Showing 447 items matching "american made"

-

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Jewellery, tie stud and chain and a small, velvet covered box, c1900

A tie pin is a neckwear-controlling device, originally worn by wealthy English gentlemen to secure the folds of their cravats. They were first popularized at the beginning of the 19th century. Cravats were made of silk, satin, lace and lightly starched cambric, lawn and muslin, and stickpins were necessary accoutrements to keep these expensive fabrics in place and safe. Stickpins commonly used pearls and other precious gemstones set in gold or other precious metals and were designed specifically for their owners. By the 1860s, wearing cravats had been embraced by the English upper middle classes with a consequently lower quality of materials and designs used in both the neckwear and in the stickpins used to keep it in place. By the 1870s Americans had embraced stickpins and designs were mass-producedThe family of Lorna Risstrom were early settlers in Moorabbin ShireA tie-stud and chain in a small, blue velvet covered, silk lined, hinged jewellery box with . The tie-stud has a red stone set in gold metalmoorabbin, bentleigh, cheltenham, early settlers, pioneers, market gardneners, jewellery, risstrom lorna, tie-pins, tie- studs, cravats, silk, lace, -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Clocks, small 'Ansonia' c1887, c1887

Ansonia Clocks were made by a clock manufacturing business which started in Ansonia, Connecticut, in 1851 and which moved to Brooklyn, New York, in 1878. An enormously successful business, it turned out thousands of clocks in a large number of styles.This Ansonia clock was owned by the pioneer family of Miss Carol Green in Moorabbin Shire c 1887This Ansonia clock was owned by the pioneer family of Miss Carol Green in Moorabbin Shire c 1887A small ANSONIA clock. c1887 with a winding key and pendulum and a hinged front glass door This Ansonia clock was restored by Mr Frank M. Gowan.c 1960damaged label on back : AWARD PARIS..... / SMALL SHAR..... / ANSONIA CLOCK / none genuine without ' ( symbol) ' / factories at ANSONIA Conn. Brook / Salesroom .....19 Cliff Street ....../ansonia clock company, connecticut, america, phelps anson, terry theodore, andrews franklin, brighton, moorabbin, furniture, pioneers, clocks, market gardeners, early settlers, green carol, gowan frank -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Clocks, ANSONIA large c1900, c1900

Ansonia Clocks were made by a clock manufacturing business which started in Ansonia, Connecticut, in 1851 and which moved to Brooklyn, New York, in 1878. An enormously successful business, it turned out thousands of clocks in a large number of styles.This Ansonia clock was owned by the pioneer family in Moorabbin Shire c1900This Ansonia clock was owned by the pioneer family in Moorabbin Shire c1900A large ANSONIA clock. c1900 with a winding key and pendulum and a hinged front glass door with clip lock ANSONIAansonia clock company, connecticut, america, phelps anson, terry theodore, andrews franklin, brighton, moorabbin, furniture, pioneers, clocks, market gardeners, early settlers -

City of Moorabbin Historical Society (Operating the Box Cottage Museum)

City of Moorabbin Historical Society (Operating the Box Cottage Museum)Functional object - Lamp fitting double holders, Middy's Aust, c 1930

Made in Australia by Middy's Used by a pioneer family in Moorabbin. Manufactured by Middy's: Arriving in Australia at age 19 by ship at Port Melbourne, Dutch immigrant Petrus Cornelis Nicolaas Middendorp (1891-1963) settled in Melbourne to apply his trade as a cigar maker for the British American Tobacco Co. Retiring from the cigar industry and following his work as an honorary orderly tending WW1 Australian casualties in Paris and Melbourne, Petrus began selling Dutch manufactured light globes, vacuum cleaners and other electrical products imported from Holland and England. Warehousing and sales of the goods were undertaken from 1928 by the ‘Middendorp Goods Supply Company’ initially located in Flinders Lane in Melbourne’s CBD, then moving to McKillop Street, followed by a basement store at 148 Queen Street. During the 1940s a manufacturing plant known as ‘Middendorp and Sons’ was established in the Melbourne suburb of Preston, where Petrus’ three teenage sons Peter, Nick and Hugh joined him. Peter and Hugh worked with a small team of staff to produce rubber plug tops, extension sockets, double adaptors and a small range of bakelite accessories, whilst Nick became the first sales rep calling on customers and construction sites. The products were sold under the brand name of ‘Middy’. A name change of the distribution business took place in the late 40s and Middendorp Electric Company Pty Ltd was officially registered in 1948. The manufacturing operation ceased during the late 50s due to the introduction and acceptance of plastic and injection moulding. However, the Middendorp family had positioned itself to further establish its electrical wholesale business with the first branch and Head Office opening in 1956, located at 520 Latrobe Street, Melbourne. By 1962 there were five trading branches, growing to 25 in 1986 and 101 by 2018 Australia wide. Middendorp Electric, more commonly known as Middy’s and readily identified by its trademark colour of Middy’s pink, has developed into the largest privately owned Electrical Wholesaler in Australia. In 2015 Middy’s acquired Mekolec lifts fire and electrical adding presence and sector expertise in Melbourne’s inner south. In Sep 2018 Middy's acquired Salmon Brothers Electrical, with 5 Branches in Sydney's Metro region and in 2019 they acquired Goulburn Electrical Wholesalers greatly adding to Middy's location coverage in NSW and providing Middy’s the ability to better service NSW contractors. Bakerlite electrical fittingMiddy - Made in Australiamiddy's, moorabbin pioneers, electrical, bakerlite -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageCeramic - Stoneware Bottle, Dundas Pottery, 1856-1910

