge is aesthetically significant for its visually impressive viaduct form, crossing a deep and steep-sided valley that is part of a rich cultural landscape. Within close proximity of the bridge are mullock dumps, tailings, shaft sites and other relics of the deep-lead alluvial mining era. The bridge is the most visually spectacular timber-trestle rail bridge in Western Victoria and is among the most spectacular timber-trestle rail bridges surviving anywhere in Victoria. It is part of the Ballarat-Skipton Rail Trail. Classified by the National Trust :02/10/2000 (http://vhd.heritagecouncil.vic.gov.au/places/67986)Colour photograph of a log bridge known as Nimon's Bridge.ballarat-linton, nimons bridge, nimon's bridge, log bridge, viaduct, timber-trestle rail bridge -

Stawell Historical Society Inc

Stawell Historical Society IncPhotograph, Whitehall Property Greens Creek

... lived in while house was rebuilt after fire 15 Jan 1877 20... in while house was rebuilt after fire 15 Jan 1877 20. Whitehall c ...Hutchings family 1. Wimmera River in flood below Whitehall running a banker c. 1920. Ted & Col Hutchings in foreground. 2. Wimmera River in flood looking downstream. No date but possibly same time as no. 1. from same place. 3. Looking over the Wimmera River to Island paddock towards Greens Creek 4. Wimmera River half a banker at Whitehall 5. Wimmera River in flood upstream from carpenter's shop looking towards engine house at Whitehall 5a. Wimmera River in flood. Left to right - blacksmith shop and carpenters' shop. 5b. Taken from the same spot with Emily & Ada Hole, E G (Ted) & Col Hutchings. Blacksmith shop & carpenters' shop, Whitehall. 5c. Wimmera River upstream from the carpenters' shop. Foreground is possibly Belladonna lilies which were all over the river bank in 1992. Whitehall. 5d. Looking downstream towards the loose boxes, Whitehall. 5e. Blacksmiths' shop and carpenters' shop from the pumping station. Wimmera River, Whitehall. 6. Wimmera River in flood at Whitehall. 7. Wimmera River half a banker in front of old hut at Whitehall. 8. Wimmera River Emily Hayes, Edward G (Ted) Hutchings & Colin J Hutchings. 9. Morrl-Morrl - Greens Creek Road opposite back paddock. Whitehall. Black Ford in distance. c. 1919 10. Whitehall woolshed north east aspect, Drive to the right of photo 11. Whitehall woolshed - north east aspect showing the drive to the right 11a. Whitehall woolshed - north aspect 11b. Same tree near woolshed 11c. Same tree again in centre, other trees came up after the 23 flood. Woolshed to the right out of photo. 12. Whitehall woolshed - south aspect, sheep entrance end 13. Whitehall. left to right, Stackyard, stables in the centre and the Wimmera River behind following the trees. 14. Whitehall horse paddock c. 1920. left to right, Machinery shed, stable in the centre. Homestead to the right in distance. There is no windmill. 15. Load of wool from Whitehall woolshed to right. 16. Whitehall c. 1920 before the windmill. left to right, garage and mens' hut. Wimmera river runs along the tree line. 16a. Stables, garage and mens' hut after the construction of the windmill. River behind. 17. Whitehall c. 1922. Note windmill addition. Garage to left, Mens' Hut to right. Jack Donnelly & Edward G (Ted) Hutchings with pet lambs. River behind trees. 18. Whitehall gardens. Summer house to the right, pine tree lined drive in the centre background. Ted & Col Hutchings on the lawn. C. 1920 19. Edward G. (Ted) & Colin J. Hutchings in Whitehall garden. Wimmera River in the background. The building behind the fence is the carpenters' shop which the family lived in while house was rebuilt after fire 15 Jan 1877 20. Whitehall c. 1920. left to right, cattle yard, killing house, Wimmera river behind the fence, and the loose box on the right. Black Orpington chooks in foreground. 21. Bay window (original blinds) in the master bedroom. Whitehall 20 Sep 1992 22. Master bedroom (original wallpaper) Joyce & Col Hutchings, Moyu, Ben & Rebecca Roe 20 Sep 1992 23. Col & Ted's bedroom (original) Marble mantlepiece had been removed. Whitehall. 20 Sep 1992 24. Whitehall kitchen. Large yellow meat oven to left of stove, bread oven far left, extreme right is oven where milk heated to skim cream. Chimney was a central one shared with meat oven. Bread oven chimney separate. 20 Sep 1992 25. Whitehall dairy, made of natural stone with dried brick corners. Entrance behind creeper which is over trellis. 