Showing 280 items matching "hardwood"

-

National Wool Museum

National Wool MuseumPhotograph - Portrait of Jarrah Wadsworth, Nicole Marie, 2021

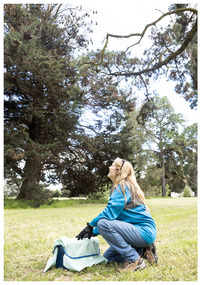

Thousands of volunteers work tirelessly to conserve and protect the environment of Geelong and the Bellarine. Their work often goes unnoticed. In 'The Work of Nature' the National Wool Museum and the Environment Department at the City of Greater Geelong worked with photographer Nicole Marie to showcase the significant contribution of environment volunteers in our region. Each of the eight people showcased in these portraits were nominated by their peers and members of the community for their significant contribution to conserving and protecting the environment. Jarrah Wadsworth - Friends of Bats and Bushcare Geelong Grey-headed flying foxes are listed as nationally threatened. They play a critical role in hardwood forest pollination and seed dispersal. They are often not well liked and can be seen as more of a nuisance than an asset to an area. Their numbers are rapidly declining. As the world warms and we experience more days of extreme heat they are increasingly threatened. Jarrah is a registered vet nurse and in her spare time heads up the Friends of Bats and Bushcare Geelong volunteer group. She is the coordinator of the FBBG and plays a key role in supporting the Geelong grey-headed flying fox population in Eastern Park and ensuring they survive extreme heat events. Photo at Eastern Park flying fox camp by Nicole Marie.Image showing an environmental portrait of a woman crouched on grass below trees where fruit bats are roosting.environment, conservation, portraits, geelong, nature, exhibition, work of nature, geelong nature forum, volunteers, eastern park -

Hepburn Shire Council Art and Heritage Collection

Hepburn Shire Council Art and Heritage CollectionPublic Art Work, Patrick Jones, 'Poemscape: a physical anthology' - Patrick Jones. 1999, 1999

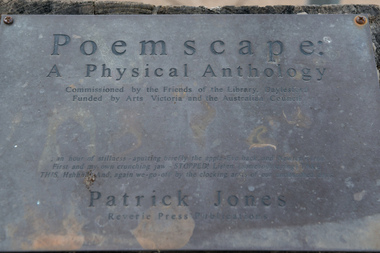

The work was installed at the cnr of Bridgport St and the Midland Hwy, adjacent to the Daylesford Library, in 1999. The work was commissioned by the Friends of the Library, Daylesford and funded by Arts Victoria and the Australia Council. Poemscape: a physical anthology is a much loved site specific installation work commissioned by the Friends of the Library, funded by Arts Victoria and the Australia Council, made by Daylesford resident Patrick Jones in response to his interests in the provision of public food, the development of locavore sensibilities and the rethinking of economies of material accountability and regard. Patrick Jones is a poet and non-fiction writer, a visual artist and ecological thinker. In 2013 Patrick Jones was awarded the degree of Doctor in Creative Arts from the University of Western Sydney for his thesis, 'Walking for food. Regaining permapoesis.'Public Art Environmental installation work installed near the Daylesford Library. Poemscape: a physical anthology comprises of 19 apple trees (18 Fuji apple trees and 1 Granny Smith apple tree) planted on the corner of Bridgport St and the Midland Hwy, adjacent to the library. Adjacent to each tree is a hardwood plinth at topped with a laser engraved brass plate that has been screwed in place. The text of each plate is by 19 poets including the artist and Daylesford resident Patrick Jones, local poets Peter O'Mara, Toby Sime and Robert Campbell, Australian poets Geoff Page, Kath Walker, D T Sime, Judith Wright, Ramona Barry, Jack Davis, Robert Campbell, Christopher Brennan and International Poets Dylan Thomas - Welsh, Sylvia Plath - American, Choku Kanai - Japanese, William Blake - English, Duo Duo - Chinese (translated from the Chinese by John Rosenwald), Yannis Ritsos- Greek (translated from the Greek by Kimon Friar & Kostas Myrsiades), Michel Deguy - French (translated from the French by Clayton Eshleman), Seamus Heaney - Irish and Rainer Maria Rilke - German. The title plate adjacent to the Granny Smith apple tree is by the artist/poet - Patrick Jones. See photographs with images of each of the laser engraved brass plates. permapoesis, artist as family, patrick jones, william blake, kath walker, chaku kanai, peter o'mara, sylvia plath, dylan thomas, geoff page, duo duo, d.t. sime, judith wright, yannis ritsos, michel deguy, ramona barry, seamus heaney, jack davis, rainer maria rilke, robert campbell, christopher brennan, hepburn shire, daylesford library, public art, installation art, environmental art, hepburn shire public art collection -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph - Mont Albert Primary School, 1926