This bottle is part of the John Chance Collection of shipwreck artefacts. The Dundas Pottery works were established in 1828 by William Johnstone in partnership with John Forsyth and John Mc Coll. Located where the Forth and Clyde Canal joined the Monkland Canal, North of Glasgow. Johnstone sold the pottery in 1835 to Robert Cochran and James Couper. Mc Coll was retained as manager until 1837when in 1839 Cochran & Couper sold the pottery and purchased the St Rollex Glass Works. George Duncan took over briefly but died in 1841, with the pottery possibly being run by his widow Helen and a potter named Alexander Paul. James Miller was the manager at the time and he bought the pottery in 1856, in partnership with John Moody. Miller's long and careful stewardship of the pottery saw success from the export market which allowed him to purchase the North British pottery in 1867 until 1874 when it was sold. In 1875, Miller, in partnership with John Young, leased part of Caledonian Pottery, naming it Crown Pottery, however, it burned down in 1879. In the early 1880s, Young extended the pottery and named it Milton Pottery. Miller’s son, James W., became a partner in Milton pottery in 1905. James Miller Snr died in 1905 and the company continued as a limited liability company, being sold to the Borax Consolidation Ltd in 1929, but it was unsuccessful and Possil pottery purchased some of the company's equipment before it finally closed in 1932. From 1828 until the James Miller period of circa 1856, the pottery produced salt-glazed stoneware for the local industrial trade; mainly bottles and drain pipes. James Miller produced various bottles, whisky and acid jars, casks, butter crocks, jam jars and domestic wares in Bristol glaze. He streamlined the water filter manufacturing, which had become a speciality of the pottery, and a dedicated section of the pottery was created solely for their production, which was exported worldwide. A significant item of salt-glazed ceramic stoneware made by the Dundas potteries in Scotland who were renowned for making quality ironstone pottery. The bottle that was in common use throughout the British colonies and America for the containment of ale The bottle is also significant as it was recovered by John Chance, a diver, from a wreck on the coast of Victoria in the 1960s-70s. Items that come from several wrecks along Victoria's coast have since been donated to the Flagstaff Hill Maritime museum collection by his family Illustrating the level of historical value the subject item has.Beige salt glazed stoneware, bottle with discolorations above base. Manufacturer's oval Inscription lozenge stamped near base. Stamp: [symbol of concentric ovals], text within the symbol "PORT DUNDAS POTTERY COY." and "GLASGOW". Stamp:[Symbol - square with short vertical line in centre of base line]flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, john chance, stoneware bottle, pottery, port dundas pottery, william johnstone, bottles, shipwreck artefact, stoneware, ironstone, bottle, glasgow, antique bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied, double collar lip; square upper with flared lower. Neck has seams and shoulder seam from 3-piece mould. Body with horizontal ripples tapers inwards to base. Push-up base with pontil mark and embossed inscription. Tape over wire around mouth. Cork remnants inside mouth. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper with flared lower. Push-up base with pontil mark and embossed inscription. Base is uneven, glass composition has imperfections.Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Neck has seams and shoulder seam from 3-piece mould. Body tapers towards base. Push-up base with pontil mark and embossed inscription. Base is uneven. Mouth has remnants of the seal in it and tape remnants around its outside. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, olive green glass, handmade. Tall slim, Gallon style liquor bottle. Applied double collar lip; square upper with flared lower. Neck is slightly bulged and there is a mould seam where shoulder joins base. Body tapers inward to base. Uneven base with deep push-up centre with small pontil mark. Scratches and imperfections in glass. Also encrustations on surface. flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, olive green glass, handmade. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Mouth has remnants of tape and wire seal. Mould seam around shoulder. Body tapers slightly inward to the base. Push-up base has pontil mark and is embossed in large letters. Base is uneven. Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. However, this bottle is rare, in that the base has been embossed then over-embossed with the same text, letters overlapping. It is one of many artefacts recovered from unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is a rare find, in that the base has been over-embossed with the same lettering, letters overlapping one another. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, over embossed, brown glass, handmade, rare. Tall slim Gallon style liquor bottle. Applied double collar lip; square upper and flared lower. Mouth has sealing tape remnants around top. Mould seam around shoulder. Body tapers inwards to push-up base. Top edge of lip has application faults. There is also a rectangular indent in the upper edge of lip. Base is embossed and over embossed, with the letters overlapping each other. Embossed on base "6 TO THE GALLON", then over-embossed with the same "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable, over embossed, rare -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1840s to 1910