20 Sep 1992. This building still remains in 1 Jun 2023 26. Inside charcoal lined meat cellar. Bottom right is concrete vat for pickling meat in brine. Top of brickwork slightly above ground level. Whitehall 20 Sep 1992 27. Fire foreground was stable flooring which was to left of photo. Machinery shed (thatch roof). 4 posts far left remains of cowshed. Large post in centre foreground is the gate post of corral. River to right. 20 Sep 1992 28. Whitehall machinery shed. Posts on far right are cow shed. Over the river is the island paddock. Wimmera river runs behind machinery shed. 20 Sep 1992 29. Posts of 10 sided corral. Killing house by side of gum tree in centre of photo on far side of corral. To left is one of the bales of the cowshed. Whitehall. 20 Sep 1992 29a. Similar photo in the 1920's. To the right is horsebreaking corral, then cow shed, loose box, haystacks and stable on left. Whitehall. 30. Dining room fire place put in the open fire of the mens' hut, only the chimney remains. To the left is the drive & river. Rebecca Roe, Col Hutchings granddaughter. 20 Sep 1992 30a. Looking down the Whitehall Drive. Mens' Hut (Jack Donnelly in doorway) and garage far left. 1920's 30b. The Drive, Whitehall taken from in front of the mens' hut. Wimmera River on the left. Gum tree on left still there 20 Sep 1992. 30c. Reverse from 30a. Whitehall drive from the front gate looking towards the mens' hut and garage. c. 1926 30d. Curly Donohue leaving for Warracknabeal. Ex mail contractor Omeo to Bright Victoria. C. 1926 30e. Looking down the drive towards front gate. Mens' hut on the right, river on the left. 31. Whitehall from the side. Building in centre behind David is separater room. 2 roomed hut to left of separater room and remains of mens' hut chimney. Photo 16 taken from similar spot. 20 Sep 1992 32. Benjamin Roe (Col Hutchings grandson) in the Carpenters' shop. The family lived in this building after the fire in the 1870's. Whitehall 20 Sep 1992 33. Ford across the Wimmera River at Whitehall (River abt. 5 feet higher than normal) 20 Sep 1992 33a. Wimmera River, Whitehall 34. Site of old bridge before Col Hutchings time. Tree in foreground to right still has bolt from bridge work protuding. A large post was in the centre of photo to make equal distance. 20 Sep 1992 35. Entrance to the old ford. Colin J Hutchings & his daughter, Moyu Roe. Wimmera River, Whitehall 20 Sep 1992 36. Summer house at Whitehall 20 Sep 1992 looking down to the orchard, dark green trees in distance old fruit trees. 36a. Edward & Colin Hutchings in front of the Summer house, Whitehall c. 1921 36b. Summer house looking towards front gate. Whitehall. 36c. Grey thrush in nest box which can be seen in previous photo with summer house in the background. Whitehall. 36d. Summer house from the orchard side. Whitehall. 37a. South side of Whitehall. First window Edith Sutherland's room, 2nd window, Ted & Col's room, bay window master bedroom 38. Taken in middle of front path looking towards front gate. Edith Sutherland in garden. Date palm in centre, cotton palm to left. Whitehall c. 1920's 38a. Garden at Whitehall taken from near the cotton palm. 39. Whitehall 20 Sep 1992 Bay window-master bed, small window to r. of bay-Colin Hutchings born in, front door, window to right-dining room, round the corner- drawing room, window on right, spare bed, verandah on left is spare bed. 39a. Whitehall c. 1920's Date palm on the right. 39b. Win, Colin T & Colin J Hutchings. Date palm in background. Whitehall 1943 39c. Edward George, Colin Thomas, Elizabeth Ambler & Colin James Hutchings wearing RAAF uniform. Date Palm in background. Whitehall c. 1943 39c. Front garden of Whitehall looking from the front right side of the house towards the drive & Wimmera River. Date palm on right, cotton palm on left 20 Sep 1992 40. Taken from bottom left corner of front garden looking towards the summer house. Cotton palm on right. River to the left. 41. Elizabeth A Hutchings beside master bedroom window. Whitehall c. 1920 42. Whitehall (photo of a painting by Wallace) owned by Colin T Hutchings 1982. 42a. Whitehall painting by Wallace after restoration now owned by Nick Hutchings 2021 42b. Whitehall c. 1923 42c. Taken from the side garden looking towards the right side of house. Front door is to the left out of photo. The cotton palm is to the left. c. 1923 43. Signpost showing Whitehall 20 Sep 1992, All ground up to the tree line behind the signpost was Whitehall property. 44. Colin T. Hutchings age 9 mths. Mar 1943 Whitehall 45. Colin James, Elizabeth Ambler & Edward George Hutchings. Front garden by the date palm, Whitehall c. 1939-40 45a. Colin James, Edward George, Edward Thomas Hutchings & E. Winifred May & Barney (dog) Whitehall. c. 1939-40. 