This was reproduced from a copy of the 1926 flyer relating to the Annual Speech Night. See vertical file re Mont Albert Primary / Mont Albert Central School. It was reproduced with the consent of the school archives in the early 1980's by Kenneth Tudor Hall. Mont Albert Primary was built in 1917 and was designated as a Central School in 1918 when Forms 1 & @ were added. It remained as such until the 1964 when the secondary years formed the basis of a new high school, known as the Box Hill North High School, (later changed to Koonung Secondary College). The original building was constructed of solid red brick and consisted of seven rooms. In May 1924 a further four rooms, also in red brick, were added. The school opened with an initial enrolment of 147 students in Prep to Grade 6. A further 72 children were admitted during the year, making a total enrolment in the first year of 219. The land facing Kenmare Street was purchased in 1919, adding another 2 acres to the 5.5 acres which the school occupied in 1917. The first Principal was Charles Hyland, who was assisted by three teachers. The first official meeting of the School Council in May 1917 reveals that the building was in some senses a shell, requiring additional input from parents. Mention is made of the need for asphalting of playing areas, providing a letter box and electric lights for the lobby, double room, office and sewing room. Mont Albert was the first School in Victoria to have the interior purely constructed of Victoria hardwood, from floor to ceiling. An Honour Board was erected in 1919. mont albert central school, mont albert primary school, mont albert, schools -

Forests Commission Retired Personnel Association (FCRPA)

Forests Commission Retired Personnel Association (FCRPA)Branding Hammer issued to FCV overseer Jim Browning at Beechworth

Metal branding hammers were the most common way to control the sale and movement of hardwood timber produce like logs, railway sleepers, fence posts, and poles from Victorian State forests. Royalty was also paid on this basis. The hammer has a crown stamp on one end with a unique number in the middle (453) which identified its owner, and a crows foot or broad arrow on the other. The broad arrow was a symbol traditionally used in Britain and its colonies to mark government property. Forest regulations state that an authorised officer may use the crown mark to identify produce which has been sold and may be removed from the forest, whereas the broad arrow can be used to brand and mark trees which are not to be felled, or to indicate forest produce which has been seized. Hammers were traditionally only ever issued to forest officers and were an important, and closely guarded tool-of-trade. They were not transferred between staff and lending hammers was not permitted. But it was an onerous task for staff to hammer and tally hundreds of logs, or thousands of fence posts each week, so in about 1990 a system was introduced whereby hammers were allocated to logging contractors to grade logs and tally them instead. But there was still spot checking by authorised officers. A register was kept, and contractors paid a substantial deposit to make sure they didn't lose them, but they occasionally turn up by fossickers with metal detectors. While branding hammers are still used in some smaller locations, plastic tags and barcodes are now more common.Metal log branding hammer with a crown stamp on one end with a unique number (453) in the middle which identified its owner, and a crows foot or broad arrow on the other. The unusual bent metal handle was designed to protect user from banging their fingers on the log. It was also fitted with a rubber hand grip. Most FCV branding hammers were issued with wooden handles. The branding hammer 453 was initially issued to Wally Cowell at Beechworth. It was reissued to Jim Browning upon Wally’s retirement The hammer still had a wooden handle, but the it broke and became loose inside hammer head. Russel Pritchard from the Beechworth Depot replaced the handle with a new metal one and put a dog leg in it It mainly branded forest produce cut in Mt. Pilot and Reedy Creek areas. The main logging contractors were Gordon Habeck from Chiltern and Steven Goldsworthy from BeechworthCrown mark one end (453) and Crows foot other endforest harvesting, forests commission victoria (fcv) -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, John Manners, 1792-1822

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: We know little of John Manners other than his firm was acquired by Alexander Mathieson & Sons in 1822, Mathieson were one of the leading makers of hand tools in Scotland at this time. 1792 was deemed by Mathieson & Sons to be that of its foundation and it was in all likelihood the year in which John Manners had also set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, it is presumed having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker, from 1822 we hear nothing regards what happened to John Manners.A vintage tool made by a known maker John Manners the item is a significant wood working tool from the late 18th century that today is quite rare. As this maker sold his business to Alexander Mathieson another collectable tool maker in the early 19th century. This item would be sought after by wood working tool collectors and it gives us a snapshot of how cabinet makers went about creating furniture during this time period. Wood Moulding plane Side Bead - Single Box type Stamped Manners (Maker) (also inside stamped GN, & W, M. Nicol also F W. probably owners of item over the years.)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood smoothing plane coffin pattern, 18th to early 19th century

Being smaller than other bench planes, the coffin-shaped smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. A vintage tool made by an unknown 18th or early 19th-century woodworking tool maker. This item would have been made for individuals or cabinet makers that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time producing either a decorative moulding or a smooth finish to furniture timber, door trims etc had to be accomplished using hand planing tools and in particular one of these types of planes. Traditionally wood planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade used for achieving a flat and smooth finish to timber. The blade or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers' shop might have many, perhaps hundreds, of moulding and flat-bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. These vintage planes are well sought after by collectors of antique tools due to their rarity. A significant tool from the 18th to early 19th century by an unknown maker that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade show the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber furniture item. Smoothing Plane Coffin type. Stamped GM inside "W" indicating sizeflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Wood Plane Coffin Pattern, 18th to Early 19th Centuries

Being smaller than other bench planes, the coffin shaped smoothing plane is better able to work on smaller work pieces and around obstructions. Since the 1700s wooden smoothing planes have predominantly been 'coffin shaped' wider in the middle and slightly rounded making them more manoeuvrable. A vintage tool made by an unknown 18th or early 19th century woodworking tool maker. This item would have been made for individuals or cabinet makers that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time to produce either a decorative moulding or a smooth finish to furniture timber, door trims etc had to be accomplished using hand planing tools and in particular one of these types of planes. Traditionally wood planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade use for achieving a flat and smooth finish to timber. The blade, or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and flat bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. These vintage planes are well sought after by collectors of antique tools due to their rarity. A significant tool from the 18th to early 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves hand made shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber furniture item. Wood smoothing plane known as a coffin plane due to it's shape, wood insert screwed on front of base. Stamped "MILLER". Inscribed "X" (probably the size)flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, cabinet makers tools, woodworking tools, wood plane, smoothing plane, timber finishing, furniture manufacture -