This handmade ‘gallon’ style of bottle was generally used for storing and transporting wine and ale. Many bottles similar to this one have their bases embossed with “6 TO THE GALLON”. It is one of many artefacts recovered from an unidentified shipwrecks along Victoria’s coast between the late 1960s and the early 1970s. It is now part of the John Chance Collection. The capacity of this is one-sixth of a gallon (imperial measure), which is equal to 758 ml. (American bottles were often inscribed “5 TO THE GALLON”, which is one-fifth of an American gallon, equal to 757 ml.) Contemporary home brewers can purchase new ‘6 to gallon’ bottles that hold 750 ml. and are sold in cases of 36 bottles, which is equal to 6 gallons of wine. Glass was made thousands of years ago by heating together quartz-sand (Silica), lime and potash. Potash was obtained from burnt wood, but these days potash is mined. The natural sand had imperfections such as different forms of iron, resulting in ‘black’ glass, which was really dark green or dark amber colour. The ‘black’ glass was enhanced by residual carbon in the potash. Black glass is rarely used nowadays but most beer, wine, and liquors are still sold in dark coloured glass. Glass vessels were core-formed from around 1500 BC. An inner core with the vessel’s shape was formed around a rod using a porous material such as clay or dung. Molten glass was then modelled around the core and decorated. When the glass had cooled the vessel was immersed in water and the inner core became liquid and was washed out. Much more recently, bottlers were crafted by a glassblower using molten glass and a blow pipe together with other hand tools. Another method was using simple moulds, called dip moulds, that allowed the glass to be blown into the mould to form the base, then the glassblower would continue blowing free-form to shape the shoulders and neck. The bottle was then finished by applying a lip. These moulded bottles were more uniform in shape compared to the free-form bottles originally produced. English glassblowers in the mid-1800s were making some bottles with 2-piece and 3-piece moulds, some with a push-up style base, sometimes with embossing in the base as well. Improvements allowed the moulds to also have embossed and patterned sides, and straight sided shapes such as hexagons. Bottles made in full moulds usually displayed seam seams or lines. These process took skill and time, making the bottles valuable, so they were often recycled. By the early 20th century bottles were increasingly machine made, which greatly reduced the production time and cost. This bottle is historically significant as an example of a handmade, blown inscribed glass bottle manufactured in the mid-to-late 1800s for specific use as a liquor bottle with a set measurement of one-sixth of gallon. It is also historically significant as an example of liquor bottles imported into Colonial Victoria in the mid-to-late 1800s, giving a snapshot into history and social life that occurred during the early days of Victoria’s development, and the sea trade that visited the ports in those days. The bottle is also significant as one of a group of bottles recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection of shipwreck artefacts by his family, illustrating this item’s level of historical value. Bottle, brown glass, Tall slim gallon style. Applied double collar lip; upper is straight, lower is flared. Lip has bumps around the top. Neck has slight taper towards shoulder, which has a shoulder seam from the mould. Body tapers inwards towards base. Push up base has a pontil mark. Base is embossed.Embossed on base "6 TO THE GALLON"flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, glass bottle, antique bottle, gallon bottle, 6 to the gallon bottle, handmade, dip mould, mouth blown, pontil mark, blown bottle, liquor bottle, ale bottle, double collar, 19th century bottle, collectable -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Spoon, SSP Sheffield Silver Plate & Cutlery Co. Ltd, About 1913 to early-1930s