45b. Colin James & Colin Thomas Hutchings during drought & World War ll c. 1944-45 in front of cotton palm, date palm to right. 46. Garden at Whitehall. Jack Donnelly on the hand mower. Cotton palm on left, date palm behind Jack and roof of carpenters shop to right. 47. Colin J Hutchings on tractor, E. Tom Hutchings behind. Whitehall, c. 1933 48. Jack Donnelly (Tad) & Colin J. Hutchings. Cotton palm to right. Whitehall c. 1917-18 49. Edward G (Ted) & Colin J Hutchings with cockatoo outside the dairy in rear garden. Whitehall c. 1923 50. Taken from the windmill looking across the roof of the mens' hut to the garden, orchard and drive in Winter time. House is behind the trees to right, Wimmera River to the left out of picture. Whitehall. 50a. Not labelled by Col Hutchings. It is an aerial shot looking towards the house in the trees & seems to be taken from the top of a tree...on the river side. 51. E. Tom Hutchings & George Chambers dam sinking. Whitehall. 51a. Tom Hutchings & George Chambers dam sinking. Whitehall. 51b. E. Tom Hutchings dam sinking. 52. Emily Hayes & Ada Hole (sisters) with Tom, Col & Ted Hutchings at the woolshed. 53. E T (Tom) Hutchings on reaper & binder. Whitehall. 54. Orchard looking towards the house. Carpenters' shop and river on the right. Whitehall. 54a. Orchard looking from the house, dark trees in background form part of the drive. 55. Grasshopper plague, Christmas Day 1933. Whitehall 56. Frost on the front lawn, Whitehall. 57. Little red hen & chicks with the river in the background 58. Edward (Ted) G. Hutchings muscovy ducks, hay shed and trees along the river in the background. 58a. Edward (Ted) G Hutchings muscovy ducks. 59. Swimming in the Wimmera River, either Ted or Col Hutchings in the foreground. 60. Looking towards the fowl house and pigsty, Whitehall. 61. Snake on the path, Whitehall. c. 1923 61a. E. Tom Hutchings killing a snake, Whitehall. c. 1923 61b. E. Tom Hutchings killing a snake, Whitehall. c. 1923 62. Notice of clearing sale, Stawell News & Pleasant Creek Chronicle on 5 Apr 1916 where the stock & whole of the household furniture was to be sold by James Hutchings widow. 63. Back to Greens Creek 7 Jun 1987 Colin J Hutchings left and Belle Kindred centre looking at photo 64. Back to Greens Creek 7 Jun 1987 Colin J Hutchings centre, Graham Stewart holding photograph on the right. 65. Colin J Hutchings & Bill Walker. Back to Greens Creek 7 Jun 1987 66. Colin J Hutchings delivering a speech before the plaque unveiling. Back to Greens Creek 7 Jun 1987 67. Graeme Williamson & Colin J Hutchings (2 'old boys') Greens Creek School Site 7 Jun 1987 68. Graeme Williamson talking to Moyu Roe (Hutchings) in background is May Williamson. Back to Greens Creek 7 Jun 1987 69. Greens Creek SS, Edward (Ted) & Colin J Hutchings attended. 70. Original students of first Greens Creek School 7 Jun 1987 Back row left 1. Kindred 3. Colin J Hutchings 4,5,6 not known 7. Graeme Williamson Sitting left 1. Not an original 2,3,4, not known 5. Belle Kindred 71. Terrier at Greens Creek State School 72. The new school students Back to Greens Creek 7 Jun 1987. Perry twins standing in centre and the teacher kneeling front left. 73. Will Rees water colour 1925 signature 74. Will Rees water colour 1925 75. Shearing at Kirkellar. Allen Simpson's 76. Back to Greens Creek 7 Jun 1987 Colin J Hutchings left and Belle Kindred centre looking at photo 77. Back to Greens Creek 7 Jun 1987 Colin J Hutchings centre, Graham Stewart holding photograph on the right. 78. Colin J Hutchings & Bill Walker. Back to Greens Creek 7 Jun 1987 79. Colin J Hutchings delivering a speech before the plaque unveiling. Back to Greens Creek 7 Jun 1987 80. Graeme Williamson & Colin J Hutchings (2 'old boys') Greens Creek School Site 7 Jun 1987 81. Graeme Williamson talking to Moyu Roe (Hutchings) in background is May Williamson. Back to Greens Creek 7 Jun 1987 82. Greens Creek SS, Edward (Ted) & Colin J Hutchings attended. 83. Original students of first Greens Creek School 7 Jun 1987 Back row left 1. Kindred 3. Colin J Hutchings 4,5,6 not known 7. Graeme Williamson Sitting left 1. Not an original 2,3,4, not known 5. Belle Kindred 84. Shearing at Kirkellar. Allen Simpson's 85. Terrier at Greens Creek State School 86. The new school students Back to Greens Creek 7 Jun 1987. Perry twins standing in centre and the teacher kneeling front left. Digital Copy of Parish Maps Kara Karahomestead -