Surrey Hills Historical Society Collection

Surrey Hills Historical Society CollectionPhotograph - Mont Albert Primary School, 1926

This was reproduced from a copy of the 1926 flyer relating to the Annual Speech Night. See vertical file re Mont Albert Primary / Mont Albert Central School. It was reproduced with the consent of the school archives in the early 1980's by Kenneth Tudor Hall. Mont Albert Primary was built in 1917 and was designated as a Central School in 1918 when Forms 1 & 2 were added. It remained as such until the 1964 when the secondary years formed the basis of a new high school, known as the Box Hill North High School, (later changed to Koonung Secondary College). The original building was constructed of solid red brick and consisted of seven rooms. In May 1924 a further four rooms, also in red brick, were added. The school opened with an initial enrolment of 147 students in Prep to Grade 6. A further 72 children were admitted during the year, making a total enrolment in the first year of 219. The land facing Kenmare Street was purchased in 1919, adding another 2 acres to the 5.5 acres which the school occupied in 1917. The first Principal was Charles Hyland, who was assisted by three teachers. The first official meeting of the School Council in May 1917 reveals that the building was in some senses a shell, requiring additional input from parents. Mention is made of the need for asphalting of playing areas, providing a letter box and electric lights for the lobby, double room, office and sewing room. Mont Albert was the first School in Victoria to have the interior purely constructed of Victoria hardwood, from floor to ceiling. An Honour Board was erected in 1919. mont albert central school, mont albert primary school, mont albert, schools -

Department of Energy, Environment and Climate Action

Department of Energy, Environment and Climate ActionLog Branding Hammers (various)

Metal branding hammers were the most common way to control the sale and movement of hardwood timber produce like logs, railway sleepers, fence posts, and poles from Victorian State forests. Royalty was also paid on this basis. Hammers most commonly had a crown stamp on one end with a unique number in the middle which identified its owner, and a crows foot or broad arrow on the other. The broad arrow was a symbol traditionally used in Britain and its colonies to mark government property. Other local configurations were used by sawmillers, post cutters and pulpwood contactors. Forest regulations state that an authorised officer may use the crown mark to identify produce which has been sold and may be removed from the forest, whereas the broad arrow can be used to brand and mark trees which are not to be felled, or to indicate forest produce which has been seized. Hammers were traditionally only ever issued to forest officers and were an important, and closely guarded tool-of-trade. They were not transferred between staff and lending hammers was not permitted. But it was an onerous task for staff to hammer and tally hundreds of logs, or thousands of fence posts each week, so in about 1990 a system was introduced whereby hammers were allocated to logging contractors to grade logs and tally them instead. But there was still spot checking by authorised officers. A register was kept, and contractors paid a substantial deposit to make sure they didn't lose them, but they occasionally turn up by fossickers with metal detectors. While branding hammers are still used in some smaller locations, plastic tags and barcodes are now more common.Log Grading hammersforests commission victoria (fcv), hand tools, forest harvesting -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Fillister Wood Plane, A Mathieson and Son, Mid to late 19th Century