This electroplated silver teaspoon was made by the Sheffield Silver Plate & Cutlery Company Limited from about 1913 to early-1930s. It was recovered from an unknown shipwreck in the coastal waters of Victoria in the late 1960s to early 1970s. The shipwrecks in the area range from around the 1840s to the early-1930s. It is part of the John Chance Collection. Sheffield manufactures produced high quality silverware products. In the mid-1700s a cutler, Thomas Boulsover, invented a process to fuse copper between two sheets of silver, which could still be like solid silver then the edges were bound in silver. Items made this way are now referred to as Old Silver Plate. The modern method of electroplating has a much thinner layer of silver. The firm Sheffield Silver Plate and Cutlery Co. Ltd. was established in 1913 by Mappin & Webb to make spoons and forks using the American Wilzin process, which was a failure. In 1923 the company was incorporated then re-financed and reverted back to the older production method for electroplating. The maker’s stamp usually had the letters “S.S.P. & C. Co Ltd EPNS” and often included an octagon stamp with “SSP”. The firm had the registered trademarks of ‘SILCUTA’ and ‘SILTONA’ and has also used the name ‘Sheffield Nickel & Silver Plating Co. Ltd.’ The firm had manufacturing Works at Priestley Street, Sheffield from 1913 until the 1960s. They also had a London office in 1919 at Atlantic House, 40a Holborn Viaduct, London, E.C.1., then in 1921 at Union Bank Buildings, Charterhouse Street, E.C.1. The company was dissolved in 2000, the last office address being 23 Albemarle Street London, W1S 4AS. Although this spoon is not linked to a particular shipwreck, it is recognised as being historically significant as an example of cutlery, possibly from a passenger’s luggage or imported for use in Colonial Victoria in the 19th to early 20th century. The spoon is the only example in Flagstaff Hill’s collection that is connected to the manufacturer Sheffield Silver Plate and Cutlery Co. Ltd., historically significant also, as in 1939 the same manufacturer was a recognised supplier to the British Government. The spoon is also significant as it was recovered by John Chance, a diver in Victoria’s coastal waters in the late 1960s to early 1970s. Items that come from several wrecks have since been donated to the Flagstaff Hill Maritime Village’s museum collection by his family, illustrating this item’s level of historical value.Spoon; teaspoon, nickel plated silver, discoloured to brown. Old English design. Inscription on handle. Made by Sheffield Silver Plate & Cutlery Co Ltd., Sheffield. Spoon has dimpled surface, nicks and dents. Embossed logo within sunken elongated octagon [SSP] Embossed letters following logo, “S S P C & CO LTD EP/NS” flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, shipwreck artefact, john chance, sheffield, cutlery, eating utensils, electroplate, silver plate, silverware, flatware, antique flatware, old english flatware pattern, spoon, teaspoon, silver flatware, dining, silver plated, epnns, sheffield silver plater & cutlery, ssp, ssp & c co ltd, 20th century silverware -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageContainer - Bottle, 1850's - 1900

This bottle is sometimes referred to as a black glass 'Gallon' bottle. It is used for storing and transporting liquor such as port or madeira. Glass bottles and glass jars are in many households around the world. The first glass bottles were produced in south-east Asia around 100 B.C. and the Roman Empire around 1 AD. America's glass bottle and glass jar industry were born in the early 1600s when settlers in Jamestown built the first glass-melting furnace. The invention of the automatic glass bottle blowing machine in 1880 industrialized the process of making bottles. In 2019, plans were made to re-introduce milk glass bottle deliveries to Auckland in early 2020. The earliest bottles or vessels were made by ancient man. Ingredients were melted to make glass and then clay forms were dipped into the molten liquid. When the glass cooled off, the clay was chipped out of the inside leaving just the hollow glass vessel. This glass was very thin as the fire was not as hot as modern-day furnaces. The blowpipe was invented around 1 B.C. This allowed molten glass to be gathered at the end of the blowpipe and blown into the other end to create a hollow vessel. Eventually, the use of moulding was introduced, followed by the invention of the semi-automatic machine called the Press and Blow. In 1904 Michael Owens invented the automatic bottle machine. Before this time most glass bottles in England were hand blown. This is one of four bottles in Flagstaff Hill Maritime Museum collection that were recovered by a local diver from the quarantine area just inside the Port Phillip Heads. Ships were required to pull into this area to check for diseases and other medical issues before they could head up to Melbourne. Quite often they would drink and throw the bottles overboard. Handmade glass bottle, manufactured in the 1850s. The bottle gives a snapshot into history and a social life that occurred during the early days of Melbourne's development and the sea trade that visited the port in those days. Bottle, glass, solid dark purple (black), round, matt surface. Glass ring below mouth, neck is slightly bulbous, body tapers slightly inward from shoulder to base. Base is concave with pontil mark. Bottle has no inscription. Generally used for storing port.flagstaff hill, warrnambool, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, handmade bottle, handmade english beer bottle, pontil bottle, black glass, gallon, purple bottle, ale bottle, porter bottle -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Sewing machine in cabinet, Ward Brothers (G & S Ward), ca. 1933