Eltham District Historical Society Inc

Eltham District Historical Society IncNewspaper - News Clipping, Herald, The big Eltham clean-up gets under way, Herald, 4 March, p3, 1965

... hours after the fire started it raced suddenly down a gully... hours after the fire started it raced suddenly down a gully ...Full page newspaper clipping featuring the March 1965 Victorian bushfires. Items include: Photograph - TWO-WOMAN BUCKET BRIGADE, Mrs Henry Marsden (left) and Mrs Moureen Ellis, whose fire-fighting efforts yesterday were highly praised today by their Eltham neighbours, carry out mopping-up operations Photograph - DOGS MADE HOMELESS by the fire in North Eltham yesterday are being cared for at First-Constable Doug. Mummery's kennels at Eltham and here is kennel maid Helen Oliver, 17, with some of them today. The two basset hounds are owned by Mr Bill Guy who lost about 100 daschund and basset hound puppies and dogs in the fire. Photograph - He died at Eltham [Picture of John Lawrence Coleman] Builder Mr John Lawrence Coleman, 31, of Main Rd., Eltham, one of three men burnt to death yesterday in the fire at North Eltham. The other two were XXXXX, 33 who lives opposite the Colemans and Mr William Elwers, 64 of Batman Rd., Eltham. John Lawrence Coleman (1934-1965) born January 10, was the son of Raymond John Coleman and Hanna May (Gillet) Coleman. He married Margaret Frances Dare in 1955 and was the father of two children. He died whilst attempting to rescue an older man trapped in the bushfire at North Eltham on March 3, 1965 Other news stories of the day: Bushfires rage in Victoria, Snowy: Three dead (1965, March 4). The Canberra Times (ACT : 1926 - 1995), p. 1. Retrieved May 19, 2022, from http://nla.gov.au/nla.news-article131758981 Includes two photos of the fire in North Eltham “Firemen make for safety as fire rages in Upper Glen Park Road, North Eltham, Victoria. The smoke hides a house.” and “A house explodes into flames at North Eltham, Victoria. Firemen said bottled gas went up.” Canberra Times (ACT : 1926 - 1995), Thursday 4 March 1965, page 1 ________________________________________ Firemen make for safety as fire rages in Upper Glen Park Road. North Eltham. Victoria. The smoke hides a house. A house explodes into flames at North Eltham. Victoria. Firemen said bottled gas went up. Bushfires rage in Victoria, Snowy: Three dead MELBOURNE, Wednesday.—Three people died today in a bush» fire which raged through North Eltham, about 15 miles from Melbourne. The victims were three men. A fourth man is feared to be dead. Another bushfire. sparked off by the heatwave sizzling over south-eastern Australia, is burning out of control in the Kosciusko State Park, in the Snowy Mountains. Firefighters fear that if it reaches pine forests up the Yarrangobilly River, they will be powerless to stop it. The three victims of the North Eltbam fire were trapped by flames in a valley. Their bodies were found only a few yards apart. They were named by police tonight as Mr. George Crowe, 78, of North Eltham, William John Ewers, 64, and John Laurence Coleman, 31, both of Eltham. The other two have not been identified. They are believed to be a man aged about 40 and an 18-year-old youth. At least 12 homes were destroyed by the fire, the worst in Victoria since 1962, when eight lives were lost and hundreds of homes burnt down at Warrandyte. At one time the township of Eltham was threatened, but a cool change swept in from the south and held back the wall of flames. More than 100 dogs, worth about £4,000, died when the fire raced through two kennels in Short Street, Eltham. and Upper Glen Park Road, North Eltham. A trickle of water Residents ran into the streets as the blaze raced towards their houses. Others frantically dug firebreaks around their homes. Mrs. Sue Recourt wept when firemen arrived while she was vainly trying to stop the flames with a trickle of water from the garden hose. A stack of firewood was blazing, but the firemen managed to save the house and rescue four goats. Many homes in Eltham were saved after flames had crept to within feet of their fences. Students at North Eltham State School had to be evacuated when the blaze threatened the building. Fire fighters were severely hampered by lack of water and narrow roads. The blaze, which began in above century heat, turned toward Wattle Glen, where two houses were gutted. Then the flames raced towards Hurstbridge to the north. Firemen battling desperately, controlled the fire late this afternoon. Five forest fires were still