The British wooden sash fillister plane is an old plane designed for rebate or rabbet work on sash windows to cut a groove or channel to allow a window to move up and down. The function and design of the sash fillister plane is a cross between the wooden moving fillister plane and the wooden plough plane. The wooden sash fillister plane is equipped with a fence, depth stop, nicker, skewed cutter and wedge. The plane has a hardwood main body, a hardwood moving fence and usually a variety of brass decorative and functional parts. The body and fence are nearly always made from beech as this was the hardwood of choice at the time these plane were made due to price and availability. Sometimes these planes are seen in other types of wood with the best examples being made from boxwood, rosewood and also there are some ebony fillister planes. Manufacturer: In 1792 John Manners had set up a workshop making woodworking planes at 14 Saracens Lane Glasgow. He also had employed an apprentice Alexander Mathieson (1773-1851). But in the following year at Saracen's Lane, the 1841 census describes Alexander Mathieson as a master plane-maker now at 38 Saracen Lane with his son Thomas Adam working with him as a journeyman plane-maker. Presumably, Alexander must have taken over the premises and business of John Manners. Now that the business had Thomas Adam Mathieson working with his father it gradually grew and became more diversified, and it is recorded at the time by the Post-Office Glasgow Annual Directory that by 1847-1848 Alexander Mathieson was a “plane, brace, bit, auger & edge tool maker” In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company went on to acquire the Edinburgh edge-tool makers “Charles & Hugh McPherson” and took over their premises in Gilmore Street. In the Edinburgh directory of 1856/7, the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street Edinburgh. The 1851 census Alexander is recorded as working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 Post-Office Glasgow Annual Directory the firm is now listed as Alexander Mathieson & Son, with further entries as "turning-lathe and vice manufacturers". By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, off the Gallowgate area, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses report the firm's growth in 1861 stating that Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm so the company was still in his fathers' name. In September 1868 Thomas Mathieson put a notice in the newspapers of the Sheffield & Rotherham Independent and the Sheffield Daily Telegraph stating that his firm had used the trade-mark of a crescent and star "for some time" and that "using or imitating the Mark would be proceeded against for infringement". The firm had acquired its interest in the crescent-and-star mark from the heirs of Charles Pickslay, the Sheffield cutler who had registered it with the Cutlers' Company in 1833 and had died in 1852. The year 1868 seems also to be the one in which the name Saracen Tool Works was first adopted; not only does it figure at the foot of the notice in the Sheffield press, it also makes its first appearance in the firm's entry in the Post-Office Glasgow Annual Directory in the 1868/9 edition. As Thomas Mathieson's business grew, so too did his involvement in local public life and philanthropy. One of the representatives of the third ward on the town council of Glasgow, he became a river bailie in 1868, a magistrate in 1870 and a preceptor of Hutcheson's Hospital in 1878. He had a passion for books and was an "ardent Ruskinian". He served on the committee handling the bequest for the setting up of the Mitchell Library in Glasgow. When he died at Coulter Maynes near Biggar in 1899, he left an estate worth £142,764. Company's later years: Both Thomas's sons, James Harper and Thomas Ogilvie were involved in the continuing life of the firm. James followed in his father's footsteps in becoming a local public figure. He was appointed Deputy Lieutenant of the County of the City of Glasgow and was made a deacon of the Incorporation of the Hammermen of Glasgow in 1919. His brother Thomas Ogilvie was recorded as tool manufacturer and employer in the 1911 census. Thomas Ogilvie's son Thomas Alastair Sutherland Ogilvie Mathieson was born in 1908 took a rather different approach to engineering, however, by becoming a racing driver. In 1947 he wed the French film actress Mila Parély. The firm had won many awards at world fairs for their goods. At the Great Exhibition, London, 1851. Prize medal for joiners' tools in the class of Cutlery & Edge Tools, Great London Exposition, 1862. Prize medal honoris causa. International Exhibition, Melbourne, 1880. Gold medal International Exhibition of Industry, Science and Art, Edinburgh, 1886. Prize medalThe firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperages and other industries, both locally and far and wide.Sash Fillister Plane, with iron set skewed, the iron is 1 3/4 inches wide. Plane has a sliding adjusting fence, thumb screw depth stop and two knocking iron . Stamped W. Worrall, (owner) No 17. Maker A Mathieson & Sonflagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, fillister sash plane, window making tool, carpenders tools, alex mathieson & sons, sash windows -

Orbost & District Historical Society

Orbost & District Historical Societydisplay cabinet and tools

This display was put together by the Curlip Committee and used as promotion in the shed during the construction of Curlip 11 A community project, this boat was constructed out of local hardwood timbers utilizing the traditional skills of wooden boat builders and is powered by a steam engine. Paddle Steamer Curlip II is a replica of an historic paddle steamer of the Snowy River, in Far East Gippsland, Victoria. The original Paddle Steamer Curlip was built by Sam Richardson and his sons Mark, Albert and Frank, at their sawmill at Tabbara, a pioneering settlement on the Brodribb River, a tributary of the Snowy River. The keel was laid on 14th October 1889 and PS Curlip was launched in 1890. The name “ Curlip” is derived from the indigenous name for the area where Tabbara is located and includes land to the east of the Snowy and Brodribb Rivers towards Cape Conran. PS Curlip was registered in 1893 and the Passenger Certificate issued on 30th January 1903 to Captain Alan Richardson by the Marine Board of Victoria entitled her to carry 25 passengers and only 10 passengers when engaged in towage service. Two children under 12 years of age to be reckoned as one passenger. PS Curlip towed five barges at a time, traveling upstream as far as Bete Bolong, 20 km upstream of the mouth to collect produce to be transferred to schooners near Marlo. She towed vessels in and out through the Snowy river entrance and was also used for social functions such as Sunday School picnics. She was the main means of transport for imports and exports on the Snowy River for almost 30 years. The Curlip era ended abruptly on Friday 28th February when a flash flood carried her and 2 barges down river and out to sea, where she washed ashore at Marlo and broke up.More than eighty years after the original Paddle Steamer Curlip was wrecked at sea, the Orbost community launched a replica which it hoped would draw tourists to the region. The P.S. Curlip II, is based on drawings of the original Curlip that made its home in the Snowy and Brodribb Rivers of East Gippsland in the 1890s and early 1900s, It took six years of planning and hundreds of hours of volunteer work from the local community.A display cabinet containing tools and sundry items related to the Paddle Steamer Curlip. (More information on individual items in Catalogue 1400-1600)p.s.curlip richardson-samuel boat-building-tools transport -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Smoothing Wood Plane, John Welsh & Co, 1845-1850

A vintage tool made by a obscure early 19th century woodworking Scottish tool maker. This item would have been made commercially for firms and individuals that worked in wood and needed a tool that could produce a flat smooth finish to timber. These tools were used before routers and spindle moulders came into use in the late 19th and early 20th centuries before this time to produce a decorative moulding or to smooth a piece of furniture timber, door trims etc. had to be accomplished using hand tools and in particular one of these types of planes. The subject item is a smoothing plane Known as a Coffin Plane due to its shape. Traditionally wood planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding or had a flat blade use for achieving a flat and smooth finish to timber. The blade, or iron was likewise formed to the intended moulding profile or for smoothing and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and flat bladed planes for a full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. All we known about John Welsh is that he was a tool maker and possibly a retailer that operated a business in Dundee Scotland between 1845-1850. This is the only record we have to date that he existed and is from the Master Catalogue of Scottish woodworking tool makers. His tools in particular moulding planes are well sought after by collectors of vintage tools due to their rarity. A significant tool from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture and other decorative finishes were created on timber by the use of hand tools. Tools that were themselves handmade shows the craftsmanship used during this time not only to make a tool such as the subject item but also the craftsmanship needed to produce a decorative finish that was needed to be made for any timber item. Wood Plane Rounded base, blade attached. Owner J Huband Marked J Welsh, Dundee maker and "J Huband" (Owner)flagstaff hill, warrnambool, shipwrecked coast, flagstaff hill maritime museum, maritime museum, shipwreck coast, flagstaff hill maritime village, great ocean road, plane, compass plane, j welsh, j huband -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageDomestic object - Wooden Rolling Pin, First half of 20th Century