The donor inherited this Wardana machine from her mother, who bought it in about 1933 and used it to sew garments for her sister's dressmaking business in Frankston, Victoria. The donor often used this machine until she purchased an updated model. There were originally three Ward Brothers who owned the North Melbourne sewing machine business but they had a falling out. This machine's decals on the map of Australia only include the two remaining brothers. The Ward Brothers, G & S Ward, established their sewing machine business in North Melbourne in 1888. The cabinets and ironwork of the machines were made in Australia and the Ward Bros. imported their machines from overseas manufacturers in England, America and Germany. The assembled machines were sold under brand names that included Ward, A.N.A. the patriotic-sounding Australian Sewing Machine Company. The "Wardana" was one of their brands.This sewing machine was fabricated in Australia from imported parts from England, giving a snapshot into the early manufacturing industries that were operating at the time just after Federation.Sewing machine in a wooden cabinet with iron foot-operated cast iron treadle mechanism. The hinged cabinet top opens out to form a worktop. The sewing machine lifts out of the cabinet to sit level with the worktop, resting on two supports within the cabinet. The lockable cabinet door opens from right to left revealing fitted shelves and spikes for spools and bobbins. The gold-painted maker's name is cast into the black treadle. The machine has its original instruction book, oil can, and eighteen accessories in an enclosed cardboard box. The round shallow oil bottle has a rubber dispensing tube. Colourful decals decorate the black body of the machine. Inscriptions include a Serial Number stamped on the bed of the machine. The Wardarna Central Bobbin machine was made in England for the Ward Brothers of North Melbourne.TREADLE: cast into metal ACROSS THE TOPE AND ON THE FOOTPLATE "WARD", "WARD" SERIAL NUMBER stamped into oval plate "28383" DECAL: (Map of Australia ) with images of [two brothers] , "WARDANA" above (logo of the rising sun) DECAL: (Decorative floral design with heraldic-like emblems) above "MADE IN ENGLAND" ARM: "WARDANA" PEDESTAL: "C.B." (representing Central Bobbin) "MADE IN ENGLAND" "MADE IN ENGLAND / FOR / WARD BROS / NORTH MELBOURNE" BOOK TITLE: "Instructions for Treadle Machine" ACCESSORIES: some have indecipherable embossed stamps OIL BOTTLE base: (image of log and short lines radiating from a central inscription (indecipherable)sewing machine, domestic, wardana, ward bros., central bobbin, made in england, north melbourne, c.b., flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, treadle sewing machine, home industry, clothing, dressmaking, clothing manufacturer -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageAnimal specimen - Whale bone, Undetermined