burning in Victoria tonight. IN VICTORIA THIS WEEK Tragic lack of central fire authority (1965, March 9). The Canberra Times (ACT : 1926 - 1995), p. 2. Retrieved May 19, 2022, from http://nla.gov.au/nla.news-article131759928 Canberra Times (ACT : 1926 - 1995), Tuesday 9 March 1965, page 2 ________________________________________ IN VICTORIA THIS WEEK Tragic lack of central fire authority From Rohan Rivett It was the worst week for Victorian fire fighters since Black Friday 27 years ago. On that day one pilot up in a spotter plane said afterwards: "It seemed at times that half the State was on fire." This time, for three days on end, Gippsland men, women and children had moments of conviction that their towns would have blackened into anonymity before the weekend was out. The week began with horror at Eltham on the North-eastern edge of Melbourne. Eltham today is something of an artists' colony. Oil painters, water colourists, potters and sculptors proliferate. A number of University folk have emulated the example of Professor MacMahon Ball who pioneered the way by moving to Eltham and carving a home out of the bush in the thirties. Innermost Eltham is barely 14 miles from the G.P.O. Farthest Eltham stretches miles beyond. It served to illustrate the tragi-ludicrous truncation of Victoria's fire control. Part of Eltham is under the protection of the Melbourne Fire Brigade. But this responsibility ceases at some invisible and incomprehensible line — apparently determined by the meanderings of the water mains. At this point everybody's property throughout the rest of Eltham is dependent on the Country Fire Authority. Half an hour before midday on Wednesday, a fire suddenly started on the West side of Upper Glen road on the edge of Eltham. Before the fire brigade could arrive, it was burning on a widening front through timber and high grass north of Eltham. Two wind changes in rapid succession saw the fire leaping Diamond Creek. With a freshening wind it struck home after home in three streets. More than one of them exploded suddenly as if hit by an incendiary bomb. There is no piped gas in the Eltham area, hence many housewives use bottle gas. The flames outside caused the bottles to explode. Altogether twelve homes were completely incinerated and four more were badly damaged. Thirty prize dogs perished. About three hours after the fire started it raced suddenly down a gully hillside trapping an elderly man. Two other men apparently raced to the rescue. Flames caught the three men within yards of each other, not 200 yards off the Upper Glen Park Road where safety lay. They were burned to death. Next evening an angry and convincing secretary of the Fire Brigade Union, Mr. W. M. Webber, came on television and appealed to the people of Victoria to end the ridiculous and dangerous dualism in fire-fighting control. The Eltham fire, he said, had precisely illustrated the situation. The Metropolitan Fire Brigade area touched Eltham, but where the fire had gutted and killed, was just outside its area. Mr. Webber said his union had constantly urged one authority for the State with a complete reorganisation of fire protection. On Wednesday the union had repeated its call for an inquiry into fire protection in Victoria to the Chief Secretary, Mr Rylah. "No matter how close the liaison between the two organisations, there are always divided sections of thinking," Mr. Webber told viewers. "I don't know how much tragedy the com-munity can take before it demands that it is properly protected." Rumours that differences in gauge between taps and hose nozzles (as between the two authorities) accentuated the damage were denied by fire chiefs who said that all appliances were now carrying adaptors so that hoses could be linked to mains everywhere. But there is grave concern in the Metropolitan Fire Brigade's higher councils at the action of several Federal authorities with projects in and around Melbourne. They are installing non-standard equipment without reference to the State authorities or any dovetailing of appliances and equipment. Public alarm was not diminished by the publication on Friday and Saturday of a heart tearing letter from the young widow of John Lawrence Coleman, 31 year old father of two, who had died in the flames apparently trying to rescue the old man trapped in the gully. By that time, a Vast area of Gippsland was in flames and the troops had been sent in to back up the overworked and often helpless fire-fighters. By Saturday, the Leader of the Opposition, Mr. Stoneham, who