A rolling pin is a simple tool used to flatten dough. The first civilisation known to have used the rolling pin was the Etruscans. Their advanced farming ability, along with a tendency to cultivate many plants and animals never before used as food and turn them into sophisticated recipes, were passed to invading Greeks, Romans, and Western Europeans. Thanks to the Etruscans, these cultures are associated with gourmet cooking. To prepare their inventive foods, the Etruscans also developed a wide range of cooking tools, including the rolling pin. Although written recipes did not exist until the fourth century B.C., the Etruscans documented their love of food and its preparation in murals, on vases, and on the walls of their tombs. Cooking wares are displayed with pride; rolling pins appear to have been used first to thin-roll pasta that was shaped with cutting wheels. They also used rolling pins to make bread (which they called puls) from the large number of grains they grew. Natives of the Americas used more primitive bread-making tools that are favoured and unchanged in many villages. Chefs who try to use genuine methods to preserve recipes are also interested in both materials and tools. Hands are used as "rolling pins" for flattening dough against a surface, but also for tossing soft dough between the cook's two hands until it enlarges and thins by handling and gravity. Tortillas are probably the most familiar bread made this way. Over the centuries, rolling pins have been made of many different materials, including long cylinders of baked clay, smooth branches with the bark removed, and glass bottles. As the development of breads and pastries spread from Southern to Western and Northern Europe, wood from local forests was cut and finished for use as rolling pins. The French perfected the solid hardwood pin with tapered ends to roll pastry that is thick in the middle; its weight makes rolling easier. The French also use marble rolling pins for buttery dough worked on a marble slab. Glass is still popular; in Italy, full wine bottles that have been chilled make ideal rolling pins because they are heavy and cool the dough. Countries known for their ceramics make porcelain rolling pins with beautiful decorations painted on the rolling surface; their hollow centres can be filled with cold water (the same principle as the wine bottle), and cork or plastic stoppers cap the ends. Designs for most rolling pins follow long-established practices, although some unusual styles and materials are made and used. Within the family of wooden rolling pins, long and short versions are made as well as those that are solid cylinders (one-piece rolling pins) instead of the familiar style with handles. Very short pins called mini rolling pins make use of short lengths of wood and are useful for one-handed rolling and popular with children and collectors. Mini pins ranging from 5 to 7 in (12.7-17.8 cm) in length are called texturing tools and are produced to create steam holes and decorations in pastry and pie crusts; crafters also use them to imprint clay for art projects. These mini pins are made of hardwoods (usually maple) or plastic. Wood handles are supplied for both wood and plastic tools, however. Blown glass rolling pins are made with straight walls and are solid or hollow. Ceramic rolling pins are also produced in hollow form, and glass and ceramic models can be filled with water and plugged with stoppers. Tapered glass rolling pins with stoppers were made for many centuries when salt imports and exports were prohibited or heavily taxed. The rolling pin containers disguised the true contents. The straight-sided cylinder is a more recent development, although tapered glass pins are still common craft projects made by cutting two wine bottles in half and sealing the two ends together so that the necks serve as handles at each end.Tiny rolling pins are also twisted into shape using formed wire. The pins will not flatten and smooth pastry, and the handles do not turn. The metal pins are popular as kitchen decorations and also to hang pots, pans, and potholders. https://www.encyclopedia.com/sports-and-everyday-life/food-and-drink/food-and-cooking/rolling-pinThe use of the rolling pin to make thin pastry or pasta.Wooden rolling pin with some damage on cylinder section.None.flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, rolling pin, cooking, pastry -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood moulding Plane, Auburn Tool Company, 1870 to 1893

Moulding Plane: A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden object. Traditionally, moulding planes were blocks of wear resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade, or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other worker to pull the plane ahead of the master who guided it. Auburn Tool Company: The Auburn Tool Company is known to exist from 1864 to 1893. George Casey reorganized the firm of Casey, Clark and Company as a joint-stock company in 1864, under the company name of Auburn Tool Company. The 1865 New York State Census noted the firm as a manufacturer of the plane, plane irons, and skates. The production that year was listed as 30,000 pairs of skates and 35,000 planes along with 25,000 dozen plane irons. The plane irons carried the trademark "Thistle". Both skates and plane irons were made from welded wrought iron and cast steel. The Auburn Tool Company was among the five leading plane manufacturing firms existing in the mid to late 19th century USA. Others were: H. Chapin's Son; Greenfield Tool Company; and Sandusky Tool Company. Auburn Tool Company, with these others, was also a founding member of the Plane Makers Association, organized around 1858 to fix prices. Most of the companies tools were manufactured by prisoners and in 1866 the firm was outbid for prison labour by J M Easterly and Co. After losing the contract with the prison authority they constructed a new building and continued in the plane manufacturing business with private labour. The 1870 US Census reported the firm had 21 machines, driven by water power, employing 66 males, producing annual products valued at us$70, 000. After A. Howland and Company was dissolved in 1874, the Auburn Tool Company again resumed using contract labour at the State Prison until 1877. The Auburn Tool Company merged with the Ohio Tool Company of Columbus, Ohio, on Nov 14, 1893. Although plane manufacturing was continued at Auburn until after 1907, after this merger the firm went under the name of the Ohio Tool Company. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. It also gives an insight into how many manufacturing companies bid for the rights to use prison labour to make their products at this time in our history. Decorative wood Moulding, plane Round type Auburn New York. Owner A Neudt Size 14 flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageVehicle - Vessel, Surf Boat, 1949