Prior to carrying out a detailed condition report of the cetacean skeletons, it is useful to have an understanding of the materials we are likely to encounter, in terms of structure and chemistry. This entry invites you to join in learning about the composition of whale bone and oil. Whale bone (Cetacean) bone is comprised of a composite structure of both an inorganic matrix of mainly hydroxylapatite (a calcium phosphate mineral), providing strength and rigidity, as well as an organic protein ‘scaffolding’ of mainly collagen, facilitating growth and repair (O’Connor 2008, CCI 2010). Collagen is also the structural protein component in cartilage between the whale vertebrae and attached to the fins of both the Killer Whale and the Dolphin. Relative proportions in the bone composition (affecting density), are linked with the feeding habits and mechanical stresses typically endured by bones of particular whale types. A Sperm Whale (Physeter macrocephalus Linnaeus, 1758) skeleton (toothed) thus has a higher mineral value (~67%) than a Fin Whale (Balaenoptera physalus Linnaeus, 1758) (baleen) (~60%) (Turner Walker 2012). The internal structure of bone can be divided into compact and cancellous bone. In whales, load-bearing structures such as mandibles and upper limb bones (e.g. humerus, sternum) are largely composed of compact bone (Turner Walker 2012). This consists of lamella concentrically deposited around the longitudinal axis and is permeated by fluid carrying channels (O’Connor 2008). Cancellous (spongy) bone, with a highly porous angular network of trabeculae, is less stiff and thus found in whale ribs and vertebrae (Turner Walker 2012). Whale oil Whales not only carry a thick layer of fat (blubber) in the soft tissue of their body for heat insulation and as a food store while they are alive, but also hold large oil (lipid) reserves in their porous bones. Following maceration of the whale skeleton after death to remove the soft tissue, the bones retain a high lipid content (Higgs et. al 2010). Particularly bones with a spongy (porous) structure have a high capacity to hold oil-rich marrow. Comparative data of various whale species suggests the skull, particularly the cranium and mandible bones are particularly oil rich. Along the vertebral column, the lipid content is reduced, particularly in the thoracic vertebrae (~10-25%), yet greatly increases from the lumbar to the caudal vertebrae (~40-55%). The chest area (scapula, sternum and ribs) show a mid-range lipid content (~15-30%), with vertically orientated ribs being more heavily soaked lower down (Turner Walker 2012, Higgs et. al 2010). Whale oil is largely composed of triglycerides (molecules of fatty acids attached to a glycerol molecule). In Arctic whales a higher proportion of unsaturated, versus saturated fatty acids make up the lipid. Unsaturated fatty acids (with double or triple carbon bonds causing chain kinks, preventing close packing (solidifying) of molecules), are more likely to be liquid (oil), versus solid (fat) at room temperature (Smith and March 2007). Objects Made From the Whaling Industry We all know that men set forth in sailing ships and risked their lives to harpoon whales on the open seas throughout the 1800s. And while Moby Dick and other tales have made whaling stories immortal, people today generally don't appreciate that the whalers were part of a well-organized industry. The ships that set out from ports in New England roamed as far as the Pacific in hunt of specific species of whales. Adventure may have been the draw for some whalers, but for the captains who owned whaling ships, and the investors which financed voyages, there was a considerable monetary payoff. The gigantic carcasses of whales were chopped and boiled down and turned into products such as the fine oil needed to lubricate increasing advanced machine tools. And beyond the oil derived from whales, even their bones, in an era before the invention of plastic, was used to make a wide variety of consumer goods. In short, whales were a valuable natural resource the same as wood, minerals, or petroleum we now pump from the ground. Oil From Whale’s Blubber Oil was the main product sought from whales, and it was used to lubricate machinery and to provide illumination by burning it in lamps. When a whale was killed, it was towed to the ship and its blubber, the thick insulating fat under its skin, would be peeled and cut from its carcass in a process known as “flensing.” The blubber was minced into chunks and boiled in large vats on board the whaling ship, producing oil. The oil taken from whale blubber was packaged in casks and transported back to the whaling ship’s home port (such as New Bedford, Massachusetts, the busiest American whaling port in the mid-1800s). From the ports it would be sold and transported across the country and would find its way into a huge variety of products. Whale oil, in addition to be used for lubrication and illumination, was also used to manufacture soaps, paint, and varnish. Whale oil was also utilized in some processes used to manufacture textiles and rope. Spermaceti, a Highly Regarded Oil A peculiar oil found in the head of the sperm whale, spermaceti, was highly prized. The oil was waxy, and was commonly used in making candles. In fact, candles made of spermaceti were considered the best in the world, producing a bright clear flame without an excess of smoke. Spermaceti was also used, distilled in liquid form, as an oil to fuel lamps. The main American whaling port, New Bedford, Massachusetts, was thus known as "The City That Lit the World." When John Adams was the ambassador to Great Britain before serving as president he recorded in his diary a conversation about spermaceti he had with the British Prime Minister William Pitt. Adams, keen to promote the New England whaling industry, was trying to convince the British to import spermaceti sold by American whalers, which the British could use to fuel street lamps. The British were not interested. In his diary, Adams wrote that he told Pitt, “the fat of the spermaceti whale gives the clearest and most beautiful flame of any substance that is known in nature, and we are surprised you prefer darkness, and consequent robberies, burglaries, and murders in your streets to receiving as a remittance our spermaceti oil.” Despite the failed sales pitch John Adams made in the late 1700s, the American whaling industry boomed in the early to mid-1800s. And spermaceti was a major component of that success. Spermaceti could be refined into a lubricant that was ideal for precision machinery. The machine tools that made the growth of industry possible in the United States were lubricated, and essentially made possible, by oil derived from spermaceti. Baleen, or "Whalebone" The bones and teeth of various species of whales were used in a number of products, many of them common implements in a 19th century household. Whales are said to have produced “the plastic of the 1800s.” The "bone" of the whale which was most commonly used wasn’t technically a bone, it was baleen, a hard material arrayed in large plates, like gigantic combs, in the mouths of some species of whales. The purpose of the baleen is to act as a sieve, catching tiny organisms in sea water, which the whale consumes as food. As baleen was tough yet flexible, it could be used in a number of practical applications. And it became commonly known as "whalebone." Perhaps the most common use of whalebone was in the manufacture of corsets, which fashionable ladies in the 1800s wore to compress their waistlines. One typical corset advertisement from the 1800s proudly proclaims, “Real Whalebone Only Used.” Whalebone was also used for collar stays, buggy whips, and toys. Its remarkable flexibility even caused it to be used as the springs in early typewriters. The comparison to plastic is apt. Think of common items which today might be made of plastic, and it's likely that similar items in the 1800s would have been made of whalebone. Baleen whales do not have teeth. But the teeth of other whales, such as the sperm whale, would be used as ivory in such products as chess pieces, piano keys, or the handles of walking sticks. Pieces of scrimshaw, or carved whale's teeth, would probably be the best remembered use of whale's teeth. However, the carved teeth were created to pass the time on whaling voyages and were never a mass production item. Their relative rarity, of course, is why genuine pieces of 19th century scrimshaw are considered to be valuable collectibles today. Reference: McNamara, Robert. "Objects Made From the Whaling Industry." ThoughtCo, Jul. 31, 2021, thoughtco.com/products-produced-from-whales-1774070.Whale bone was an important commodity, used in corsets, collar stays, buggy whips, and toys.Whale bone piece. Advanced stage of calcification as indicated by deep pitting. Off white to grey.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, whales, whale bone, corsets, toys, whips -

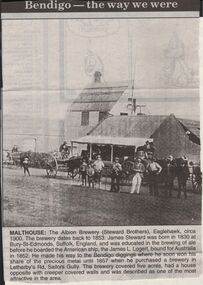

Bendigo Historical Society Inc.