has previously demanded a Royal Commission into fire-fighting arrangements, repeated his demand. To add to the Chief Secretary's worries he was publicly rebuked for allegedly implying on television that lives had been lost at Eltham because people went to the wrong place at the wrong time. In a letter to the Press, Professor MacMahon Ball pointed out that two of the men involved were experienced bushmen who had gone "to help an old man in great danger fully aware of the danger to themselves". As Victoria faced its sixth day of total State-wide fire ban, it looked likely that even official resistance was not going to silence the demand for one central authority to control the fire fiend. At the moment, the 400 square miles where two million Victorians live in Greater Melbourne are divorced from the rest of the State in planning, communications, equipment and control of personnel. No one doubts the whole-hearted co-operation and willingness to back each other up of the M.F.B. and the C.F.A., both at top-level and among the firemen themselves. However, when a city straggles so deeply into the country side, the absence of a single authority, to oversee and analyse the fire threat as a whole, suggests suicidal policy of divide and fuel. Emphasis of the tragic loss of a member of a pioneering family who died whilst helping others in his communitybushfire, cfa, country fire authority, fire brigrade, glen park road, heroes, john lawrence coleman, north eltham, victorian bushfires - 1965, volunteers, william john elwers, fire fighter, frank martin, george john crowe, ken gaston, orchard avenue, doug mummery, helen oliver, mrs henry marsden, mrs moureen ellis -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, Late 19th or early 20th Century

... to work after the glaze firing. For example – adding precious...! After firing your work will be in the student finished work ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic. Crack on side. Badly stained.Backstamp very faint and unable to be read.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, mixing bowl, food preparation, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl

... to work after the glaze firing. For example – adding precious...! After firing your work will be in the student finished work ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/ This bowl is an example of kitchenware used in the 19th century and still in use today.Bowl white ceramic plain that has two sets of edging around lip. Inside bowl has plaster designed to look like cooking mixture.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Bowl, J & G Meakin, Late 19th or early 20th Century

... to work after the glaze firing. For example – adding precious...! After firing your work will be in the student finished work ...The Process of Making Pottery Decorating, Firing, Glazing, Making, Technical There is a rhythm and flow to clay. It can’t be done all at once! Even the making process! It can take weeks to get everything done, especially if you can only work on your pottery once a week! Even though we have three hour classes, it’s often just not enough time! Here is an overview of some of the processes so you have a bit more grasp on some of the technical stuff! Step One – Design There are SO many ideas out there for making stuff in clay! From delicate porcelain jewellery, through to heavy sculptural work and everything in between. Deciding your direction is sometimes not that easy – when you first start, try everything, you will naturally gravitate to the style that you enjoy! The options and variations are endless and can get a wee bit overwhelming too! Check in with me before you start to ensure your ideas will work, what order you might do things, how you could achieve the look you are seeking and any other technical data required! Step Two – Making Clay is thixotropic. This means that as you work with it, the clay first gets sloppier and wetter, before is begins to dry in the atmosphere. For most things, you simply can’t do all parts of the project at once. An example of work order might look like: Get last weeks work out from the shelves Prepare clay for today’s work – roll your clay, prepare balls for throwing, make the first stage of a pinch pot) Clean up last week’s work and put it on the shelf for bisque firing Check that you have any glazing to do – and do enough of it that you will have time to finish your main project Do the next step of your next project – there might be a further step that can’t be complete immediately, in