In 1952 the subject surf boat crewed by Geoff Scott, Ron Blackney, Wes McLaren, Jim Tibb, and Stan Stephens, won the Victorian Surf Boat Championships. When the club had finished with the boat Mr. Harold Stephenson paid one shilling and it eventually found its way into a garage where it remained for over 20 years before being donated to Flagstaff Hill. This boat is regarded as a unique example of craftsmanship, closely resembling Bay whaleboats used around the Warrnambool area in the 1800s. This timber caravel surf boat was named “Aeroplane Jelly” and was built by N & E Towns a Newcastle boat builder in 1949 Aeroplane Jellies and David Jones as sponsors of the Sydney Surf Carnival of 1950/1951 donated jointly the vessel. George Towns started his boat-building business in 1869 on Dempsey Island on the Hunter River, NSW. George's sons took over the business as N & E Towns (Norman and Eldrid) and continued until the early 1950s. The business made a variety of small craft including fishing boats, launches, and flood boats. In 1928 they built their first surf boat it took about six weeks to build with cedar planks and hardwood frames. After World War II surf boats became their main focus and they became well known for the lighter and faster designs. Many “Towns built” craft have won events at state and national surf championships. They were renowned Boat Builders producing a much lighter and faster running boat than anything previously made, with a buoyant type bow design giving it the lift necessary to get out and through heavy surf. while its sleek lines from amidships aft provided very fast running qualities. Either side of its bows, it bore the bright silver aircraft transfer of the Aeroplane Jellies Company. After a surf competition at Narrabeen NSW, the competing Warrnambool surf lifesaving team returned home to Warrnambool their club committee decided to purchase the "Aeroplane Jellies" Surf boat if and when it became available as the team had been so impressed with the boat. On 30 October 1951 a cheque for £207-2/6' was raised, £180 for the boat, balance for oars. Transport was arranged and the boat was delivered in November 1951. When the "Aeroplane Jellies" competition days were over in the early 1960's due largely to changing surf boat design, Warrnambool Club's Secretary, Mr. Harold Stephenson, sought permission from the Committee to purchase the boat for the nominal sum of one shilling thus preserving the vessel for posterity. The boat had been stored for many years at the Nullawarre Bakery where it remained until Mr. Stephenson died in 1985. After Mr. Stephenson's passing his family donated the vessel to Flagstaff Hill Maritime Museum in 1986.A very rare example of a surf lifesaving boat that for its time was a unique creation that revolutionised small vessel design in Australia. It was made by a renowned maker that today unfortunately many of his examples of boats he made, especially surf life-saving boats no longer exist making the Flagstaff Hill boat very significant to not only surf lifesaving history but to the part it played in our social life for all those who went to the beaches in 1960s Australia.Surf boat named "Aeroplane Jellies". Timber, double ender carvel, built in 1949 by N & E Towns, Newcastle, NSW. Only a few are in existence. She was a trophy prize at Sydney Surf Carnival 1950/1951, donated by Aeroplane Jellies and David Jones Dept. Store, Sydney. The boat was won by South Narrabeen Surf Club. Warrnambool Surf Club purchased her on 30/10/1951 for £207-2/6, and she was sold to Harold Stephenson in early 1960's for 1 shilling. Donated to Flagstaff Hill by the family of Harold Stephenson around 1985-1986. The name Aeroplane Jellies was lettered in gold across the boat's coaming and there is a remnant of some of the gold lettering still there.warrnambool, flagstaff hillflagstaff hill maritime museum, great ocean road, ememgency, historic boat, surf boat, n & e towns, carvel, vintage boat, double ender boat, lifesaving boat, geoff scott, south narrabeen surf club, warrnambool surf life saving club, lifeboat -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1819-1901

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools. Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, Anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset and they began trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter died in 1826, trading under the name Holtzapffel & Deyerlein. Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel's lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required "for building purposes". The firm then moved to 13 and 14 New Bond Street and was in premises in the Haymarket from 1907 to 1930. John's son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co. Charles continued to run the business after his father's death. He wrote a 2,750-page treatise entitled Turning and Mechanical Manipulation, published in 1843 which came to be regarded as the bible of ornamental turning. The final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928. A vintage tool made by a well-known firm made for firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Holtzaffel 64 Charing & Owner J Heath 9/16" marked opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Wood Smoothing Plane, Late 19th to Early 20th century