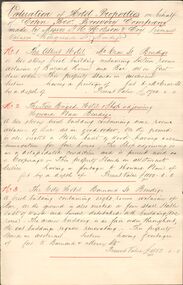

Bendigo Historical Society Inc.Financial record - COHN BROTHERS COLLECTION: HANDWRITTEN VALUATIONS OF HOTELS

394 c, Six handwritten pinned pages including abstract and Valuation of Hotel Properties on behalf Cohn Bros Brewery Company made by Messrs G M Hobson & Co licensed valuers Hargreaves St Bendigo dated 10/11/91 and signed G M Hobson. Nineteen hotels are valued. 1. Albert Hotel. 2. Fire Brigade Hotel. 3. City Hotel. 4. British & American. 5. Hustlers Reef. 6. Garden Gully. 7. Universal. 8. Brougham Arms. 9. Victoria. 10. United Kingdom. 11. West End. 12. View Bend. 13. Sparrowhawk. 14. Greyhound. 15. Normandy. 16 Noahs Ark. 17. Saw Mill. 18. Royal. 19. South Elmore. Total value £14305.00bendigo, industry, cohn bros brewery -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Book - A BENDIGONIAN ABROAD, 1892

A Bendigonian Abroad, Being sketches of Travel made during a ten months' tour through Europe and America. Inside front cover there is reference to a David O'Keefe Arnold Street Bendigo, and page number to this reference. On the opposite page is the name James Harrison Bendigo, significance not known. 258 pages.Alfred Josephbook, world travel. -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Souvenir - Views of Bendigo, 1902