that case, wrap your work well and put onto the shelves. Letting your work rest for a while can really help keep your work clean and professional looking. Many things require bagging under plastic to keep it ready for work the next week – put your name on the outside of the bag so you can find your work easily. We have stickers and markers. Consider how you want to decorate your work – coloured slip can be applied at a fairly wet stage (remembering that it will make your work even wetter!). Trying to apply slip to dry clay won’t work! If you want to do sgraffito – you will need to keep the work leather hard (a state of dryness where you can still work the clay with a little effort and a little water and care). Step Three – Drying Most of the time your work can go into the rack uncovered to let it dry out for the following week. If you want to continue forming or shaping you will need to double bag your work – put your work on a suitable sized bat and put the bat in a bag so the base of the bag is under the bat, then put another bag over the top of the work and tuck the top of the bag under the bat. If you want to trim (or turn) your thrown work the following week, it should also be double bagged. If your work is large, delicate, or of uneven thicknesses, you should lightly cover your work for drying. When considering the drying process, bare in mind the weather, humidity and wind! The hotter and dryer, the faster things dry and work can dry unevenly in the shelves – this can lead to cracking – another time to lightly cover your work for drying. Step Four – Trimming and Cleaning Up Your work is dry! It is called greenware now and it is at it’s most fragile! Handle everything with two hands. I often refer to soft hands – keep everything gentle and with your fingers spread as much as possible. Try to not pick up things like plates too much, and always with both hands! Before your work can be bisque fired it should be “cleaned up”. You work won’t go into the kiln if it has sharp edges – when glazed, sharp edges turn into razor blades! Use a piece of fly wire to rub the work all over – this will scratch a little so be light handed. Use a knife or metal kidney to scrape any areas that require a bit more dynamic treatment than the fly wire offers! Finally, a very light wipe over with a slightly damp sponge can help soften and soothe all of your edges and dags! Trimming thrown work: If you are planning to trim (or turn) your thrown work (and you should be), make sure you bag it well – your work should be leather hard to almost dry for easiest trimming. Use this step to finish the work completely – use a metal kidney to polish the surface, or a slightly damp sponge to give a freshly thrown look. Wipe the sponge around the rim after trimming, and check the inside of the pot for dags! Trimming slip cast work: Usually I will trim the rims of your work on the wheel the following day to make that stage easier, however you will still need to check your work for lumps and bumps. Last but not least – check that your name is still clearly on the bottom of your work. Step Five – Bisque Firing When the work is completely dry it can go into the bisque kiln. The bisque kiln is fired to 1000°C. This process burns off the water in the clay as well as some of the chemically bound water. The structure of the clay is not altered that much at this temperature. Inside the bisque kiln, the work is stacked a little, small bowl inside a larger bowl and onto a heavy plate. Smaller items like decorations or drink coasters might get stacked several high. Consideration is paid to the weight of the stack and shape of the work. A bisque kiln can fire about one and a half times the amount of work that the glaze kiln can fire. The firing takes about 10 hours to complete the cycle and about two days to cool down. Once it has been emptied the work is placed in the glaze room ready for you to decorate! Step Six – Glazing Decorating your work with colour can be a lot of fun – and time consuming! There are three main options for surface treatment at this stage: Oxide Washes Underglazes Glazes Washes and underglazes do not “glaze” the work – It will still need a layer of glaze to fully seal the clay (washes don’t need glaze on surfaces not designed for food or liquid as they can gloss up a little on their own). Underglazes are stable colourants that turn out pretty much how they look in the jar. They can be mixed with each other to form other colours and can be used like water colours to paint onto your