A Jack plane is used for smoothing timber that is used in the manufacture of furniture or other wooden objects. Traditionally, smoothing planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to smooth or even out timber. The blade or iron was likewise secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding and smoothing planes for the full range of work to be performed. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used for the smoothing of a piece of timber that was then used in some form of cabinet manufacture or wood working. A significant item from the mid to late 19th century that today is sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made. Jack Plane; a wooden smoothing plane, made by Alex Mathieson & Son, Glasgow. Plane has inscriptions."Alex Mathieson & Son Glasgow" Stamped "GN" inside with a "W" on endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, jack plane, smoothing plane, woodworking tool, woodwork, cabinet making -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Plane, 1819-1901

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The Holtzapffel dynasty of tool and lathe makers was founded in Long Acre, London by a Strasbourg-born turner, Jean-Jacques Holtzapffel, in 1794. The firm specialized in lathes for ornamental turning but also made a name for its high-quality edge and boring tools. Moving to London from Alsace in 1792, Jean-Jacques worked initially in the workshop of the scientific-instrument maker Jesse Ramsden, Anglicizing his name to John Jacob Holtzapffel. In 1794 he set up a tool-making partnership in Long Acre with Francis Rousset and they began trading under the name of John Holtzapffel. From 1804 he was in partnership with the Mannheim-born Johann Georg Deyerlein until the latter died in 1826, trading under the name Holtzapffel & Deyerlein. Holtzapffel sold his first lathe in June 1795, for £25-4s-10d, an enormous price at the time. All of Holtzapffel's lathes were numbered and by the time he died in 1835, about 1,600 had been sold. The business was located at 64 Charing Cross, London from 1819 until 1901 when the site was required "for building purposes". The firm then moved to 13 and 14 New Bond Street and was in premises in the Haymarket from 1907 to 1930. John's son, Charles Holtzapffel (1806–1847) joined the firm in 1827, at around which time the firm became known as Holtzapffel & Co. Charles continued to run the business after his father's death. He wrote a 2,750-page treatise entitled Turning and Mechanical Manipulation, published in 1843 which came to be regarded as the bible of ornamental turning. The final two volumes were completed and published after his death by his son, John Jacob Holtzapffel (1836–1897). When Charles Holtzapffel died in 1847 his wife Amelia ran the business until 1853. John Jacob II, the son of Charles and Amelia, was head of the firm from 1867 until 1896. A nephew of John Jacob II, George William Budd (1857–1924) became head of the firm in 1896. His son John George Holtzapffel Budd (1888–1968) later ran the business. By the early twentieth century, ornamental turning was going out of fashion, and the firm sold its last lathe in 1928. A vintage tool made by a well-known firm made for firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane Holtzaffel 64 Charing & Owner J Heath 9/16" marked opposite endflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, plane moulding, plane, j heath -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Side bead Moulding Plane Alex Mathieson & Son. flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Moulding Plane side beadStamped Mathieson and Son also ( size "W" & ¾" )also GN (previous owner)flagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Moulding wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Round Moulding plane size 12 Alex Mathieson & Son Glasgow makerflagstaff hill, warrnambool, shipwrecked-coast, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village -

Flagstaff Hill Maritime Museum and Village

Flagstaff Hill Maritime Museum and VillageTool - Complex Wood Plane, Late 19th to Early 20th century

A moulding plane is a specialised plane used for making the complex shapes found in wooden mouldings that are used to decorate furniture or other wooden objects. Traditionally, moulding planes were blocks of wear-resistant hardwood, often beech or maple, which were worked to the shape of the intended moulding. The blade or iron was likewise formed to the intended moulding profile and secured in the body of the plane with a wooden wedge. A traditional cabinetmakers shop might have many, perhaps hundreds, of moulding planes for the full range of work to be performed. Large crown mouldings required planes of six or more inches in width, which demanded great strength to push and often had additional peg handles on the sides, allowing the craftsman's apprentice or other workers to pull the plane ahead of the master who guided it. Company History: The firm of Alexander Mathieson & Sons was one of the leading makers of hand tools in Scotland. Its success went hand in hand with the growth of the shipbuilding industries on the Firth of Clyde in the nineteenth century and the emergence of Glasgow regarded as the "second city of the Empire". It also reflected the firm's skill in responding to an unprecedented demand for quality tools by shipyards, cooperage's and other industries, both locally and far and wide. The year 1792 was deemed by the firm to be that of its foundation it was in all likelihood the year in which John Manners had set up his plane-making workshop on Saracen Lane off the Gallowgate in the heart of Glasgow, not far from the Saracen's Head Inn, where Dr Johnson and James Boswell had stayed on their tour of Scotland in 1773. Alexander Mathieson (1797–1851) is recorded in 1822 as a plane-maker at 25 Gallowgate, but in the following year at 14 Saracen's Lane, presumably having taken over the premises of John Manners. The 1841 national census described Alexander Mathieson as a master plane-maker at 38 Saracen Lane with his son Thomas Adam working as a journeyman plane-maker. In 1849 the firm of James & William Stewart at 65 Nicolson Street, Edinburgh was taken over and Thomas was put in charge of the business, trading under the name Thomas A. Mathieson & Co. as plane and edge-tool makers. Thomas's company acquired the Edinburgh edge-tool makers Charles & Hugh McPherson and took over their premises in Gilmore Street. The Edinburgh directory of 1856/7 the business is recorded as being Alexander Mathieson & Son, plane and edge-tool makers at 48 Nicolson Street and Paul's Work, Gilmore Street. The 1851 census records indicate that Alexander was working as a tool and plane-maker employing eight men. Later that year Alexander died and his son Thomas took over the business. Under the heading of an edge-tool maker in the 1852/3 (Post-Office Glasgow Annual Directory) the firm is now listed as Alexander Mathieson & Son. By the early 1850s, the business had moved to 24 Saracen Lane. The directory for 1857/8 records that the firm had moved again only a few years later to East Campbell Street, also off the Gallowgate, and that through further diversification was also manufacturing coopers' and tinmen's tools. The ten-yearly censuses log the firm's growth and in 1861 Thomas was a tool manufacturer employing 95 men and 30 boys; in 1871 he had 200 men working for him and in 1881 300 men. By 1899 the firm had been incorporated as Alexander Mathieson & Sons Ltd, even though only Alexander's son Thomas appears ever to have joined the firm. A vintage tool made by a well-known firm made for other firms and individuals that worked in wood. The tool was used before routers and spindle moulders came into use after World War ll, a time when to produce a decorative moulding for a piece of furniture or other items this had to be accomplished by hand using one of these types of planes. A significant item from the mid to late 19th century that today is quite rare and sought after by collectors. It gives us a snapshot of how furniture was made predominately by hand and with tools that were themselves hand made shows the craftsmanship used to make such a unique item. Ogee Complex Moulding Plane Alex Mathieson & Son. Stamped W Worrel, (owner) & No 2.flagstaff hill, warrnambool, flagstaff-hill, flagstaff-hill-maritime-museum, maritime-museum, shipwreck-coast, flagstaff-hill-maritime-village, alexander mathieson & sons, complex moulding plane, carpenders tools, cabinet makers tools, wood working tools, wood planes -