The Victorian Gold Jubilee Exhibition, held at Bendigo from 13 November 1901 to 14 May 1902. The courts were numbered from one, or had titles like “Machinery”, “Agricultural”, “Naval & Military Court” and “Art”. The female visitors to the Exhibition were able to view exhibits deemed suitable for the fairer sex and located within their own “Women’s Court”. There were exhibits such as “Parasols & Umbrellas”, cotton and haberdashery from Manchester and Staffordshire, “Corsets & Embroideries” from Paris. The most valuable exhibits were mining machinery such as Taylor Horsfield’s £850 “Air Compressor & Rock Borer”. “Bohemian Glassware” brought down from Sydney was valued at £600. The profits from this Exhibition were used to fund the sculpture known as the Gold Monument, which still gazes along Pall Mall (from the McCrae Street end). The Exhibition’s Cash Book shows payments, which totalled £1160, were made to then up and coming sculptor C.D.Richardson. Recently a City of Greater Bendigo staff member used both these volumes to write a detailed report about this monument, for Heritage Victoria.Carol Holsworth Collection: Small book Souvenir, 29 pages plus cover; each page. has a photo of the exhibit. Exhibition was held on the site of the present Bendigo Library between Hargreaves St and Lyttleton Terrace. * 8662.1a Victorian Gold Jubilee Exhibition - Front Cover: Printed 'Souvenir', 'Bendigo 1901-1902'; a photo of the Entrance to the exhibition beside the Town Hall. * 8662.1b Victorian Gold Jubilee Exhibition - Inside Front Cover - Page 1 of 29. Portraits of Exhibition President S.H. Cowen esq.; and G.V. Allen esc., General Secretary. Photos by W.H. Robinson publisher. Printed by T. Cambridge, Market Square Bendigo. * 8662.1c Victorian Gold Jubilee Exhibition - Page 1 of 29 The Governor General at the Exhibition. Photo of the crowd, police, trooper and horse drawn vehicles. * 8662.1d Victorian Gold Jubilee Exhibition - Page 2 of 29 Procession Passing the Fountain, Pall Mall. The crowd and horse drawn vehicles. *8662.1e Victorian Gold Jubilee Exhibition - Page 3 of 29 James Martin and Co's Exhibit. James Martin & Co was an Australian engineering company which progressed from making agricultural equipment to making railway locomotives. * 8662.1f Victorian Gold Jubilee Exhibition - Page 4 of 29 Old Pioneers. Elderly gentlemen on foot and carriage - at the Bendigo Railway Station. * 8662.1g Victorian Gold Jubilee Exhibition - Page 5 of 29 Robert Harper and Company's Exhibit. From Trove - The Brisbane Courier 25 Aug 1891: One of the best known firms in the Southern hemisphere is Messrs. Robert Harper and Co , tea importers, coffee, rice, and spice merchants and manufacturers Then productions circle this continent, and every thrifty housewife is familiar with their Empire tens, their Star' brand of goods, then oatmeal, wheatmeal, and other breakfast table luxuries The headquarters of the firm are placed at Port Melbourne, and the manufactory there occupies over an acre of ground, while the mills at Sydney and Adelaide are as great in proportion It is eight cars since the firm opened business in this colony. The step was taken with much confidence, the principals the firm being quite attracted. * 8662.1h Victorian Gold Jubilee Exhibition - Page 6 of 29 The Electric Tram * 8662.1i Victorian Gold Jubilee Exhibition - Page 7 of 29 G. Weymouth Proprietary Ltd. The business of G. Weymouth & Co was founded in 1898 by George Andrew Philip Weymouth, who began operating from a small workshop on City Road, South Melbourne (opposite Princes Bridge). An early advertisement describes the firm's activities at this time as being 'makers of dynamos, (electric) motors, x-ray apparatus and electrical instruments, &c' together with 'repairs to every class of electrical work'. * 8662.1j Victorian Gold Jubilee Exhibition - Page 8 of 29 The Exhibition Fernery * 8662.1k Victorian Gold Jubilee Exhibition - Page 9 of 29 Cohn Bros'. Exhibit. In 1857 at the height of the gold rush, with people pouring into Central Victoria from all over the world, three brothers from Denmark – Moritz, Julius and Jacob Cohn – founded a small cordial factory in the booming town of Bendigo. They went on to build an empire and, through introducing lager, which is served cold, to the country, changed the drinking preferences of Australians. * 8662.1l Victorian Gold Jubilee Exhibition - Page 10 of 29 Ornamental Lake in the Exhibition Grounds * 8662.1m Victorian Gold Jubilee Exhibition - Page 11 of 29 Australian Explosives and Chemical Co.'s Exhibit. The Australian Explosives and Chemical Company began manufacturing explosives in Melbourne's outskirts (the area now known as Deer Park) in 1875. In 1897 the Company was purchased by Nobel, forming Nobel (Australasia) Ltd. * 8662.1n Victorian Gold Jubilee Exhibition - Page 12 of 29 Tasmanian Court * 8662.1o Victorian Gold Jubilee Exhibition - Page 13 of 29 N. Guthridge's Limited Exhibit. Guthridge sold a variety of mining supplies and equipment; also 'Rackarock' which was used to fill the mining drill holes before blasting. * 8662.1p Victorian Gold Jubilee Exhibition - Page 14 of 29 Navel and Military Court (LARGE File) * 8662.1q Victorian Gold Jubilee Exhibition - Page 15 of 29 Women's Court * 8662.1r Victorian Gold Jubilee Exhibition - Page 16 of 29 T. J. Connelly and Co's Exhibit. T.J. Connelly an American immigrant came to the Bendigo goldfields where he later established Connelly’s Tin Shop on the corner of High and Forest Streets 1853. Connelly was named after Thomas Jefferson the famous statesman who wrote much of the American Declaration of Independence in 1776 and became the third United States President. Connelly, along with other prominent citizens of the time established Bendigo’s first Fire Brigade, Mechanics Institute. * 8662.1s Victorian Gold Jubilee Exhibition - Page 17 of 29 The Potter's Wheel * 8662.1t Victorian Gold Jubilee Exhibition - Page 18 of 29 G. D. Guthrie and Co.'s Exhibit. In 1863 the Bendigo Pottery was set up by Guthrie. * 8662.1u Victorian Gold Jubilee Exhibition - Page 19 of 29 The Ladies' Committee * 8662.1v Victorian Gold Jubilee Exhibition - Page 20 of 29 J. Kitchen and Sons Exhibit. In Port Melbourne since the 1850s they made such products as Velvet Soap and Electrine Candles from the tallow and other animal fats from the nearby slaughter yards. In recent decades the company has become Kitchen & Lever then Unilever and most recently Unichema. * 8662.1w Victorian Gold Jubilee Exhibition - Page 21 1of 29 The Executive Committee * 8662.1x Victorian Gold Jubilee Exhibition - Page 22 of 29 Taylor Horsfield Exhibit. The most valuable exhibits were mining machinery such as Taylor Horsfield’s £850 “Air Compressor & Rock Borer” * 8662.1y Victorian Gold Jubilee Exhibition - Page 23 of 29 A Peep at the Education Department 8662.1z Victorian Gold Jubilee Exhibition - Page 24 of 29 John Danks and Co's Exhibit. John Danks & Son was a major manufacturing company in Melbourne, Victoria and Sydney, New South Wales. * 8662.1aa Victorian Gold Jubilee Exhibition - Page 25 of 29 Glance at the Agricultural Department's Court * 8662.1bb Victorian Gold Jubilee Exhibition - Page 26 of 29 T. York's Exhibit. Thomas York was an instrument repairer and brass instrument maker that resided in Melbourne in the late 19th to the early 20th century. While old newspaper advertisements suggested he repaired all instruments, it appears the focus of his business were military and brass band instruments. (BrassandWoodWind.com) * 8662.1cc Victorian Gold Jubilee Exhibition - Page 27 of 29 T. McPherson and Son's Exhibit. Possibly monumental masons. * 8662.1dd Victorian Gold Jubilee Exhibition - Page 28 of 29 T. Lewis and Whitty's Exhibit - Inside Back Cover. Lewis & Whitty were prominent boot blacking manufacturers as well as a number of other chemical products such as “Odourbane" disinfectant. * 8662.1ee Victorian Gold Jubilee Exhibition - Page 29 of 29 Singer Manufacturing Coy's Exhibithistory, bendigo, victorian gold jubilee exhibition bendigo, carol holsworth collection -

Bendigo Historical Society Inc.

Bendigo Historical Society Inc.Functional object - ALARM CLOCK, 1932

Black tin plate alarm clock with two tone cream and white dial labelled Westclox America, black hands and numerals, convex glass and chrome bezel.RD1932 Made in Canada made by Western Clock Co Limited Peterborough Canada.horology, clocks, alarm -

Coal Creek Community Park & Museum

Coal Creek Community Park & MuseumBottle, glass, c. 1885