work. Mostly they should have a clear glaze on top to seal them. Oxides are a different species – the pink oxide (cobalt) wash turns out bright blue for instance. They don’t always need a glaze on top, and some glazes can change the colour of the wash! The glazes need no other “glaze” on top! Be careful of unknown glaze interactions – you can put any combination of glaze in a bowl or on a plate, but only a single glaze on the outside of any vertical surface! Glazes are a chemical reaction under heat. We don’t know the exact chemicals in the Mayco glazes we use. I can guess by the way they interact with each other, however, on the whole, you need to test every idea you have, and not run the test on a vertical surface! Simply put, glaze is a layer of glass like substance that bonds with the clay underneath. Clay is made of silica, alumina and water. Glaze is made of mostly silica. Silica has a melting point of 1700°C and we fire to 1240°C. The silica requires a “flux” to help it melt at the lower temperature. Fluxes can be all sorts of chemicals – a common one is calcium – calcium has a melting point of 2500°C, however, together they both melt at a much lower temperature! Colourants are metal oxides like cobalt (blue), chrome (green through black), copper (green, blue, even red!), manganese (black, purple and pink) iron (red brown), etc. Different chemicals in the glaze can have dramatic effects. for example, barium carbonate (which we don’t use) turns manganese bright pink! Other elements can turn manganese dioxide brown, blue, purple and reddish brown. Manganese dioxide is a flux in and of itself as well. So, glazes that get their black and purple colours, often interact with other glazes and RUN! Our mirror black is a good example – it mixes really well with many glazes because it fluxes them – causes them to melt faster. It will also bring out many beautiful colours in the glazes because it’s black colouring most definitely comes from manganese dioxide! Glaze chemistry is a whole subject on it’s own! We use commercial Mayco glazes on purpose – for their huge range of colour possibilities, stability, cool interactions, artistic freedom with the ability to easily brush the glazes on and ease of use. We currently have almost 50 glazes on hand! A major project is to test the interactions of all glazes with each other. That is 2,500 test tiles!!!! I’m going to make the wall behind the wheels the feature wall of pretty colours! Step Seven – Glaze (Gloss or sometimes called “Glost”) Firing Most of the time this is the final stage of making your creation (but not always!) The glaze kiln goes to 1240°C. This is called cone 6, or midrange. It is the low end of stoneware temperatures. Stoneware clays and glazes are typically fired at cone 8 – 10, that is 1260 – 1290°C. The energy requirement to go from 1240°C to 1280°C is almost a 30% more! Our clay is formulated to vitrify (mature, turn “glass-like”) at 1240°, as are our glazes. A glaze kiln take around 12 hours to reach temperature and two to three days to cool down. Sometimes a third firing process is required – this is for decoration that is added to work after the glaze firing. For example – adding precious metals and lustres. this firing temperature is usually around 600 – 800°C depending upon the techniques being used. There are many students interested in gold and silver trims – we will be doing this third type of firing soon! After firing your work will be in the student finished work shelves. Remember to pay for it before you head out the door! There is a small extra charge for using porcelain clay (it’s more than twice the price of regular clay), and for any third firing process! Once your work has been fired it can not turn back into clay for millennia – so don’t fire it if you don’t like it! Put it in the bucket for recycling. https://firebirdstudios.com.au/the-process-of-making-pottery/This bowl was made by renowned pottery company J & G Meakin of England. The firm was established in the mid-1800's. The bowl is an example of kitchenware used in the 19th century and still in use today.Bowl; white ceramic, round and tapering inwards towards base. Made by J and G Meakin England.On base, 'Ironstone China Reg SOL 391413' with symbolflagstaff hill, flagstaff hill maritime museum and village, warrnambool, maritime museum, maritime village, great ocean road, shipwreck coast, mixing bowl, food preparation, j & g meakin, pottery, stoke-on-trent, kitchen equipment, ceramic -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Plate