Victorian Interpretive Projects Inc.

Victorian Interpretive Projects Inc.Photograph - digital, LJ Gervasoni, Murtoa Stick Shed 00031, 13/08/2011

From the Victorian Heritage Register statement of significance H0791 The Marmalake/Murtoa Grain Store, originally the No.1 Murtoa Shed, is located within the Murtoa Grain Terminal, adjacent to the grain elevator tower and railway line. The shed is 280m long, 60m wide and 19m high at the ridge with a capacity of 3.4 million bushels. The hipped corrugated iron roof of the shed is supported on approximately 600 unmilled hardwood poles set in a concrete slab floor and braced with iron tie rods. These poles are the reason for use of the term "stick shed". With its vast gabled interior and the long rows of poles the space has been likened to the nave of a cathedral. An elevator at one end took wheat from railway trucks to ridge level where it was distributed by conveyor along the length of the shed, creating a huge single mound of grain. Braced internal timber bulkheads on either side took the lateral thrust of the wheat, and conveyors at ground level outside the bulkheads took wheat back to the elevator for transport elsewhere. Wheat had been handled in jute bags from the start of the Victorian wheat industry in the mid nineteenth century. Bulk storage had been developed in North America from the early 1900s. NSW began building substantial concrete silos from 1920-21. In Western Australia, farmers' co-operatives, who had to supply their own bulk storage from 1934-5, pioneered the use of low-cost horizontal sheds of timber and corrugated iron for bulk storage. Following its establishment in 1935 the Victorian Grain Elevators Board (GEB) planned a network of 160 concrete silos in country locations, connected by rail to the shipping terminal at Geelong. By the outbreak of the Second World War there was a worldwide glut of wheat, and Australia soon had a massive surplus which it was unable to export. Only 48 silos had been established under the Victorian Silo Scheme so far, and wartime material and labour restrictions prevented progress with this scheme. The storage deficit had become an emergency by 1941 as Britain obtained its imports from North America, rather than over the lengthy and difficult shipping route from Australia. In 1941 the GEB, under chairman and general manager Harold Glowrey, proposed large temporary versions of the horizontal bulk storage sheds already in use in Western Australia. The proposal was approved by the Victorian Wheat and Woolgrowers Association, who considered the use of shed storages as a longer term proposition. After initial resistance from the Australian Wheat Board, some of whose members represented wheat bagging interests, the Commonwealth and Victorian governments agreed to split the costs, and Murtoa was chosen as a suitable site for the first emergency storage. The main contractor, Green Bros, commenced work on the No.1 Murtoa Shed in September 1941, deliveries of bulk wheat began in January 1942, and the store was full by June of the same year. In the following years the Council for Scientific and Industrial Research (later CSIRO) conducted valuable research and experiment on the impacts and control of insect pests at the Murtoa No.1 shed. With these discoveries, and the development of more effective pesticides, use of the No.1 shed and the larger No.2 shed, erected in 1942/43, continued for many years. The No.2 shed was demolished in 1975. By the 1990s, pest resistance to pesticides and requirements for both pest free and insecticide free grain rendered open storage of this type unviable. The No. 1 store was also becoming increasingly expensive to maintain, and its use was phased out from 1989.Image of the Marmalake/Murtoa Grain Store which is of historical, architectural, scientific (technical) and social significance to the State of VictoriaDigital colour image of the interior of the Marmaduke . Murtoa grain storage facility better known as the Stick Shed. The shed was constructed in World War Two to store grain. The supporting columns are trees.marmalake, murtoa grain store, wheat store, stick shed, murtoa -

Eltham District Historical Society Inc

Eltham District Historical Society IncPhotograph, Peter Pidgeon, Birch Cottage, Eltham-Yarra Glen Road, Christmas Hills, 27 September 2018, 2018